Taper threaded joint

A tapered thread and threaded connection technology, which is applied in the direction of threaded connection, pipe/pipe joint/pipe fitting, mechanical equipment, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

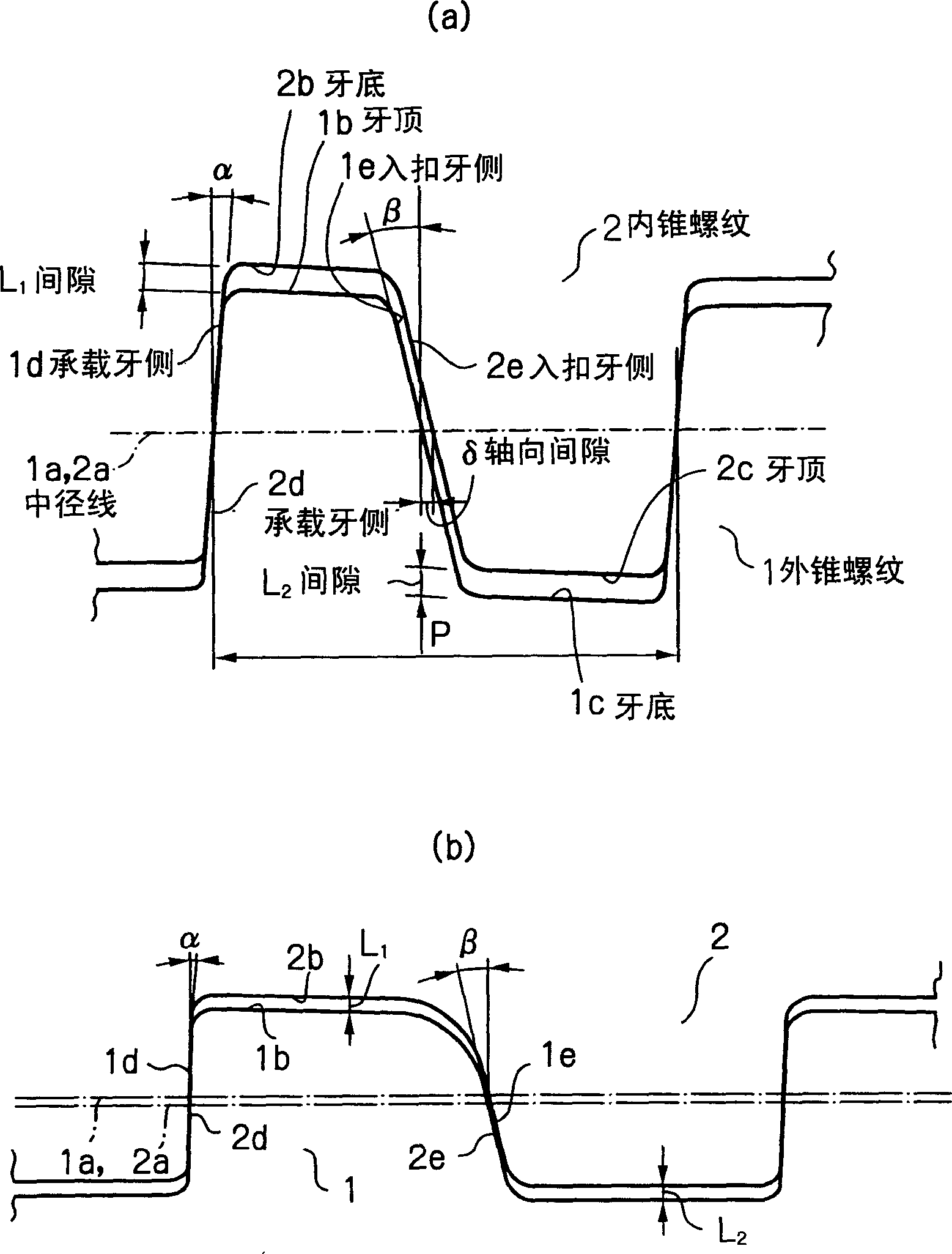

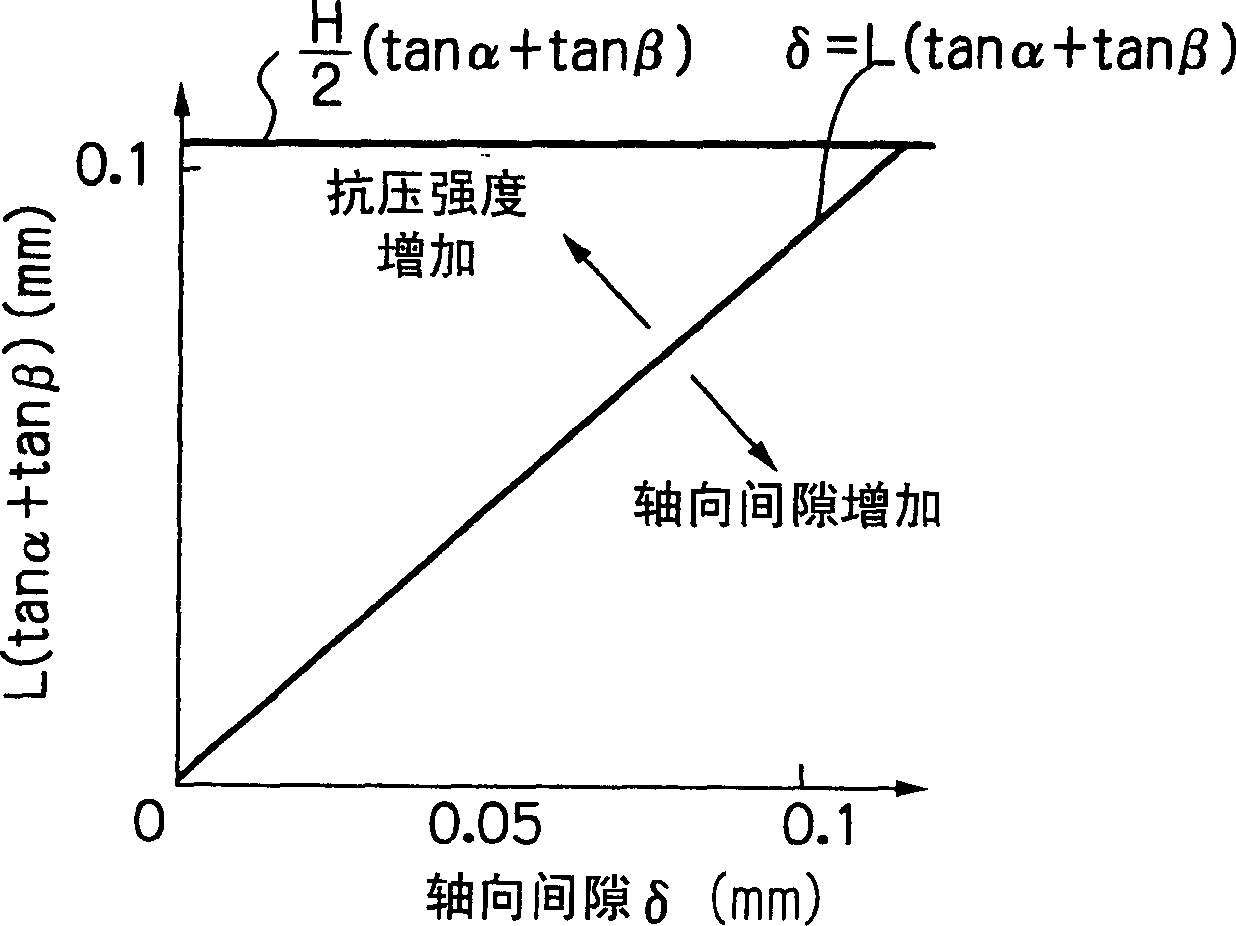

[0058] like image 3 As shown, in order to manufacture a thread in which both the load flank and the stab flank are in contact, a situation is depicted in which both surfaces are in contact due to the coincidence of the pitch diameters in a state where the threads have been engaged. Then, the dimensions of each piece can be determined. At this time, if the thread shapes of the external taper thread 1 and the internal taper thread 2 are the same, it becomes easier to determine the size.

