Equipment for automatically welding vacuum corrugated pipe

A technology of automatic welding and bellows, which is applied in welding equipment, metal processing equipment, auxiliary equipment, etc., can solve the problems of uncontrollable weld quality, low welding precision, and low degree of automation, and achieve easy maintenance and improvement, and convenient welding Precise, yield-enhancing effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be further described below in conjunction with drawings and embodiments.

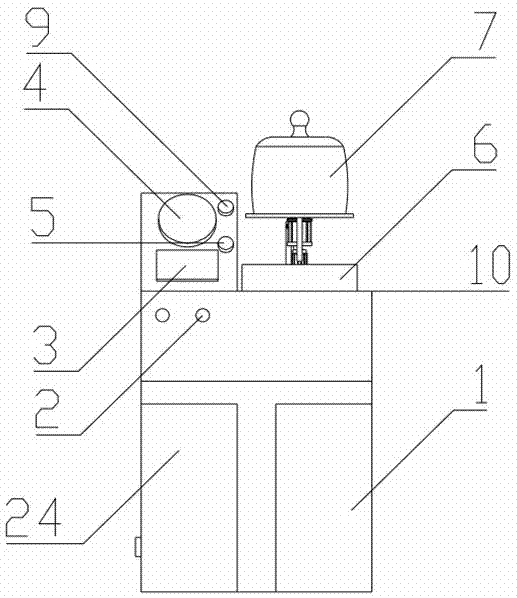

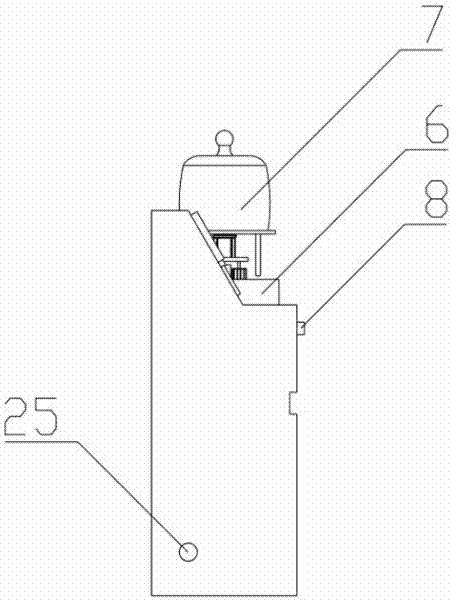

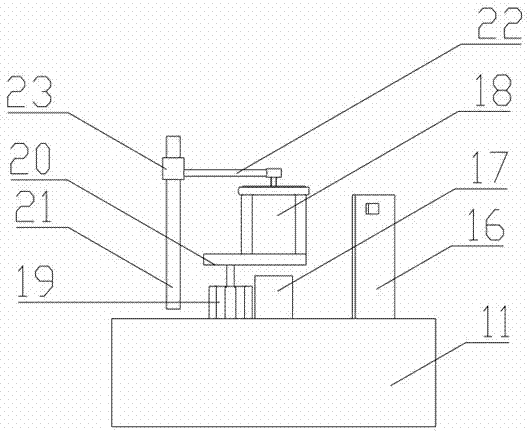

[0018] Such as figure 1 , figure 2 As shown, a workbench 10 is installed on the test bench 1 of the present invention, a bellows automatic welding tool 6 is installed on the table on one side of the workbench 10, and a cylinder inlet pressure gauge 4 and Touch screen 3, work indicator light 9 and alarm indicator light 5, be provided with start switch 8 and emergency stop switch 2 on the front panel of workbench 10, be provided with testbench front door 24 below testbench 1, and external supply gas intake connector 25 is installed on The bottom of the test bench 1 is connected to the internal gas circuit, and a circular tooling fixing base 11 is installed on the top of the workbench 10. Twelve non-penetrating equal-diameter round holes 12 are equally arranged on the bottom of the circular tooling fixing base 11 on the same circle. , corrugated tubes are respectively p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com