A non-waste mining method for underground mines

A mining method and mining technology, which are applied in open-pit mining, underground mining, surface mining, etc., can solve the problems of encroaching on a large area of farmland and land, harming the environment, polluting water sources and soil, etc., and achieving the effect of saving filling costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

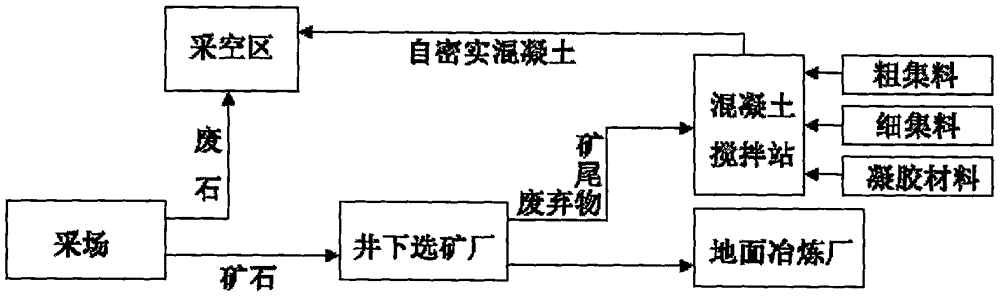

[0015] A kind of underground mine no-waste mining method of the present invention comprises the following working steps:

[0016] (1) Waste rock stockpiling: The waste rocks mined from the stope are directly transported to the goaf to be filled for stockpiling. Leveling, when the highest point of the waste rock is 0.5 meters away from the roof, the stockpiling can be stopped.

[0017] (2) Image recording; photographs are taken during waste rock storage, and information such as particle size and void ratio is obtained by means of graphic analysis, which provides a basis for the design of self-compacting concrete proportioning.

[0018] (3) Install the roof pumping pipe: In order to ensure the roof connection rate of self-compacting concrete, the pumping pipe should be installed at the highest point of the filling area, and hooks should be installed on the roof every 2 meters to facilitate the final pumping pipe.

[0019] (4) Fix the steel plate: After installing the pumping pi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com