High-tenacity bismaleimide resin carrier structure adhesive film and preparation method thereof

A technology of maleimide resin and bismaleimide resin, which is applied in the field of bismaleimide resin carrier structure adhesive film and its preparation, can solve the problems of poor toughness and low peel strength, and achieve improved toughness and improved durability. Thermal properties, effects of improving toughness and fluidity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

[0016] Specific embodiment 1: In this embodiment, a high-toughness bismaleimide resin carrier structure adhesive film is modified by 75-100 parts of bismaleimide resin and 75-100 parts by mass. agent, 75-100 parts of polymer blend alloy, 2-8 parts of polymer ultrafine powder, 1-4 parts of silane coupling agent, 15-25 parts of curing agent and carrier; wherein, the double The maleimide resin is composed of 443BMIPDBP type double horse resin containing ether ketone structure and 133BAPB type double horse resin containing ether bond in a mass ratio of 2:1.

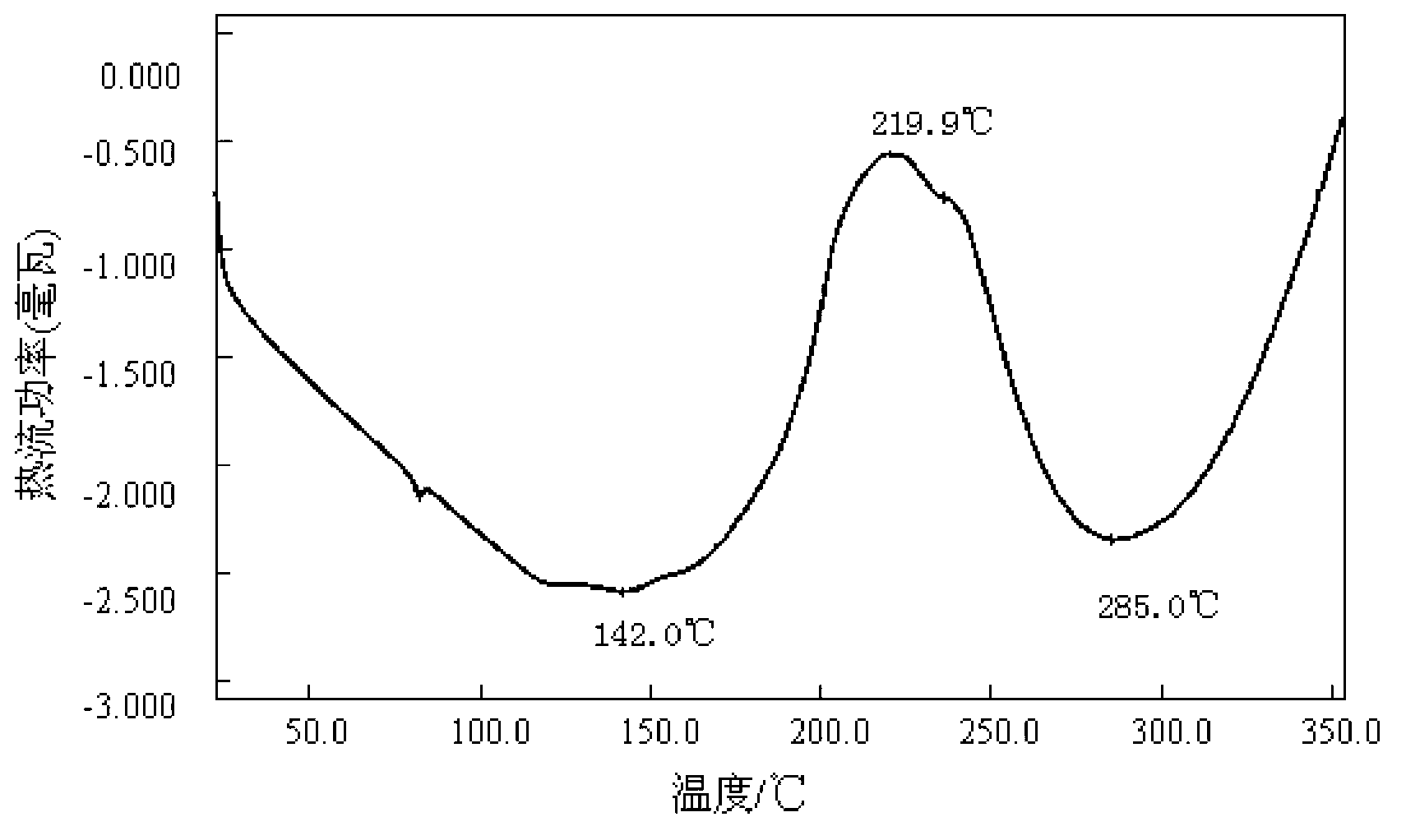

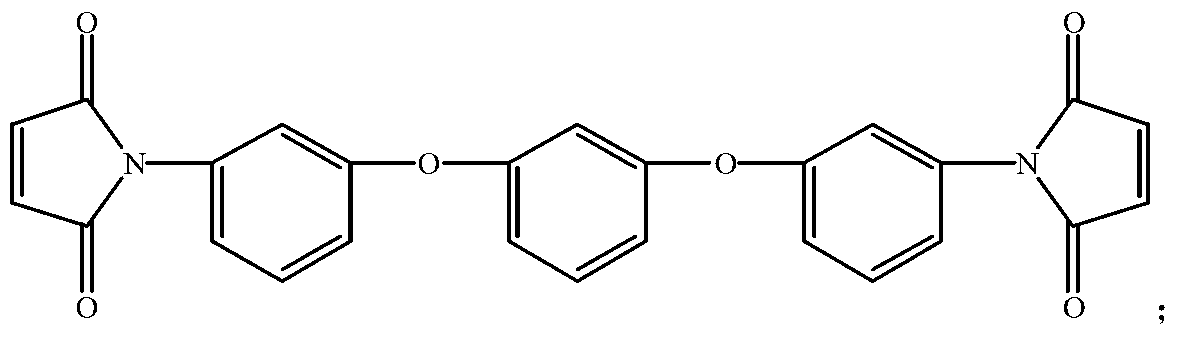

[0017] The structural formula of the 133BAPB double-maleimide resin containing ether bonds described in this embodiment is, and its preparation method can be found in (Zhu Yulong, Yu Xinhai. Synthesis of Novel Bismaleimides Containing Ether Bonds, Insulating Materials [J], 2005 (5): 6~8) The published content.

[0018]

[0019] The advantage of this embodiment is as follows:

[0020] 1. The main resin of the adhesive in ...

specific Embodiment approach 2

[0025] Specific embodiment 2: The difference between this embodiment and specific embodiment 1 is that the high-toughness bismaleimide resin carrier structure adhesive film is made of 80-90 parts by mass of bismaleimide Resin, 80-90 parts of process modifier, 80-90 parts of polymer blend alloy, 4-6 parts of polymer ultrafine powder, 2-3 parts of silane coupling agent, 18-22 parts of curing agent and carrier become. Others are the same as the first embodiment.

specific Embodiment approach 3

[0026] Specific embodiment three: the difference between this embodiment and specific embodiment one or two is that: the described process modifier consists of allyl bisphenol A, allyl ether phenolic aldehyde and hyperbranched polysiloxane in mass ratio 7:2:1 ratio composition. Others are the same as those in Embodiment 1 or 2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| shear strength | aaaaa | aaaaa |

| shear strength | aaaaa | aaaaa |

| shear strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com