Patents

Literature

36results about How to "Uniform feed rate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Method for processing potato chips

Owner:包海荣

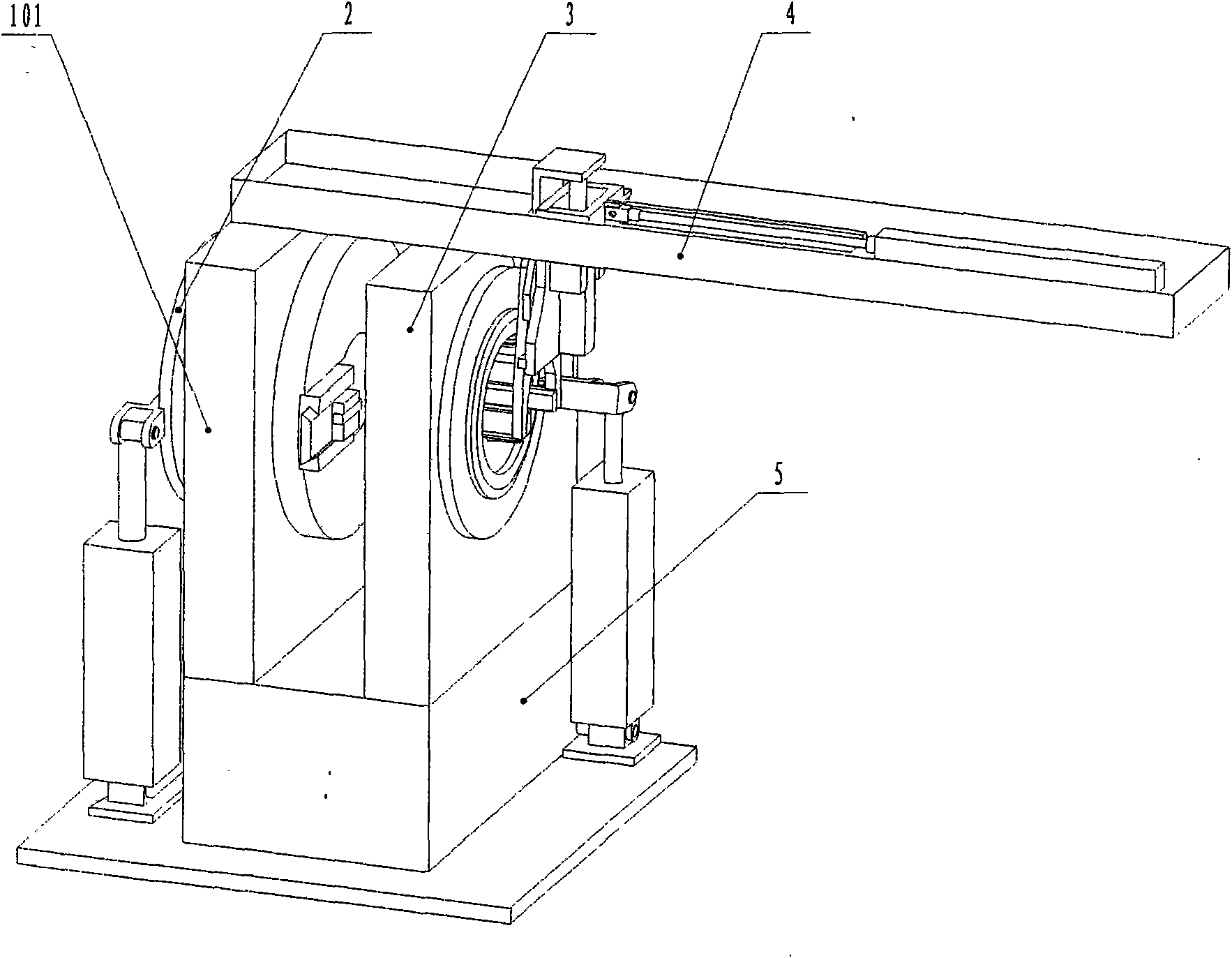

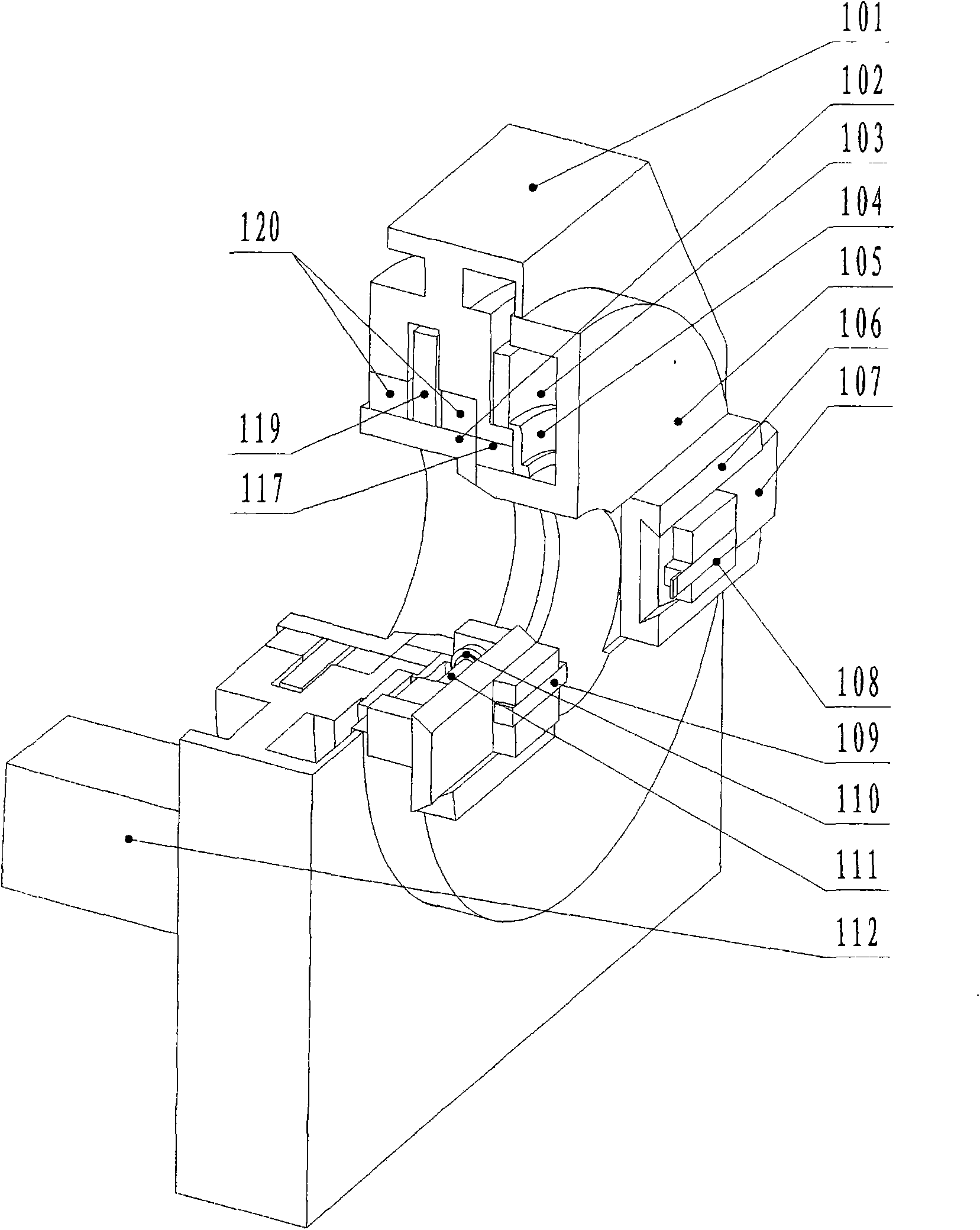

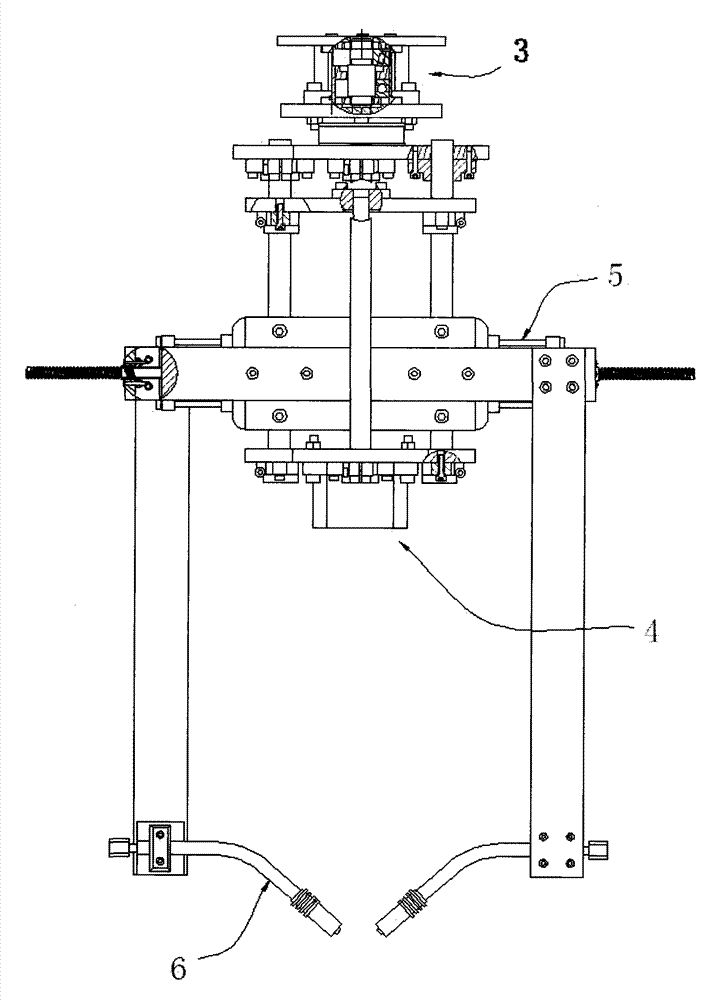

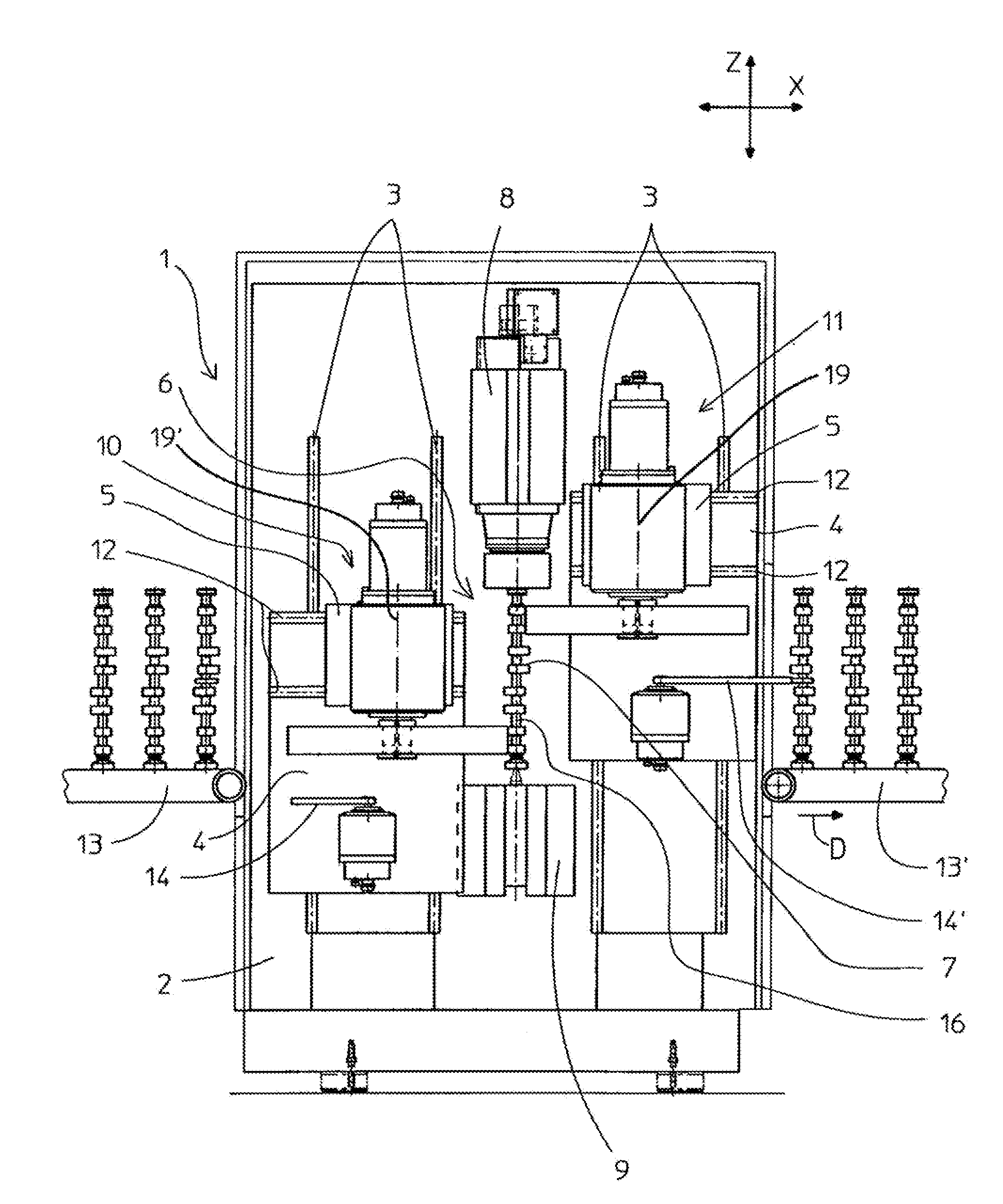

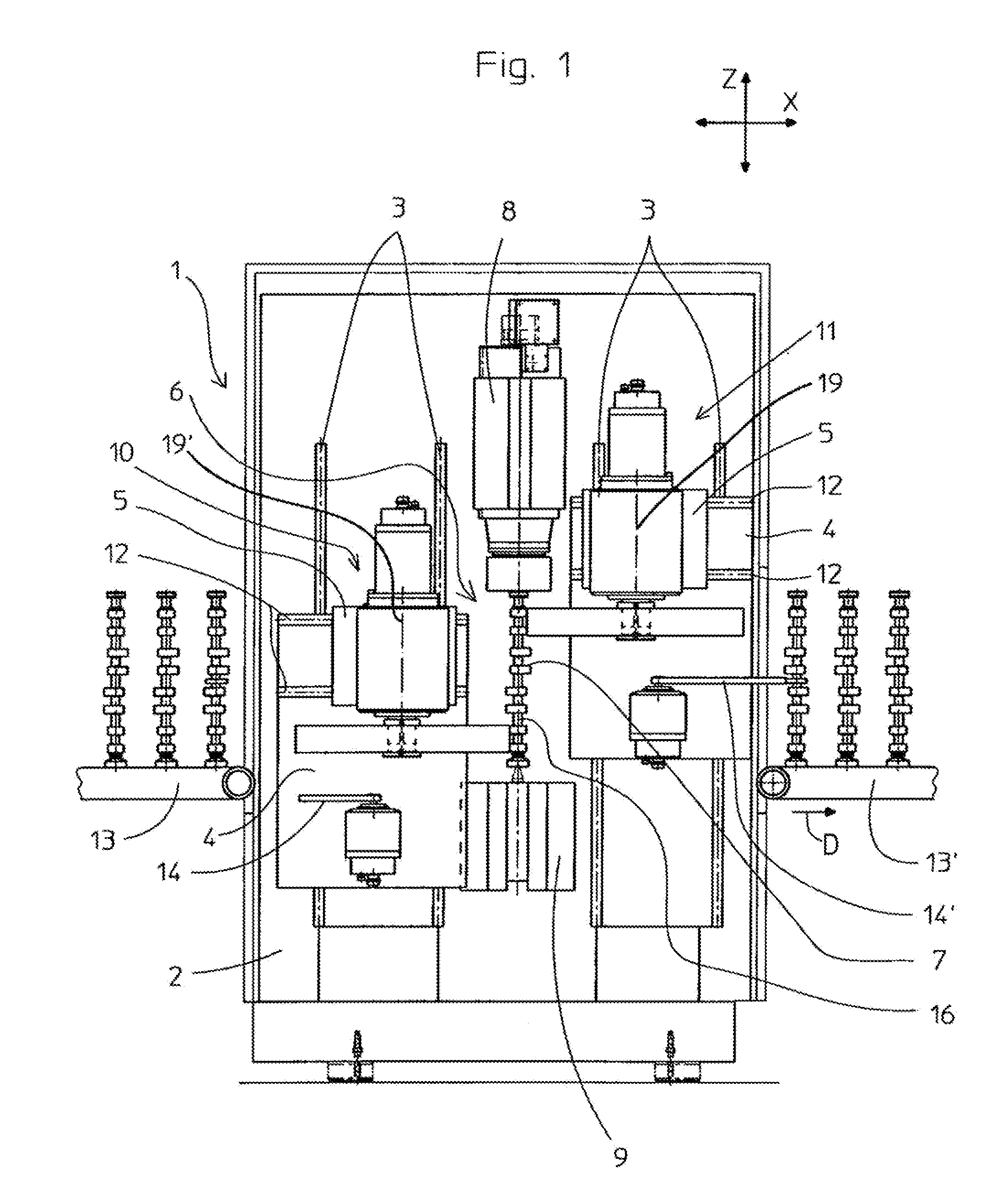

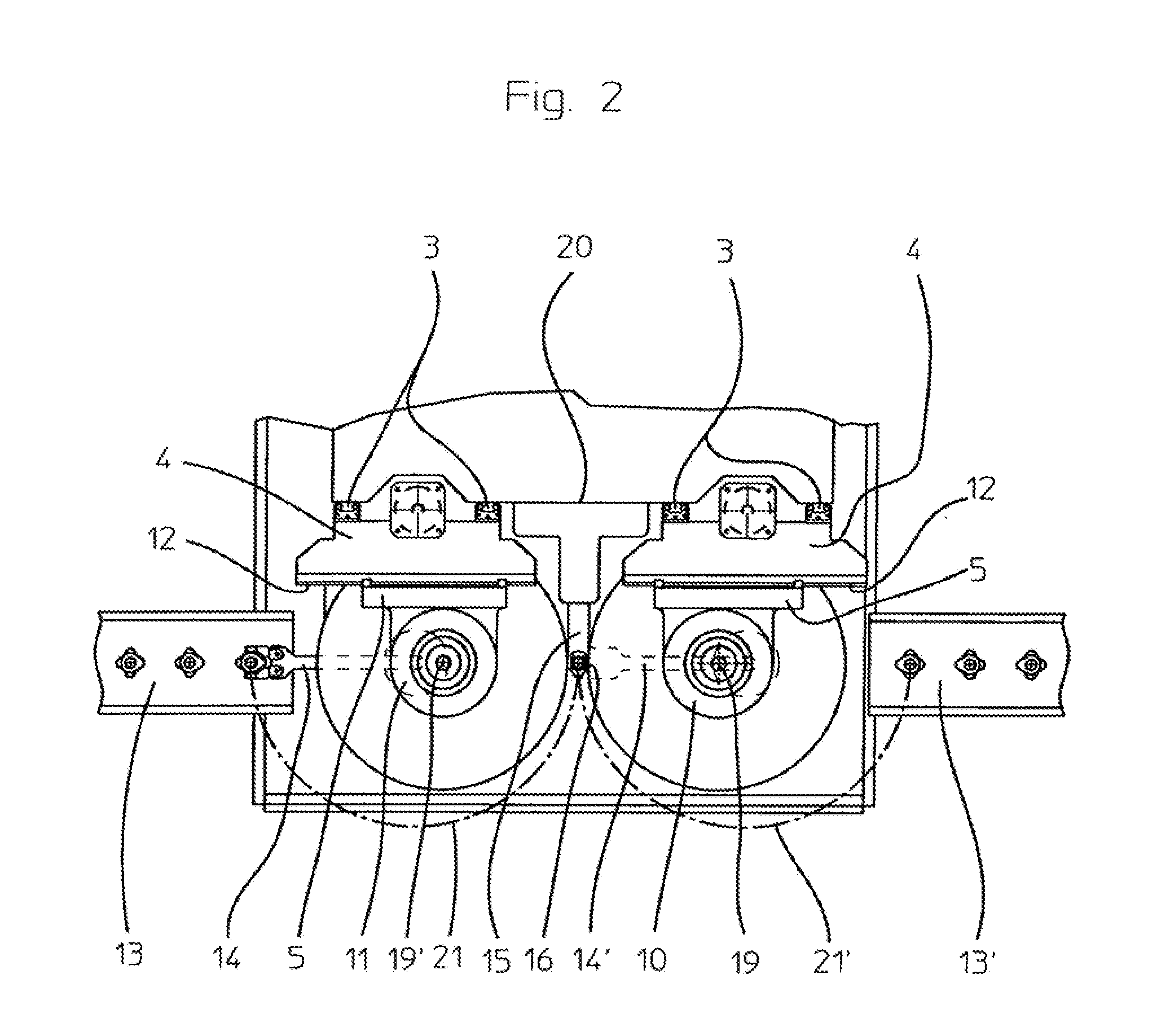

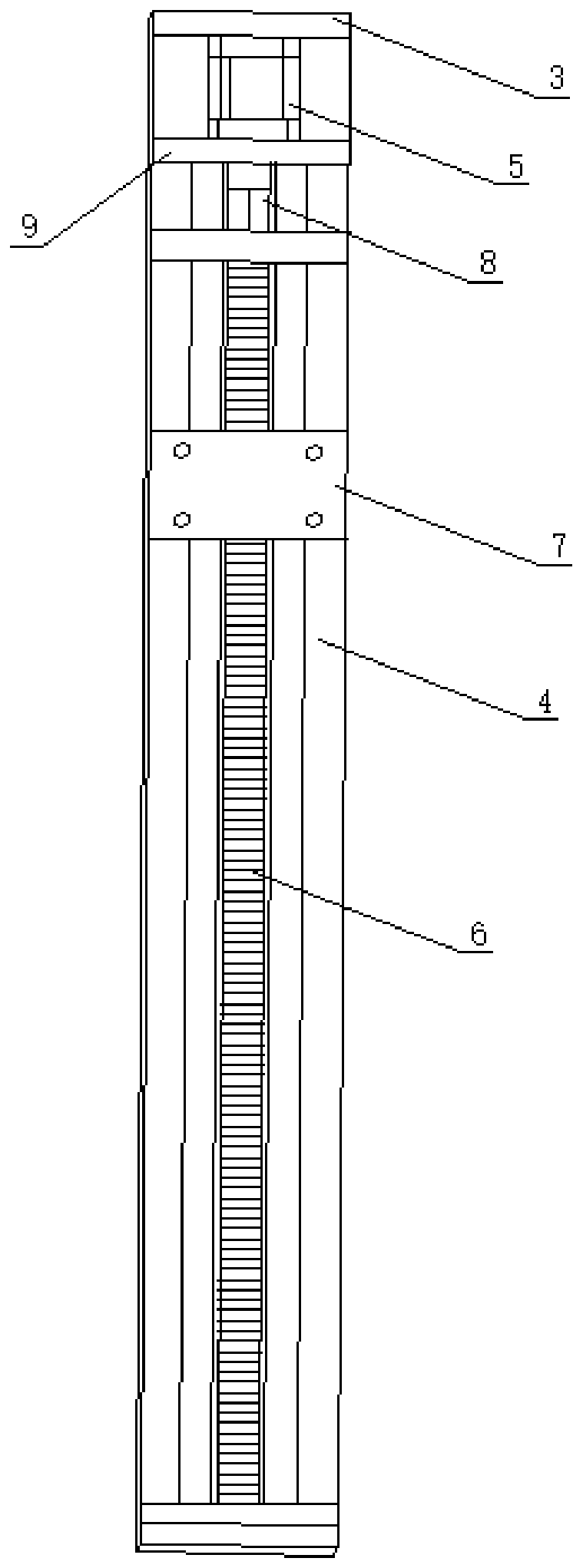

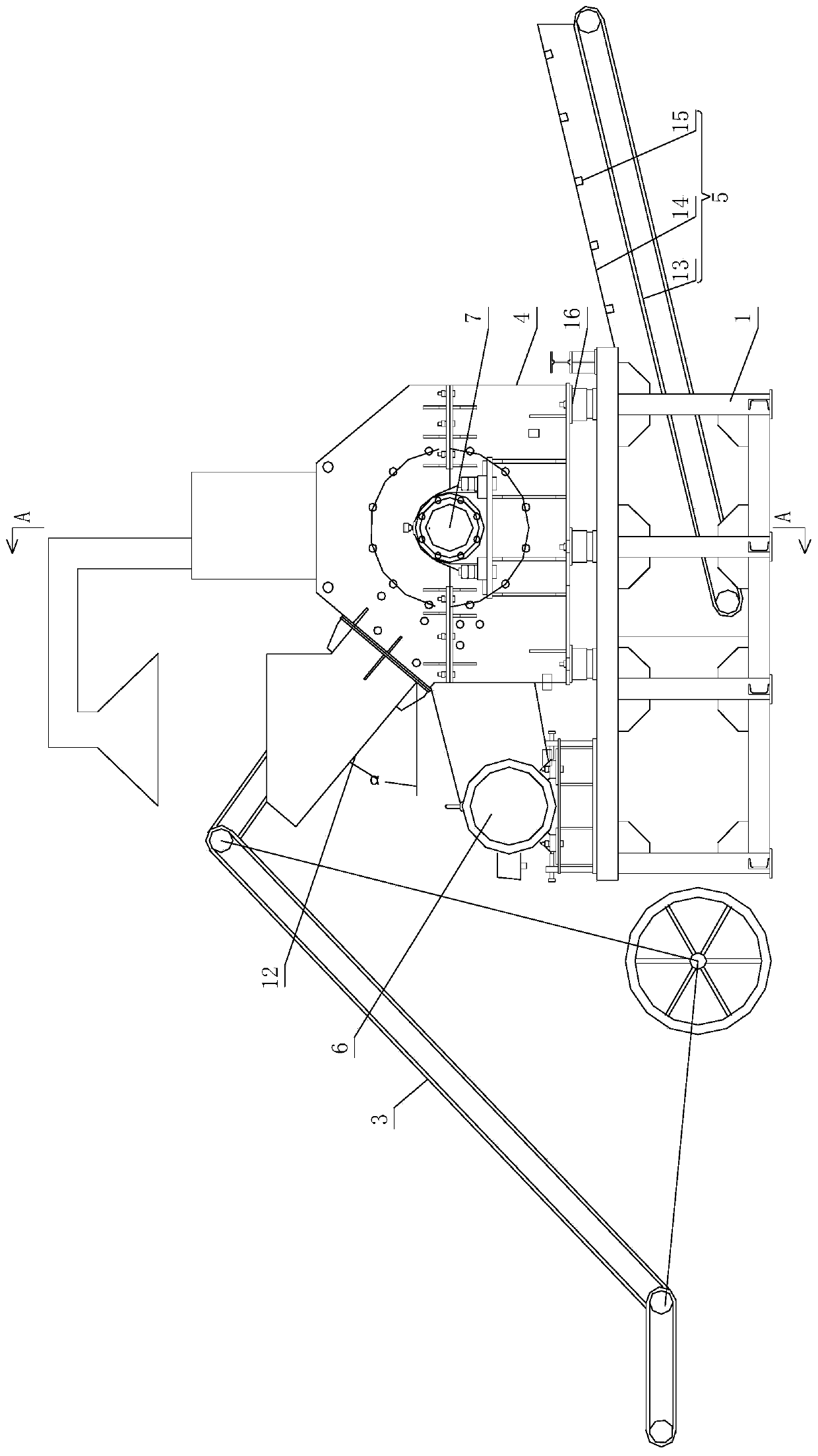

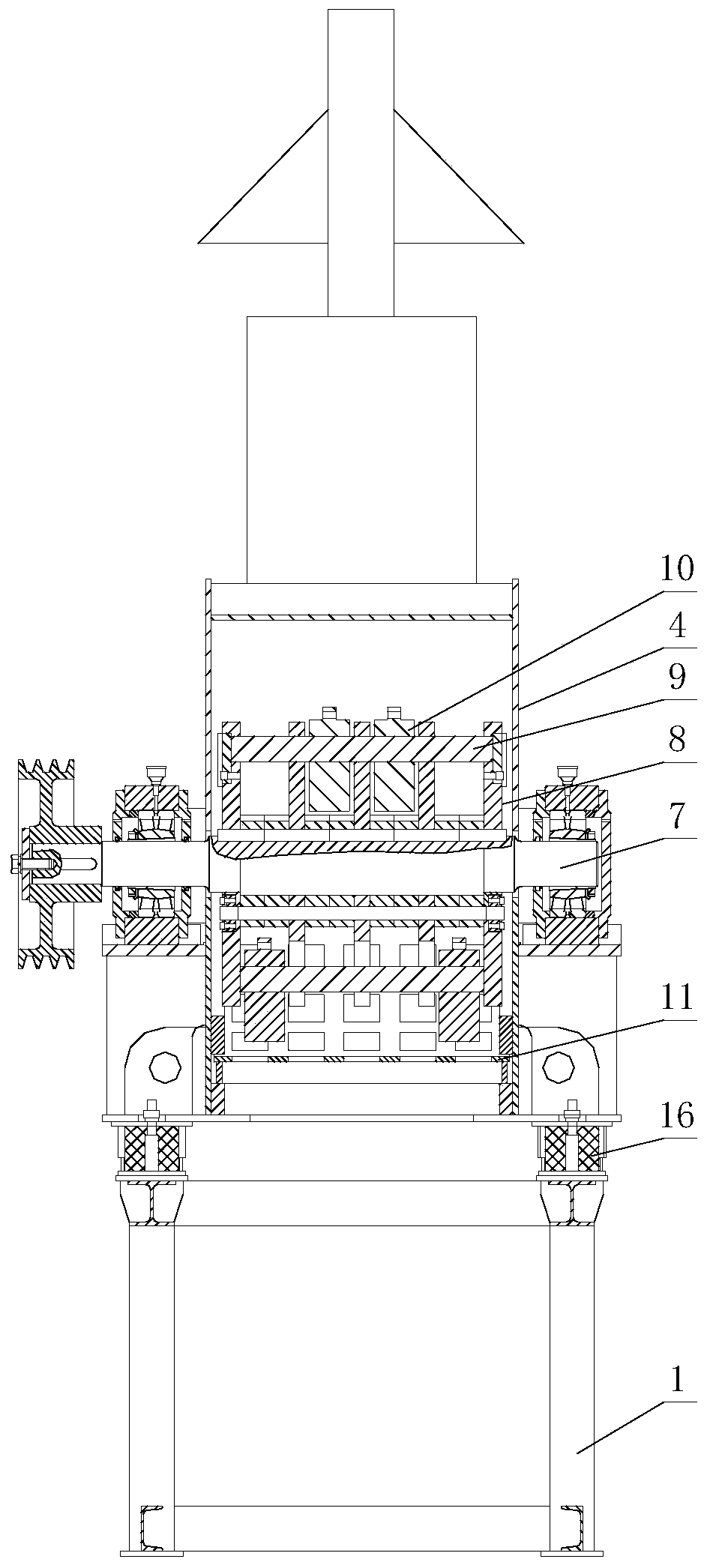

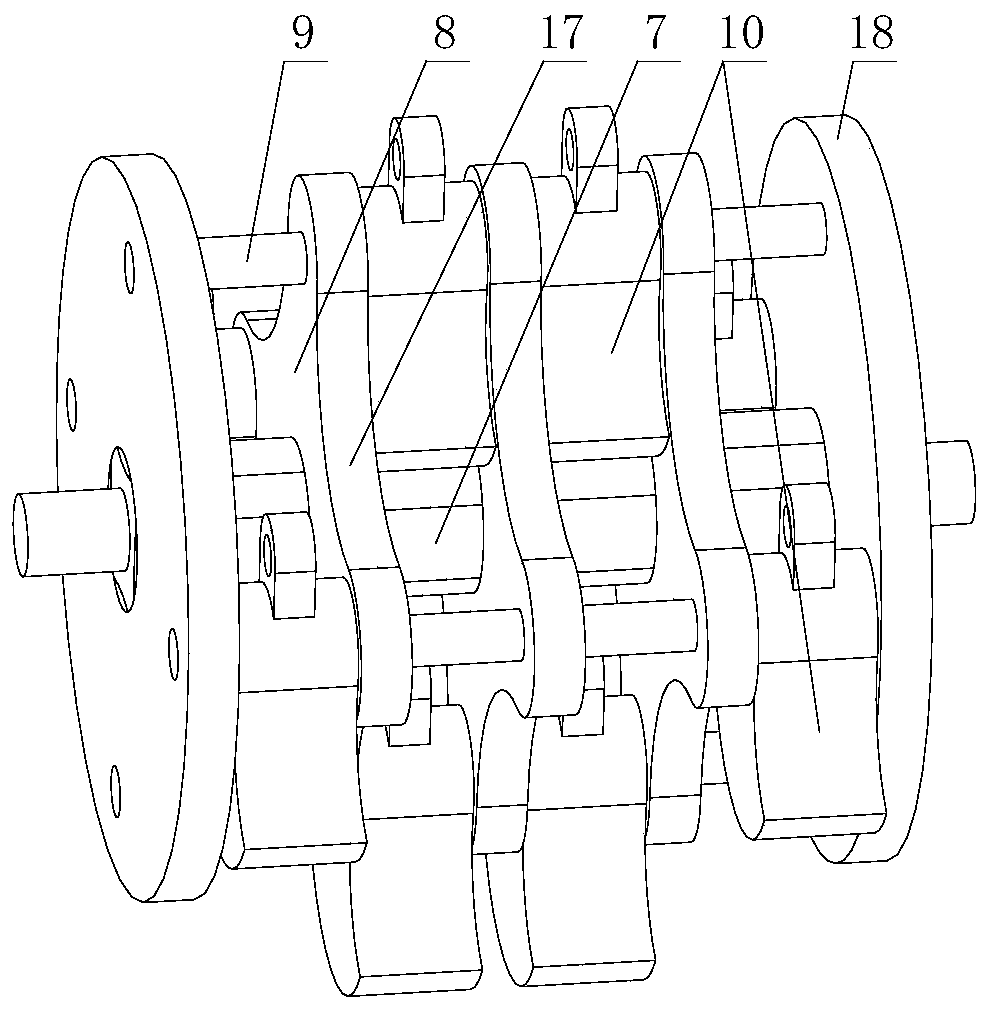

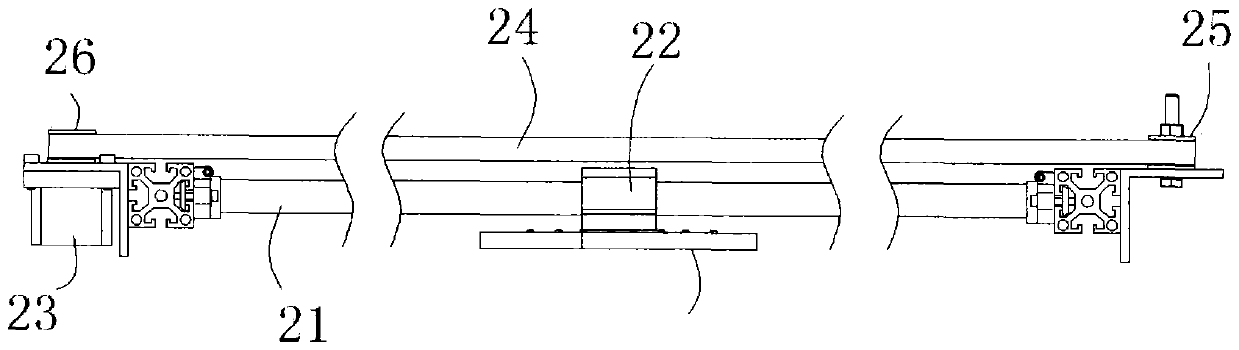

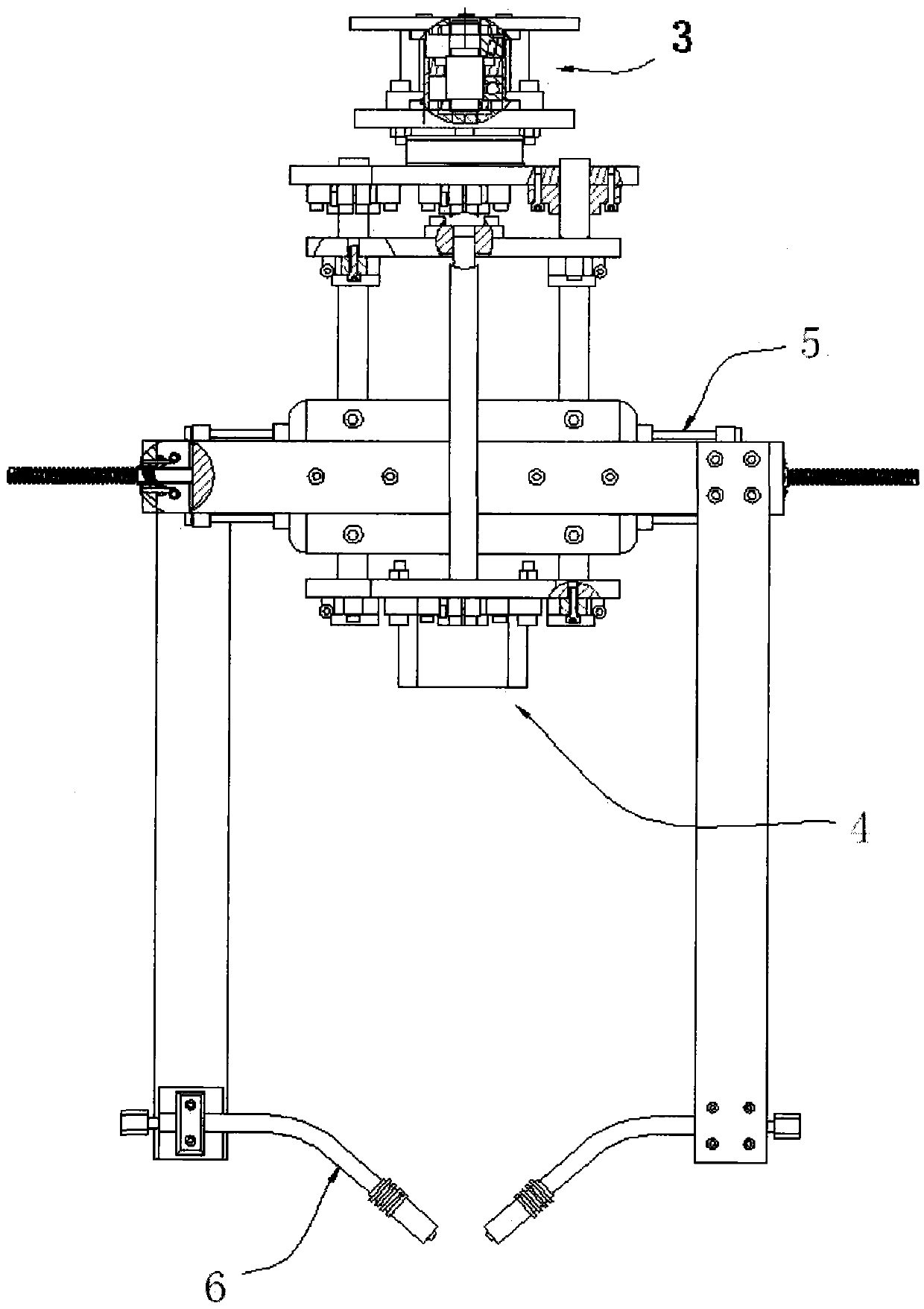

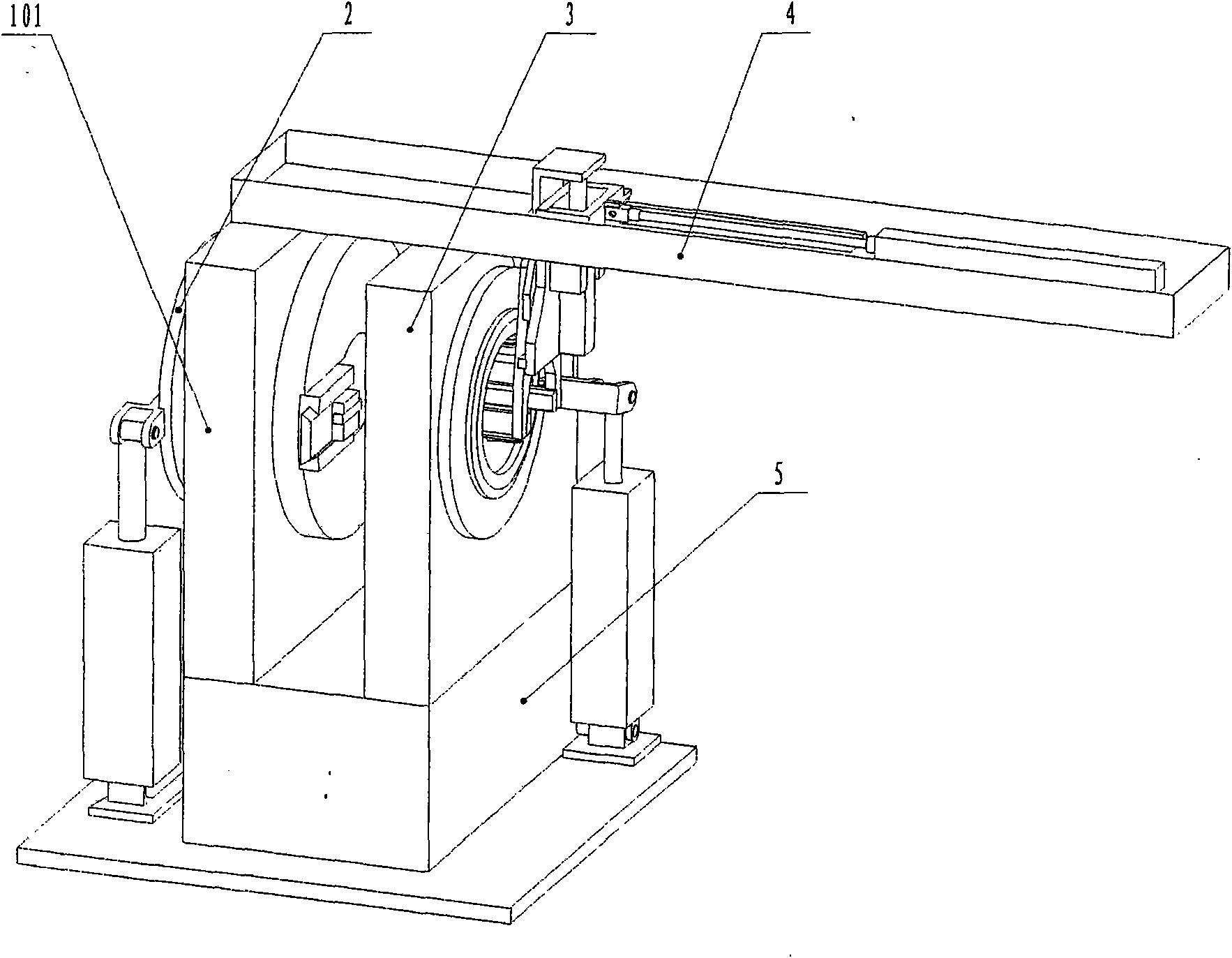

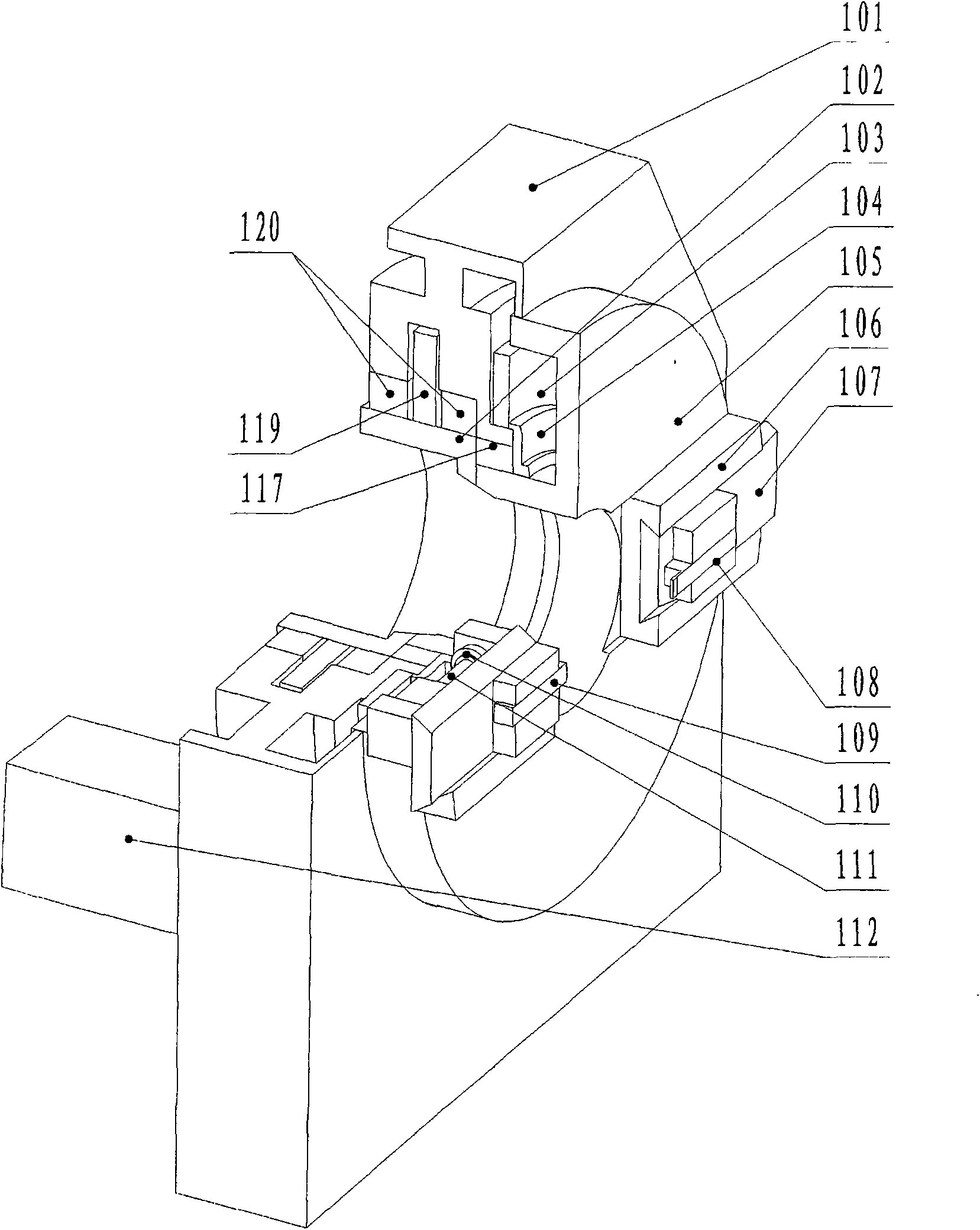

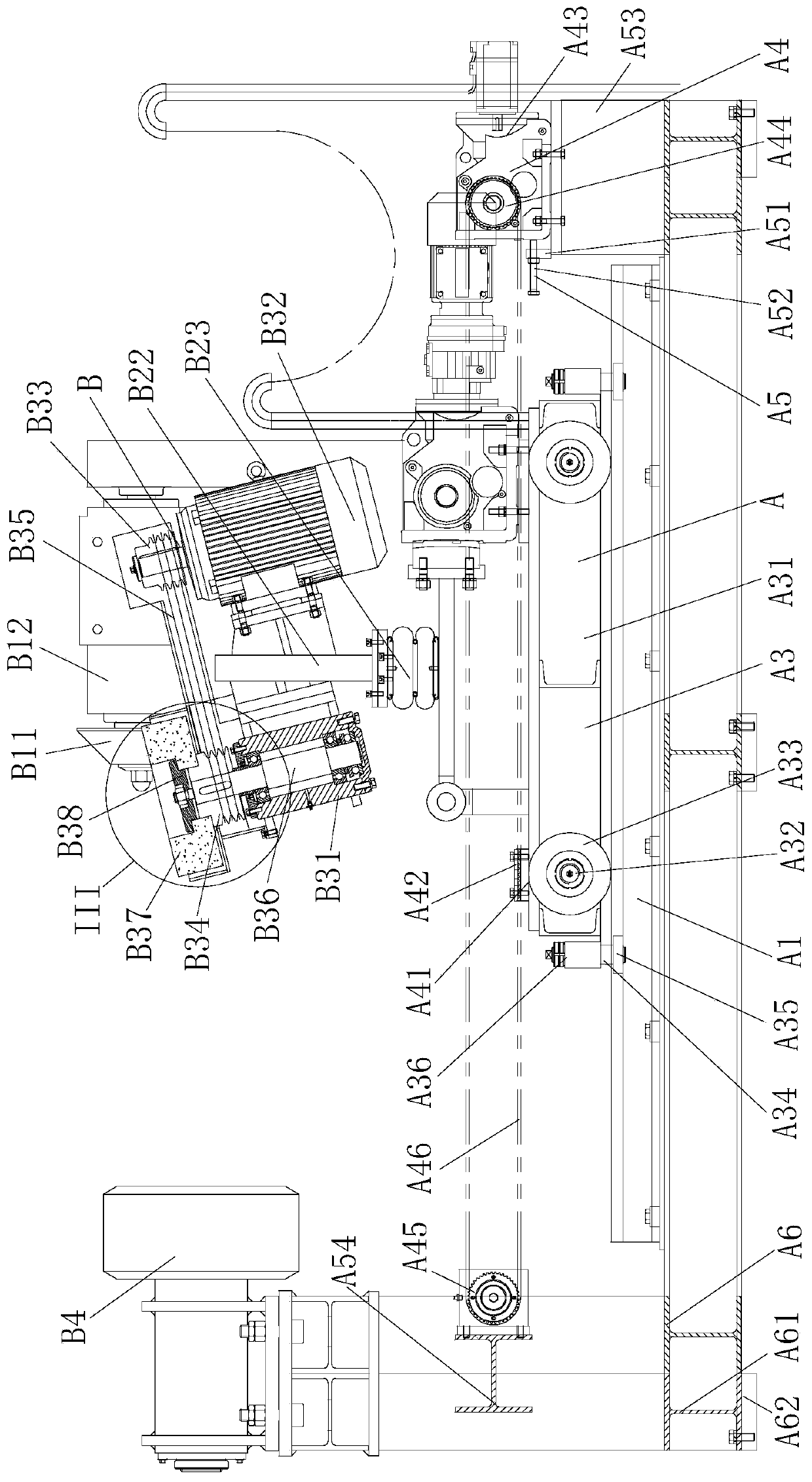

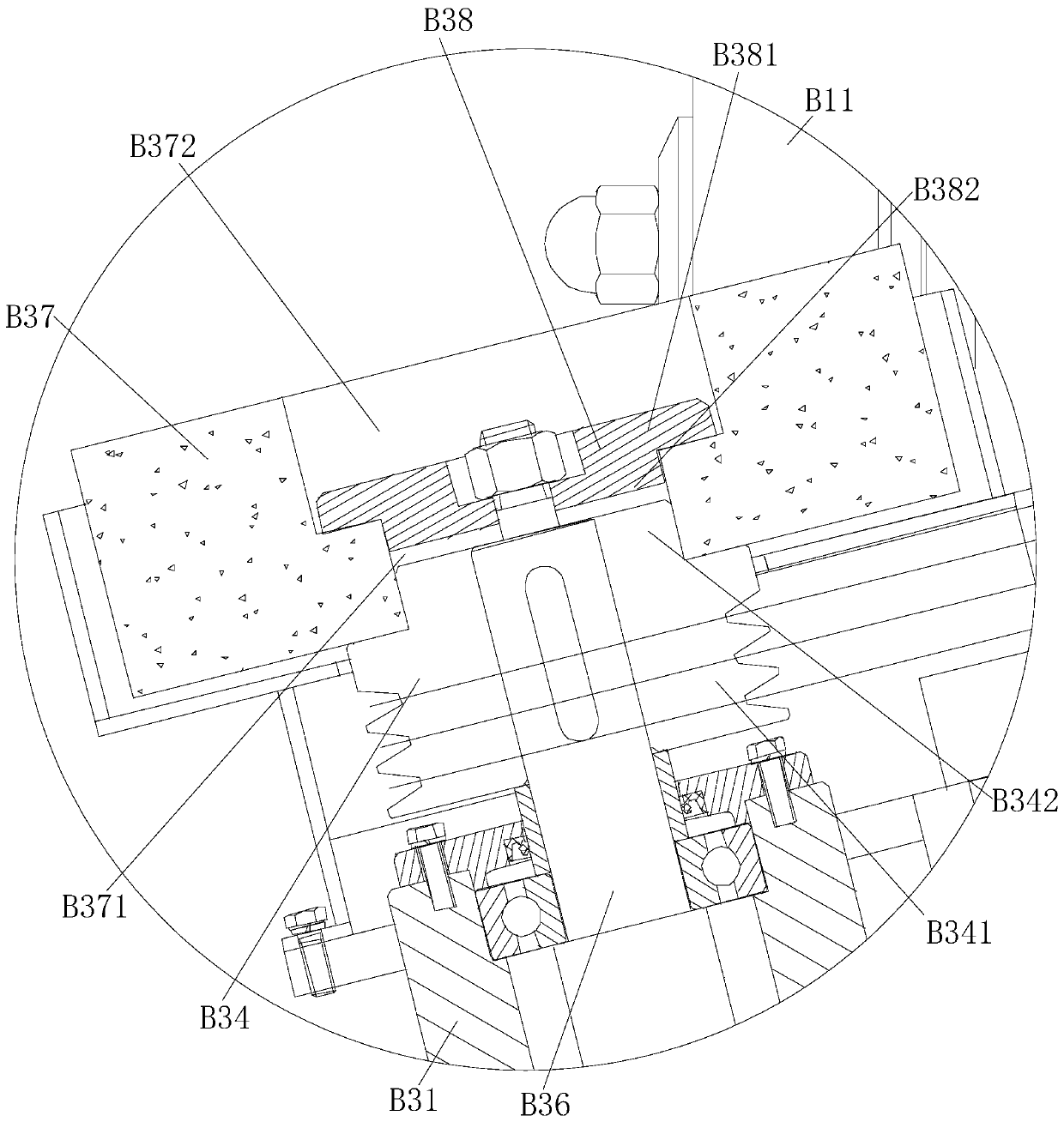

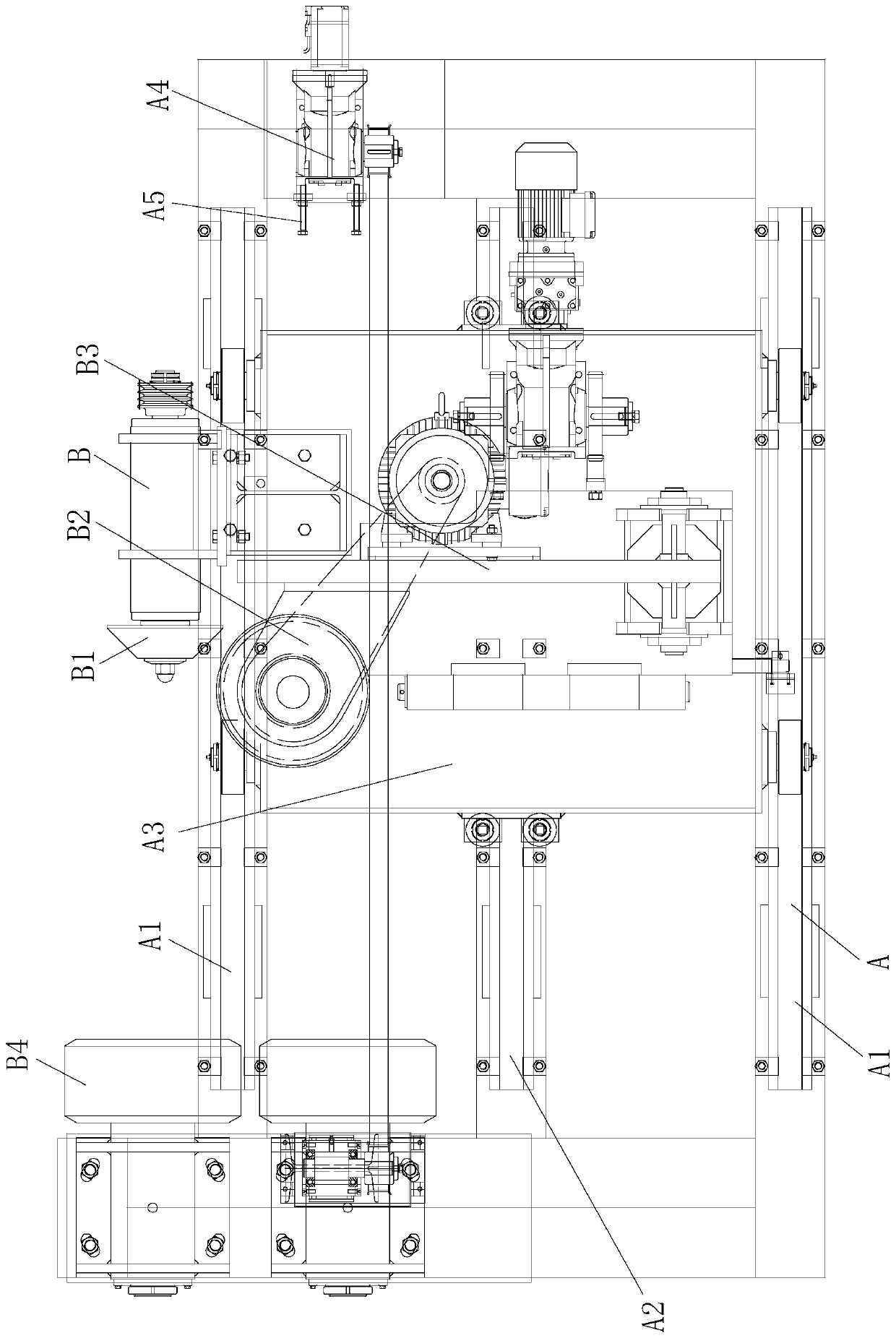

Groove pipe cutting all-in-one machine

ActiveCN102009223APrecise position controlNot easy to damageTube shearing machinesEngineeringMobile device

The invention discloses a groove pipe cutting all-in-one machine, which is characterized in that a rack is provided with a spindle, a cutter feed servo motor is fixedly arranged on the rack, a cutter rotating disk is connected with the spindle, and a cutter feed shelter is concentric with the cutter rotating disk; a transmission redirection component is arranged between the cutter feed shelter and a cutter mobile device, and the cutter rotating disk is provided with 2-4 cutter mobile devices; the front and the back of the rack are respectively provided with a clamping mechanism, and 3-6 jaws are evenly distributed on grip slippers in the front and the back clamping mechanisms respectively; and a clamping jaw, a guide rail and a horizontal expansion device are arranged in a beam above the rack and a support, and the clamping jaw is internally provided with a vertical expansion device, a guide rail and a pair of clamping jaws. By using the machine provided by the invention, the relativeangular velocity difference generated between the cutter feed shelter and the cutter rotating disk can be kept constant, and the cutter feed is stable and the movable position of the cutter can be accurately controlled, thus realizing groove manufacturing in different forms; and the cutter is not easy to damage, thereby ensuring even cutting speed and feed speed, and guaranteeing the groove manufacturing of a steel tube with different wall thicknesses.

