Composite electrode wire, and preparation method and application of composite electrode wire

A composite electrode wire and wire drawing technology, which is applied in the direction of cable/conductor manufacturing, circuits, conductive materials, etc., can solve the problems of composite electrode wire such as dull surface and low overall strength, and achieve fine diameter, excellent electrical conductivity, and better toughness Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

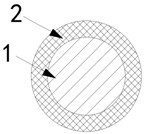

[0037] Such as figure 1 As shown, a composite electrode wire, comprising:

[0038] A core material 1 and an outer material 2 concentrically wrapped around the core material 1;

[0039] The core material 1 is a conductive alloy;

[0040] The outer material 2 is brass.

[0041] Wherein, the core material 1 is a conductive copper alloy that has undergone grain refinement treatment, and the treatment method is one of continuous extrusion or hot rolling, and the electrical conductivity of the core material 1 is greater than 50% IACS.

[0042] Further, the outer material 2 is zinc-containing brass, and the zinc content in the outer material 2 is 30%-50%, and the rest is copper and unavoidable impurities.

[0043] After the core material 1 is covered, the surface of the outer material 2 is galvanized.

[0044] It should be noted that, compared with the traditional existing composite electrode wire, the difference of the composite electrode wire in the present invention is that a ...

Embodiment 2

[0054] Such as figure 2 Shown, a kind of preparation method of composite electrode wire, comprises the following steps:

[0055] Step a, pretreatment, the core material 1 is subjected to fine-grain treatment to obtain a solid, round rod-shaped core material

[0056] Step b, fit, select a solid conductive copper alloy with a conductivity of 60% IACS as the core material and a tubular brass outer material with a zinc content of 30% to clean and fit together, the cross-sectional area of the outer material 2 and the core material 1 The ratio is 7:3;

[0057] Step c, cold pressing, circumferentially extruding the conductive copper alloy and brass fitted in step a, so that the conductive copper alloy and brass extend axially synchronously, and the circumferential extrusion pressure is 1000 MPa, the core material 1 and The diameter reduction and deformation of outer material 2 after axial extension is 40%

[0058] Step d, hot-pressed ring rolling, the core material 1 and the ou...

Embodiment 3

[0063] Such as figure 2 Shown, a kind of preparation method of composite electrode wire, comprises the following steps:

[0064] Step a, pretreatment, the core material 1 is subjected to fine-grain treatment to obtain a solid, round rod-shaped core material

[0065] Step b, fit, select a solid conductive copper alloy with a conductivity of 60% IACS as the core material and the tubular brass outer material with a zinc content of 40% to clean and fit together, the cross-sectional area of the outer material 2 and the core material 1 The ratio is 1:1;

[0066] Step c, cold pressing, circumferentially extruding the conductive copper alloy and brass fitted in step a, so that the conductive copper alloy and brass extend axially synchronously, and the circumferential extrusion pressure is 750MPa, the core material 1 and the The diameter reduction and deformation of outer material 2 after axial extension is 30%

[0067] Step d, hot-press ring rolling, the core material 1 and the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com