Patents

Literature

34results about How to "Speed can be adjusted" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

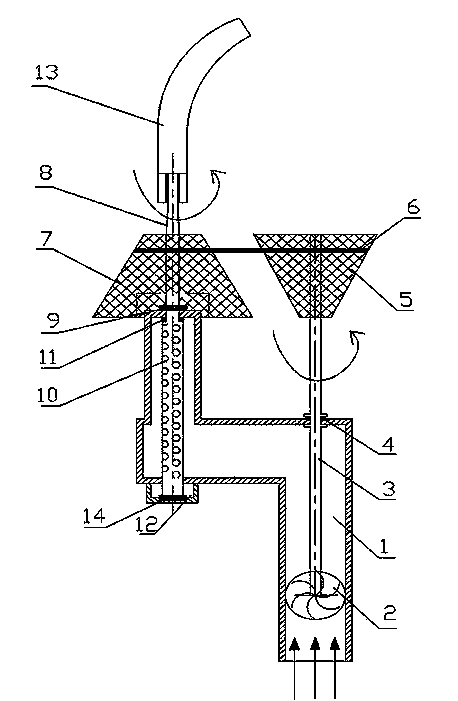

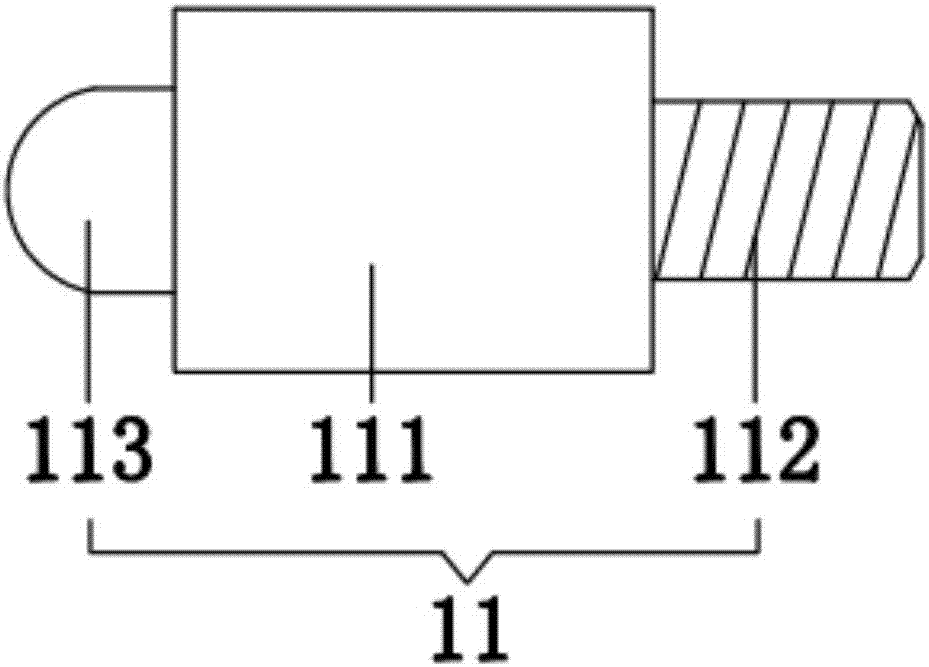

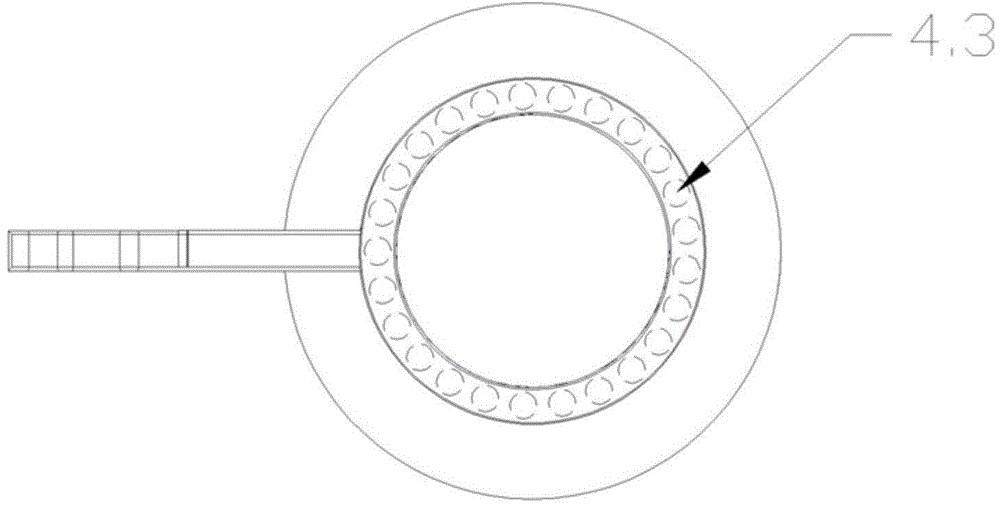

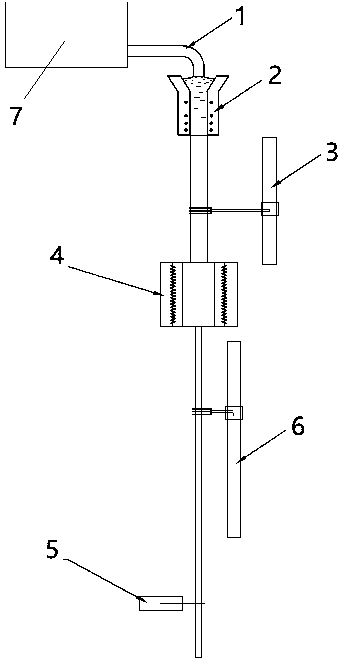

