Treatment method of dug roadway roof fall

A treatment method, the technology of roadway roof fall, applied in the direction of tunnel, tunnel lining, earthwork drilling and mining, etc., can solve the problems of insufficient applicability, limit of roof fall size, easy failure, etc., and achieve wide practicability, improve stability, and convenient operation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

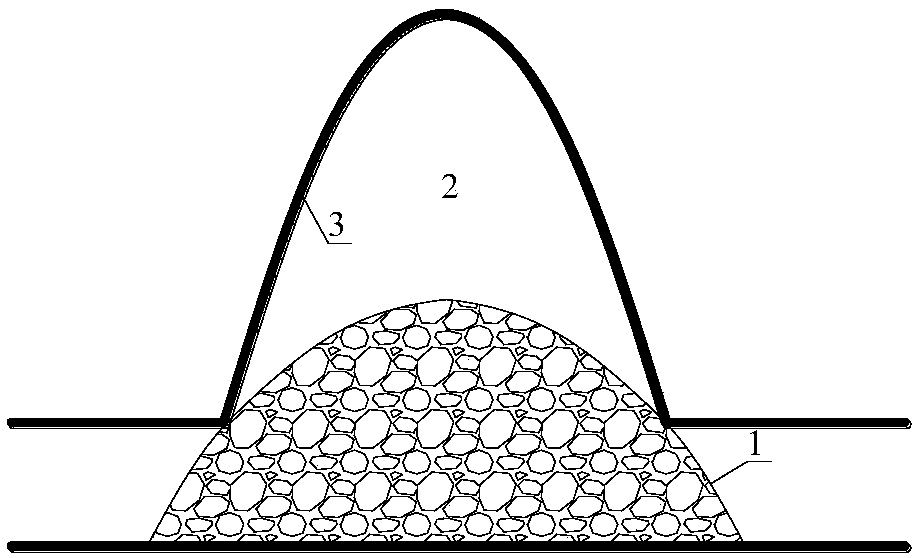

[0034] Example 1. A roof fall accident occurred in the track level roadway of a mine working face. The cross-sectional size of the roadway shaft: 4.0×3.5m, arched fall, the maximum fall height is 7.8m, and the axial length of the roadway is 5.3m. The specific processing steps are as follows:

[0035] 1) After the roof fall, clean up the fallen gangue 1 in time and pick up the loose coal and rock mass 3 on the surface of the fall-off area;

