Mine protective net

A technology for protective nets and mines, applied in the field of protective nets, can solve problems such as rising use costs, hidden dangers in the protection of large-volume falling objects, and insufficient rigidity, and achieve the effects of increasing protection levels, simple and reasonable technical structure, and reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

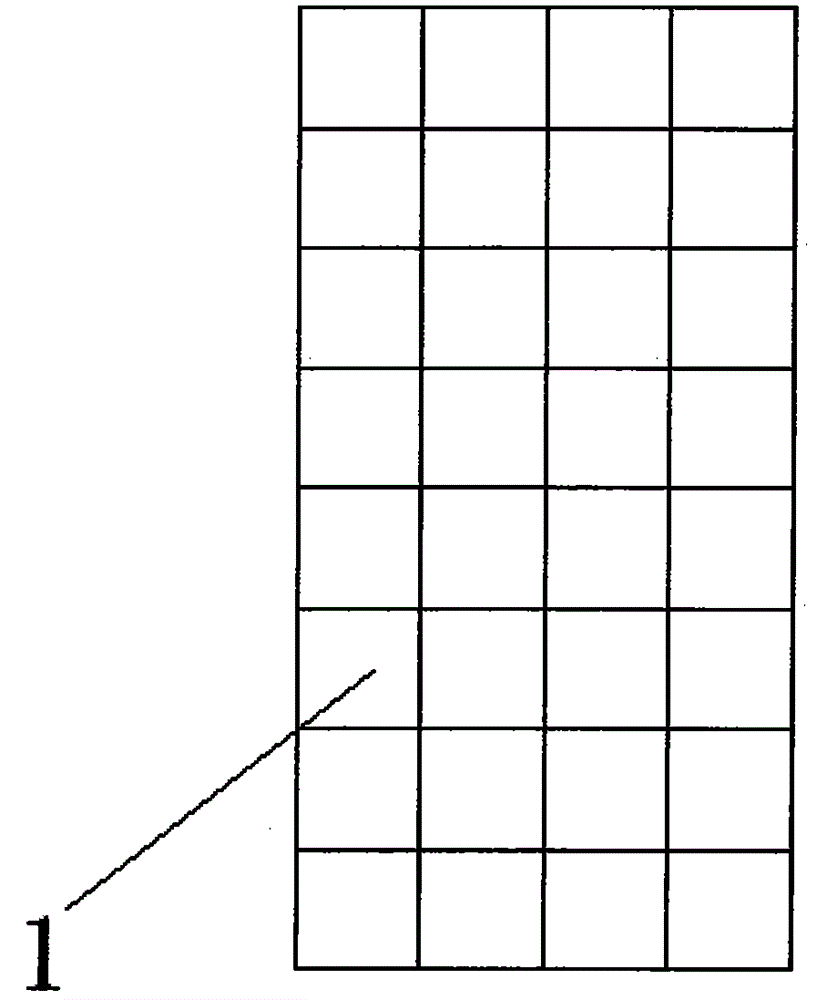

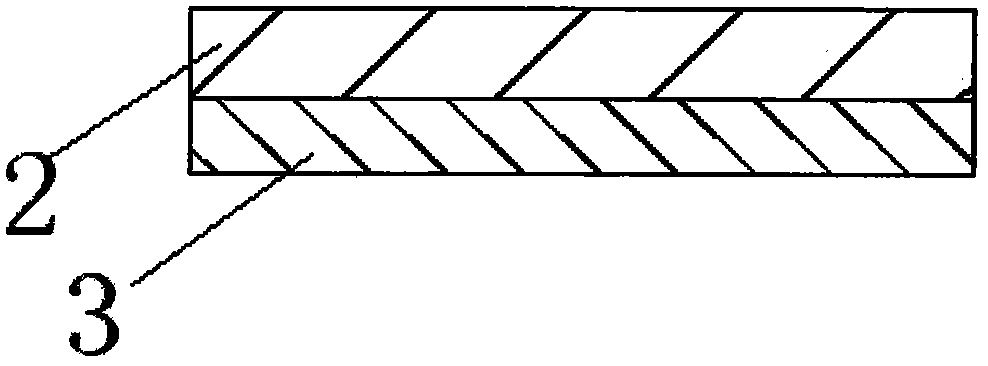

[0011] Embodiment 1: as figure 1 , 2 As shown, a mine protection net 1 includes a device body. The mine protection net 1 body is mainly composed of steel wire 2 and steel bars 3. It is characterized in that: the frame of the mine protection net 1 is rectangular, and the overall structure is The square grid, the mine protective net 1 is divided into two layers of structure, the material of the upper structure is steel bar 2, the material of the lower structure is steel wire 3, the two layers of structure are integrated by spot welding process, the frame size is 1m×2m, and the grid size is 0.1×0.1m 2 , the steel bar 2 specification is 6mm, during use, the protective net 1 on a plurality of mines is connected with each other, forms the protective net 1 group, is used for protecting falling object and certain ore pressure.

[0012] The technical structure of the present invention is simple and reasonable, and the cost is low. Compared with the mine protective net made of pure st...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com