Aluminum-boron nitride nanosheet composite coating and preparation method thereof

A composite coating, boron nitride technology, applied in pressure inorganic powder coating and other directions, to increase resistance, improve service life, and inhibit the infiltration of corrosive media

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

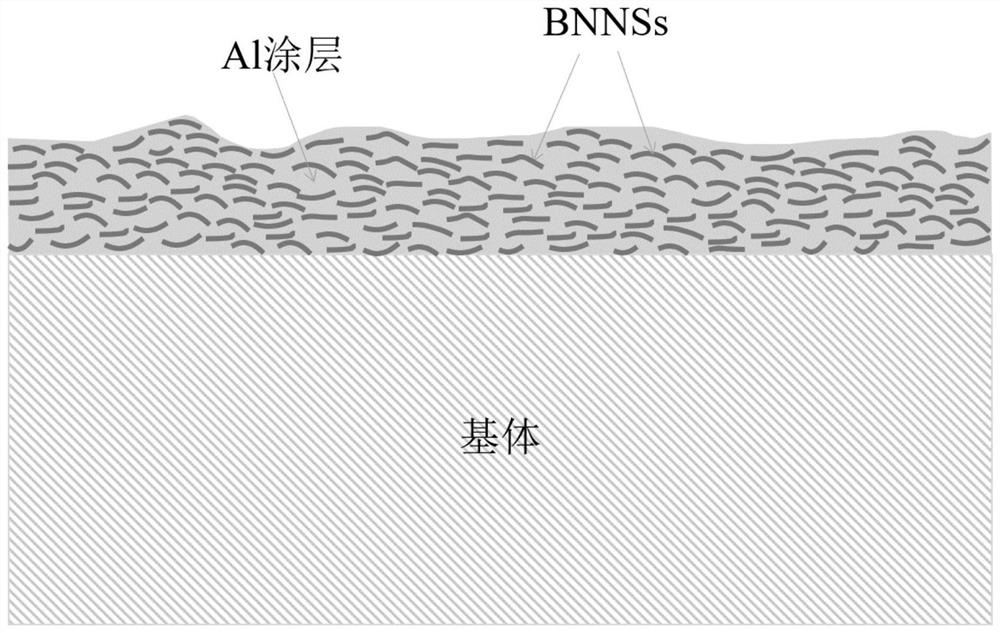

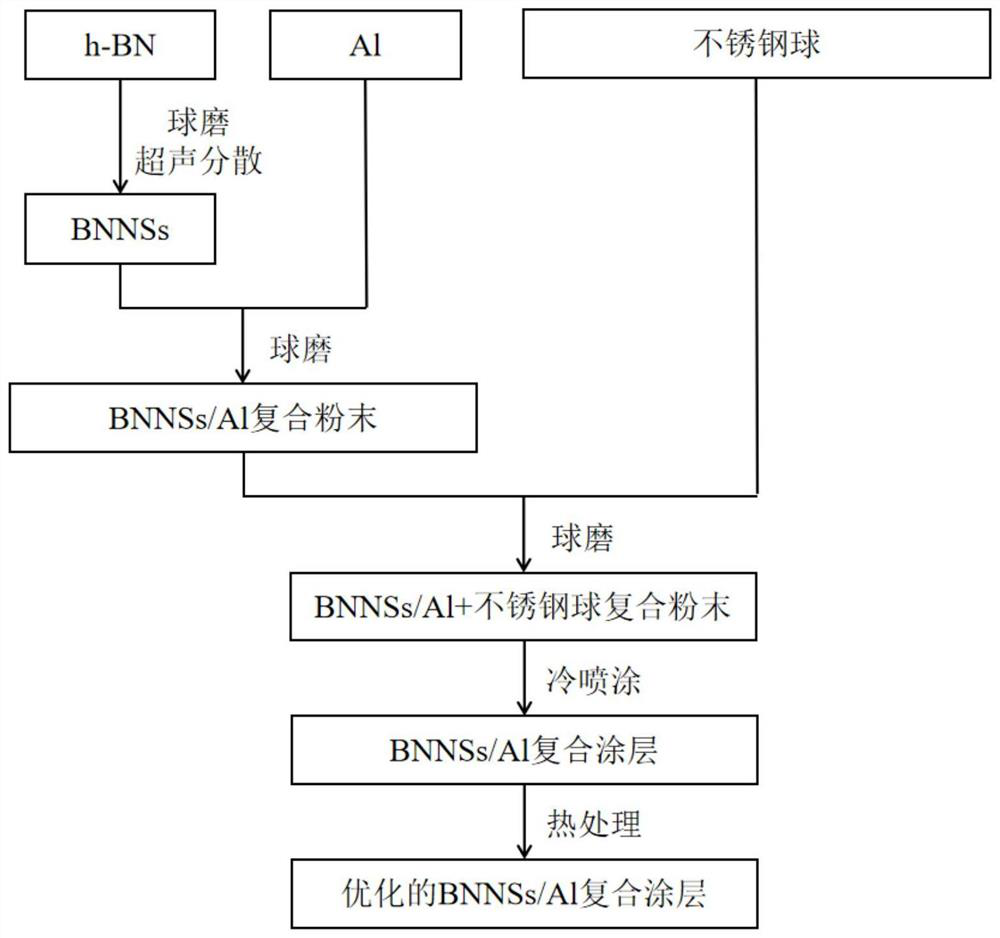

[0036] A method for preparing an aluminum-boron nitride nanosheet composite coating, using Al-BNNSs composite powder as a raw material, depositing the composite powder onto a substrate by cold spraying to obtain a composite coating, and performing heat treatment on the composite coating to obtain BNNSs The evenly distributed Al-BNNSs composite coating specifically comprises the following steps:

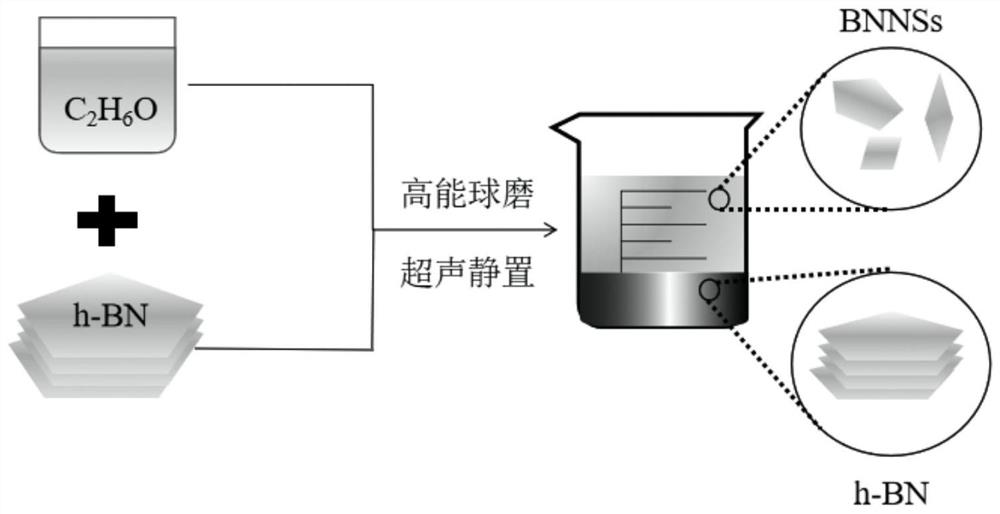

[0037] Step 1: Perform high-energy ball milling on hexagonal boron nitride (h-BN) and then ultrasonically disperse it to prepare BNNSs;

[0038] Step 2: BNNSs and Al powder are mixed and ball-milled to prepare BNNSs / Al composite powder, and the Al particle size is 10-65 μm;

[0039] Step 3: Use BNNSs / Al as the raw material for spraying composite powder, and use a nitrogen circulation cold spray system to prepare a composite coating; add stainless steel balls to the BNNSs / Al composite powder for ball milling and mix, and use a nitrogen circulation cold spray system to prepare a composi...

Embodiment

[0043] The invention innovatively proposes an Al-BNNSs composite coating with Al as a matrix and BNNSs as a reinforcing phase, and a preparation method combining ball milling, cold spraying, in-situ micro-forging technology and heat treatment.

[0044] Composite coating preparation method of the present invention specifically comprises the following steps:

[0045] Step 1: Put the h-BN powder in the ball milling jar, put 100ml alcohol and 10g h-BN in each ball milling jar, the ratio of ball to material is 20:1, and the weight ratio of large, medium and small grinding balls is 5:3:2 respectively. The diameters of the grinding balls are 15mm, 10mm, and 5mm respectively. The material of the ball milling tank and the grinding balls are all stainless steel; the atmosphere of the ball milling is Ar gas; The running time for each time is set to 2min, and the single pause time is set to 2min; after the ball milling is completed, the ball milling liquid is taken out for ultrasonic disp...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com