High-strength high-toughness low-alloy steel wire as well as preparation method and application thereof

A low-alloy steel, high-strength and high-toughness technology, applied in the field of wire material manufacturing, can solve problems such as not being able to meet the demand, and achieve the effects of small quantity, increased strength, and excellent tensile properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

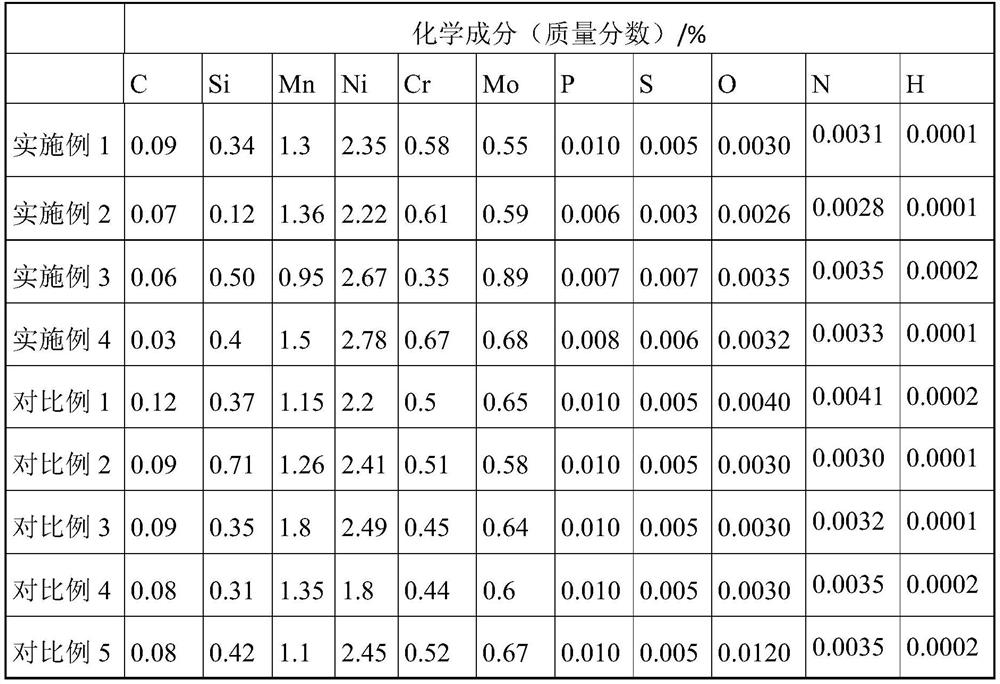

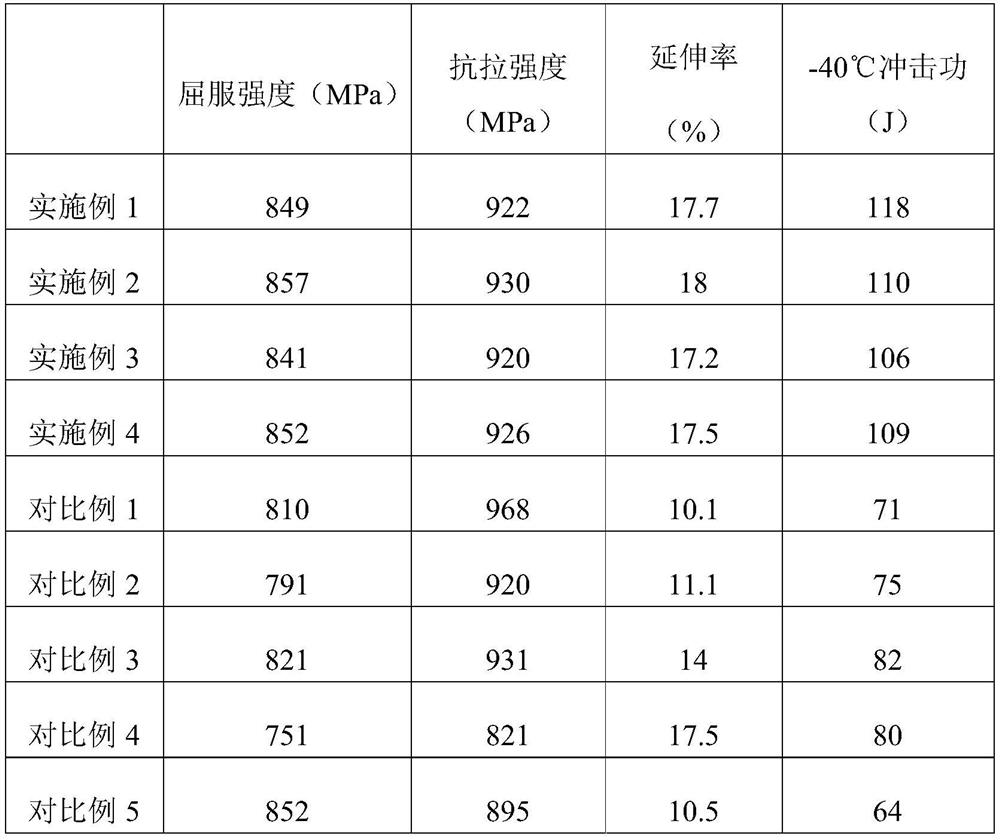

Examples

preparation example Construction

[0036] The embodiment of the second aspect of the present invention also provides a method for preparing a high-strength, high-toughness low-alloy steel wire, which includes:

[0037] a. Vacuum melting the raw materials with the designed ratio to obtain ingots;

[0038] b. Forging the ingot obtained in step a to obtain a rod;

[0039] c. Rolling the bars obtained in step b to obtain wire rods;

[0040] d. Perform annealing treatment on the wire rod obtained in step c, and then perform wire drawing to obtain high-strength, high-toughness and low-alloy steel wire.

[0041] According to the technical effects of the method for preparing high-strength, high-toughness, low-alloy steel wire according to the embodiment of the second aspect of the present invention, 1. The wire obtained by the method of the embodiment of the present invention can be used for laser additive manufacturing, and its forming stability is high , the process adaptability is good, the number of oxidized incl...

Embodiment 1