Owner:上海中船临港船舶装备有限公司 +2

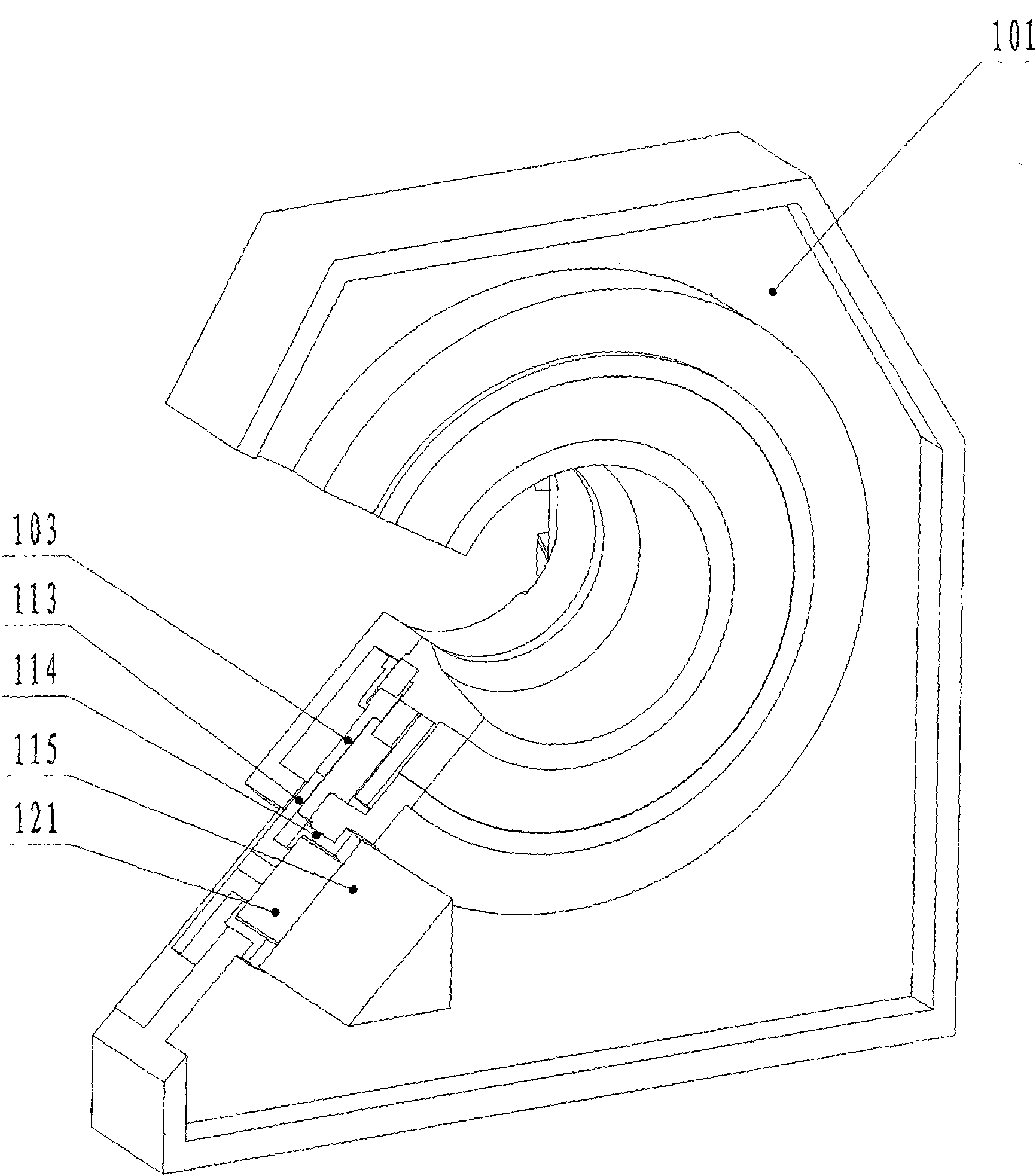

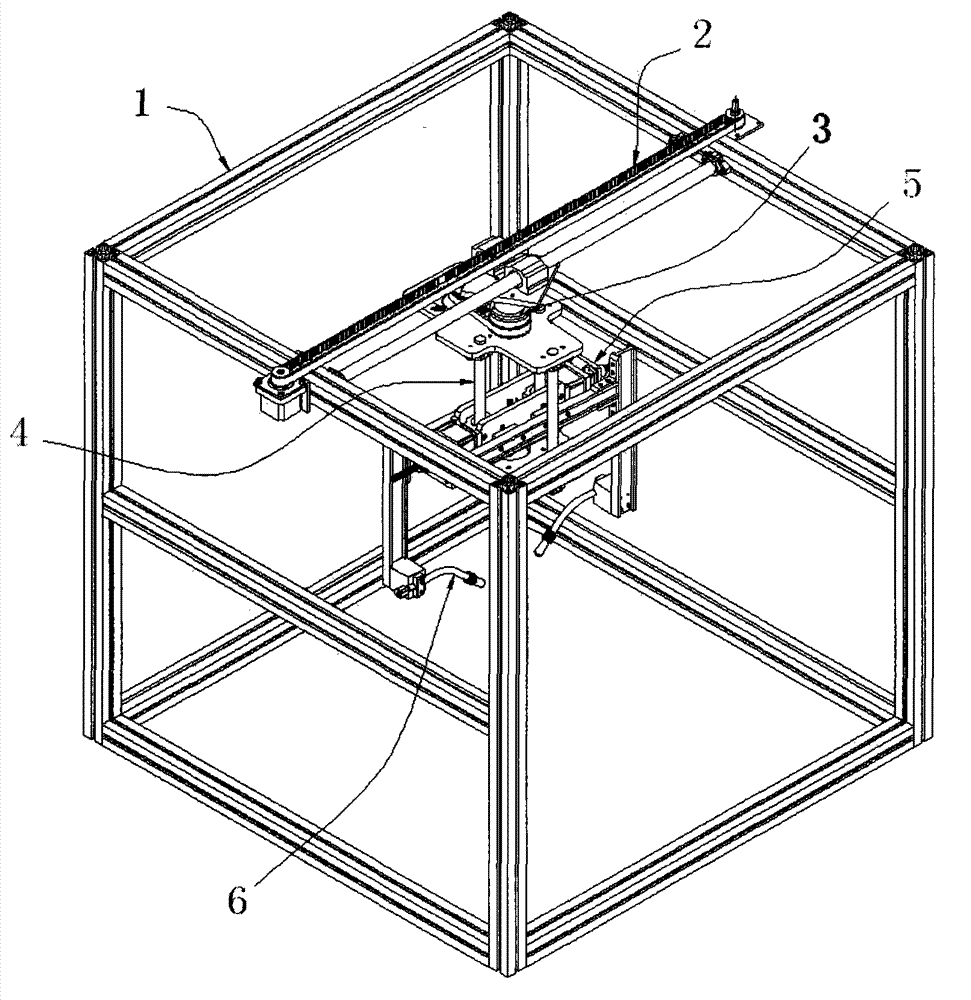

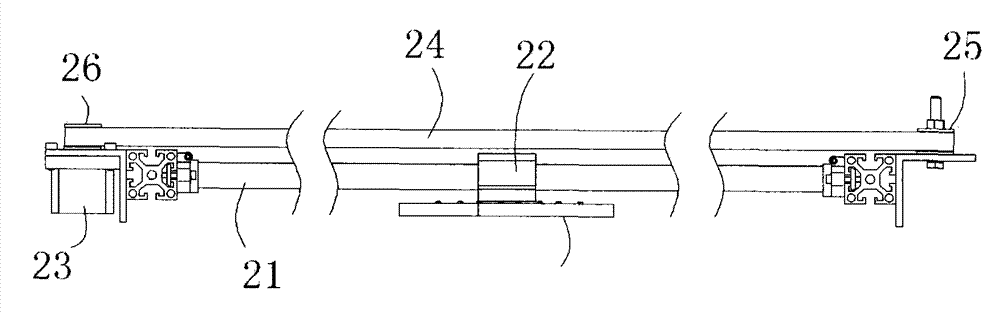

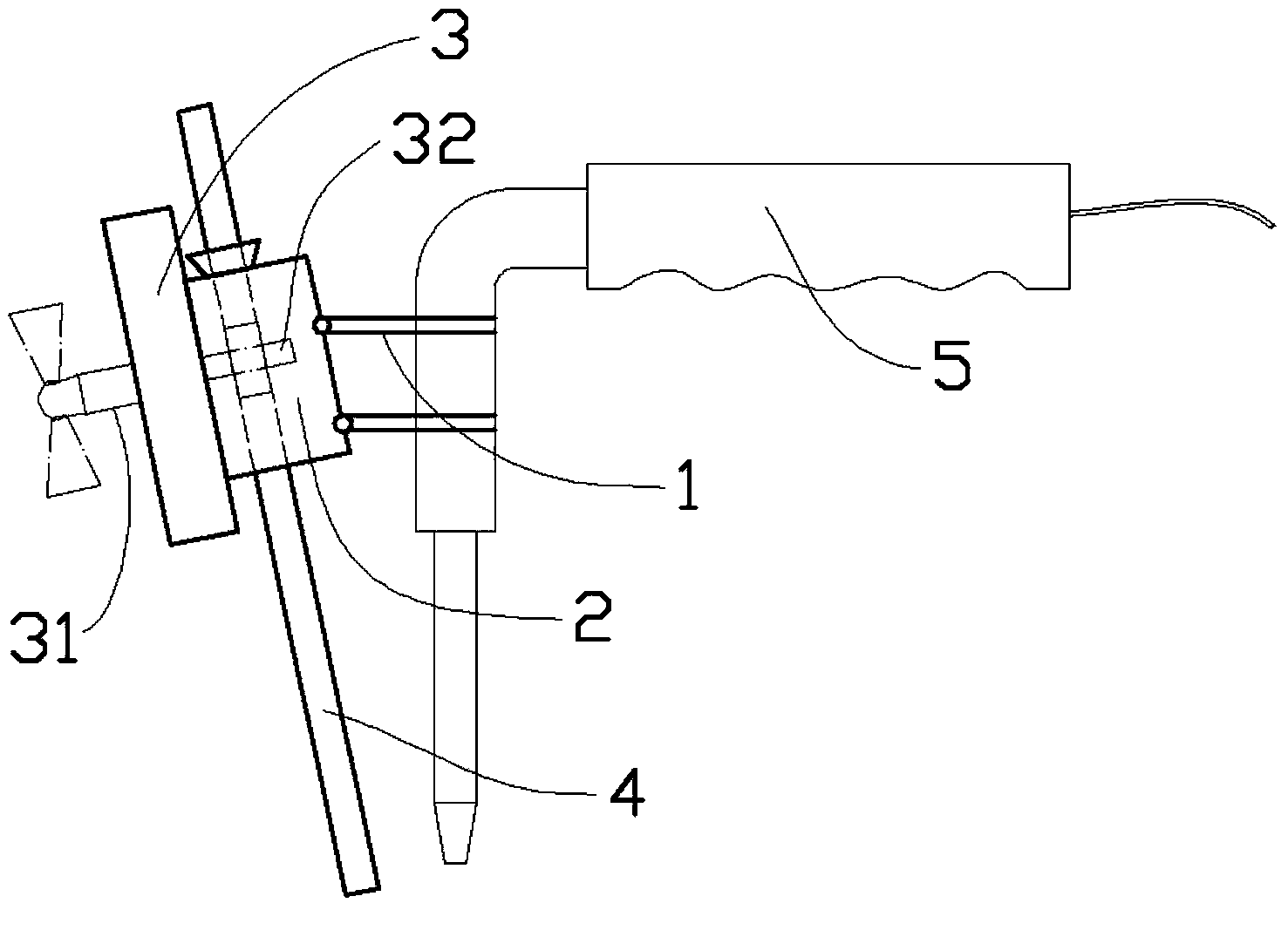

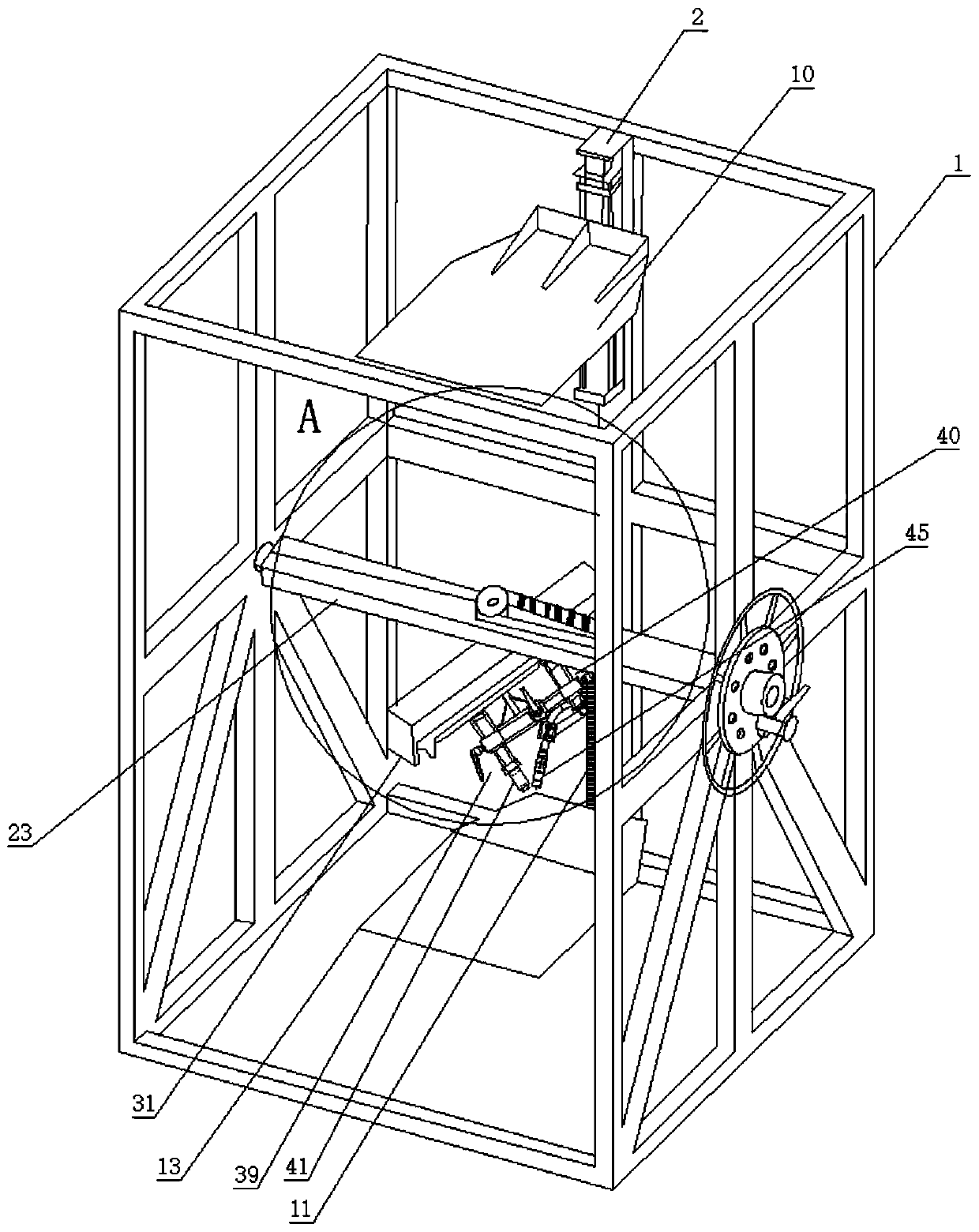

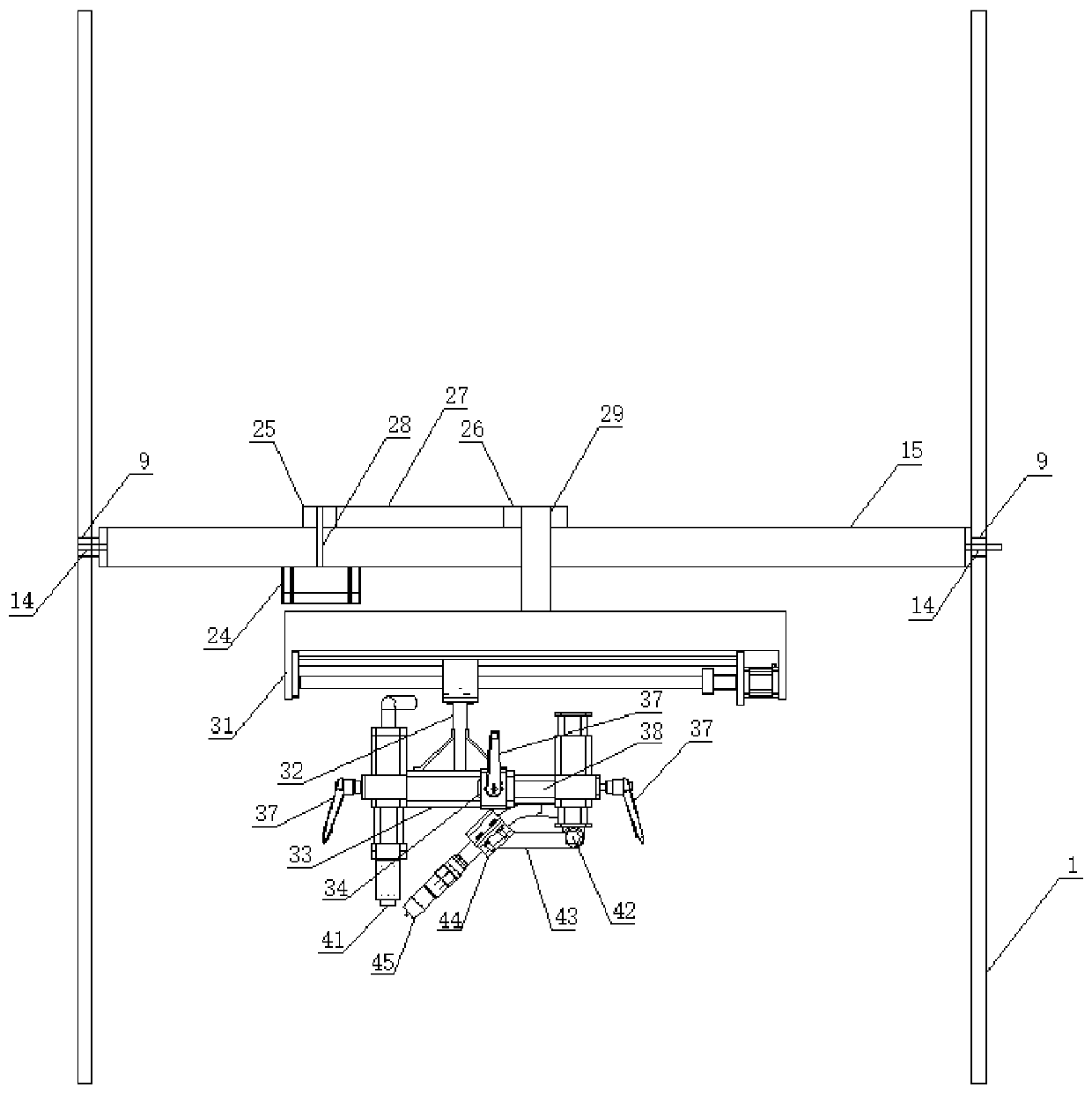

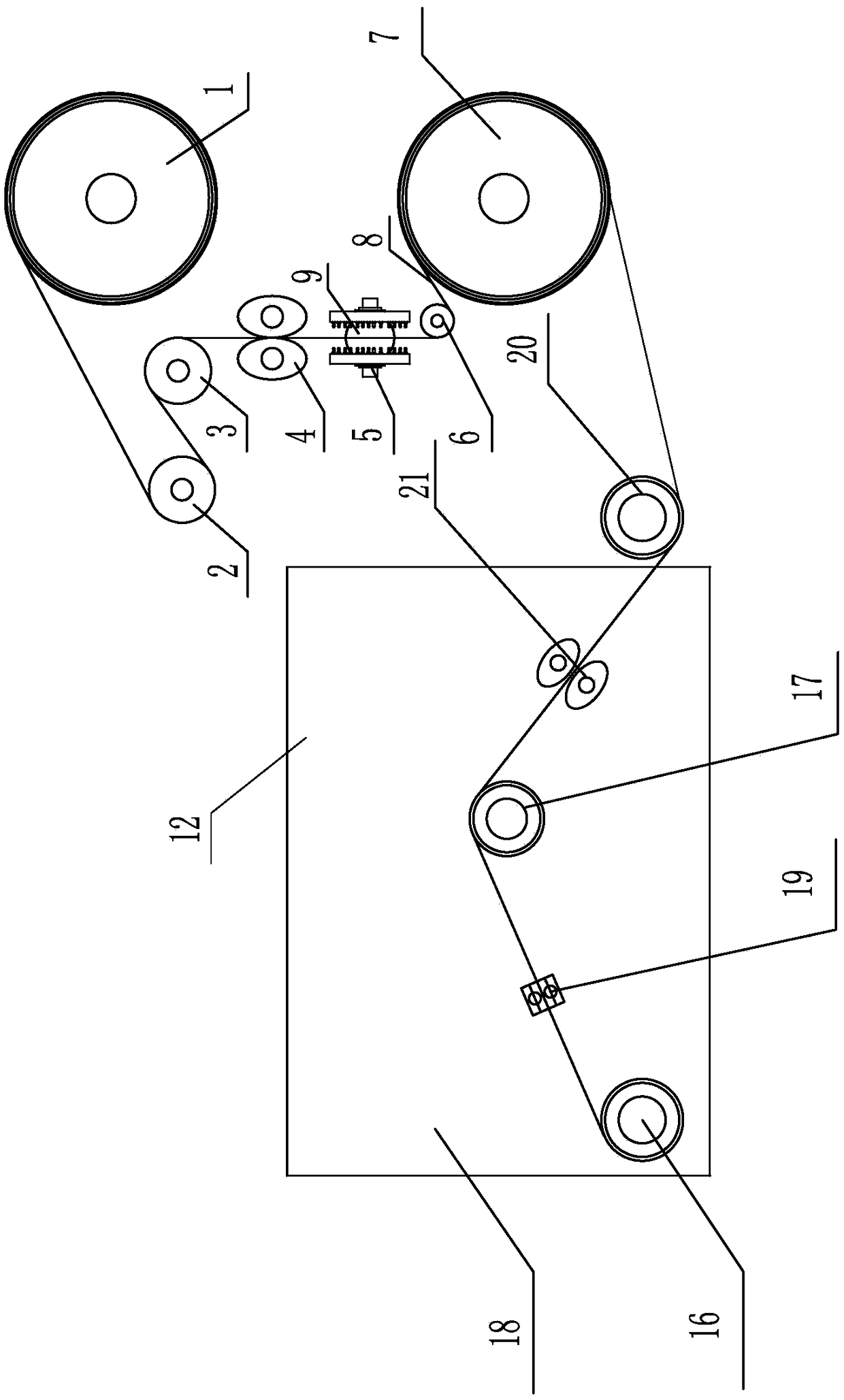

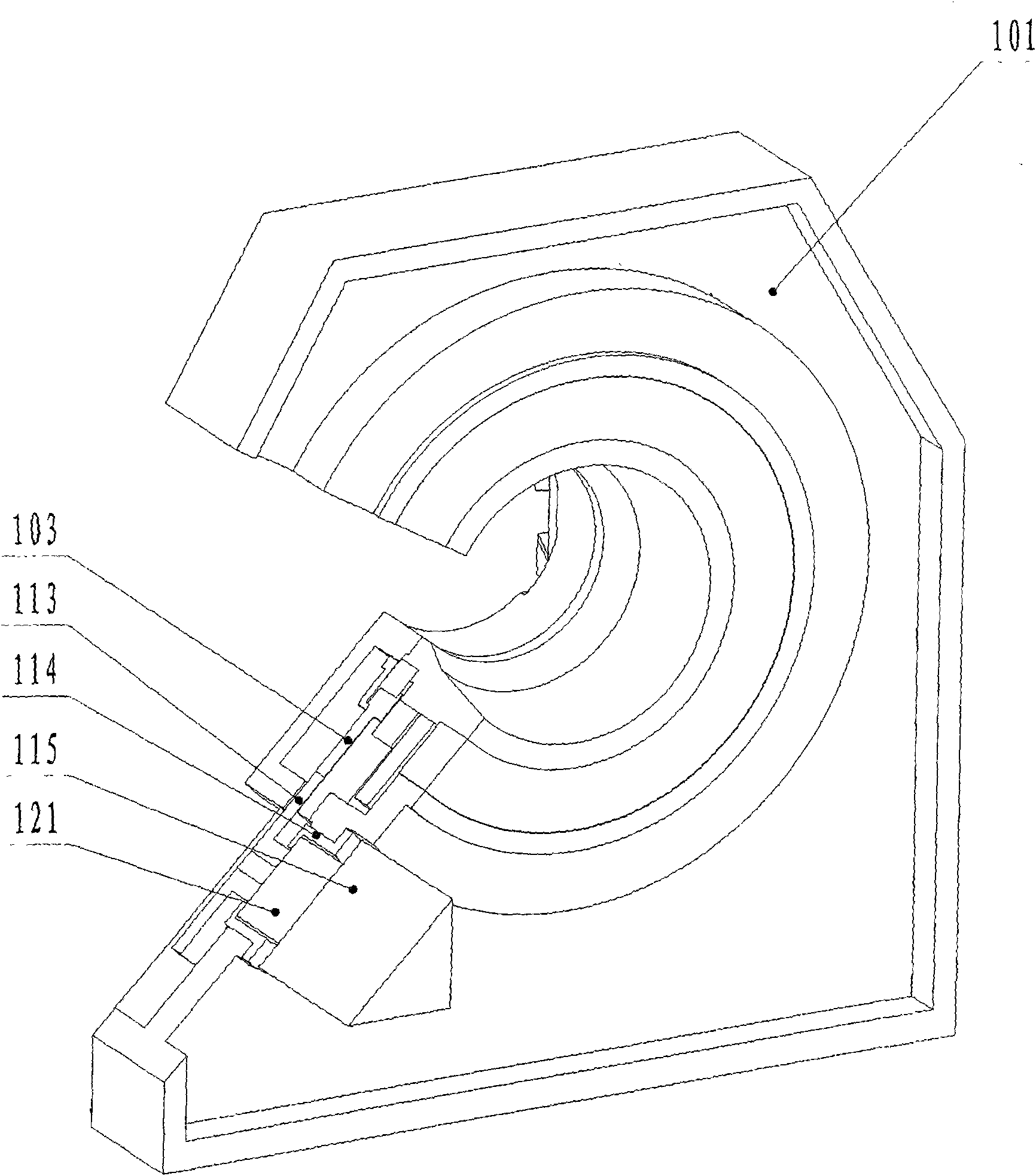

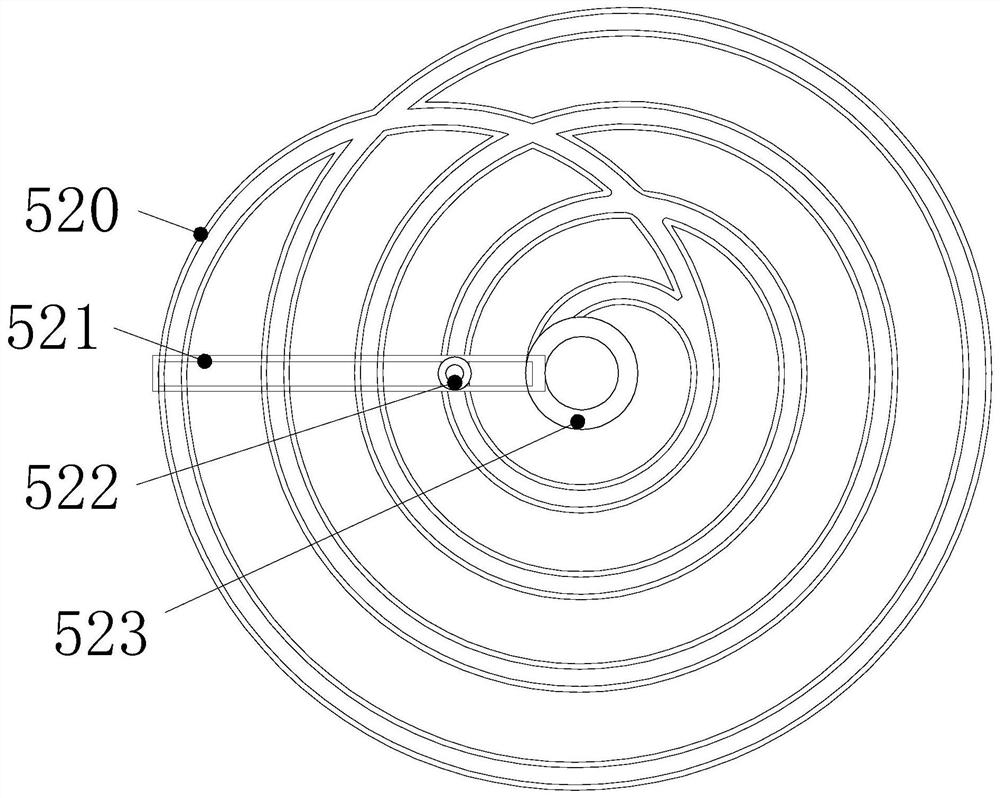

Polar coordinate numerical control fused deposition rapid prototyping machine and prototyping method thereof

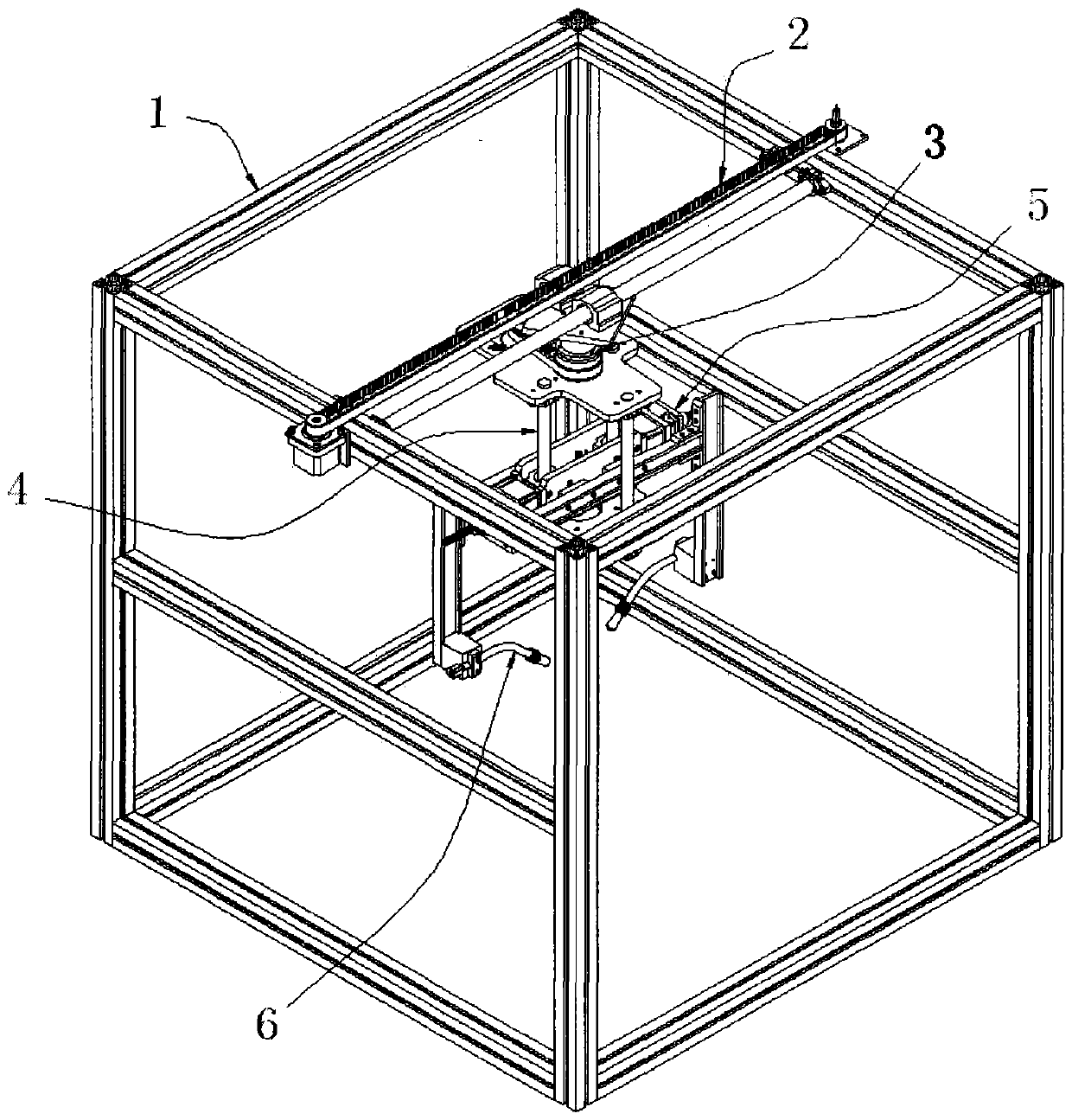

The invention discloses a polar coordinate numerical control fused deposition rapid prototyping machine and a prototyping method thereof. The rapid prototyping machine comprises a support frame, a lateral movement device, a rotary device, a lifting device, a lateral adjusting device and an extrusion sprayer, is ingenious and reasonable in structural design, adopts a polar coordinate mode for processing, is matched with the rotary device to realize rotary movement, effectively keeps the uniform feeding speed in linear and curved movement, achieves the continuity of extrusion materials in the deposition process, and has rapid prototyping speed and good effect; the whole structure is compact, the operation is convenient, and the work stability is high; according to the prototyping method provided by the invention, the work procedures are concise, the implementation is easy, the fused deposition can be implemented according to different prototyping models, not only is the whole prototyping period shortened, but also the model prototyping quality is effectively ensured, the prototyping effect is good, the efficiency is high, and wide promotion and application can be facilitated.

