Cement paste system and preparation method thereof

A cement slurry and system technology, applied in the field of cement slurry system and its preparation, can solve the problems of damage, loss of sealing annulus, cement annulus can not maintain elastic properties, etc., to ensure sealing ability and effective interlayer isolation , The effect of reducing the risk of pressure in the annular space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0031] Unless otherwise specified, the high-temperature-resistant elastic material used in each embodiment of the present invention and comparative examples is SFP-1 purchased from Dezhou Continental Shelf Petroleum Engineering Technology Co., Ltd., which is nano-silica-rubber composite particles. The preparation method includes the following steps: Add rubber particles with an average particle size of 160 mesh and nano-silicon with an average particle size of 200nm to the mixer of the particle compounding system in a certain proportion, and adjust the experimental process parameters of the quantitative metering system so that the nano-silicon and rubber particles are fully mixed in the host machine. Contacting, mixing, and under the control of the control system, the powder is finally obtained in the collection device, forming a core-shell structure of micro-silicon-coated rubber particles.

[0032] Unless otherwise specified, the G-grade oil well cement used in the examples a...

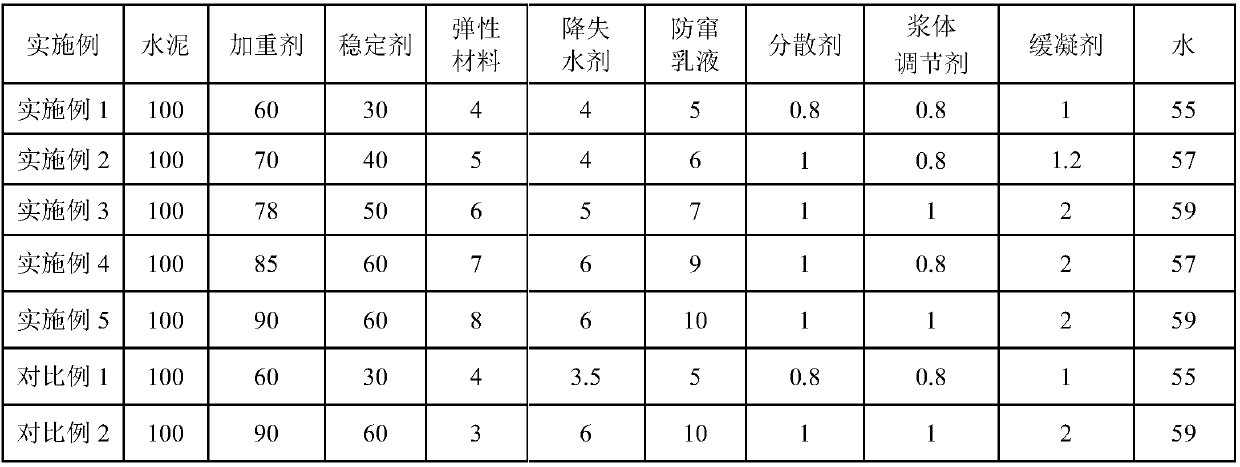

Embodiment 1

[0041] (1) Dry mix 100 parts by mass of G grade oil well pure cement, 60 parts by mass of weighting agent, 30 parts by mass of high temperature strength stabilizer and 4 parts by mass of high temperature resistant elastic material, and form a large sample of ash for storage and in a closed ash tank ready for use.

[0042] (2) Add 4 parts by mass of anti-high temperature fluid loss reducer, 5 parts by mass of high temperature resistant inorganic anti-channeling emulsion, 0.8 parts by mass of dispersant, 0.8 parts by mass of slurry regulator and 1 part by mass of retarder into 55 parts by mass of on-site water , fully circulate to ensure that the admixture is completely dissolved and mixed evenly to form a large sample of water, which can be used for construction.

[0043] (3) Pour the large-sample ash into the large-sample water and stir well to form a high-density cement slurry suitable for shale gas well cementing.

[0044] The dosage of each component is shown in Table 1. ...

Embodiment 2

[0046](1) Dry mix 100 parts by mass of G grade oil well cement, 70 parts by mass of weighting agent, 40 parts by mass of high temperature strength stabilizer and 5 parts by mass of elastic material, form a large sample of ash and store it in a closed ash tank for future use use.

[0047] (2) 4 mass parts of fluid loss reducer, 6 mass parts of high temperature resistant inorganic anti-channeling emulsion, 1 mass part of dispersant, 0.8 mass part of slurry regulator and 1.2 mass parts of retarder are added to 57 mass parts of on-site water, fully Circulation to ensure that the admixture is completely dissolved and mixed evenly to form a large sample of water, which can be used for construction.

[0048] (3) Pour the large-sample ash into the large-sample water and stir well to form a high-density cement slurry suitable for shale gas well cementing.

[0049] The dosage of each component is shown in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size (mesh) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com