Adhesive tape wrapping machine feeding mechanism with force unloading function and achieving method

A technology of feeding mechanism and encapsulating machine, which is applied to the parts of strapping machinery, etc., can solve the problems of lack of mechanical characteristics of the feeding mechanism and the lack of large-scale promotion of equipment, so as to improve the stress environment, expand the scope of application of strapping, Improve the effect of dressing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] The present invention will be further described below in conjunction with accompanying drawing.

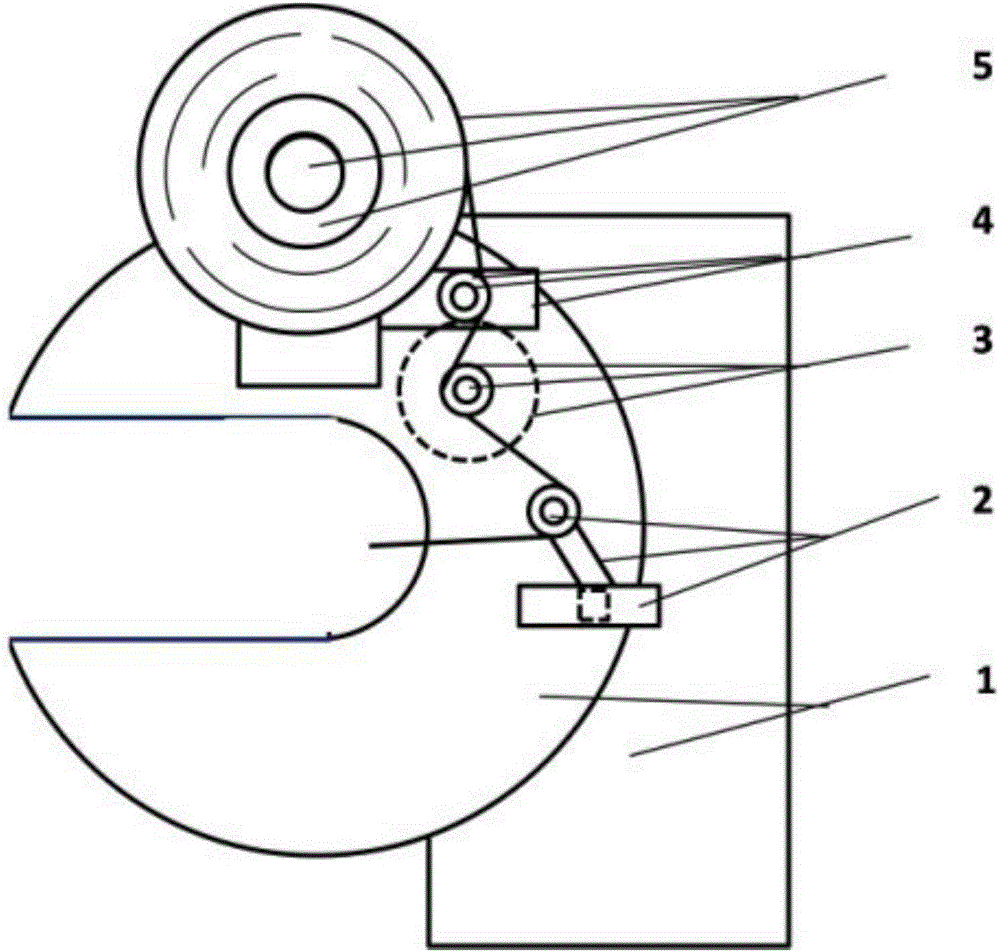

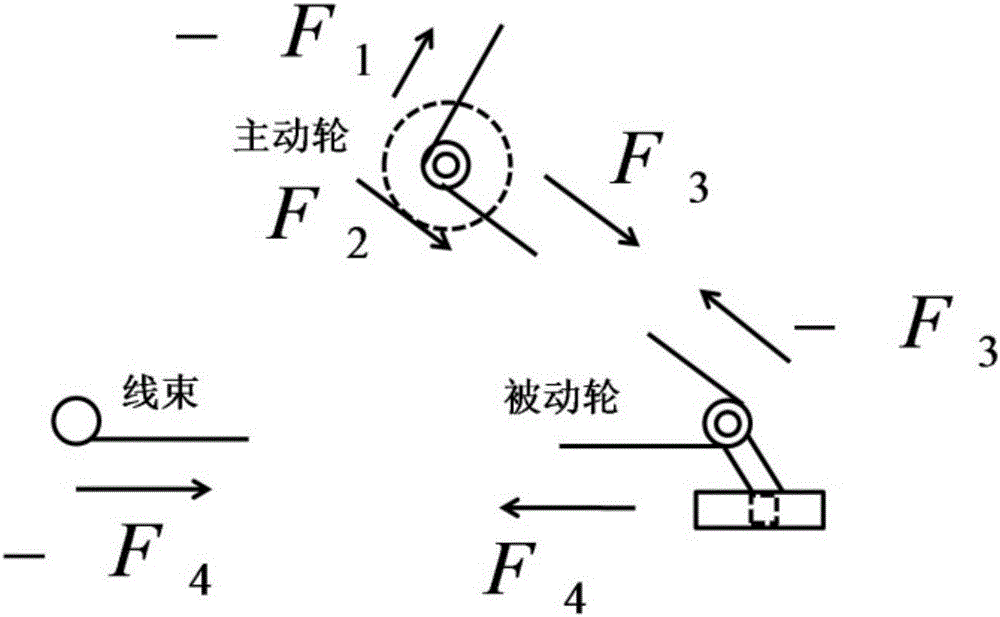

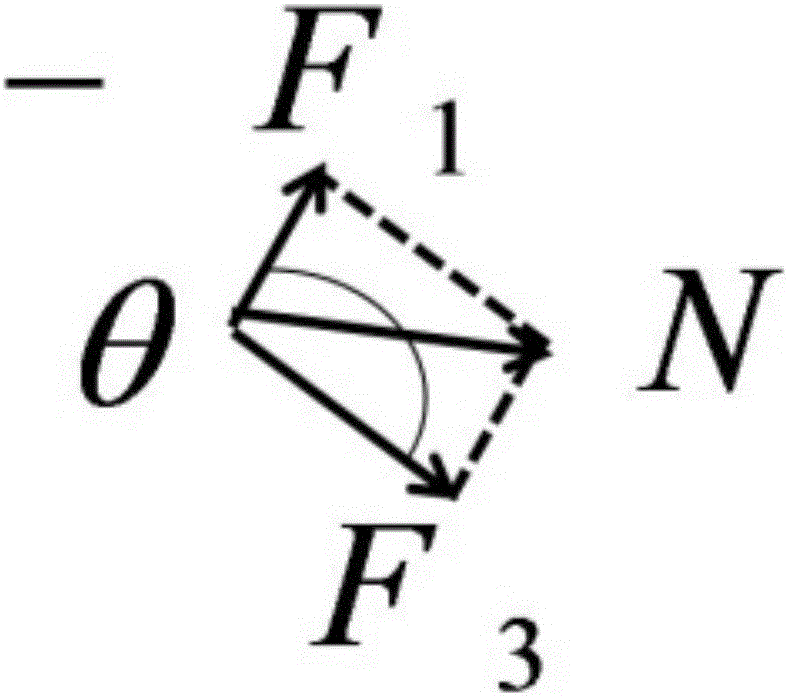

[0041] Such as figure 1 As shown, a rubber wrapping machine feeding mechanism with a force unloading function includes a main rotation mechanism 1, a feed angle adaptive mechanism 2, a force unloading mechanism 3, a force unloading angle adjustment mechanism 4 and a tray mechanism 5; The main rotating mechanism 1 is the carrier of the other four mechanisms, and the feed angle adaptive mechanism 2, the unloading mechanism 3, the unloading angle adjusting mechanism 4 and the tray mechanism 5 are all arranged on the same side of the main rotating mechanism 1; The tape pulled out by the disc mechanism 5 successively passes through the unloading angle adjustment mechanism 4, the unloading mechanism 3, and the feed angle adaptive mechanism 2, and then provides sustainable adhesive tape or strip-shaped material for the process of binding the wire harness.

[0042] The main rotati...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com