Owner:XINJIANG UNIVERSITY

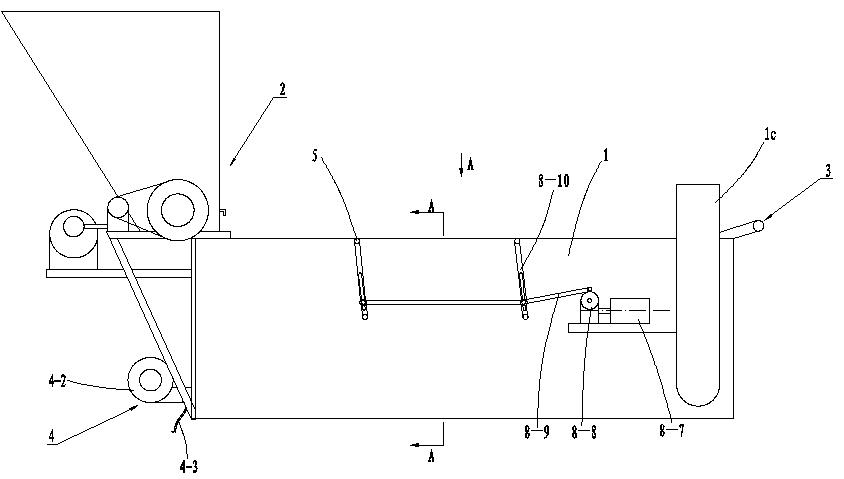

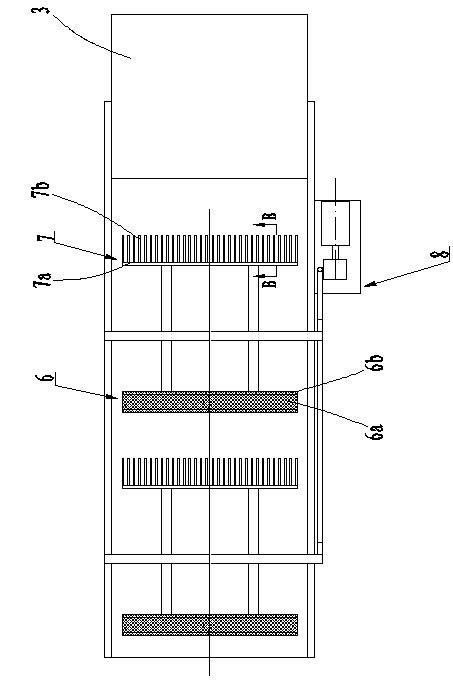

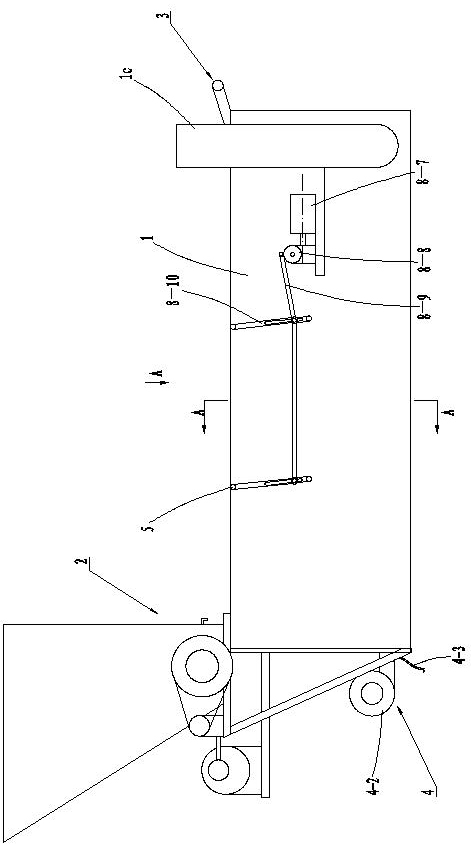

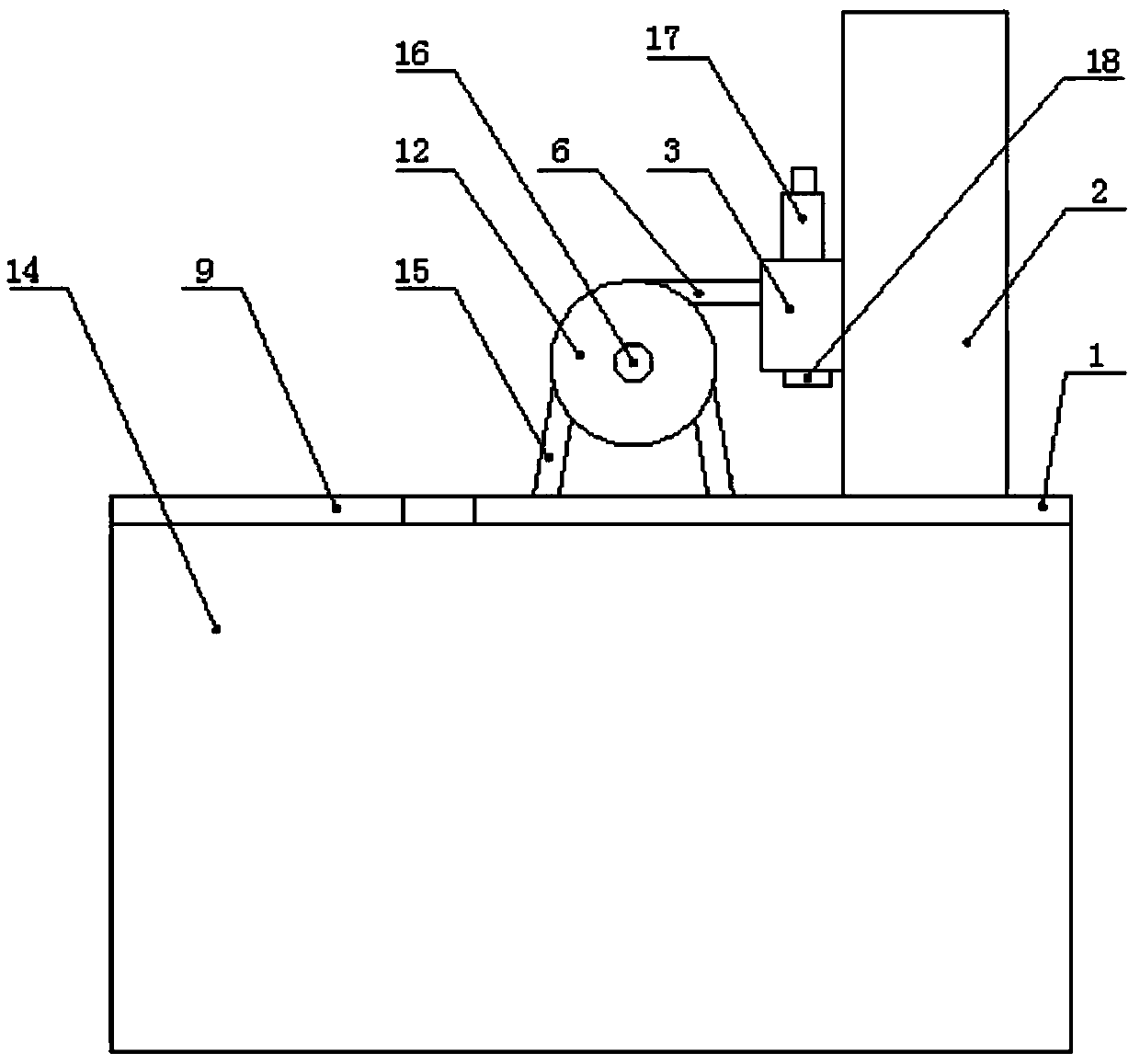

Fried food processing apparatus

InactiveCN102067894AIncrease heat transfer areaImprove heat transfer effectOil/fat bakingProcess engineeringBiology

The invention discloses a fried food processing apparatus which comprises an oil trough (1), a feeder (2) is arranged on one end of the oil though (1), a discharge conveyer belt (3) is arranged on the other end of the oil trough (1), and a heater (4) is arranged on the bottom of the oil trough (1). The fried food processing apparatus can carry out mechanized production, so that feeding, frying and discharge can be automatically carried out, consequently, the production efficiency is increased, manpower and material resources are reduced, and energy is saved.

Owner:包海荣

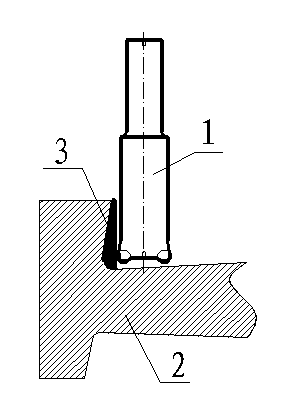

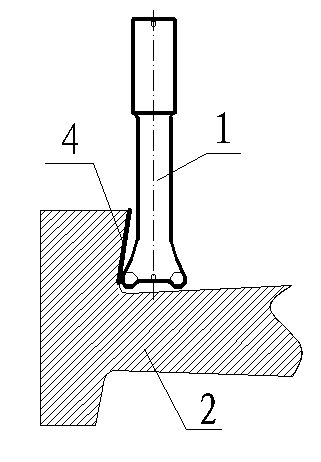

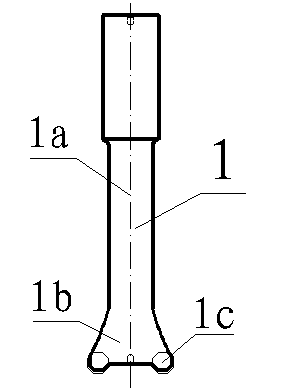

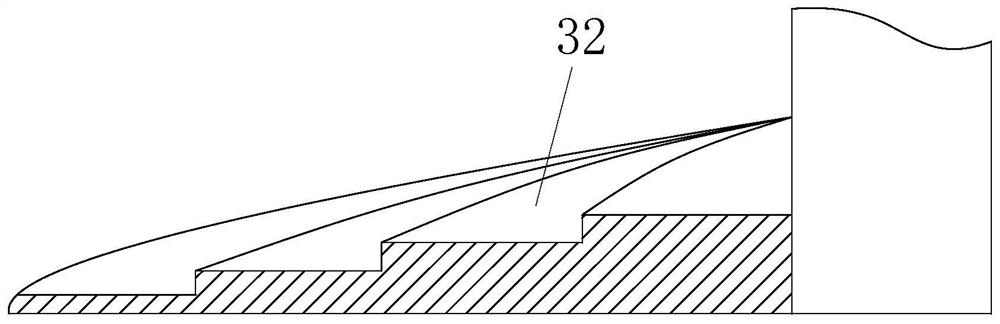

Machining method for conical inclined crown of blade

ActiveCN103056433ANot easy to damageUniform feed rateMilling cuttersMilling equipment detailsMilling cutterConstant force

The invention discloses a machining method for a conical inclined crown of a blade and belongs to the technical field of blade machining. According to the invention, the machining method for the conical inclined crown of the blade comprises the following steps: firstly, mounting the blade on a machine tool; machining a blade crown opening surface of the blade by using a milling cutter with octagonal blades, wherein the milling cutter comprises a rod-shaped handle and a cone frustum-shaped bit, and the handle is connected with the small end of the cone frustum-shaped bit; and a plurality of octagonal blades are uniformly distributed at the edge part of a big end of the cone frustum-shaped bit, so that the milling cutter machines the blade crown opening surface for two times by using a spiral feeding method. The machining method for the conical inclined crown of the blade, disclosed by the invention, has the advantages as follows: the machining efficiency is increased; the conical inclined crown of the blade can be cut in place at one time; both the opening part and the root part R can be sufficiently machined into place; due to spiral feeding, peaks and valleys are comparatively uniform and stable; the service life of the cutter is longer under the effect of a constant force; the load of a machine tool spindle is stable and the loss of the machine tool is small; the attention is unnecessarily paid to the machining state in machining at any time; and the probability of generating fatigues is low.

Owner:SICHUAN MIANZHU XINKUN MACHINERY MAKING

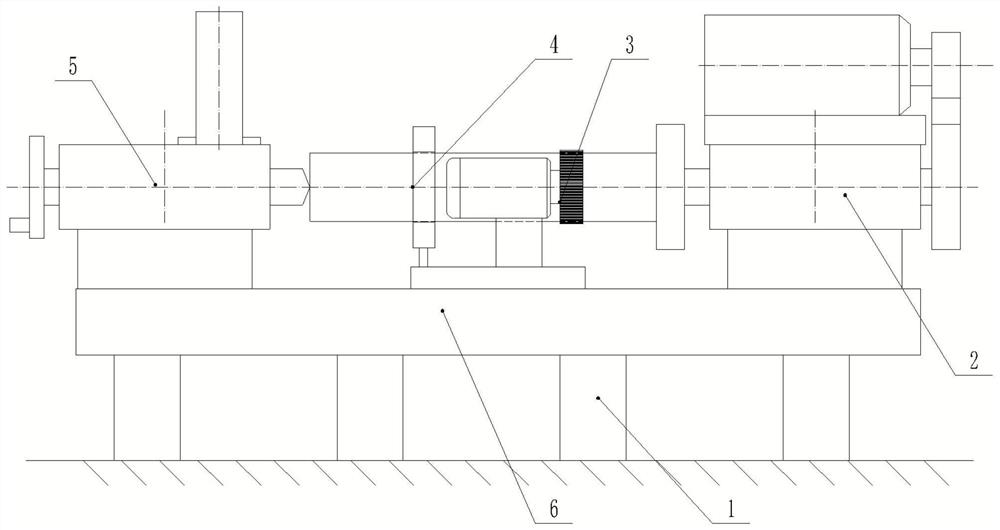

Method of and apparatus for grinding cams of a camshaft

ActiveUS8398455B2High removal rateExpand accessRevolution surface grinding machinesBelt grinding machinesSide lyingEngineering

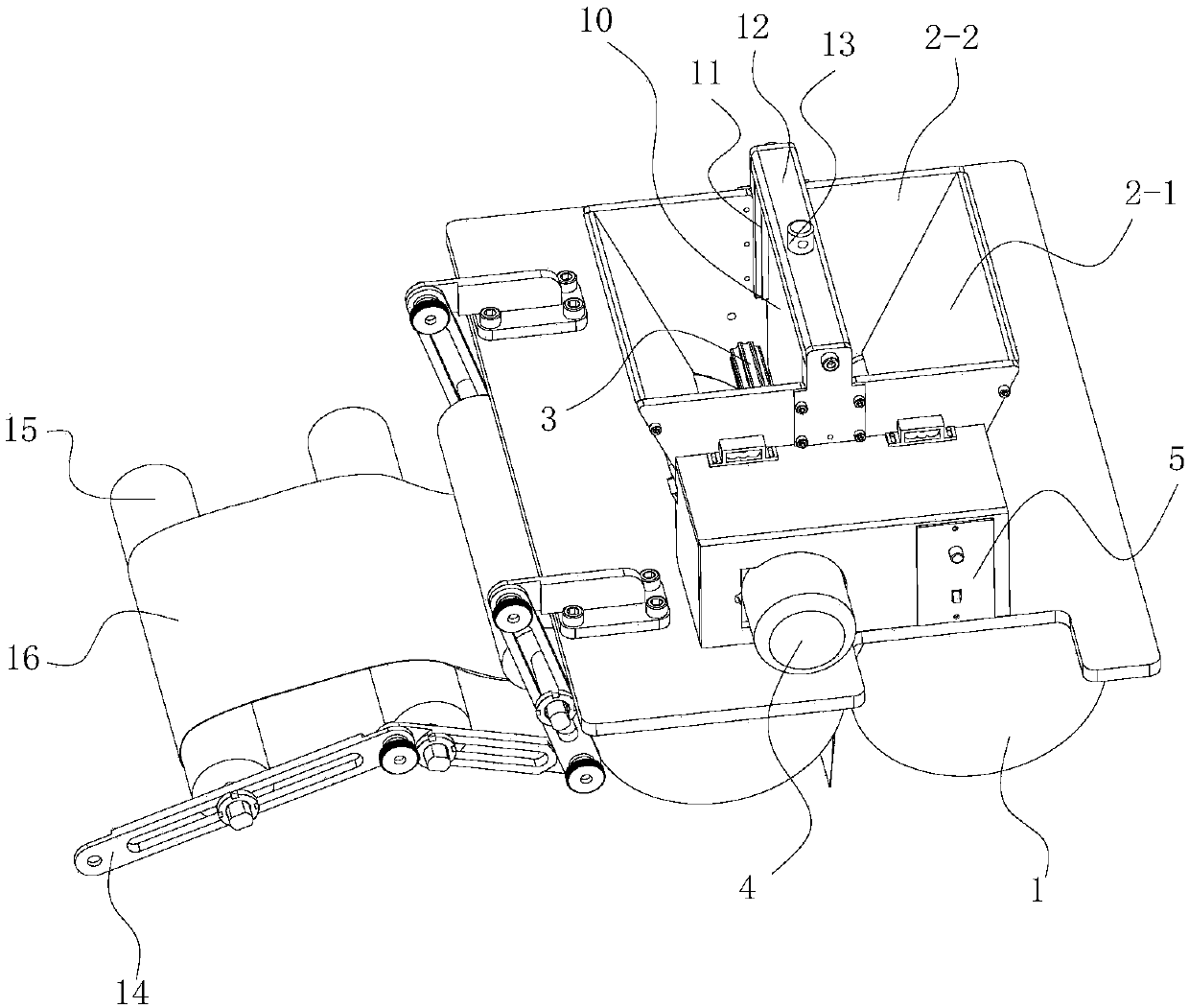

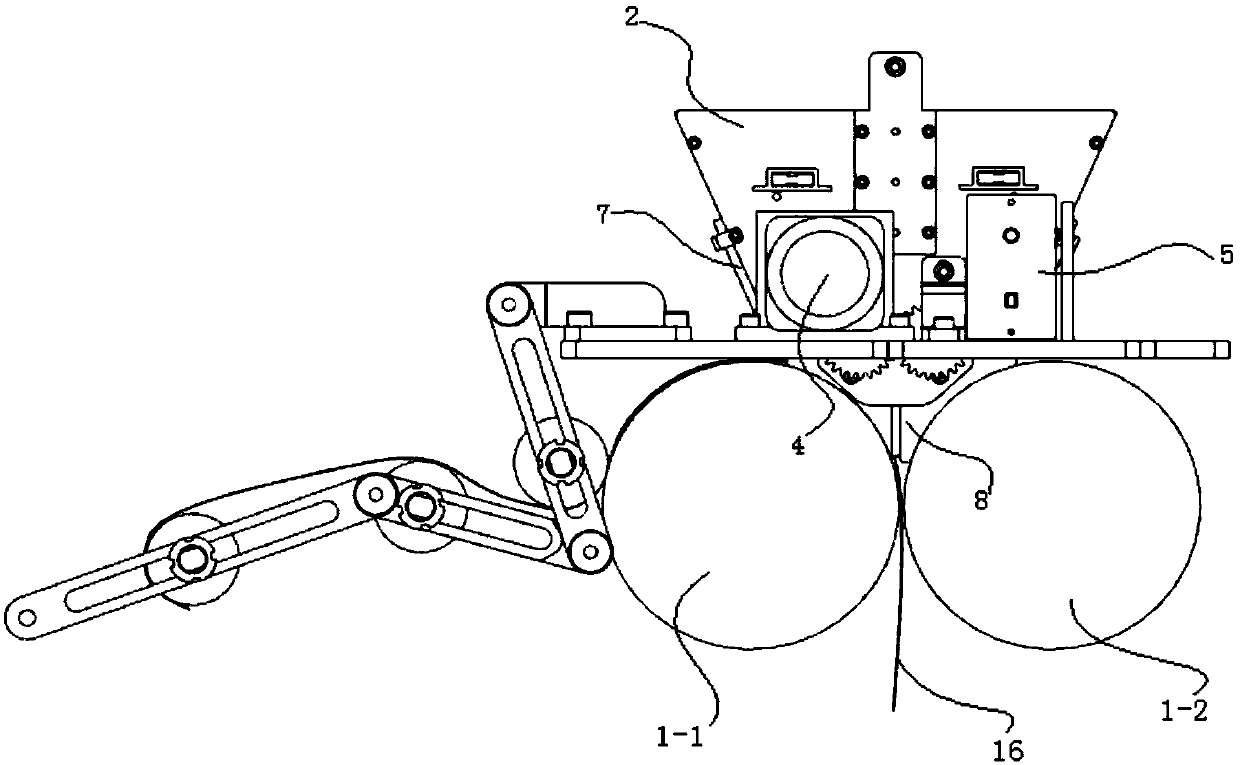

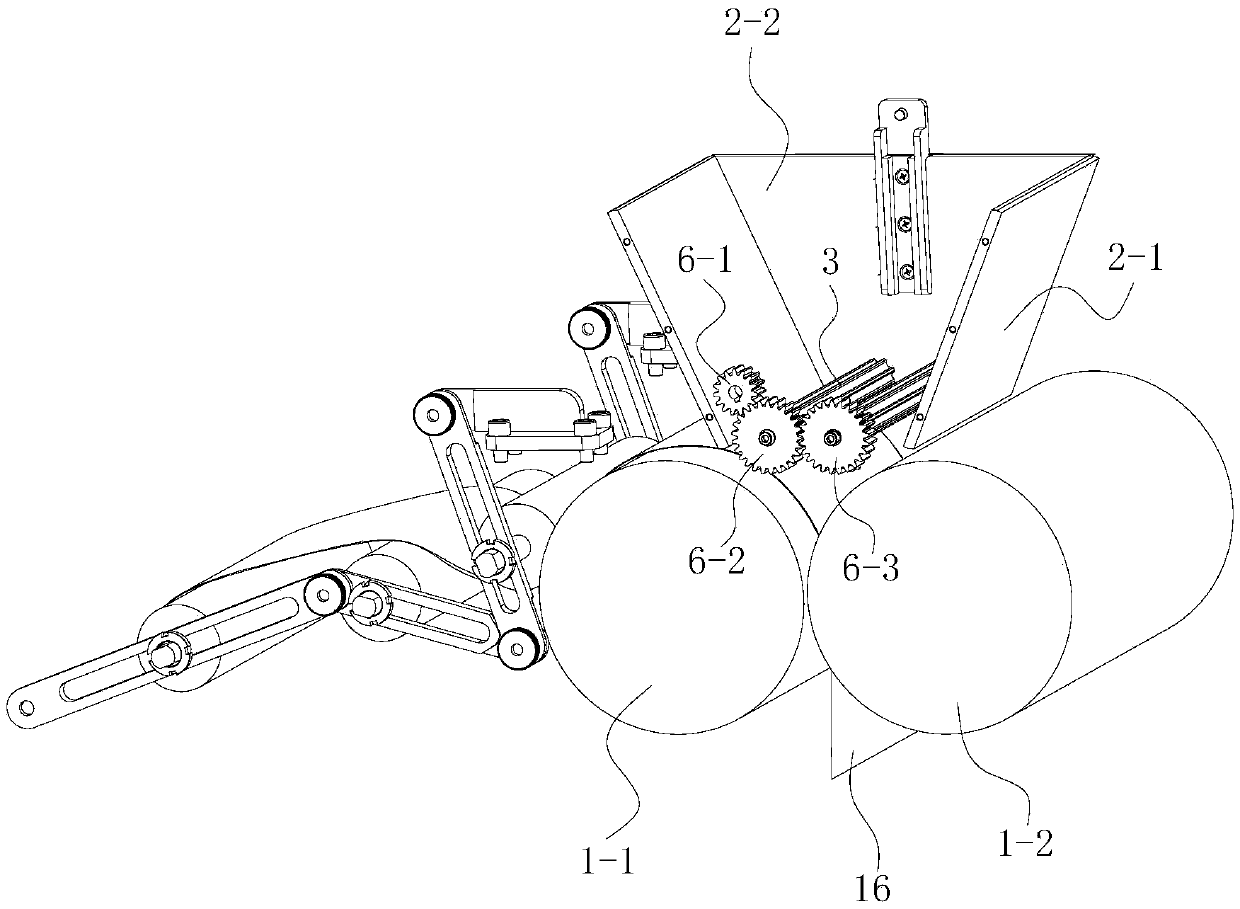

The invention relates to a method and a device for grinding cams of a camshaft (7) in a clamp with two grinding spindles (10, 11), wherein the cams or cam pairs are each arranged in a mirror image relative to the workpiece rotation axis (16), wherein the camshaft (7) is tensioned and rotated about the longitudinal axis thereof. In the device for carrying out the method, the camshaft (7) can be inserted into the workpiece receiver (6) from the side lying opposite the at least one back stay (15) by means of the loading device.

Owner:EMAG HLDG GMBH

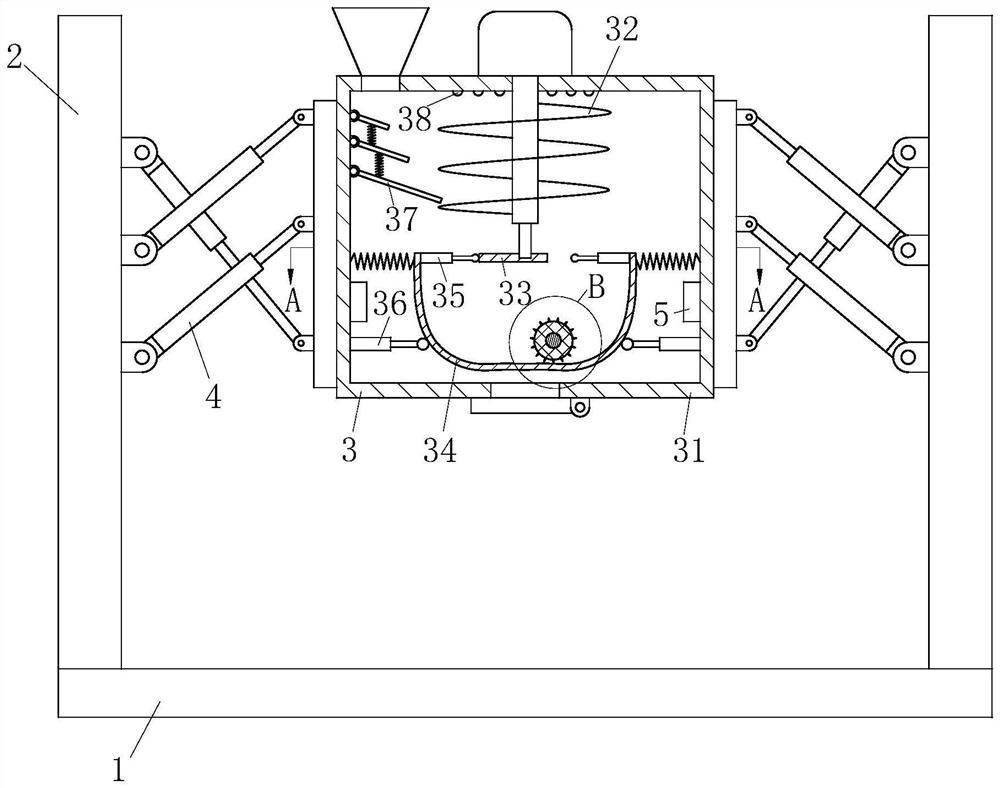

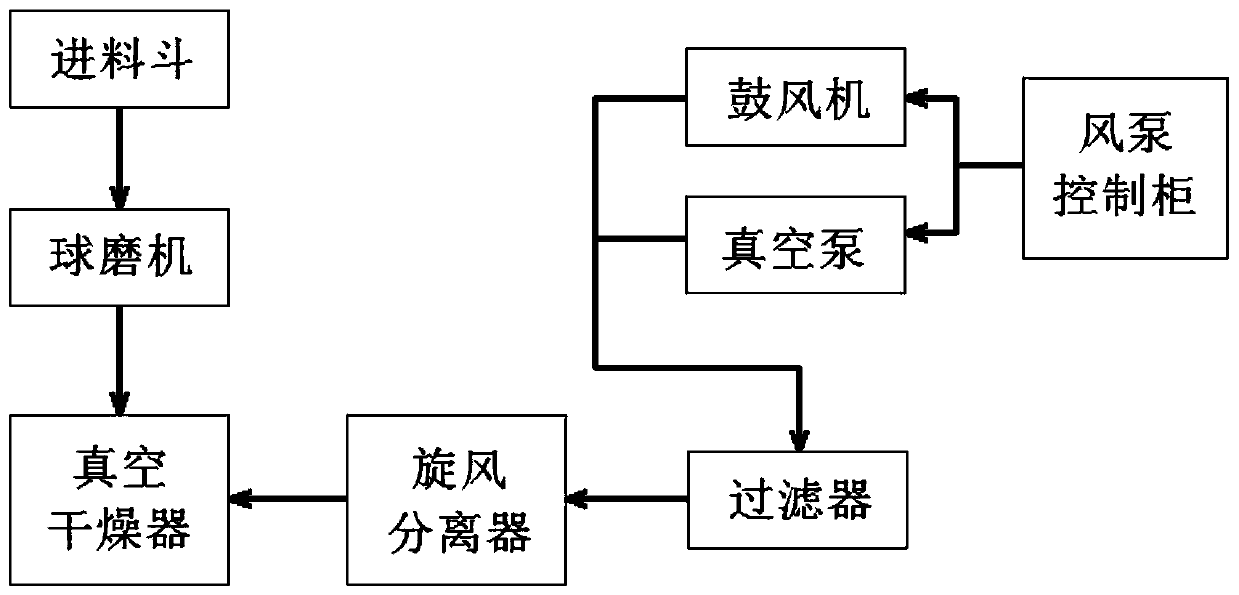

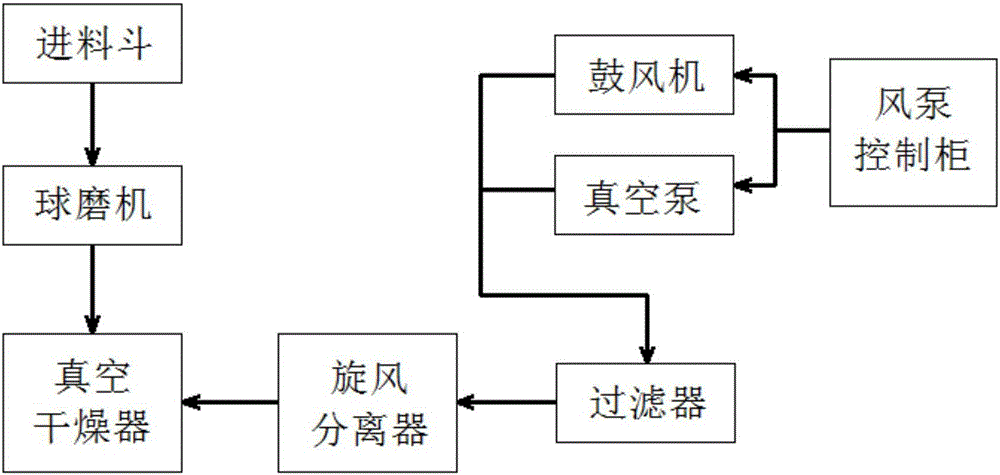

Dry powder machining process using fire extinguisher dry powder reuse machining system

ActiveCN106422124ARealize streamlined operationUniform feed rateDrying solid materials without heatFire rescueNational standardFire extinguisher

The invention provides a dry powder machining process using a fire extinguisher dry powder reuse machining system. The dry powder machining process comprises the following process steps: firstly, a hopper and a ball mill are used for finely crushing raw dry powder; then, the crushed raw dry powder is dried; components of the dried raw dry powder are detected; and according to national standard requirements and detecting results, the insufficient components are added for full mixing to realize reuse of fire extinguisher dry powder. The dry powder machining process is simple in process steps, realizes corresponding process steps by dint of corresponding machining equipment, is high in automation degree of the treatment process, and is suitable for streamlined production operation.

Owner:济南康和消防技术有限公司

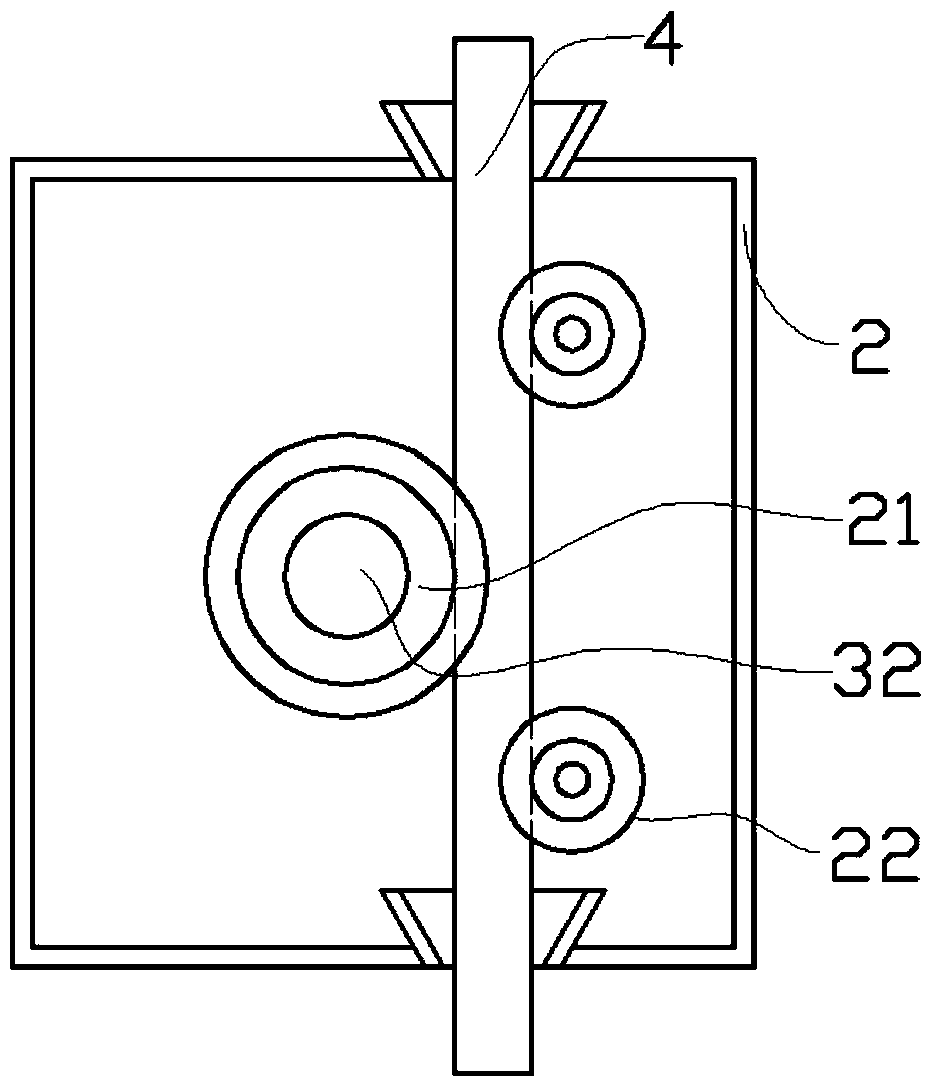

Automatic electrowelding electrode feeder

InactiveCN103909326AAutomatic even meltingUniform feed rateWelding/cutting auxillary devicesArc welding apparatusHeat flowEngineering

The invention provides an automatic electrowelding electrode feeder comprising a connecting rack, a feed box, and a power unit. The automatic electrowelding electrode feeder is fitted on a welding torch employing welding wires for welding. The feed box and the power unit are fitted to the end of the welding torch through the connecting rack. A welding wire for welding is passed into the feed box; a transmission structure is arranged in the feed box; the power unit drives the welding wire to move forward. The forward direction of the welding wire and a hot jet flow direction of the welding torch intersect at one point. Speed of feeding the welding wires in the welding manner is evener, welding quality can be improved effectively, a welder can operate with one hand using the automatic electrowelding electrode feeder, welding is more convenient, and the automatic electrowelding electrode feeder can be freely used in more complex environments.