[0049] A vacuum induction furnace is used to smelt the designed ratio of raw materials, and the vacuum degree is 5Pa. The ingot obtained by vacuum melting was kept at 1150°C for 4 hours, forged into a square bar, and the final forging temperature was 980°C, and air-cooled. The forged square bar was kept at 1150°C for 3 hours, and rolled into a Φ5.5mm wire rod through multiple hot rolling. The high-strength steel wire rod is annealed, and the annealing conditions are: heat preservation at 1100 ° C for 3 hours, and water cooling. After the annealed high-strength steel wire rod is pickled and phosphated, washed and dried, it is treated with a film, and after drying, it is drawn. The diameter of the drawing changes in the order of Φ5.5mm-Φ5.0mm-Φ4.6mm-Φ4 .3mm-Φ4.0mm-Φ3.7mm-Φ3.4mm-Φ3.2mm, followed by online annealing at 1050°C-Φ2.5-Φ2.1-Φ1.9-Φ1.7-Φ1.5-Φ1.3-Φ1 .2. After the drawing is completed, clean, dry, oil, adjust the loose diameter and warp distance, wind the coil, and vacuu...

Embodiment 2

[0052] A vacuum induction furnace is used to smelt the designed ratio of raw materials, and the vacuum degree is 5Pa. The ingot obtained by vacuum melting was kept at 1100°C for 4 hours, forged into a square rod, and the final forging temperature was 930°C, and air-cooled. The forged square bar was kept at 1100°C for 4h, and rolled into a Φ5.5mm wire rod through multiple hot rolling. The high-strength steel wire rod is annealed, and the annealing conditions are: heat preservation at 1100 ° C for 3 hours, and water cooling. After the annealed high-strength steel wire rod is pickled and phosphated, washed and dried, it is treated with a film, and after drying, it is drawn. The diameter of the drawing changes in the order of Φ5.5mm-Φ5.0mm-Φ4.6mm-Φ4 .3mm-Φ4.0mm-Φ3.7mm-Φ3.4mm-Φ3.2mm, followed by online annealing at 1050°C-Φ2.5-Φ2.1-Φ1.9-Φ1.7-Φ1.5-Φ1.3-Φ1 .2. After the drawing is completed, clean, dry, oil, adjust the loose diameter and warp distance, wind the coil, and vacuum sea...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com