Deep well coal-pillar-free gob-side entry driving method and formed roadway

A coal pillar-free, deep well technology, applied in tunnels, wellbore linings, tunnel linings, etc., can solve problems such as large engineering volume, narrow scope of application, and complex processes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

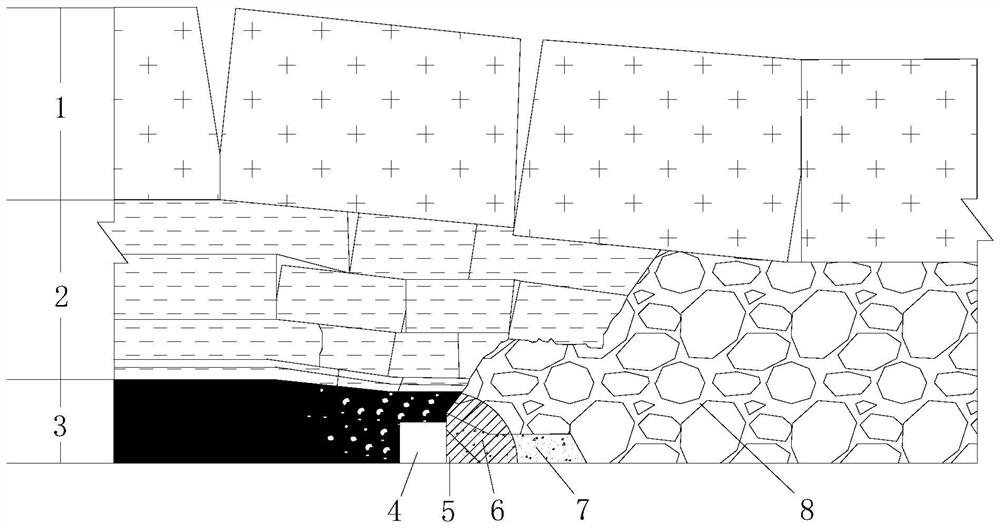

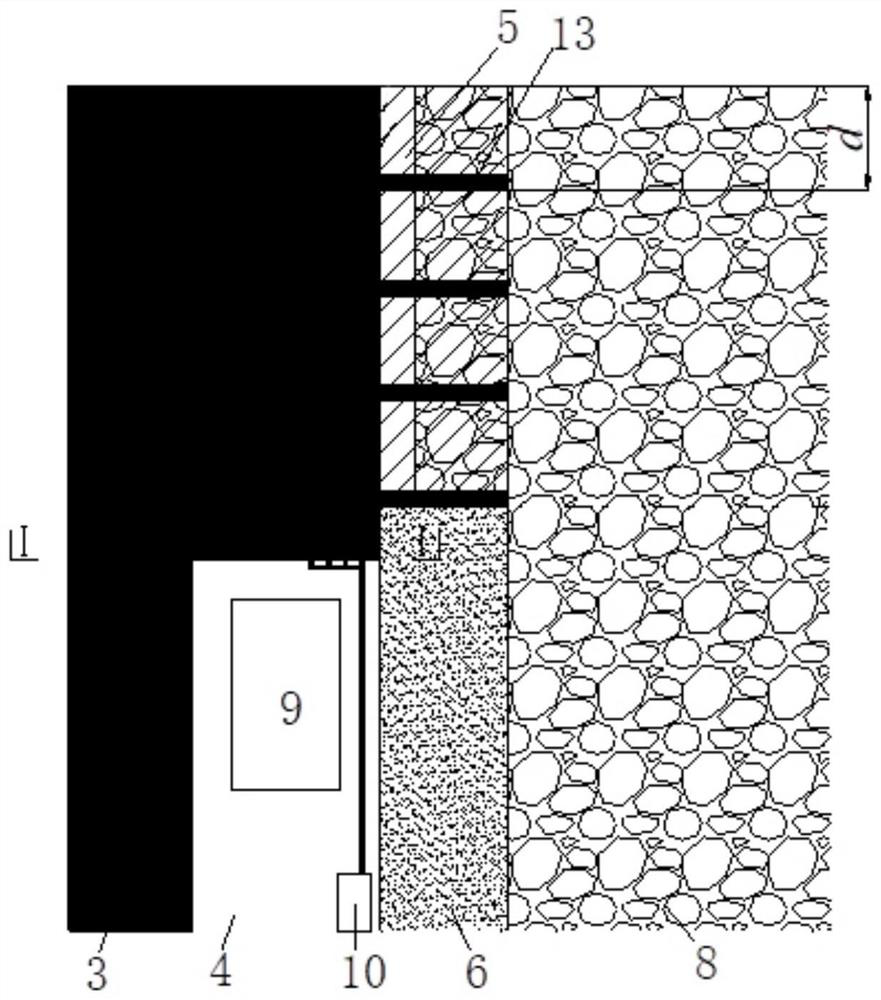

[0038] Such as Figure 1~3 As shown, a gob-side entry method without coal pillars in a deep mine comprises the following steps:

[0039] 1) Construction of airtight walls

[0040] In the mining process of the last working face, a closed wall 13 is constructed at intervals of d in the downward channel by stacking coal powder bags, where d is twice the length of the closed wall 13;

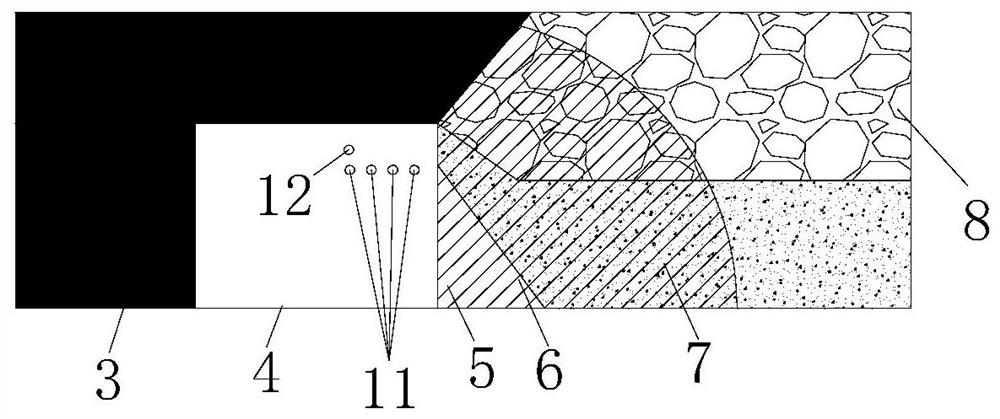

[0041] 2) Construction advanced grouting drilling

[0042] Drill four advance grouting holes 11 with a diameter of 150mm at the head-on face of the gob-side excavation roadway 1.5m away from the top plate. The advance grouting holes 11 are parallel to the bottom plate of the excavation roadway 4 and form an angle of 30° with the axis direction of the excavation roadway 4. Included angle, the first advanced grouting drilling is 0.5m away from the goaf side roadway side, and the other advanced grouting drilling holes are arranged in a straight line perpendicular to the roadway side at intervals of 0...

Embodiment 2

[0050] Such as Figure 1~3 As shown, a gob-side entry method without coal pillars in a deep mine comprises the following steps:

[0051] 1) Construction of airtight walls

[0052] In the mining process of the last working face, a sealed wall 13 is constructed at intervals of d in the downward channel by stacking coal powder bags, and d is the same length as the sealed wall 13;

[0053] 2) Construction advanced grouting drilling

[0054] Drill four advanced grouting holes 11 with a diameter of 120mm at the head-on face of the gob-side driving roadway 1.0m away from the top plate. The advanced grouting holes 11 are parallel to the bottom plate of the roadway 4 and form 20° with the direction of the axis of the roadway 4. Included angle, the first advanced grouting drilling is 0.3m away from the side roadway side of the goaf, the other advanced grouting drillings are arranged in a straight line perpendicular to the roadway side at intervals of 0.3m, and the final hole is in the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com