High nickel steel for ultralow-temperature pressure vessel and manufacturing method thereof

A technology of pressure vessel and manufacturing method, which is applied in the field of high alloy steel manufacturing, can solve problems such as increasing the difficulty of rolling, low Mn and Mo content, increasing the load of the rolling mill, etc., and achieves the effect of ensuring strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

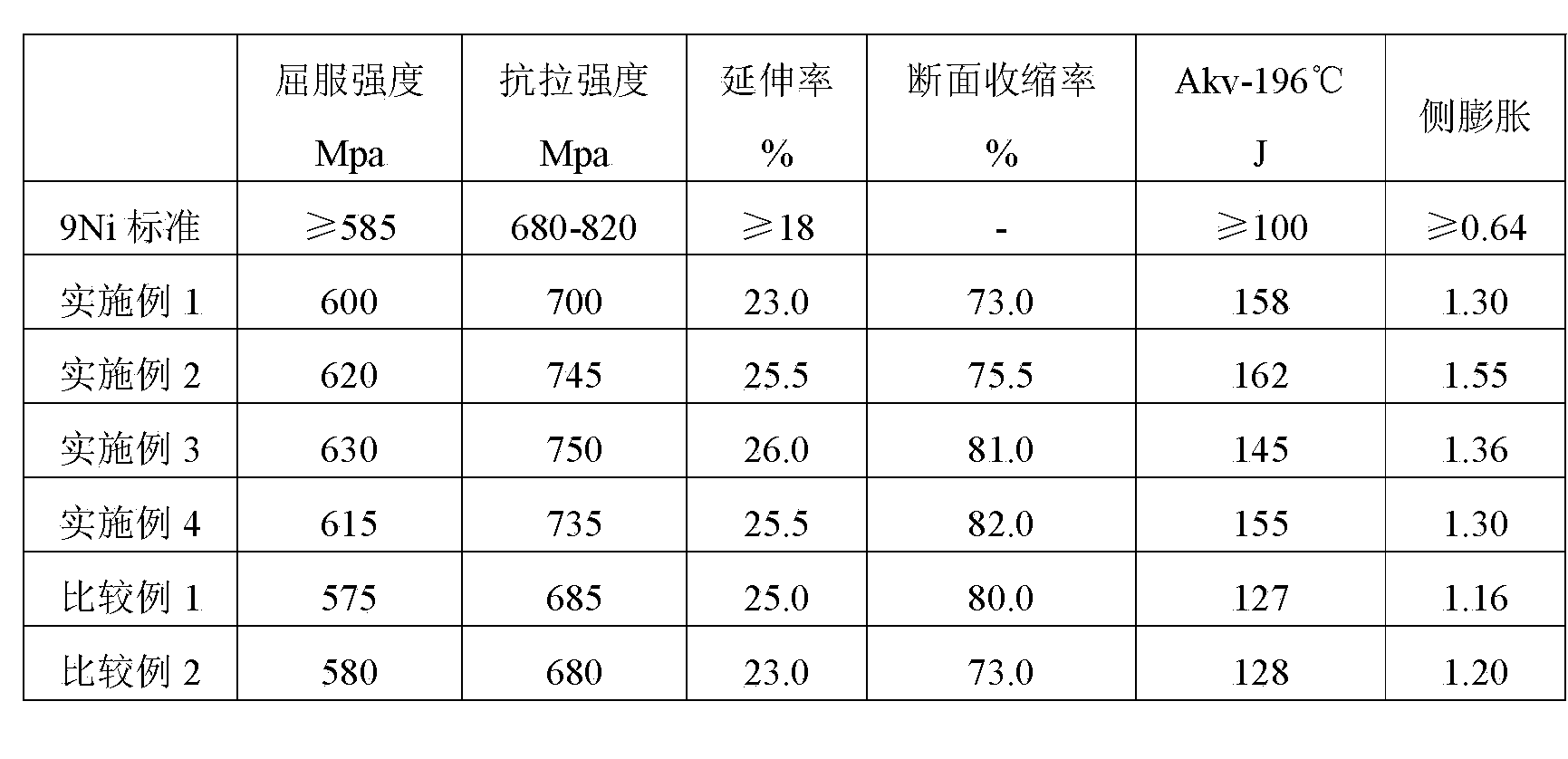

[0031] Illustrate implementation effect of the present invention below in conjunction with specific embodiment

[0032] The chemical composition of high-nickel steel for ultra-low temperature pressure vessels is shown in Table 1.

[0033] It is smelted in a 100-ton oxygen top-blown converter, and the carbon temperature is coordinated during the smelting process; the composition is adjusted during the LF refining process; the pressure is kept for 25 minutes during the VD refining process to ensure that [H]≤2ppm.

[0034] Table 1 Chemical composition of high-nickel steel for ultra-low temperature pressure vessels wt%

[0035]

C

Si

mn

P

S

Ni

Mo

Cr

Ti

Example 1

0.060

0.02

0.95

0.005

0.002

7.10

0.06

0.40

0.015

Example 2

0.071

0.03

1.20

0.005

0.002

7.20

0.08

0.45

0.017

Example 3

0.068

0.05

1.00

0.005

0.002

7.17

0.08 ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| yield strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| elongation | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com