Owner:WUJIANG SAINA ELECTRONICS TECH

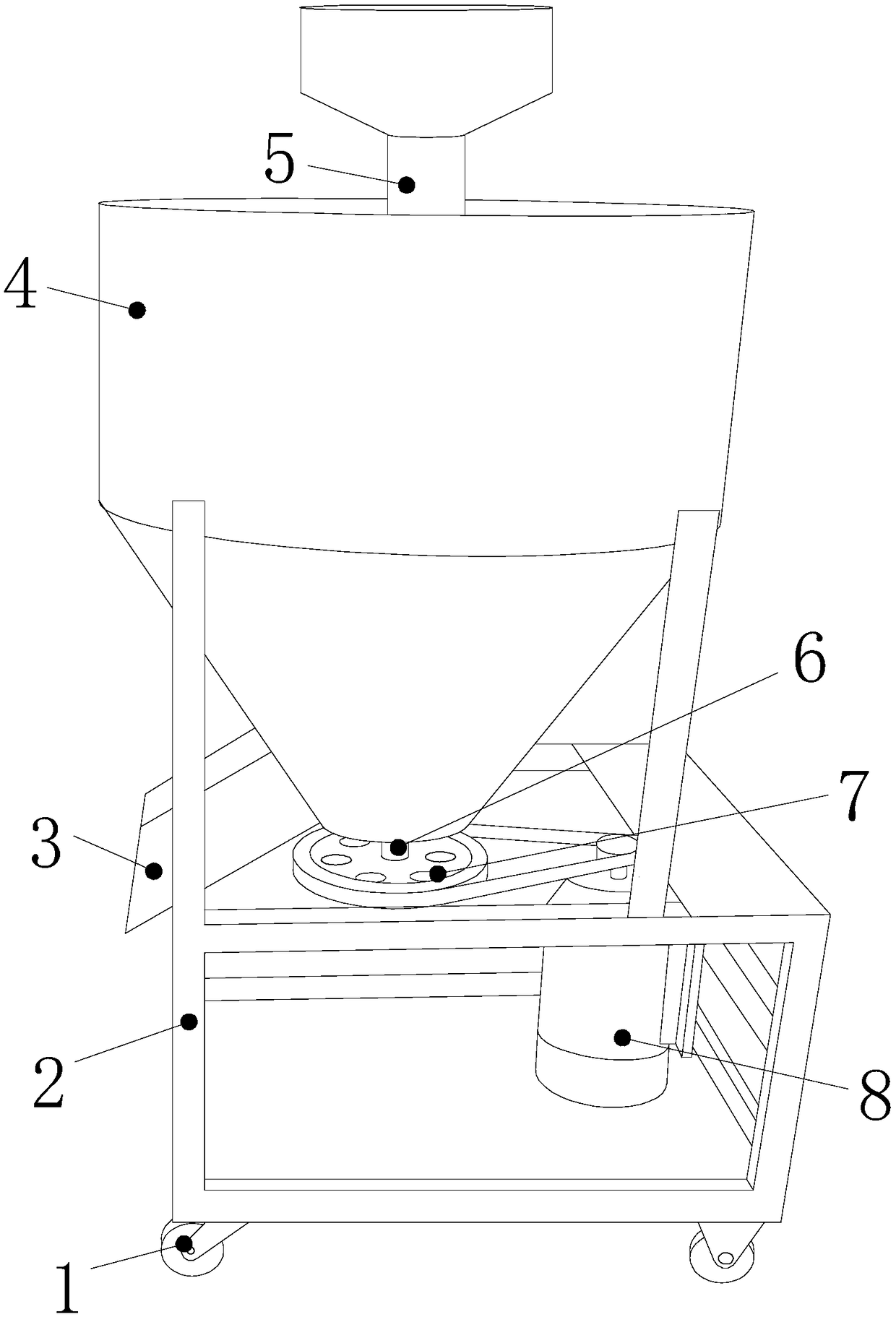

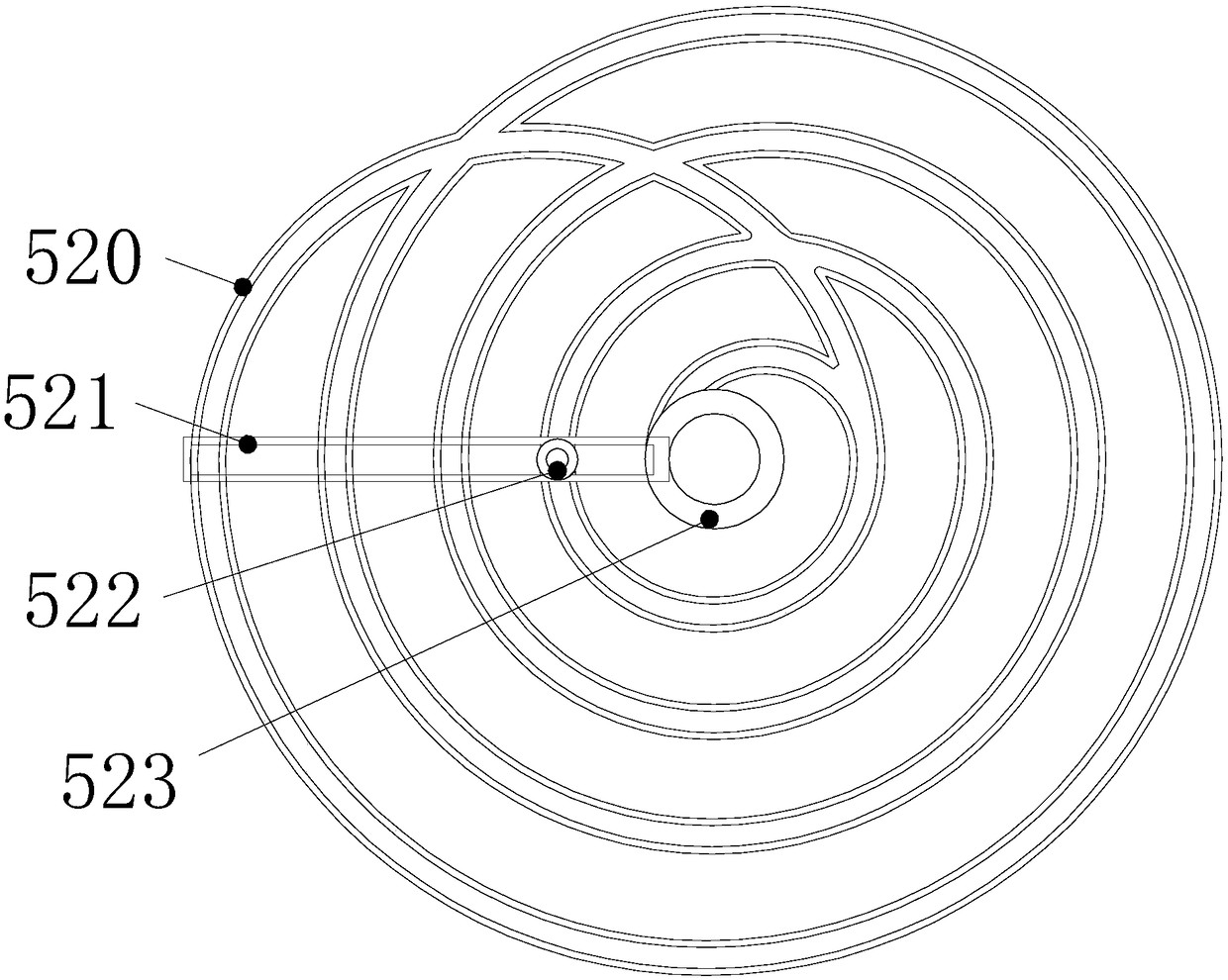

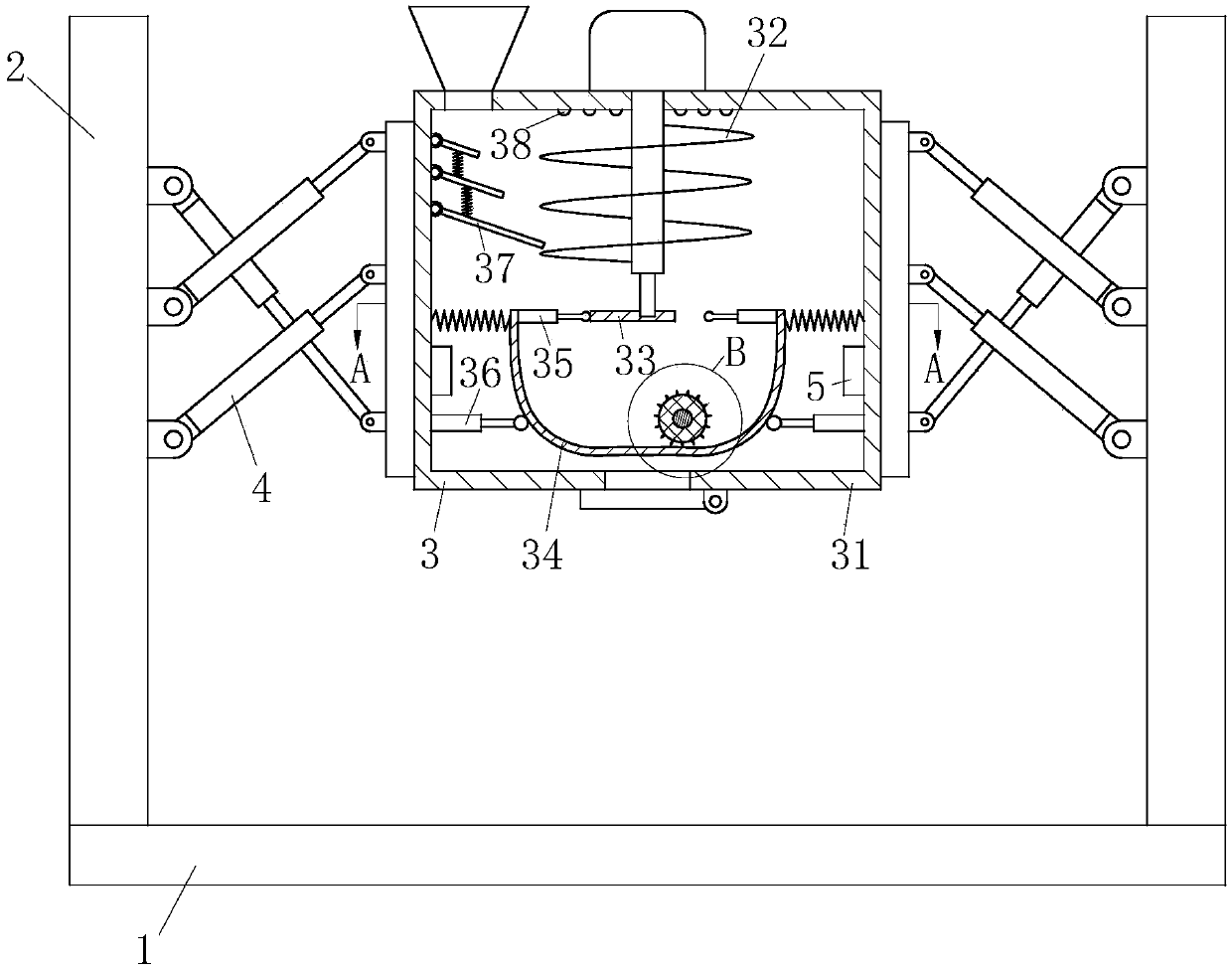

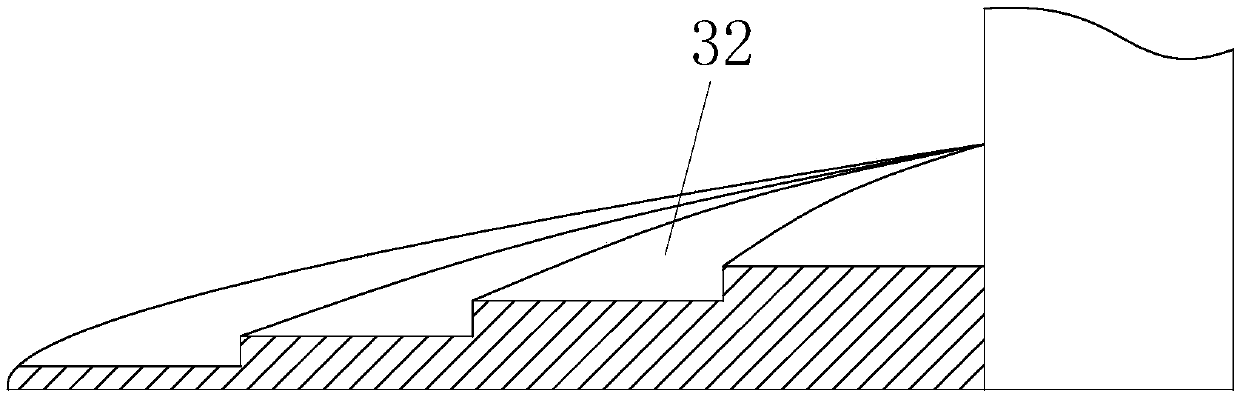

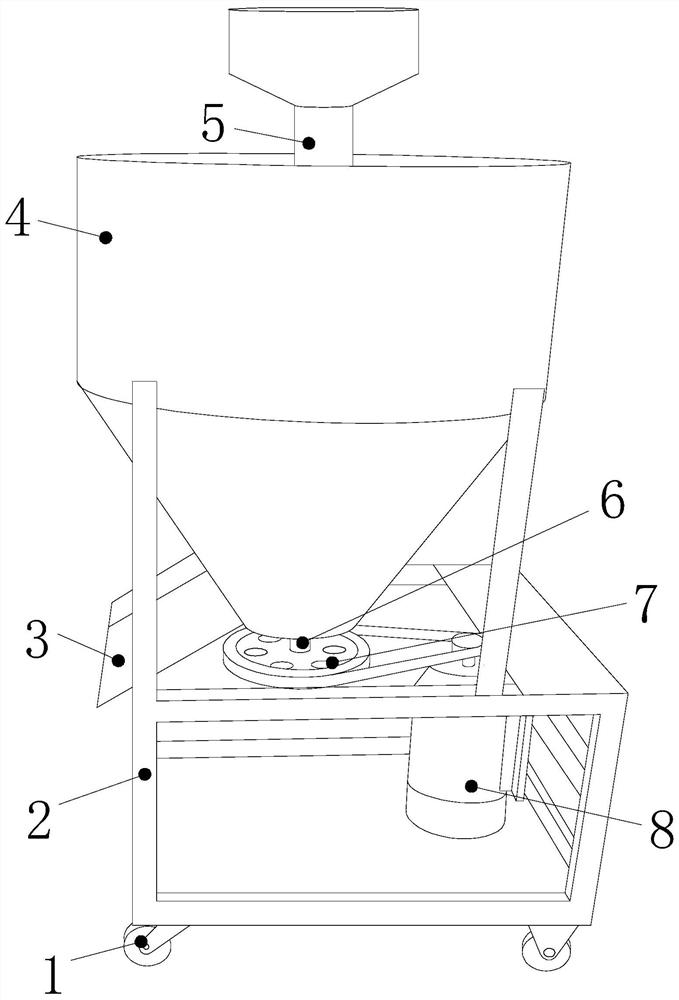

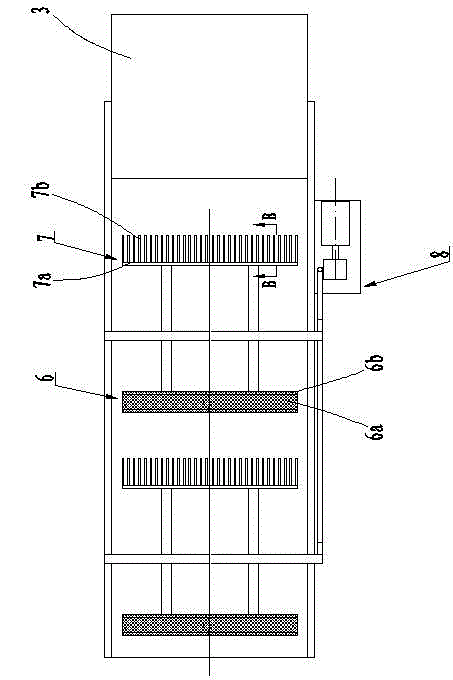

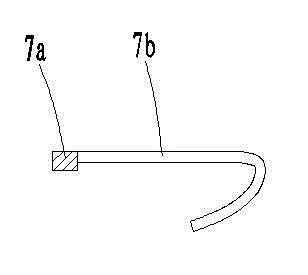

Stirrer for agricultural production combing mosquito-repellent incense rail with extrusion charging

ActiveCN108786568AIncrease contact areaImprove stirring efficiencyRotary stirring mixersTransportation and packagingAgricultural engineeringExtrusion

The invention discloses a stirrer for agricultural production combining a mosquito-repellent incense rail and extrusion charging. The stirrer structurally comprises rollers, a frame, a discharging hole, a stirring barrel, a charging device, a stirring shaft, a transmission device, a motor and stirring blades, wherein the rollers are arranged at the bottom of the frame; the stirring barrel is welded on the frame; the bottom of the stirring barrel is conical; the side face of the bottom of the stirring barrel is connected with the discharging hole; the bottom of the stirring barrel is provided with the transmission device; the stirring shaft is arranged inside the stirring barrel; the bottom of the stirring shaft is in transmission connection with the motor through the transmission device; the motor is arranged on the frame; the top of the stirring barrel is connected with the charging device. The stirrer has the beneficial effects that the mosquito-repellent incense slide rail moves incooperation with a hose, so that a fertilizer falls on water surface, the contact area with water is increased, and the stirring efficiency is increased. Uniform charging speed can be guaranteed through helical charging. The fertilizer is uniformly dispersed on the water surface in cooperation with the mosquito-repellent incense slide rail, so that the phenomenon of blocking is avoided, and convenience is brought to stirring.

Owner:嘉兴琦玥装饰材料有限公司

Laser arc side-shaft compounded surfacing machine and application method thereof

PendingCN110153561AImprove stabilityReduced flexibilityLaser beam welding apparatusFixed frameEngineering

The invention relates to the field of laser arc composite surfacing, in particular to a laser arc side-shaft compounded surfacing machine and an application method thereof. The design of a laser arc composite welding gun adopts a mode of side shaft compounding and guidance of arc by laser; the machine comprises an arc welding gun horizontal adjusting device, an arc welding gun vertical adjusting device, an arc welding gun angle adjusting device, an arc welding gun fixed frame, a laser welding gun fixed frame and a laser welding gun vertical adjusting device; the welding gun position and angleadjustment is realized; a polar coordinate mode is adopted to control; a revolving device is matched to realize a revolving motion to effectively guarantee uniform feeding speed in linear and curve motions; and the machine uses a laser arc compound quick molding technology to achieve high molding speed and good effect, realizes metal surfacing in 1G and 4G positions, can be used for molding partswith special structures, and is compact in overall structure, convenient to operate and high in working stability.

Owner:XINJIANG UNIVERSITY

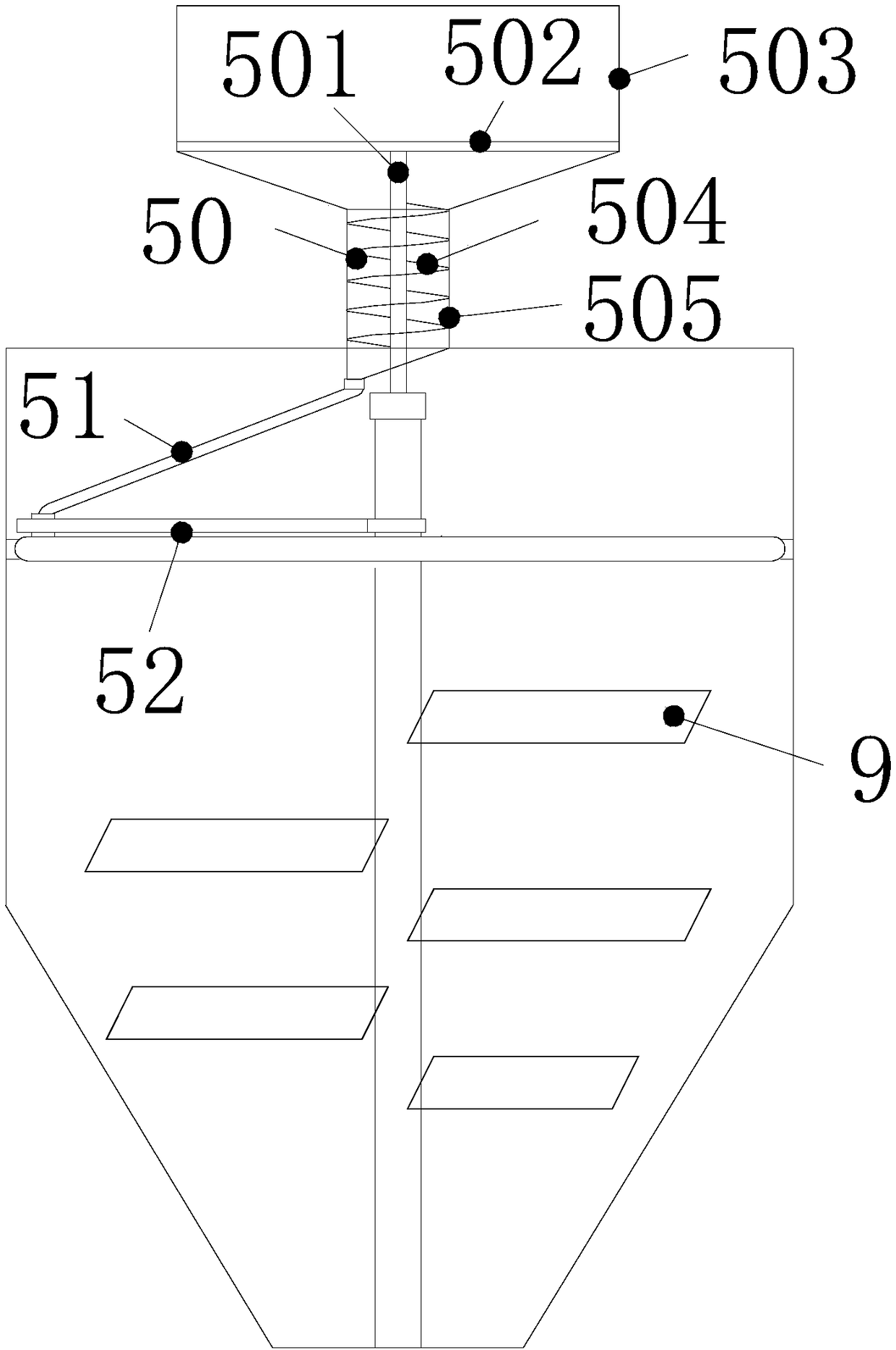

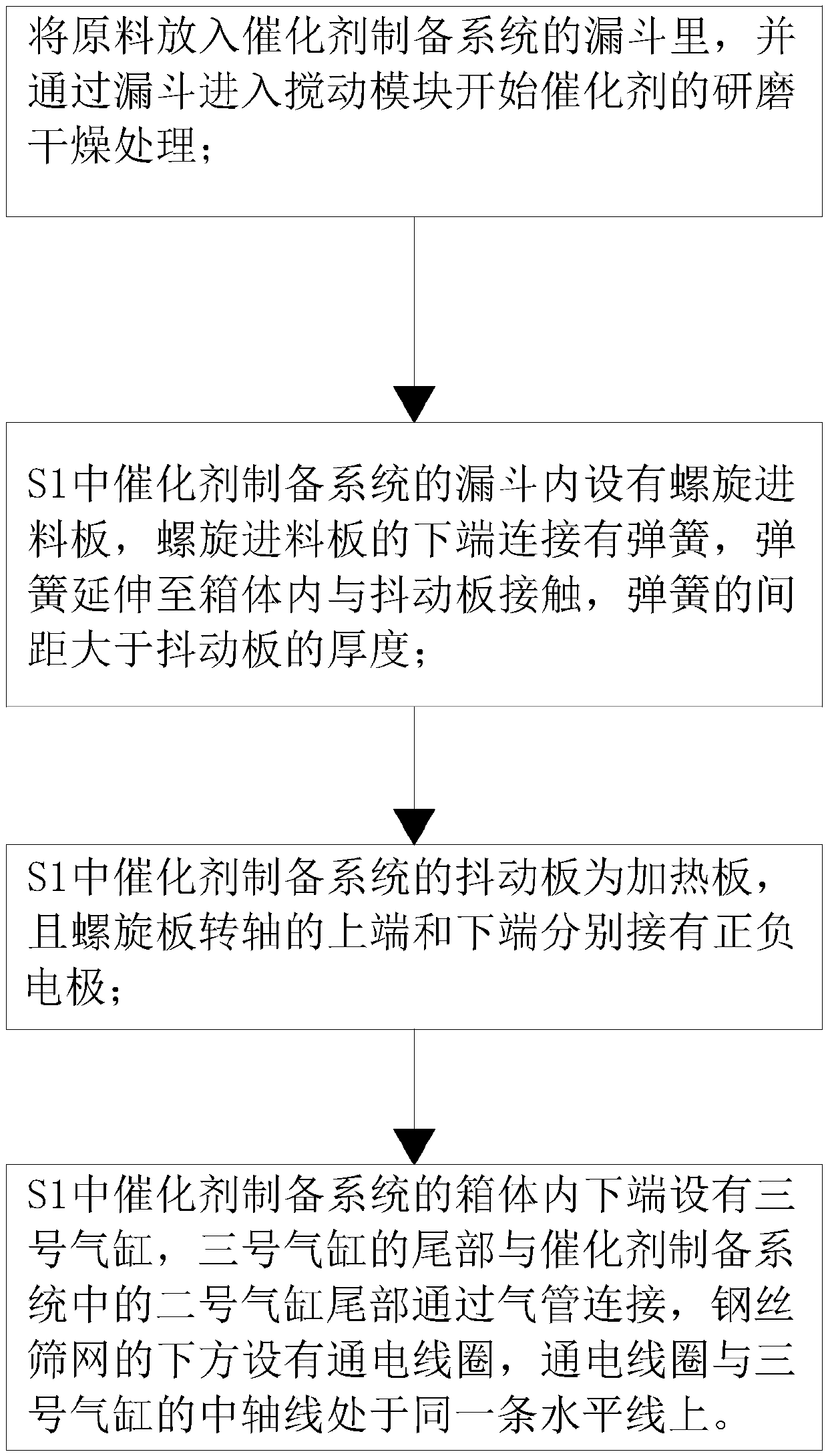

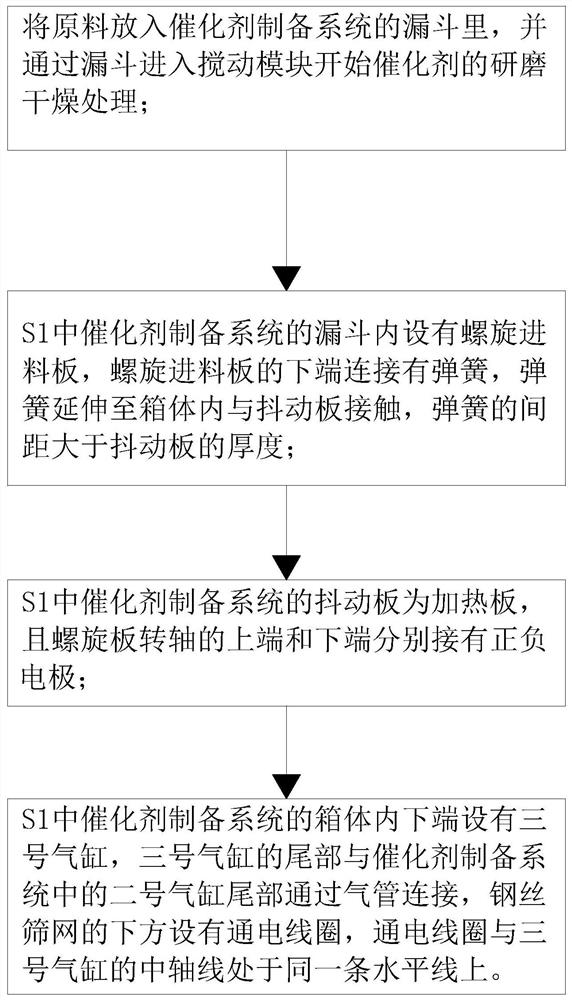

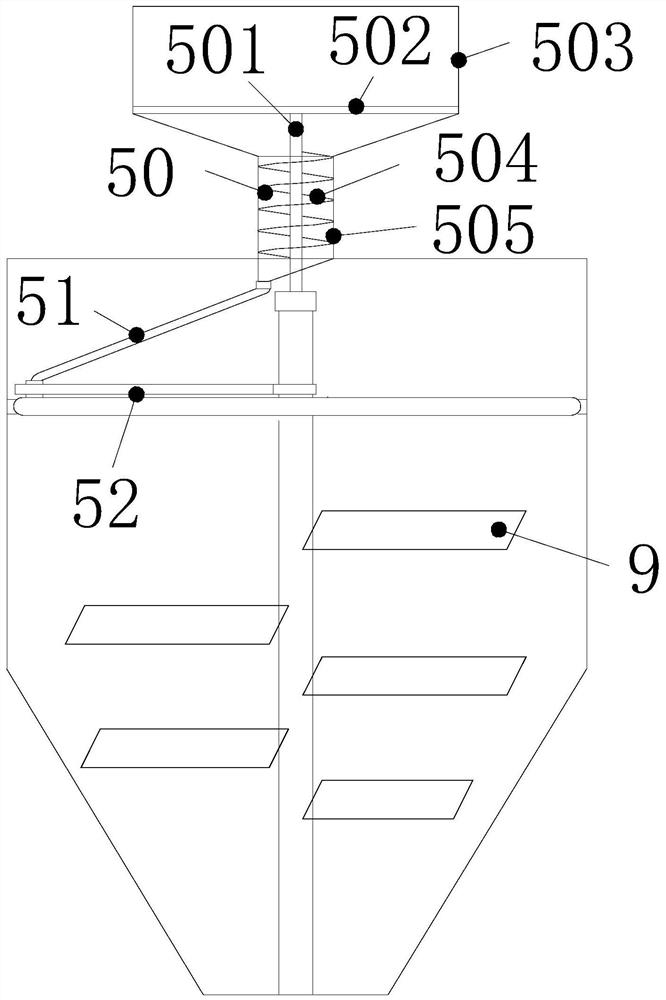

Grinding and drying technology for catalyst

ActiveCN109569829AAvoid damageImprove refinement efficiencySievingGranular material dryingPulp and paper industryRaw material

The invention belongs to the technical field of catalyst preparation, and particularly relates to a grinding and drying technology for a catalyst. The grinding and drying technology for the catalyst comprises the following steps that raw materials are putted into a funnel of a catalyst preparation system and then into a stirring module through the funnel to start the catalyst grinding and drying treatment; a spiral feeding plate is arranged in the funnel, springs are connected to the lower end of the spiral feeding plate, the springs extend into a box body so as to be in contact with shaking plates, and the distance between the springs is larger than the thickness of the shaking plates; the shaking plates are heating plates and the upper end and the lower end of a spiral plate rotary shaftare connected with a positive electrode and a negative electrode respectively; and a third air cylinder is arranged at the lower end of the box body, the tail part of the third air cylinder is connected with the tail parts of second air cylinders in the catalyst preparation system through air pipes, a power-on coil is arranged below a steel wire screen, and the central axis of power-on coil and the central axis of the third air cylinder are located on a same horizontal line. According to the grinding and drying technology for the catalyst, the springs are in contact with the shaking plates, the shaking amplitude and frequency of the shaking plates increase in the rotating process of the springs and the refining efficiency of the raw materials of the catalyst is improved.