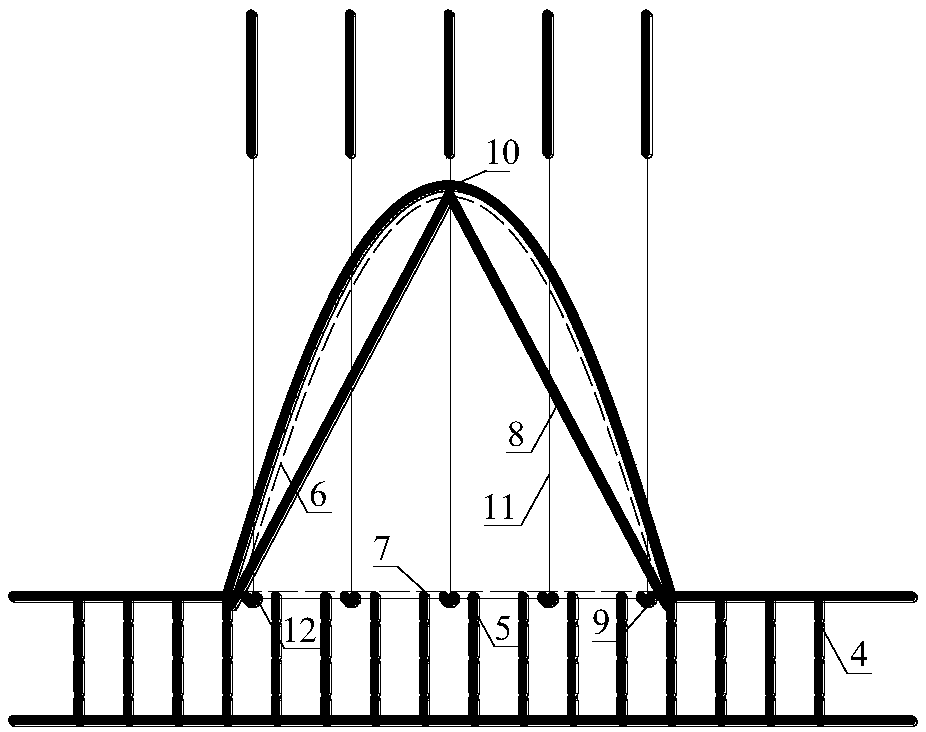

[0036] 2) Set up the I-shaped steel frame shed 4 at a distance of 1.0m in the fall area 2 and within the range of 3-5m on both sides;

[0037] 3) Spread a layer of planks 5 on the I-shaped steel frame shed 4;

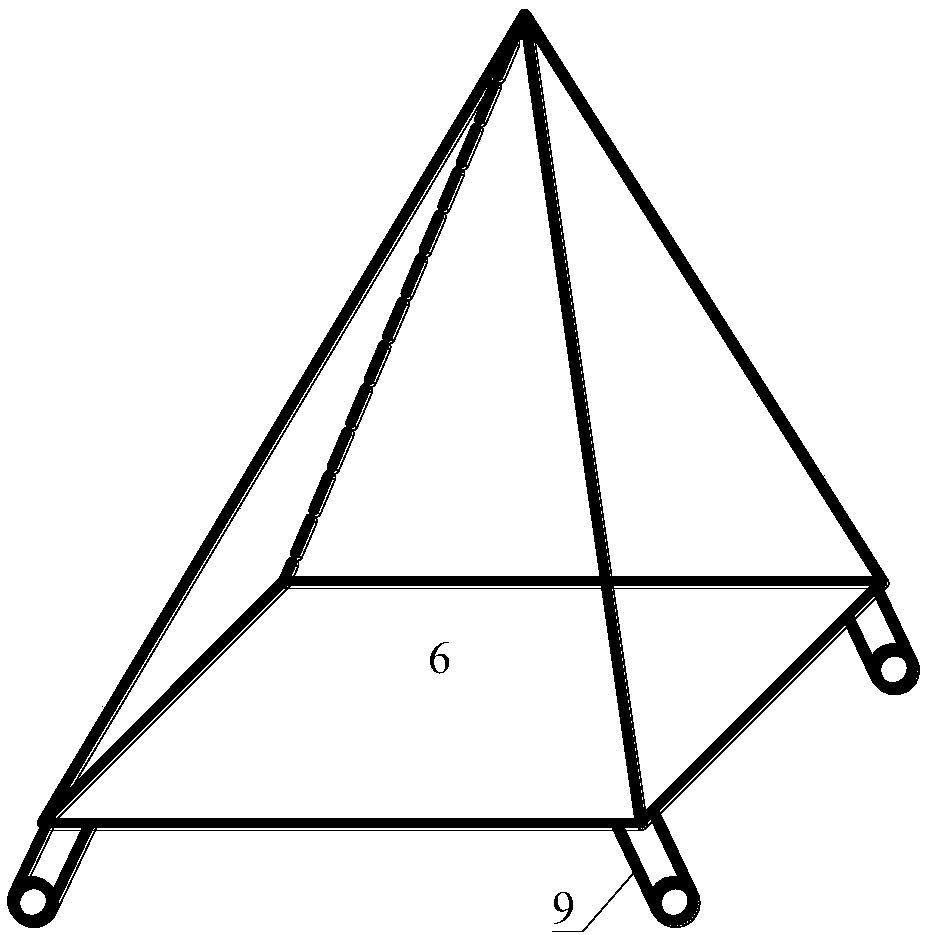

[0038] 4) Stretch the filling bag 6 and nail the bottom 7 around it on the plank 5;

[0039] 5) Extend one end of the steel or PVC pipeline 8 into the bag from the bottom cuff 9 of the filling bag and prop the top of the filling belt to the highest point 10 of the empty area, fix the steel or PVC pipeline 8 and place the other end ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com