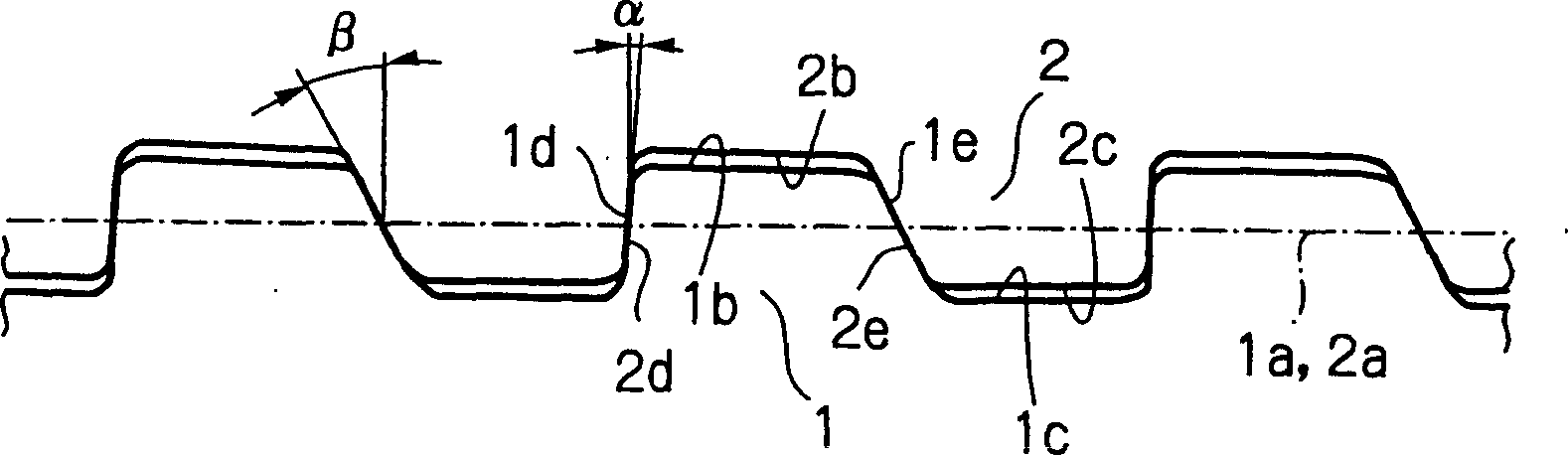

[0059] like Figure 4 (a) and 4(b) and Figure 5 As shown in (a) and 5(b), when the external taper thread 1 and the internal taper thread 2 are designed and drawn separately, the size of each part can be determined after determining the same basic thread shape and size.

[0060] However, during actual manufacturing, dimensional tolerances must be considered during machining. Manufacturing tolerances must be included when determining basic dimensions.

[0061] An embodiment of the present ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Outer diameter | aaaaa | aaaaa |

| Yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com