Owner:江苏上阳金属新材料有限公司

Paper tube crushing machine

InactiveCN110124799AImprove crushing efficiencySimple manufacturing processGrain treatmentsDrive motorEngineering

The invention relates to a paper tube crushing machine. The paper tube crushing machine comprises a rack and a feeding unit, a crushing box and a discharging system which are sequentially arranged onthe rack in the conveying direction of paper tubes; a crushing tool is arranged in the crushing box, and a driving motor of the crushing tool is arranged on the rack; and the crushing tool comprises apower shaft arranged on the crushing box by means of an installing plate, limiting plates arranged on the power shaft at intervals, a group of pin shafts which are arranged on the exterior of the power shaft and penetrate through the limiting plates and crushing hammers, the crushing hammers and the pin shafts are connected and arranged between the installing plate and the limiting plates and between the adjacent limiting plates correspondingly, the crushing hammers have the rotating freedom degree on the pin shafts, and the bottom of the crushing box is provided with a grid in the mode of being matched with the crushing hammers. According to the crushing machine, the manufacturing difficulty of the crushing tool can be effectively reduced, the service life is prolonged, the crushing timeis shortened, and the good crushing effect is guaranteed.

Owner:辛集市乾森环保科技有限公司

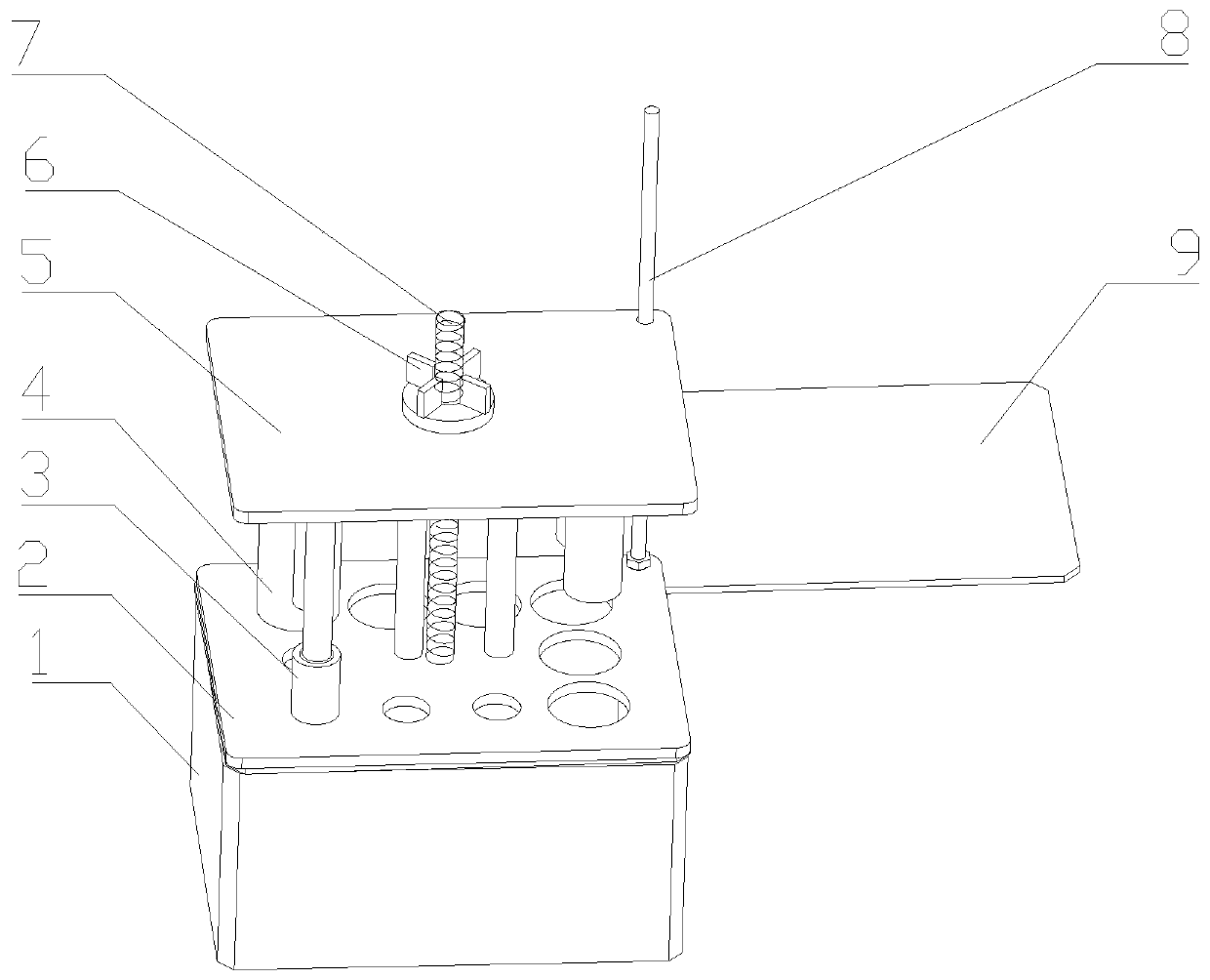

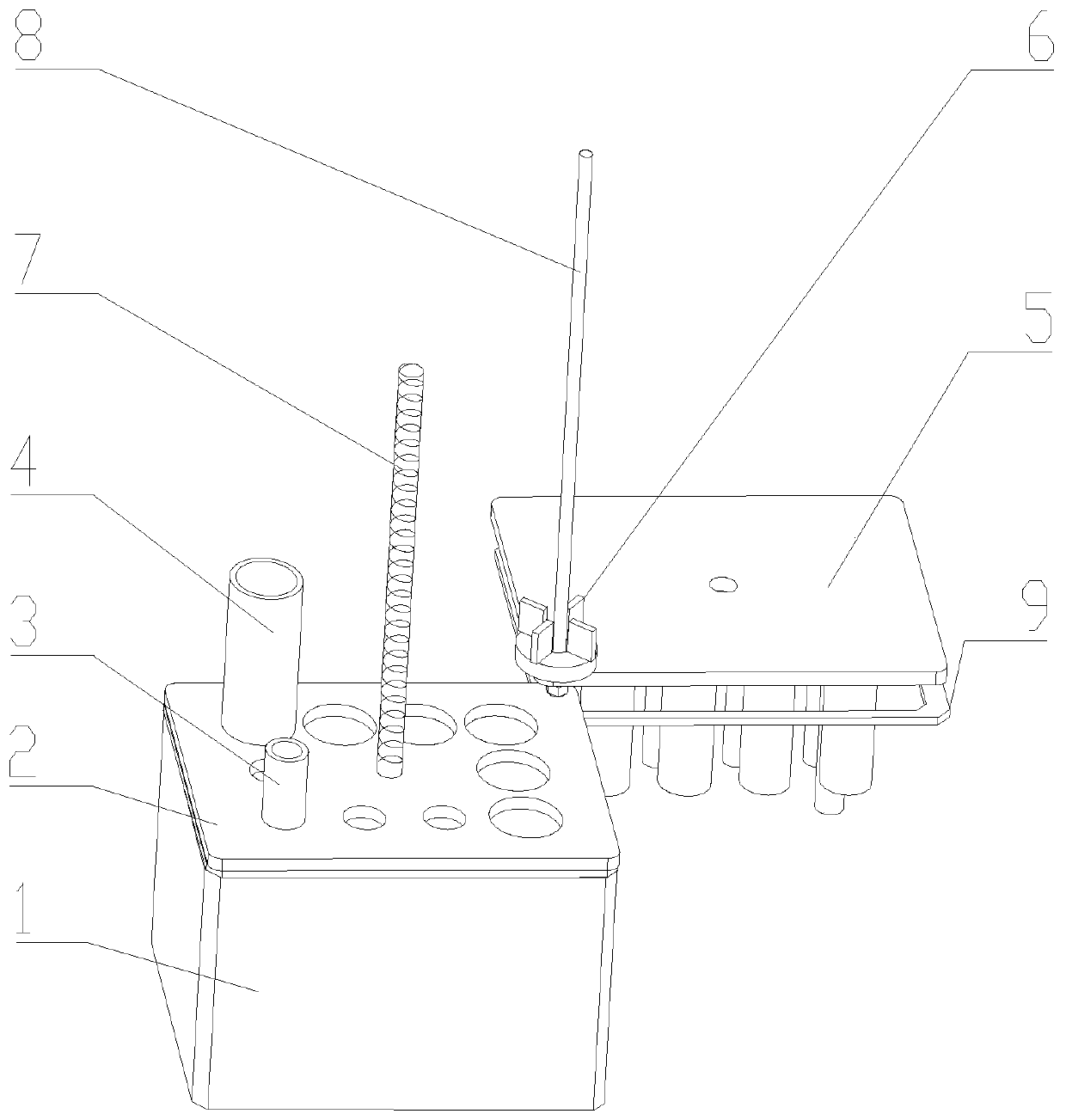

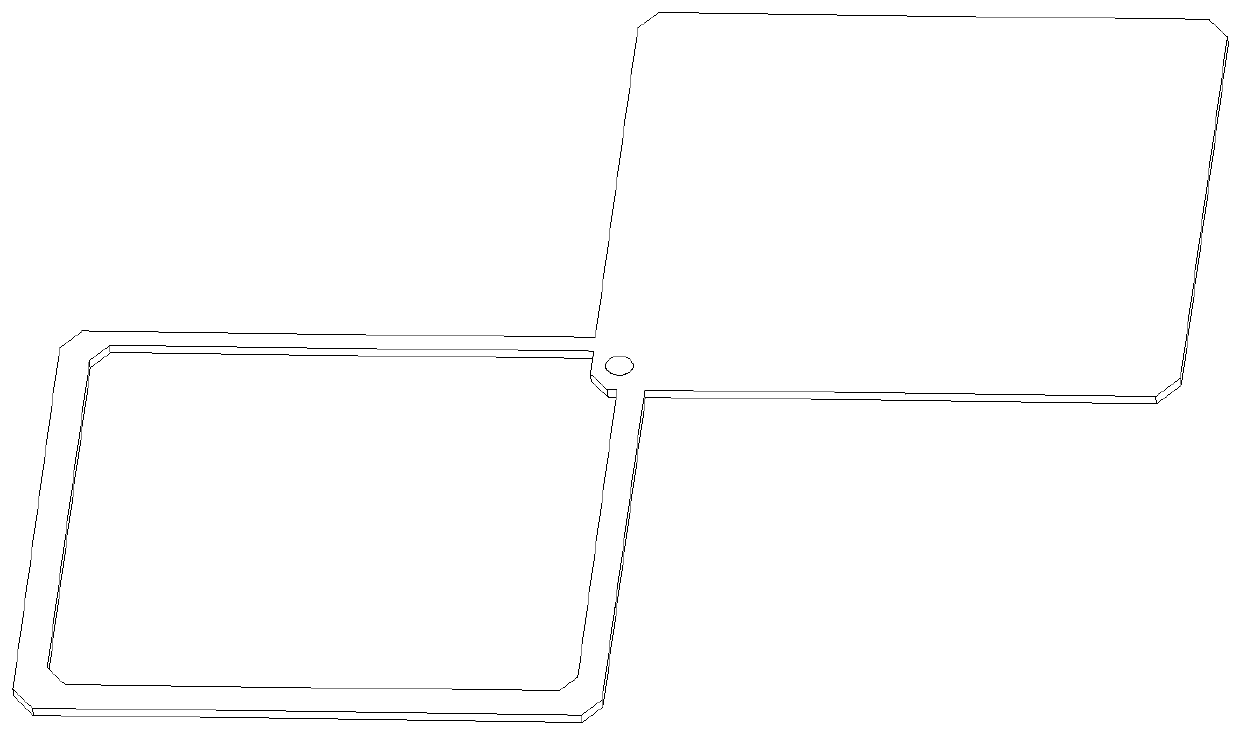

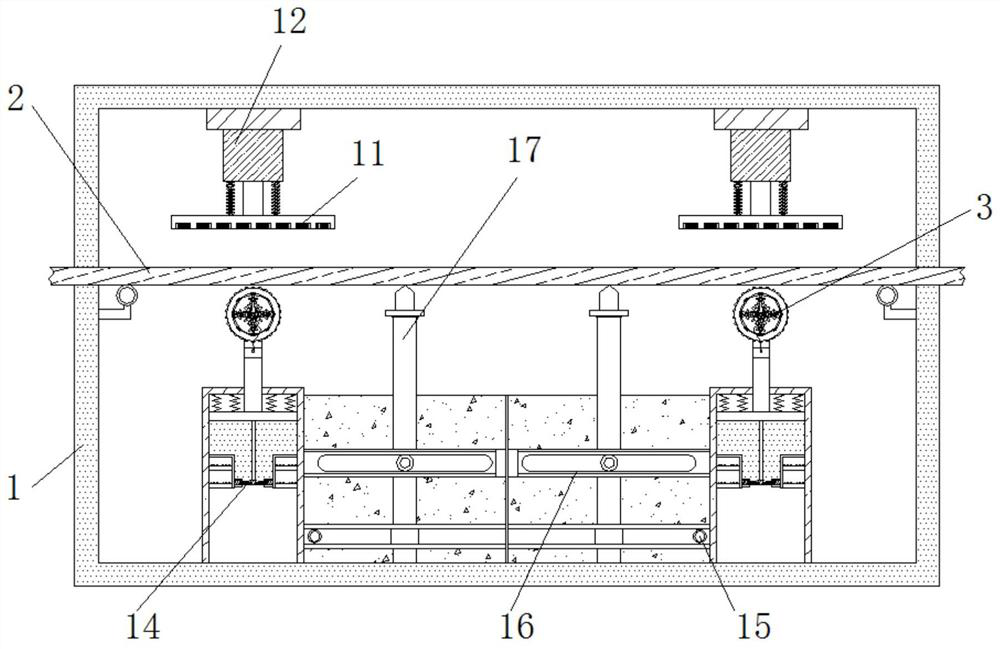

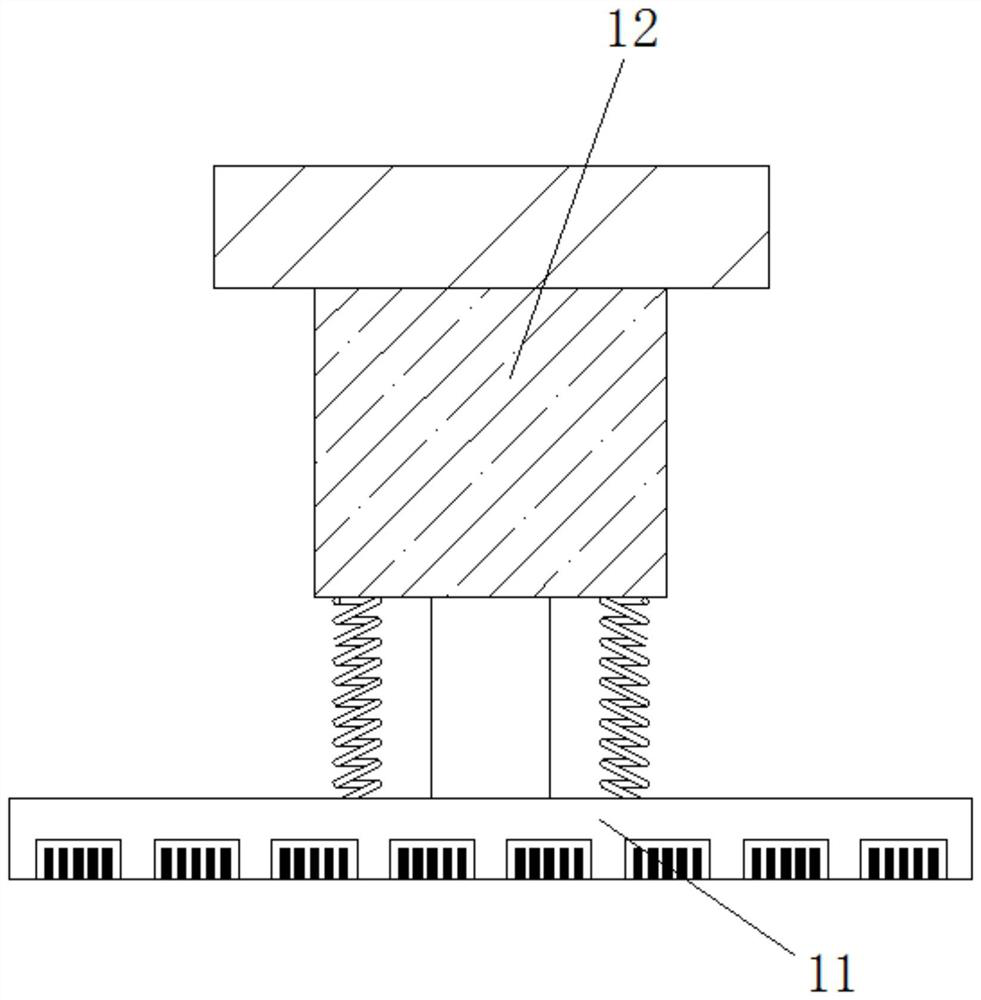

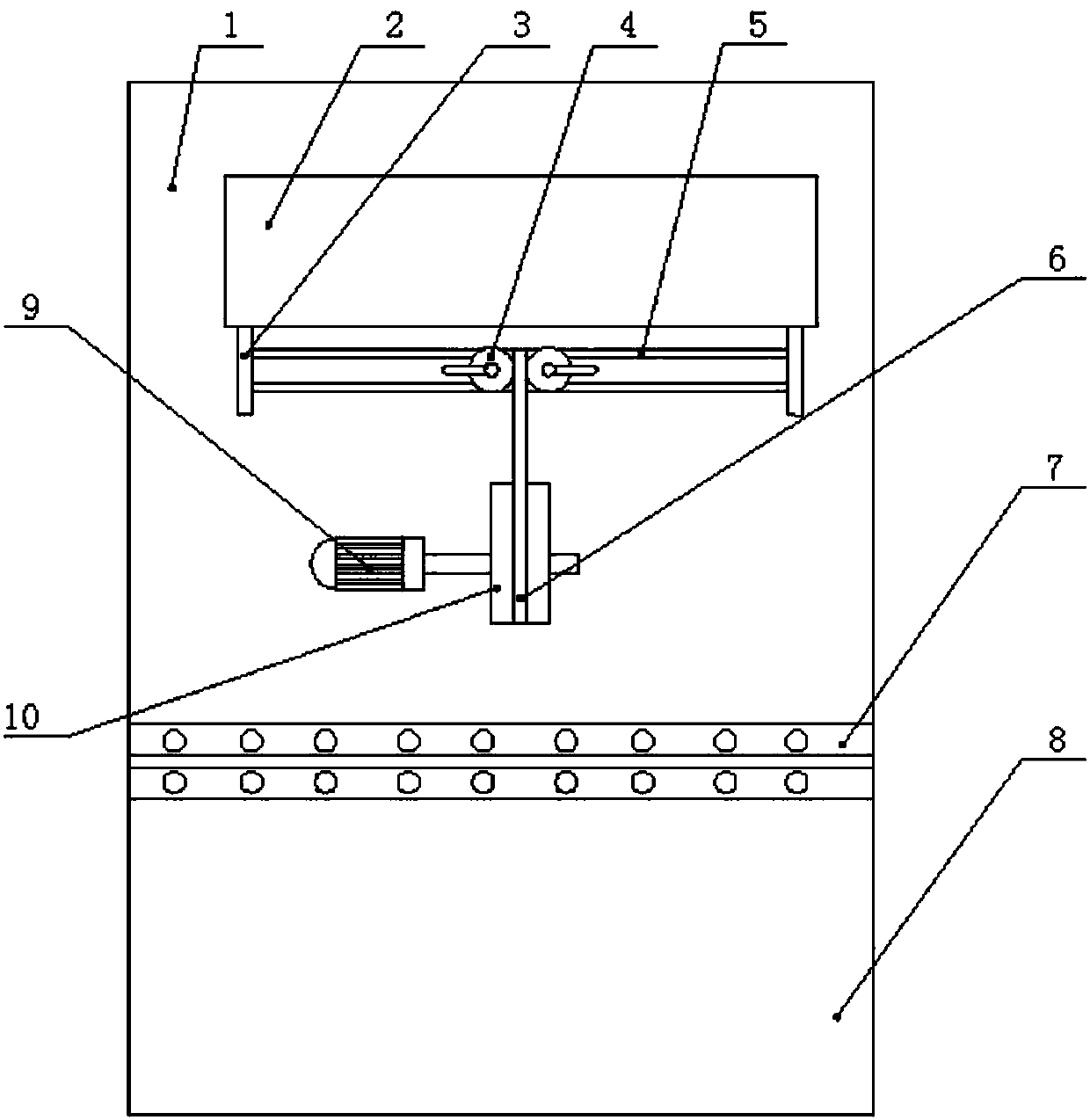

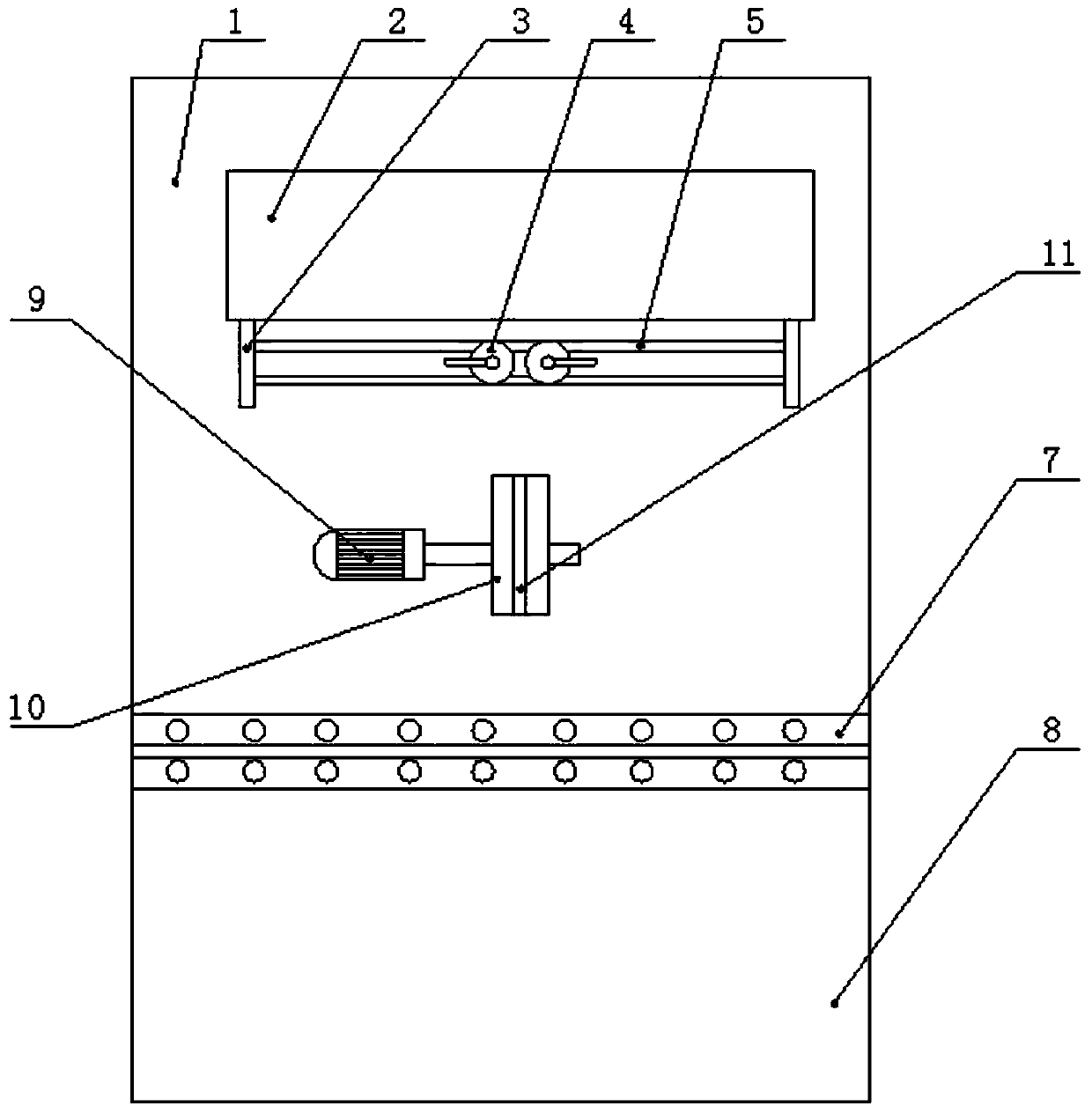

Single station paste filling test-piece preparation device

InactiveCN110186740ACompact structureReasonable distributionPreparing sample for investigationSlurryEngineering

The invention discloses a single station paste filling test-piece preparation device, aiming at achieving the manufacturing of a test-piece and a test-piece demolding function on a same machine through rotating each component, and solving the problems that when in traditional paste filling test-piece preparation, slurry leaks and the environment is polluted, and the preparation test-piece and demolding of the test-piece need different equipment, so that the stations are wasted and the efficiency is low; the high efficiency and high cleanliness are achieved; the paste filling test-piece preparation work of the station is saved; the single station paste filling test-piece preparation device comprises a bottom box, a hole plate, a small test-piece barrel, a large test-piece barrel, a demolding top plate, a knob, a screw, a connection rod and a multifunctional baffle; the device provided by the invention is convenient to operate, easy to maintain, and wide in application prospect of pastefilling test-piece preparation work.

Owner:QINGDAO UNIV OF SCI & TECH

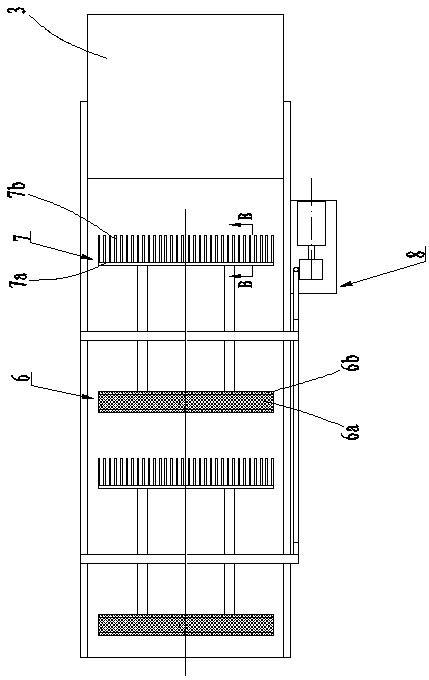

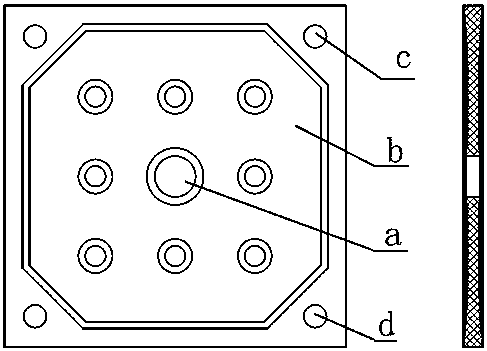

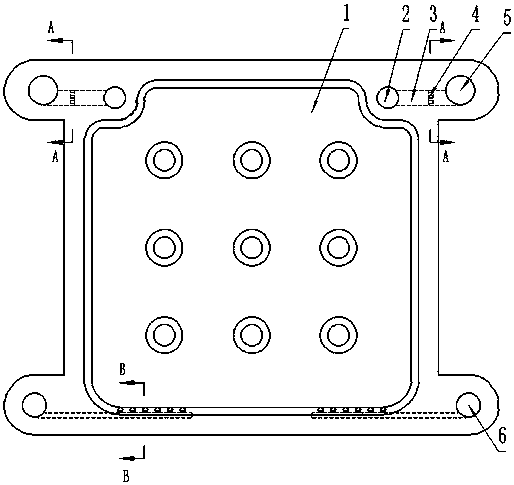

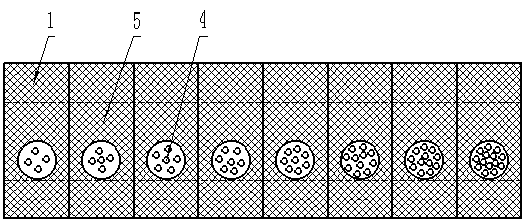

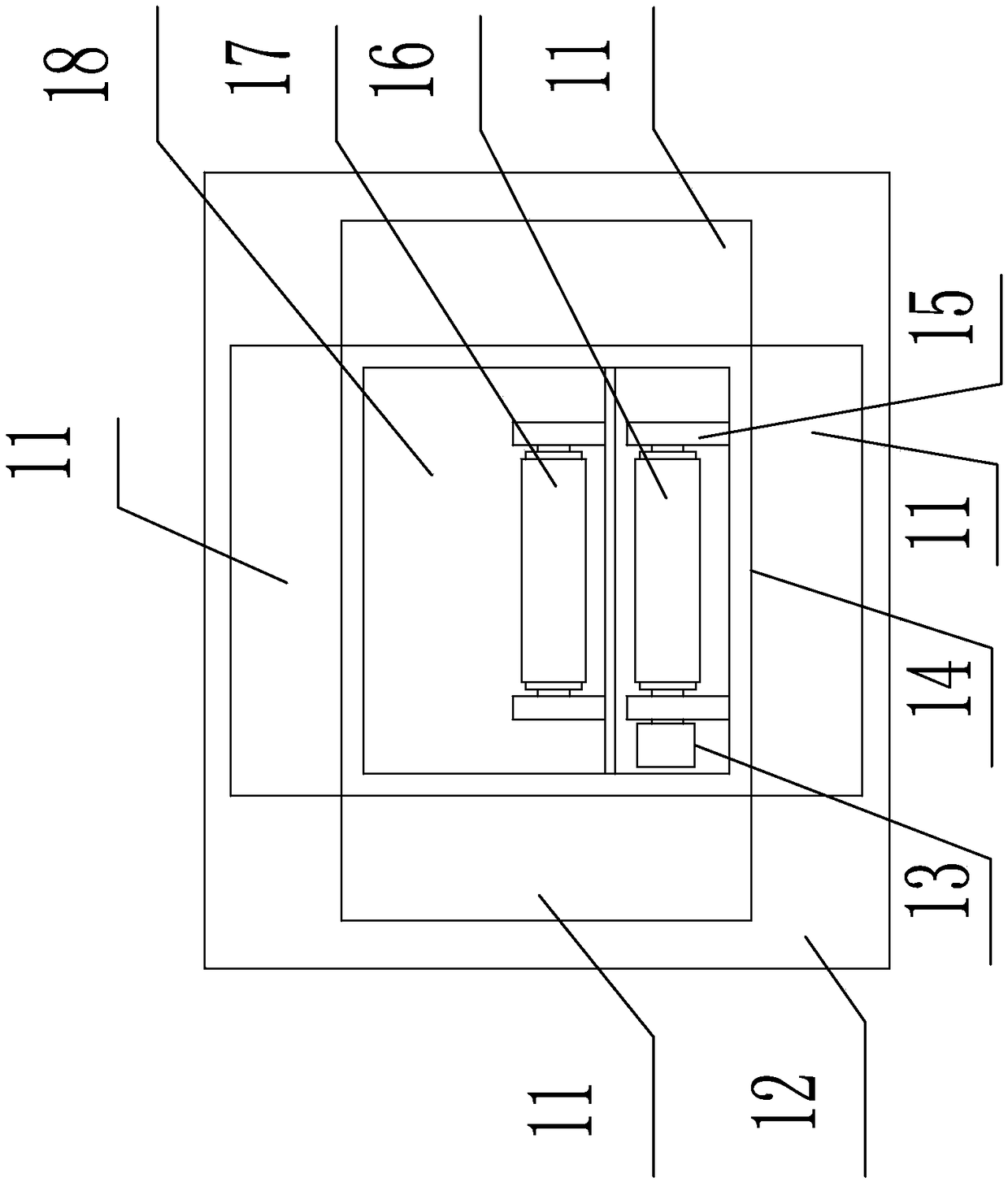

Double-feeding compartment type filter plate combination for fast and uniform feeding

The invention discloses a double-feeding compartment type filter plate combination for fast and uniform feeding. The double-feeding compartment type filter plate combination comprises a plurality of main boards and matching boards which are arranged alternately. The main boards and the matching boards have the same outer shape dimensions, and outer crossing lugs are correspondingly arranged on theupper and lower sides of the main boards and the matching boards symmetrically. Every two upper outer crossing lugs are provided with total feeding channels, and every two lower outer crossing lugs are provided with liquid outlet channels. Single-plate feeding channels perpendicular to the main feeding channels are arranged at the parts, outside filter chambers, on the main boards, and material splitting holes perpendicularly communicate with the single-plate feeding channels. The material splitting holes communicate with the filter chambers on both sides of the main boards. The single-platefeeding channels are internally provided with perforated partition plates, and the hole diameter and the number of holes of the perforated partition plates of the main boards which are sequentially arranged in the feeding direction are sequentially increased. The filter plate combination can realize fast and uniform feeding so as to achieve an ideal filter-pressing effect.

Owner:ZHONGDA BRIGHT FILTER PRESS

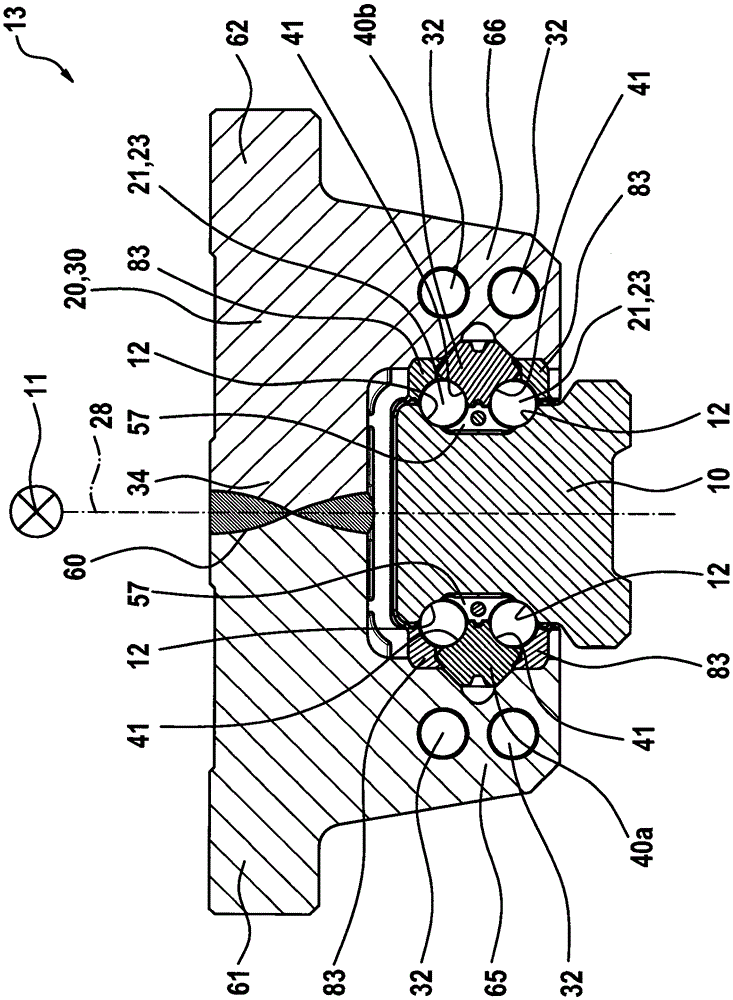

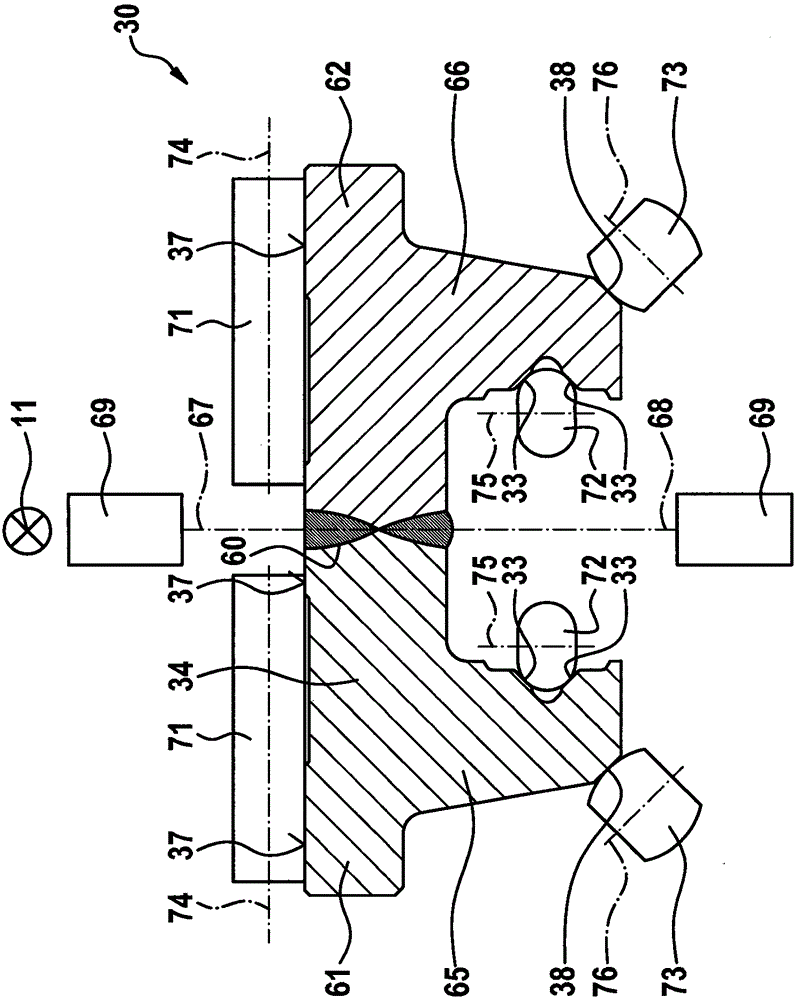

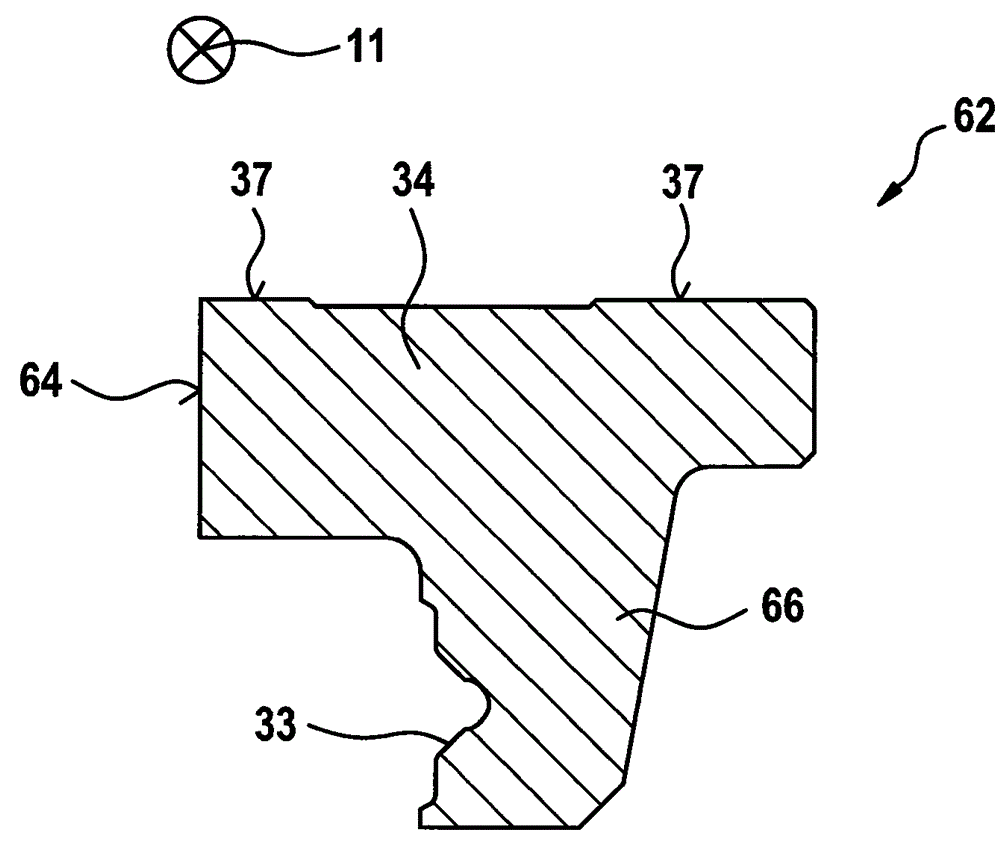

Main body of linear roller bearing

ActiveCN105587766AStrong solder connectionFull Function GuaranteeLinear bearingsBearing assemblyRolling-element bearingBiomedical engineering

The invention relates to a method for manufacturing a main body (30) of a linear roller bearing (13), which is viewed in cross section U-shape, wherein the main body has a base (34) and a first and a second U-shaped side leg; the first and the second U-shaped side leg (65; 66) are perpendicular to the base (34) and protrude from the base. According to the invention, the method comprises the following steps: a) preparing a separate first part (61) which comprises the first U-shaped leg (65) and forms a part of the base (34); b) preparing a second separate part (62) which forms the second U-shaped side leg (66) and a part of the base (34); and c) welding the first and the second part (61; 62) in the region of the base (34).

Owner:ROBERT BOSCH GMBH

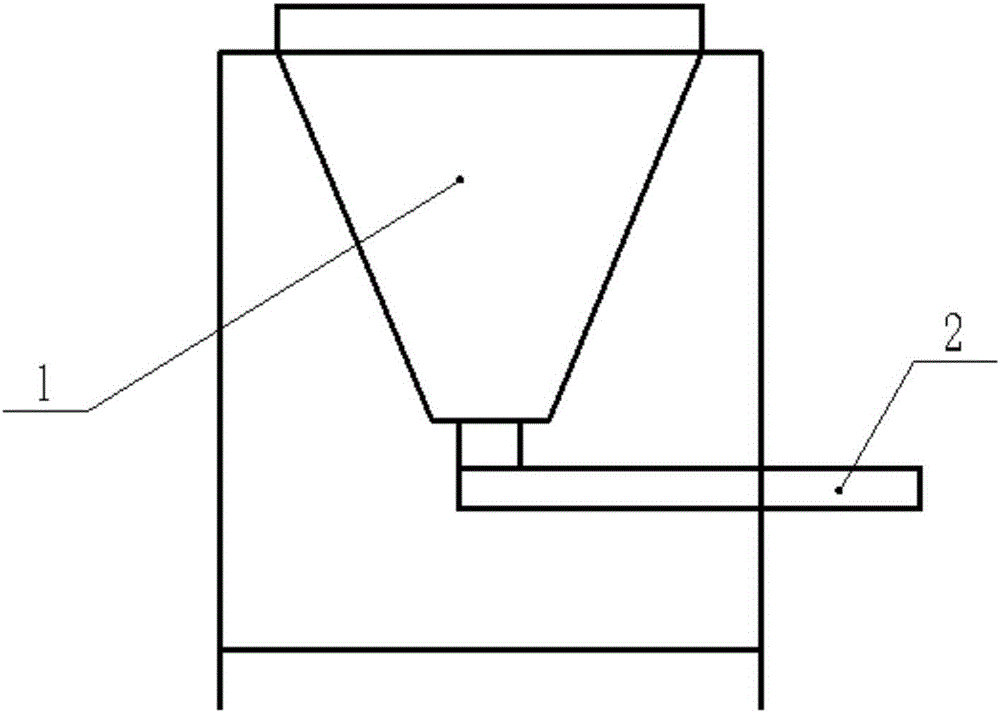

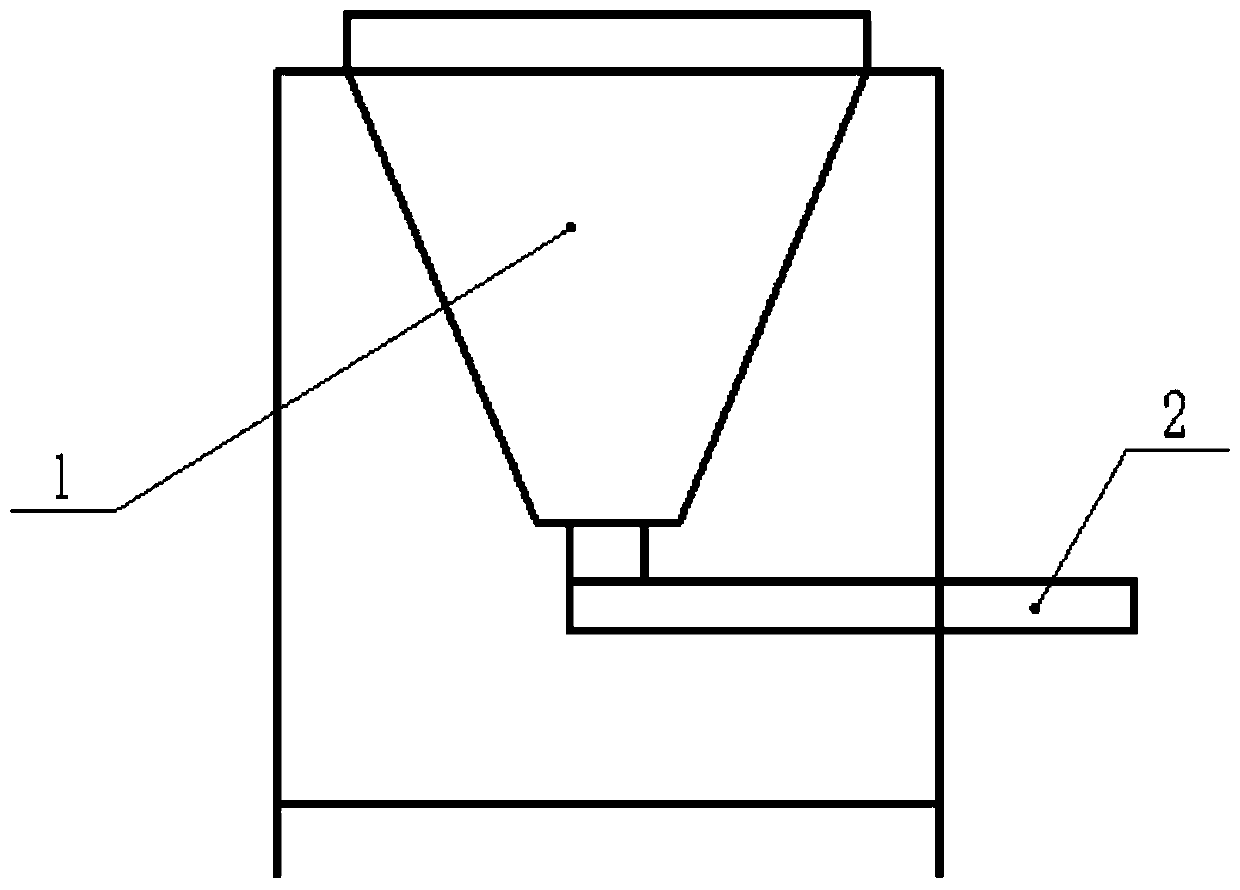

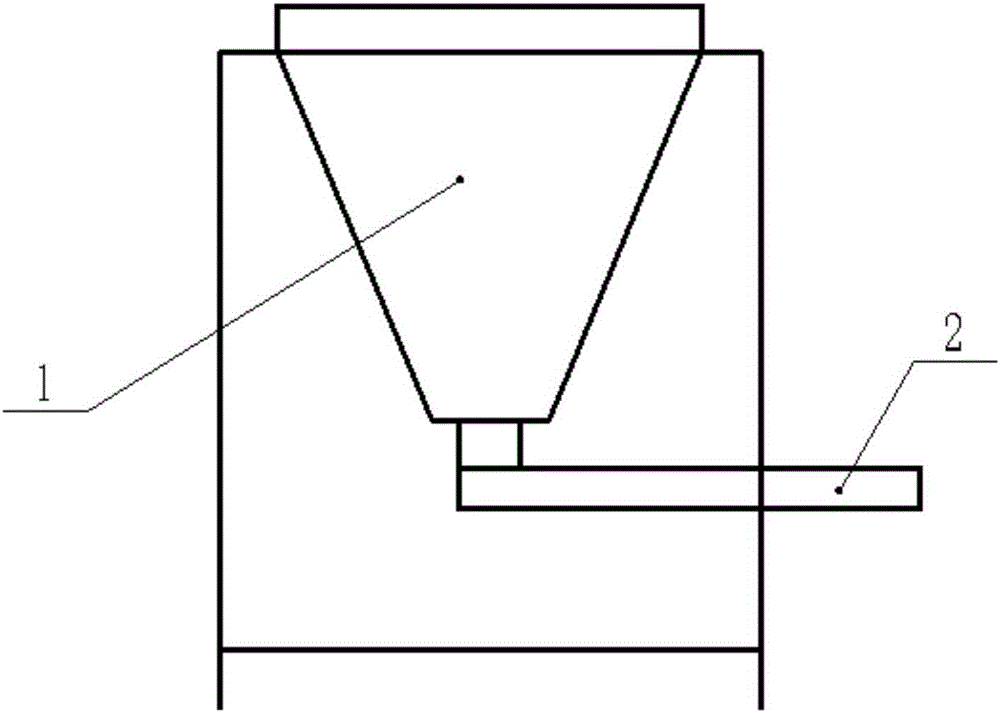

A roller feeding device for powder

The invention discloses a powder rolling feeding device, and belongs to the field of chemical power supplies. The powder rolling feeding device comprises a feed hopper; the feed hopper is positioned rightly above two pressure rollers of a rolling machine; a position for feeding powder between the two pressure rollers is a rolling port; the feed hopper is of a funnel structure for feeding the powder in the rolling port; the feed hopper consists of four baffle plates; impeller shafts parallel to pressure roller shafts are respectively arranged on the left and right sides of the rolling port; two ends of each impeller shaft are connected with two baffle plates perpendicular to the pressing roller shafts; two impeller shafts are connected with a rotary driving mechanism, and are driven by the rotary driving mechanism to oppositely rotate; each impeller shaft and the pressure roller in the same side are oppositely rotated; and the impeller shafts and the pressure rollers therebelow are provided with gaps at least capable of enabling silver pull nets to pass through. The powder rolling feeding device has such characteristics as uniform powder feeding speed, adjustable feeding quantity, capability of preleveling the silver pull nets, capability of adjusting the lengths of the silver pull nets and possession of an automatic powder leakage preventing function.

Owner:CHINA ELECTRONIC TECH GRP CORP NO 18 RES INST

Polar coordinate numerical control fused deposition rapid prototyping machine and its forming method

InactiveCN103786345BThe structural design of the rapid prototyping machine is ingenious in the structural designIngenious structural designManufacturing platforms/substratesManufacturing driving meansNumerical controlDeposition process

Owner:XINJIANG UNIVERSITY

A vacuum aluminum plating machine

ActiveCN106839713BUniform feed rateAvoid cloggingVacuum evaporation coatingDrying gas arrangementsEngineeringInjection device

The invention provides a vacuum aluminum plating machine. The vacuum aluminum plating machine comprises a centralizing mechanism and a drying mechanism which are arranged on a conveying line of an aluminum-plated film; the centralizing mechanism comprises a first roller, a first guide roller, a second guide roller, centralizing rollers, high-temperature gas injection devices, a tensioning wheel I, a second roller, the aluminum-plated film, a high-temperature evaporator and gas conveying pipes; the high-temperature evaporator is connected with the high-temperature gas injection devices through the gas conveying pipes on the two sides; the drying mechanism comprises a high-temperature gas feeding cavity, a drying device casing, a belt wheel, a heat transfer wall, support seats, a discharging roller, a third guide roller, a hollow cavity, a tensioning wheel II, a tightening roller and guiding rollers; and the aluminum-plated film located on the discharging roller sequentially passes through the tensioning wheel II, the third guide roller and the guiding rollers to wind around the tightening roller. By the aid of high-temperature gas fed into the high-temperature gas feeding cavity, the condition that the product quality is affected due to the fact that the aluminum-plated film makes direct contact with a heat source is avoided, and the high-temperature gas can be recycled, so that resources are saved, and the drying effect is good.

Owner:浙江长宇新材料股份有限公司

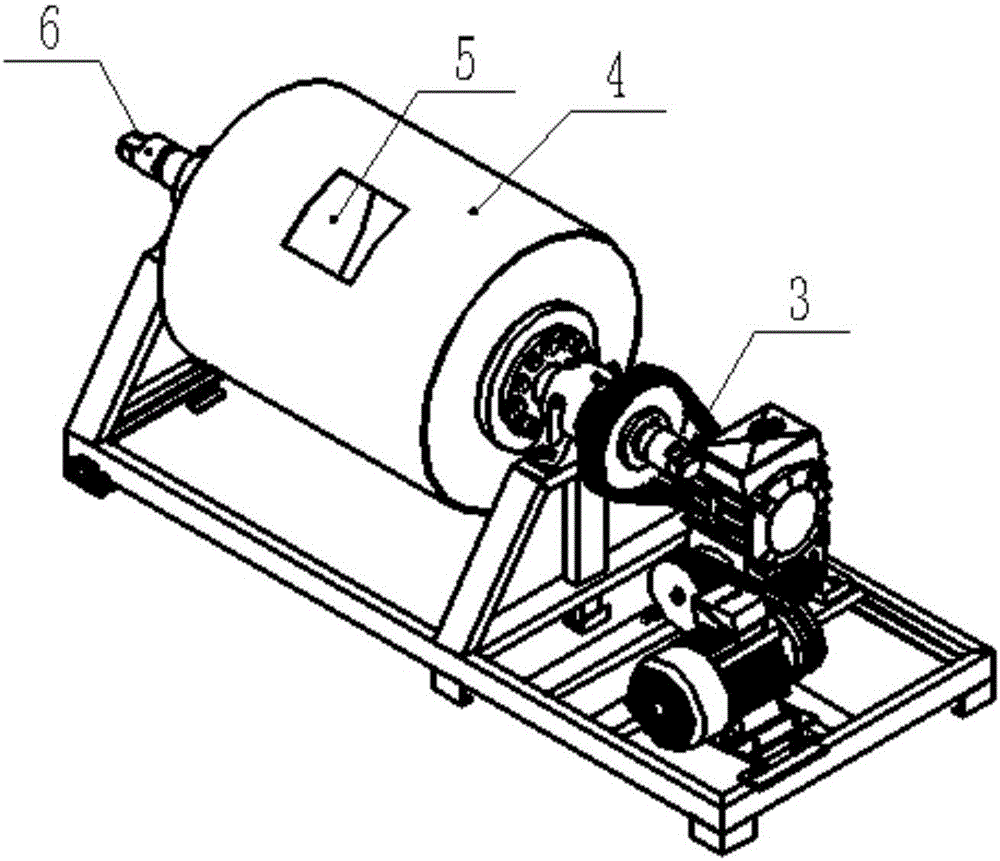

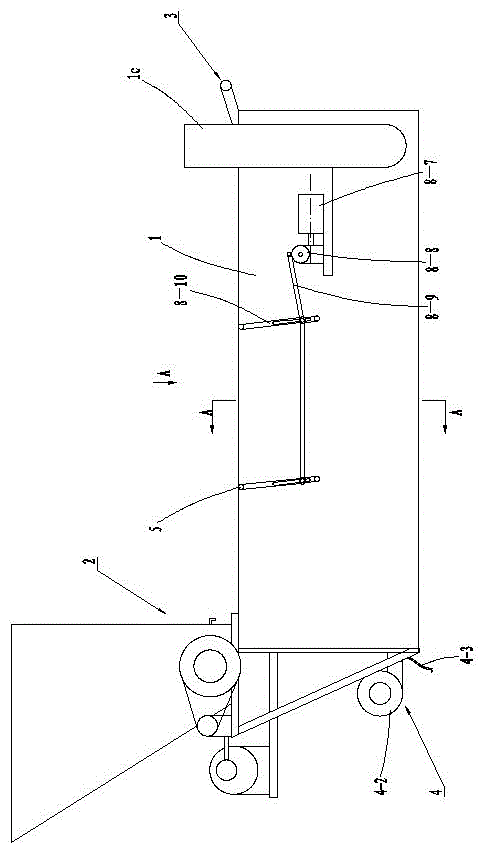

Full-automatic efficient sanding machine

InactiveCN112847115AUniform feed rateStable rotation speedGrinding carriagesPolishing machinesSurface grindingPolishing

The invention provides a full-automatic efficient sanding machine, and relates to a metal bar polishing device, in particular to an improvement to a sanding machine. The full-automatic efficient sanding machine is high in grinding efficiency and uniform in grinding. The sanding machine comprises a track arranged on a rack, wherein the track is provided with a clamping part and a sanding part which slide along the track, the clamping part comprises a fixed clamping assembly fixed to the rack and a movable clamping assembly which is arranged on the track and slides along the track, a metal bar is clamped between the fixed clamping assembly and the movable clamping assembly, and the fixed clamping assembly is driven by a first motor arranged on the rack to rotate. A polishing assembly moves on the track, at the moment, the surface of the metal bar is polished through a polishing wheel, and meanwhile the polishing assembly is driven by a first servo motor to slide back and forth along the track, so that the whole aluminum bar surface grinding procedure is completed; and since the feeding speed of the first servo motor is uniform, and the rotating speed of the first motor and the rotating speed of a second motor are stable, few pauses are caused in the whole grinding process, surface grinding is more uniform, the grinding and polishing efficiency of the metal bar is higher, and the rejection rate is lower.

Owner:扬州鑫宇电气有限公司

A catalyst grinding and drying process

ActiveCN109569829BAvoid damageImprove refinement efficiencySievingGranular material dryingPtru catalystEngineering

The invention belongs to the technical field of catalyst preparation, and specifically relates to a catalyst grinding and drying process. The process includes the following steps: putting raw materials into a hopper of a catalyst preparation system, and entering the agitation module through the funnel to start the grinding and drying process of the catalyst; There is a spiral feeding plate inside the funnel, the lower end of the spiral feeding plate is connected with a spring, the spring extends to the box and contacts the shaking plate, the distance between the springs is greater than the thickness of the shaking plate; the shaking plate is a heating plate, and the upper end of the spiral plate shaft The positive and negative electrodes are respectively connected to the lower end of the box; the lower end of the box is equipped with a No. 3 cylinder, and the tail of the No. 3 cylinder is connected to the tail of the No. 2 cylinder in the catalyst preparation system through a gas pipe. The central axis of the No. 1 cylinder is on the same horizontal line; the present invention contacts the jitter plate through the spring, and increases the jitter amplitude and frequency of the jitter plate during the rotation of the spring, thereby improving the refinement efficiency of the catalyst raw material.

Owner:江苏上阳金属新材料有限公司

Groove pipe cutting all-in-one machine

ActiveCN102009223BPrecise position controlNot easy to damageTube shearing machinesEngineeringMobile device

The invention discloses a groove pipe cutting all-in-one machine, which is characterized in that a rack is provided with a spindle, a cutter feed servo motor is fixedly arranged on the rack, a cutter rotating disk is connected with the spindle, and a cutter feed shelter is concentric with the cutter rotating disk; a transmission redirection component is arranged between the cutter feed shelter and a cutter mobile device, and the cutter rotating disk is provided with 2-4 cutter mobile devices; the front and the back of the rack are respectively provided with a clamping mechanism, and 3-6 jaws are evenly distributed on grip slippers in the front and the back clamping mechanisms respectively; and a clamping jaw, a guide rail and a horizontal expansion device are arranged in a beam above the rack and a support, and the clamping jaw is internally provided with a vertical expansion device, a guide rail and a pair of clamping jaws. By using the machine provided by the invention, the relativeangular velocity difference generated between the cutter feed shelter and the cutter rotating disk can be kept constant, and the cutter feed is stable and the movable position of the cutter can be accurately controlled, thus realizing groove manufacturing in different forms; and the cutter is not easy to damage, thereby ensuring even cutting speed and feed speed, and guaranteeing the groove manufacturing of a steel tube with different wall thicknesses.

Owner:上海中船临港船舶装备有限公司 +2

Machining production method special for nodular cast iron pipe finishing unit

InactiveCN109702563AAchieving tension adjustmentGuaranteed uptimeLiquid surface applicatorsRevolution surface grinding machinesGrinding wheelCast iron pipe

The invention relates to a machining production method special for a nodular cast iron pipe finishing unit, and belongs to the field of pipe production equipment. In the prior art, independent operation needs to be carried out, and a working period is long. The machining production method special for the nodular cast iron pipe finishing unit comprises the following steps that a to-be-chamfered pipe is placed on a chamfering station for being chamfered through a travelling crane, and the to-be-chamfered pipe is erected on a chamfering riding wheel assembly, so that one end of the to-be-chamfered pipe is in contact with a chamfering grinding wheel; the chamfered pipe is placed on an internal grinding station for inner grinding through the travelling crane, the to-be-ground pipe is erected onan inner grinding driving riding wheel and an inner grinding driven riding wheel, and one end of the to-be-ground pipe is in contact with a blocking wheel body; and the internally-ground pipe is placed on a roller coating station for roller coating through the travelling crane, the to-be-roller-coated pipe is erected on a roller coating riding wheel assembly, one end of the to-be-roller-coated pipe is erected on a roller coating positioning boss, and roller coating is conducted on the to-be-roller-coated pipe. According to the method, the working efficiency is improved, and assembly among allpipes is facilitated.

Owner:杭州春风机械工程股份有限公司

Energy-saving garment cloth cutting device capable of avoiding cutting sliding

InactiveCN112692880ASolve the problem of manual labor intensityGuaranteed cutting effectSevering textilesMetal working apparatusEngineeringMechanical engineering

The invention relates to the technical field of garment cloth production equipment, and discloses an energy-saving garment cloth cutting device capable of avoiding cutting sliding. The energy-saving garment cloth cutting device capable of avoiding cutting sliding comprises a shell; the interior of the shell is movably connected with a cloth device; the outer side of the cloth device is slidably connected with a first connecting piece; the interior of the first connecting piece is rotationally connected with a first connecting shaft; the outer side of the first connecting shaft is rotationally connected with a first gear; the outer side of the first gear is engaged with a second gear; and the outer side of the second gear is rotationally connected with a magnetic pole. According to the energy-saving garment cloth cutting device capable of avoiding cutting sliding, through the connection of the shell and the second gear, the problem that a cloth cutting device in the prior art is high in manual labor intensity is solved; a large amount of manual operation is replaced by machinery, therefore, time and labor are saved, the cost is effectively reduced, meanwhile, the rejection rate is reduced, and the cloth cutting effect is guaranteed; and the energy-saving garment cloth cutting device capable of avoiding cutting sliding is suitable for cloth of different specifications, can fix cloth during cutting and is easy to operate.

Owner:江阴灵通网络科技有限公司

A mixer for agricultural production that adopts mosquito-repellent incense track and extruded feed

ActiveCN108786568BIncrease contact areaImprove stirring efficiencyRotary stirring mixersTransportation and packagingAgricultural scienceAgricultural engineering

Owner:嘉兴琦玥装饰材料有限公司

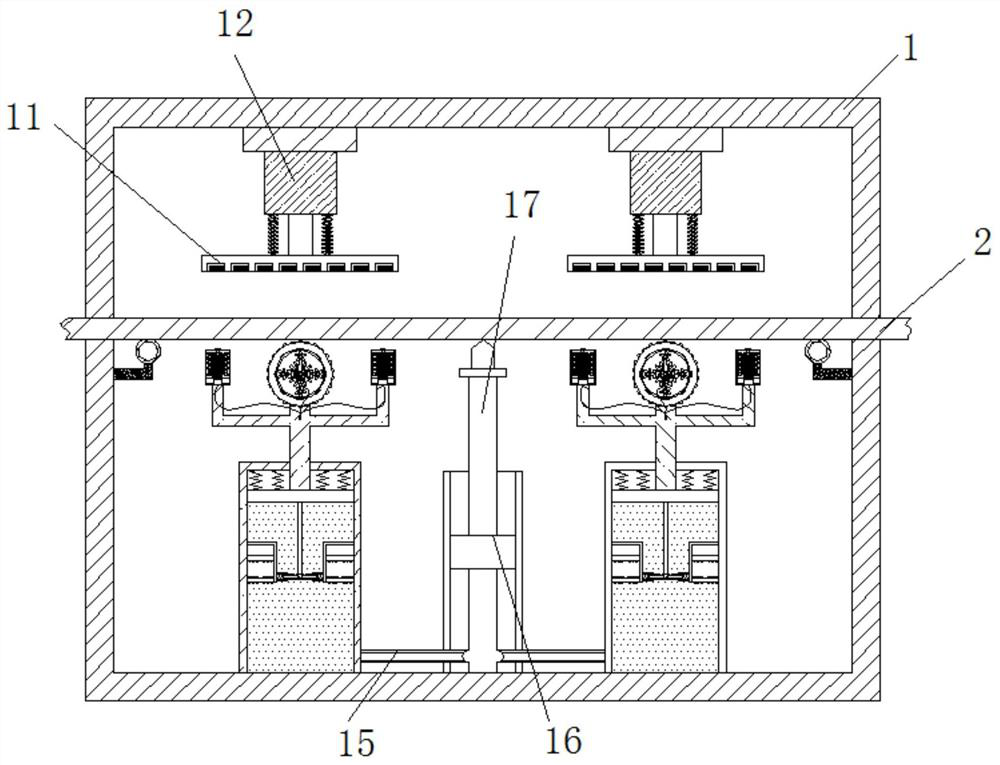

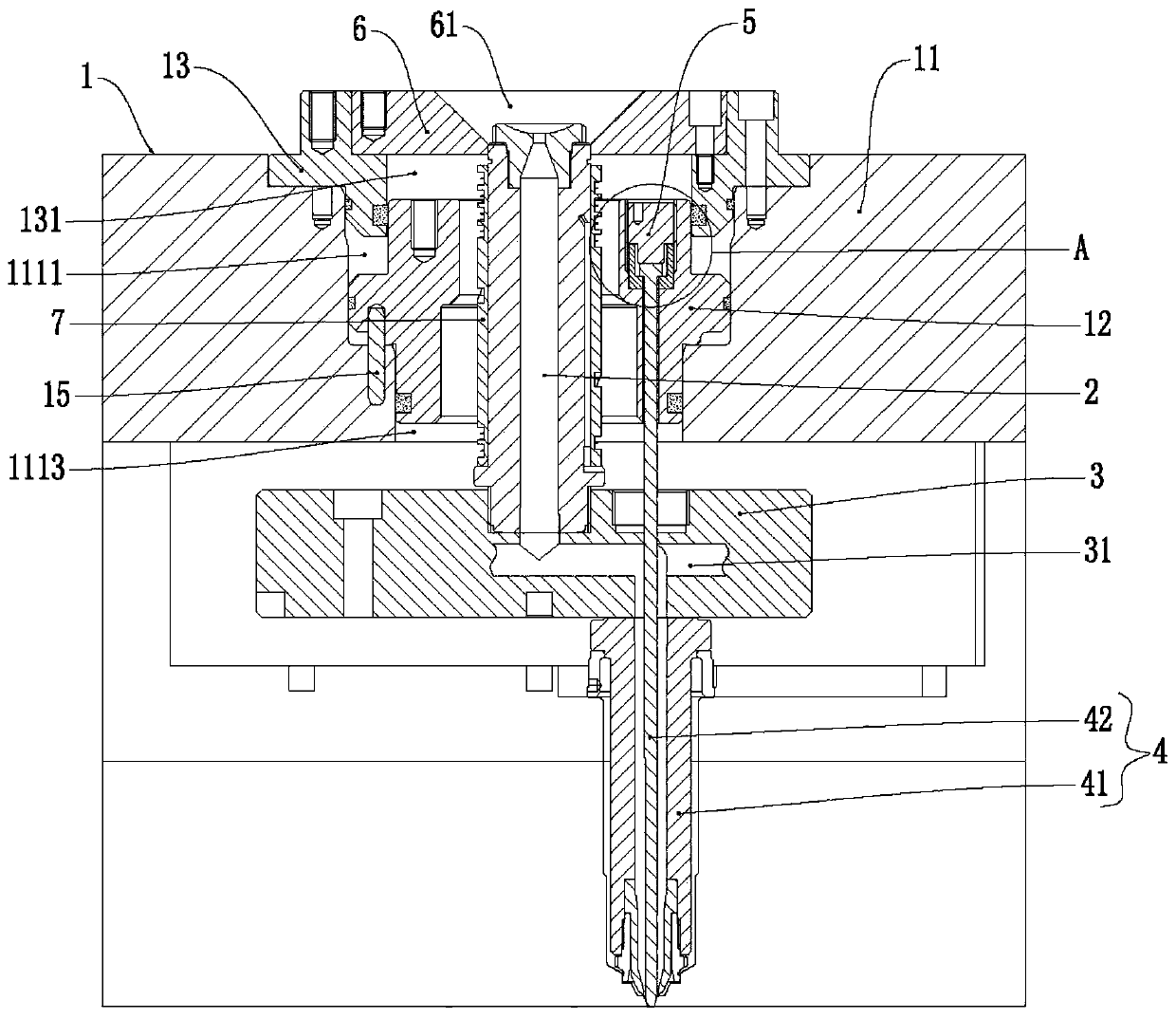

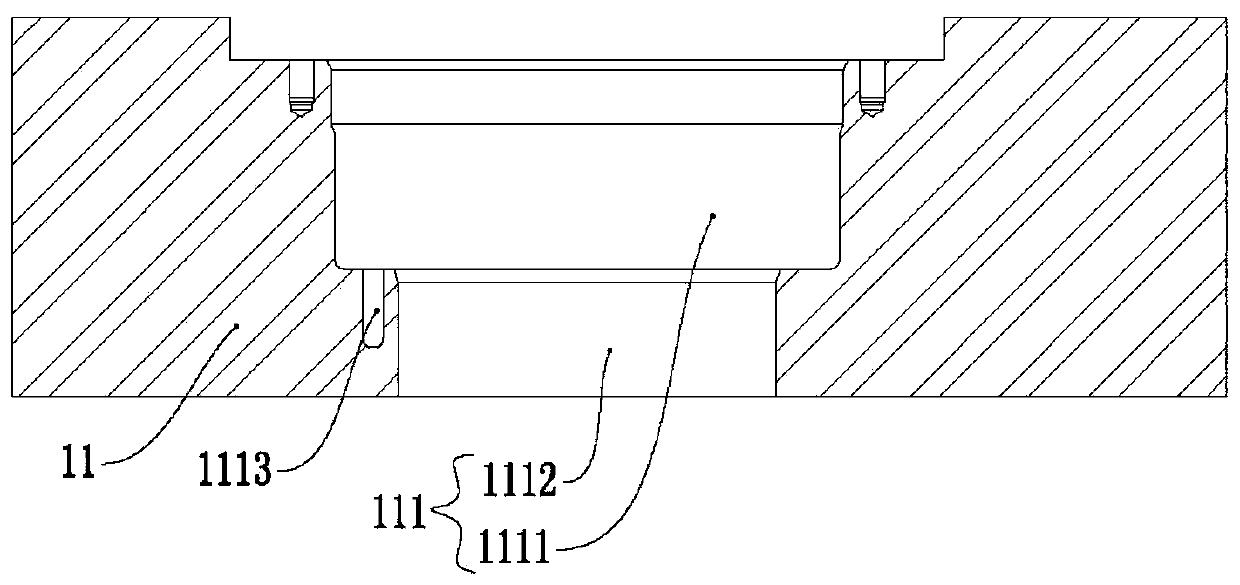

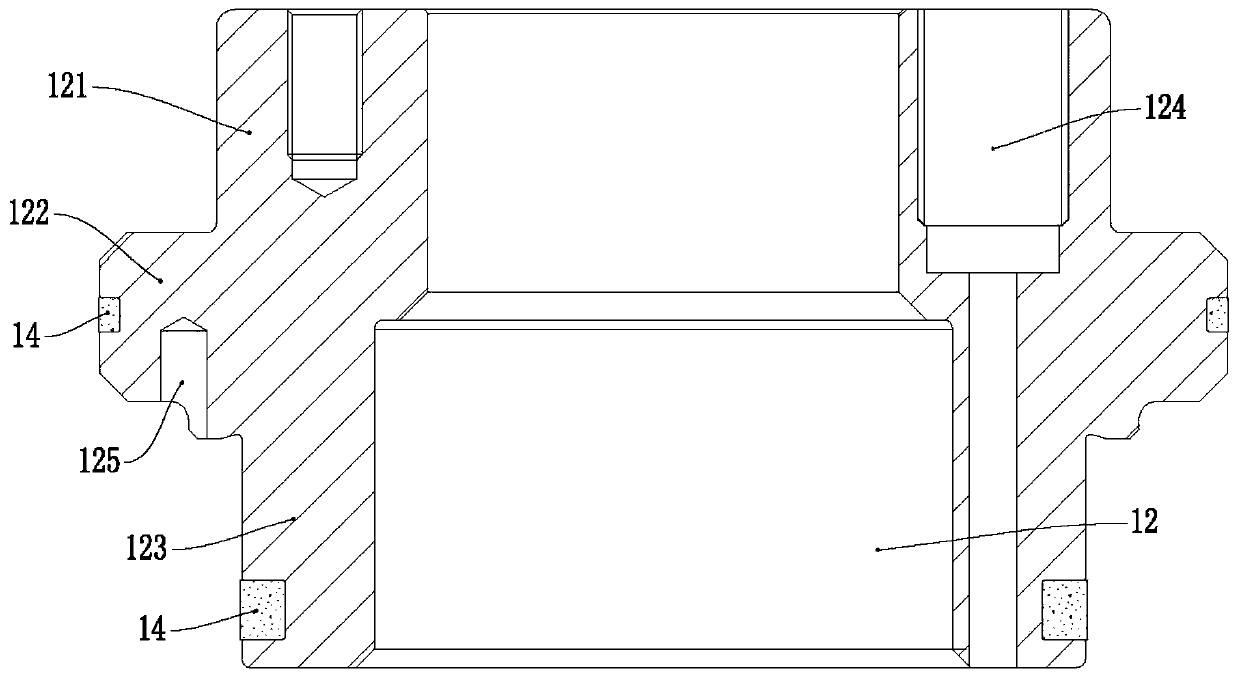

Single-cylinder multi-point hot runner system

The invention discloses a single-cylinder multi-point hot runner system, which is characterized in that a cavity is formed in a cylinder body, and an annular piston is arranged in the cavity; the annular piston is in sliding fit with the inner wall of an accommodating cavity and divides the accommodating cavity into an upper annular air cavity and a lower annular air cavity which are sealed respectively; an end cover is arranged at the opening of the cavity and is in sealed connection with the inner wall of the cavity; hot runners which are communicated with one another are arranged in a flowdividing plate, and the flow dividing plate is arranged below the cylinder body; a feeding nozzle is connected with the flow dividing plate, and an internal runner of the feeding nozzle is communicated with an inlet of each hot runner; a plurality of needle valves are arranged, each needle valve comprises a valve body and a valve needle; the upper end of the valve body is connected with the flow dividing plate, an internal runner of the valve body is communicated with the hot runner, and the valve bodies are uniformly arranged around the central axis of the annular piston; the upper end of thevalve needle is connected with the annular piston, and the lower end is inserted into the valve body; the lower end of the needle valve is connected with a pouring gate of the mold, and the valve needle is used for controlling opening and closing of the needle valve. According to the invention, the opening and closing of the needle valves can be synchronously controlled, so that the dynamic balance performance of an injection molding product is enabled to be higher.

Owner:FRENK HOT RUNNER TECH CO LTD

A dry powder processing technology using a fire extinguisher dry powder recycling processing system

ActiveCN106422124BRealize streamlined operationUniform feed rateDrying solid materials without heatFire rescueFire extinguisherNational standard

The invention provides a dry powder machining process using a fire extinguisher dry powder reuse machining system. The dry powder machining process comprises the following process steps: firstly, a hopper and a ball mill are used for finely crushing raw dry powder; then, the crushed raw dry powder is dried; components of the dried raw dry powder are detected; and according to national standard requirements and detecting results, the insufficient components are added for full mixing to realize reuse of fire extinguisher dry powder. The dry powder machining process is simple in process steps, realizes corresponding process steps by dint of corresponding machining equipment, is high in automation degree of the treatment process, and is suitable for streamlined production operation.

Owner:济南康和消防技术有限公司

Method for processing potato chips

Owner:包海荣

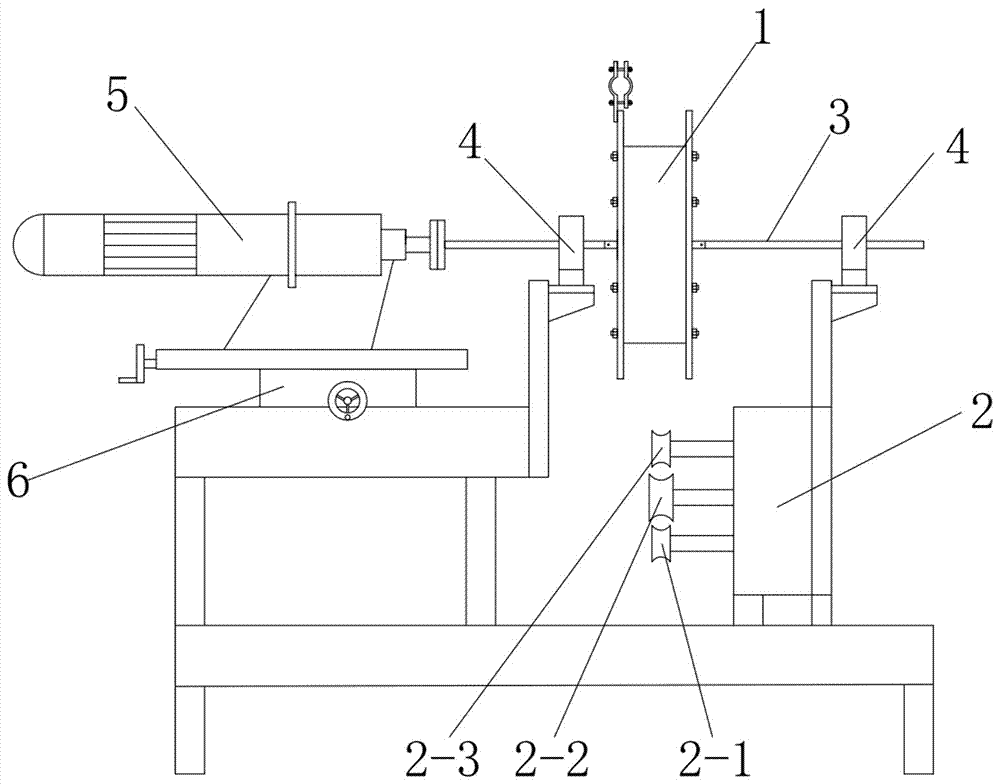

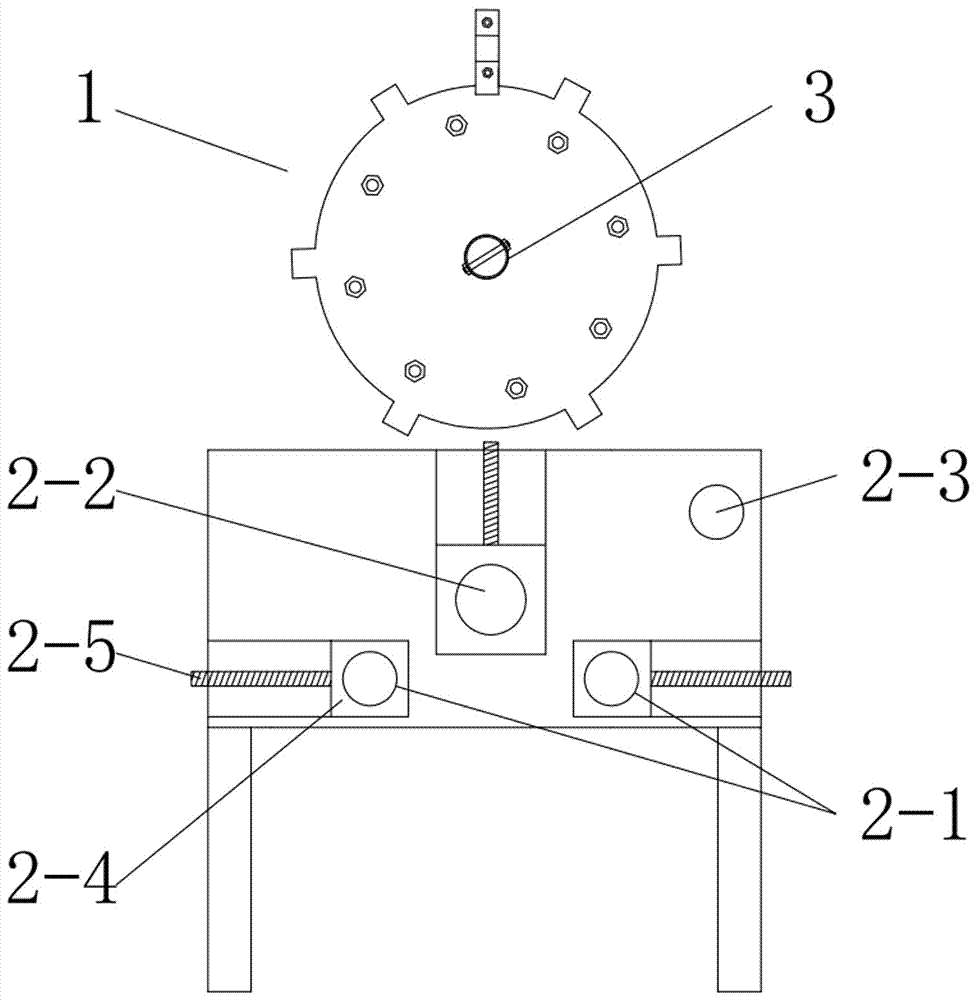

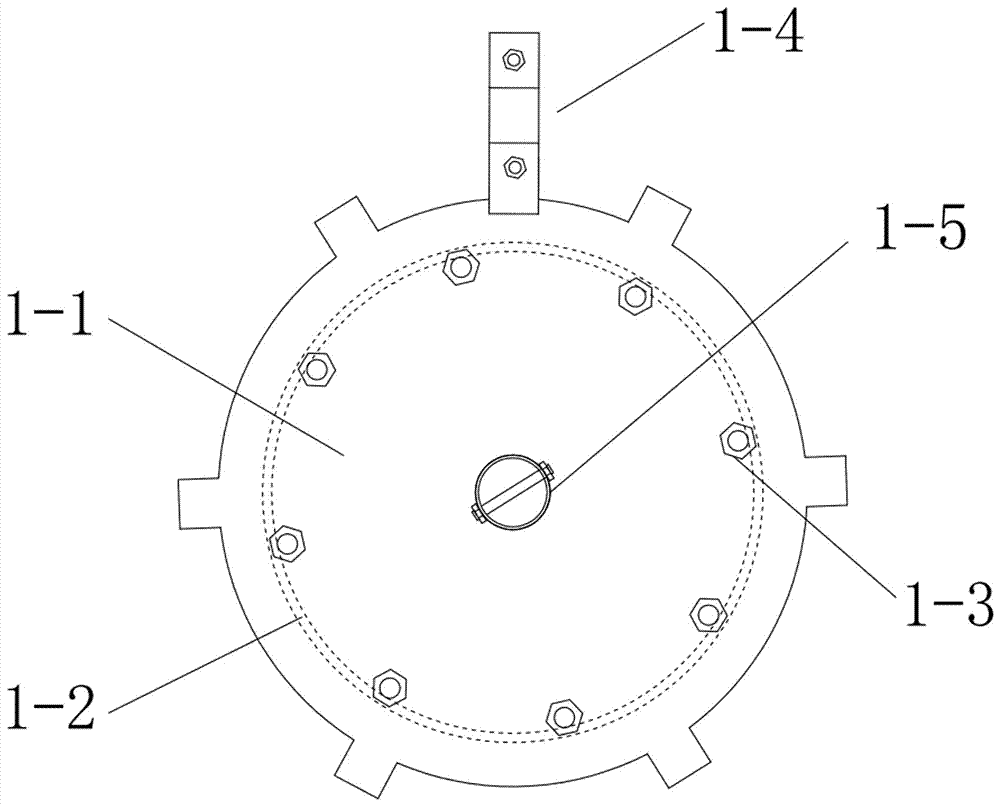

Efficient feeding system for automobile radiator flow guide plates

The invention relates to an efficient feeding system for automobile radiator flow guide plates. The efficient feeding system is characterized in that a conveying mechanism comprises a motor and a rotary disc; the motor is fixedly installed on a box body through a motor bracket; the rotary disc is installed at one end of a motor driving shaft, and the periphery of the rotary disc is provided with amaterial clamping groove; and a flow guide plate raw material is placed in the material clamping groove; a locking mechanism comprises a locking bracket, supporting beams and adjusting locking blocks; the inner side of the bottom end of the motor bracket is horizontally provided with the two parallel supporting beams in a spaced mode; and the two supporting beams are provided with the two adjusting locking blocks, and the positions of the two adjusting locking blocks on the supporting beams are adjustable. The efficient feeding system for the automobile radiator flow guide plates is scientific and reasonable in structural design, the placement cleanliness, machining flatness and machining locking of the flow guide plate raw material can be kept, and the situation that the quality of the flow guide plates is influenced due to the fact that the flow guide plate raw material shifts and deforms before entering a stamp die system is prevented; and in addition, the efficient feeding systemcan be adjusted to be suitable for machining of flow guide plates with different specifications and operated conveniently and efficiently and is wide in application range.

Owner:天津市滨盛鑫源金属制品有限公司

Copper casing coil machine

The invention relates to the field of a bending forming processing technology of casing pipe materials, in particular to the field of a preparing technology of a multi-layer spiral-structure copper casing pipe for a heat exchanger. The invention particularly discloses a copper casing pipe coiler. The copper casing pipe coiler comprises a rack, and a bending mechanism and a pipe coiling disc which are arranged on the rack, wherein the pipe coiling disc is driven by a speed reducer with a motor to rotate through a rotating shaft, the rotating shaft penetrates through a bearing and is supported by bearing pedestals arranged on the rack, and the speed reducer is fixed to a sliding table of the rack and can move on the surface of the rack in the axial direction of the rotating shaft through the sliding table; the bending mechanism comprises a dynamic pipe conveying wheel group arranged below the pipe coiling disc, a bending wheel arranged among the dynamic pipe conveying wheel group and a guide wheel which is positioned between the dynamic pipe conveying wheel group and the pipe coiling disc and is close to the periphery of the pipe coiling disc; and a pipe head positioning clamp is arranged on the pipe coiling disc. The copper casing pipe coiler can process the copper casing pipe and make a multi-layer spiral coiled pipe for the heat exchanger and has the advantages of being high in processing efficiency, neat and even in coiled pipe appearance and low in worker labor intensity.

Owner:常熟在路上创业孵化器有限公司

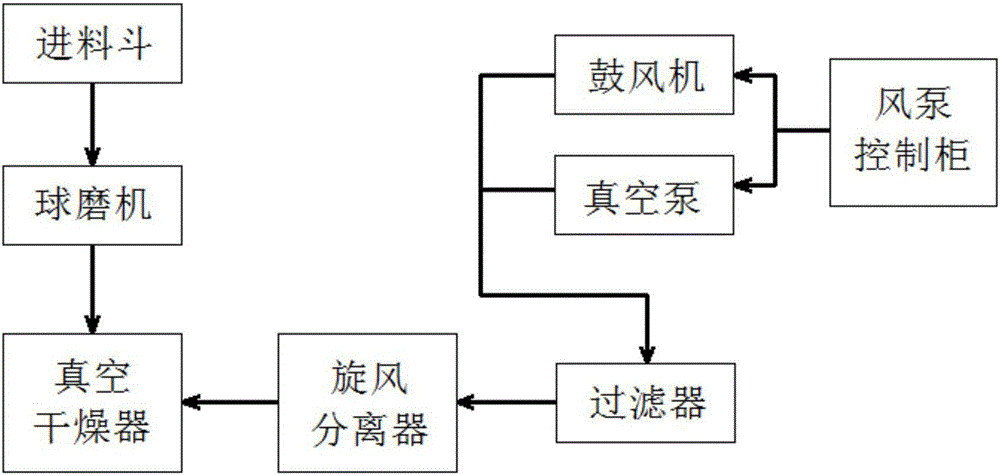

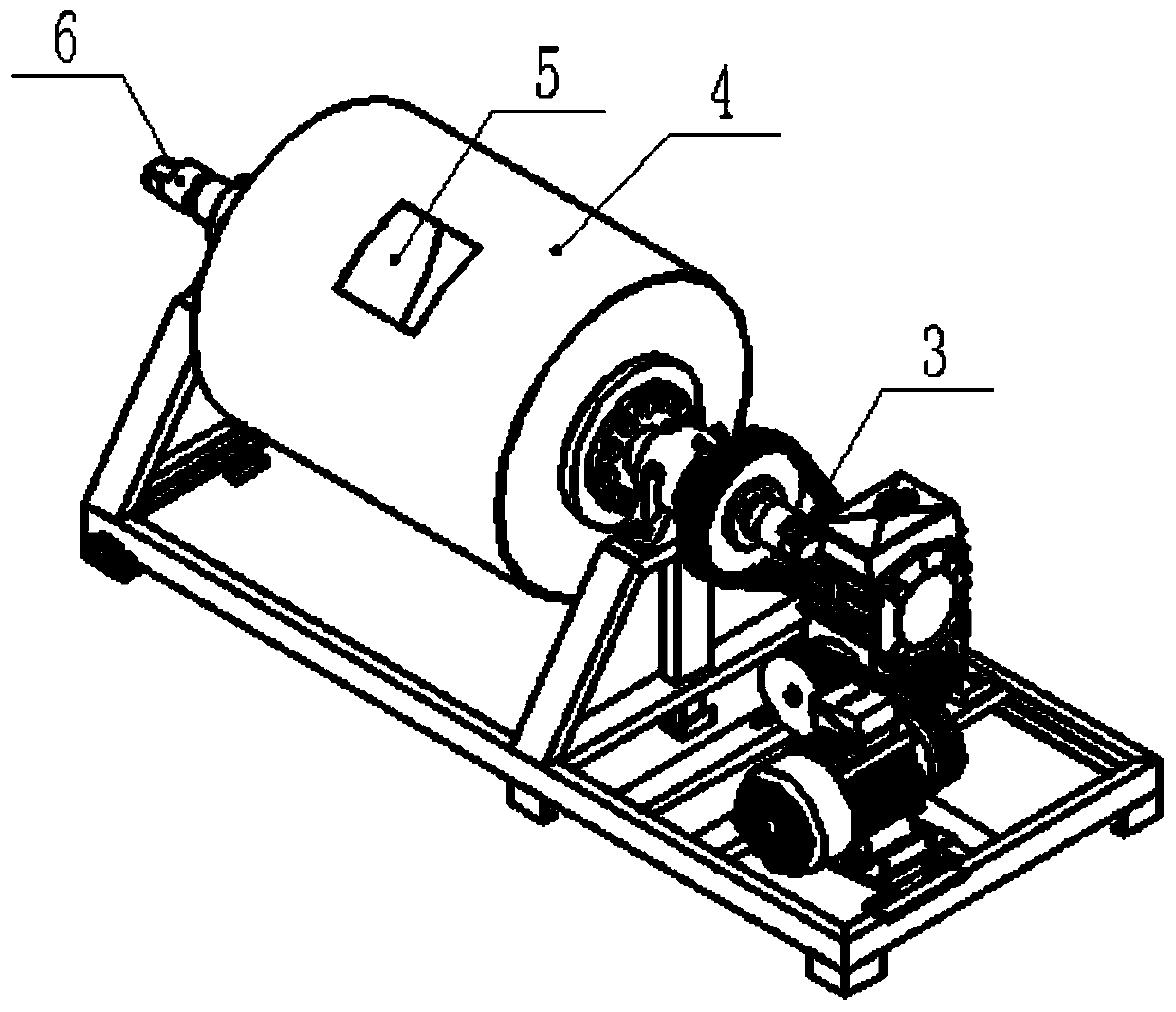

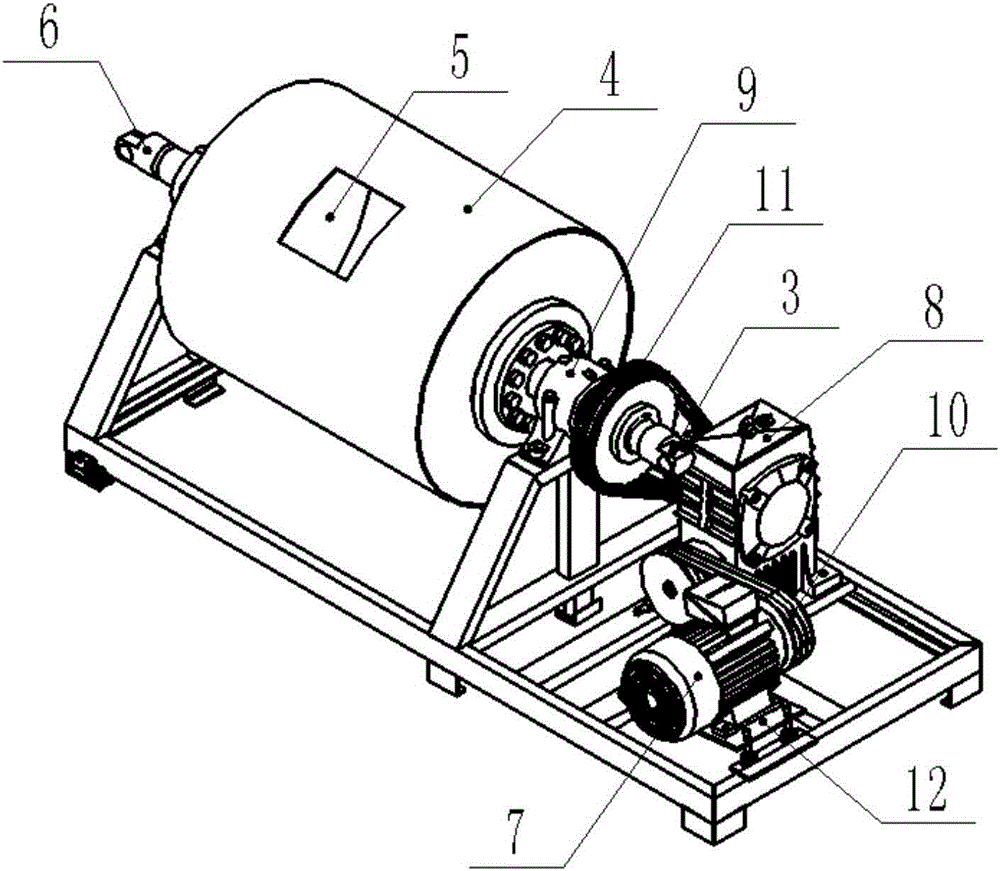

Fire extinguisher dry powder recycling processing system

ActiveCN106267633AUniform feed rateAvoid filter cloggingDrying solid materials without heatFire rescueBall millPhencyclone

The invention provides a fire extinguisher dry powder recycling processing system. The fire extinguisher dry powder recycling processing system comprises a feeding hopper, a ball mill, a vacuum dryer, an air pump control cabinet, an air blower, a vacuum pump, a cyclone separator and a filter. The basic working process of the fire extinguisher dry powder recycling processing system comprises the steps that constant-speed feeding of a dry powder primary material is achieved through the feeding hopper; grinding and refining of the dry powder primary material are achieved through the ball mill; then drying treatment is conducted through the vacuum dryer; meanwhile, the air blower and the vacuum pump jointly act to form the vacuum environment; and components of dry powder at an outlet of the vacuum dryer is detected finally, components with inadequate content are added, sufficient mixing is conducted, and then recycling processing of the fire extinguisher dry powder is achieved. According to the fire extinguisher dry powder recycling processing system, streamlined operation is achieved through the through type ball mill, and the system is complete and reliable, has a series of advantages of being high in processing efficiency, convenient to operate and maintain and the like and can achieve efficient recycling of the fire extinguisher dry powder.

Owner:济南康和消防技术有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com