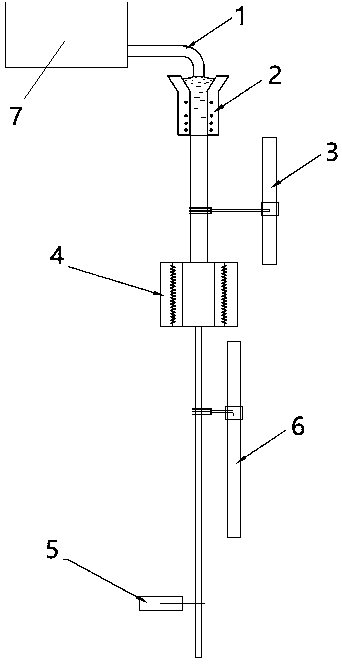

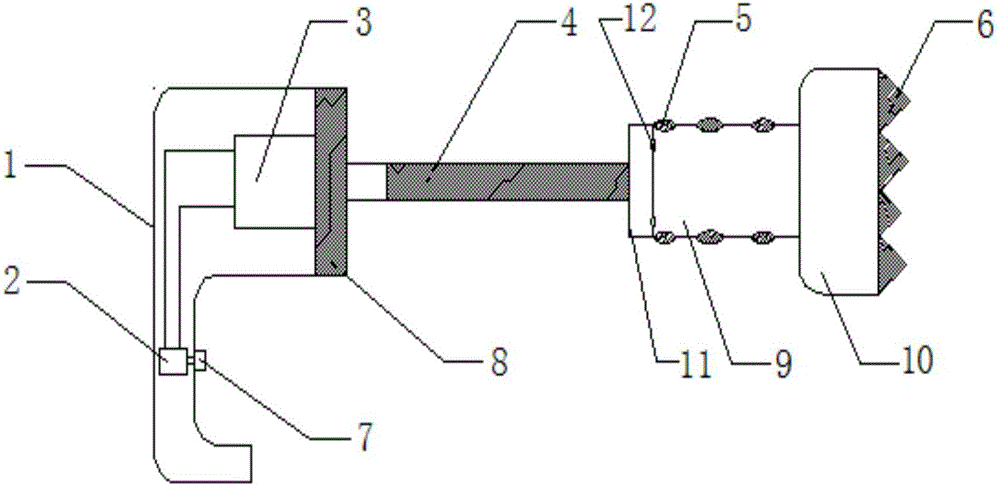

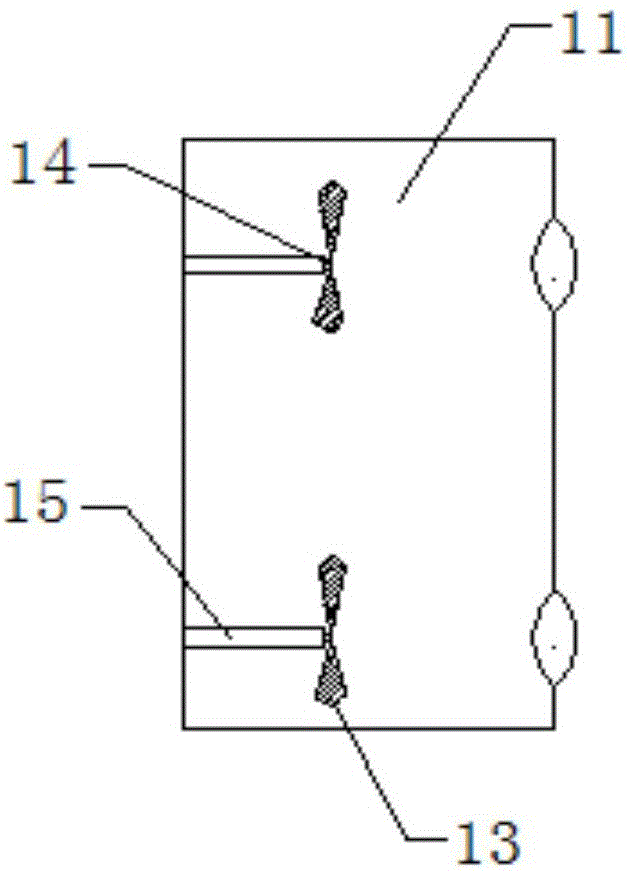

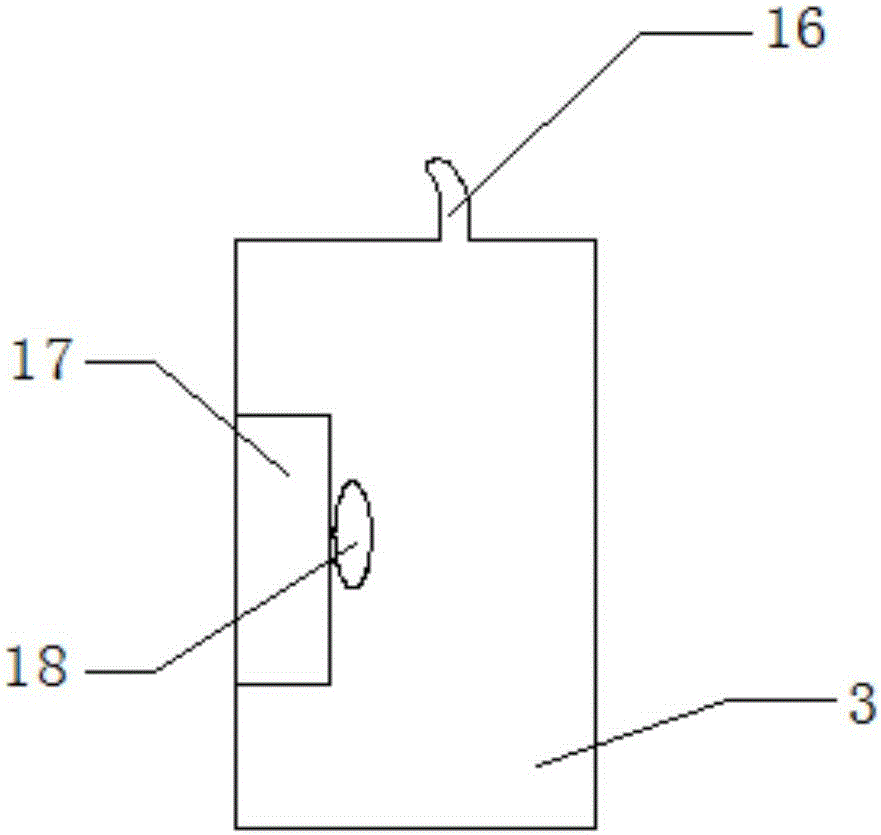

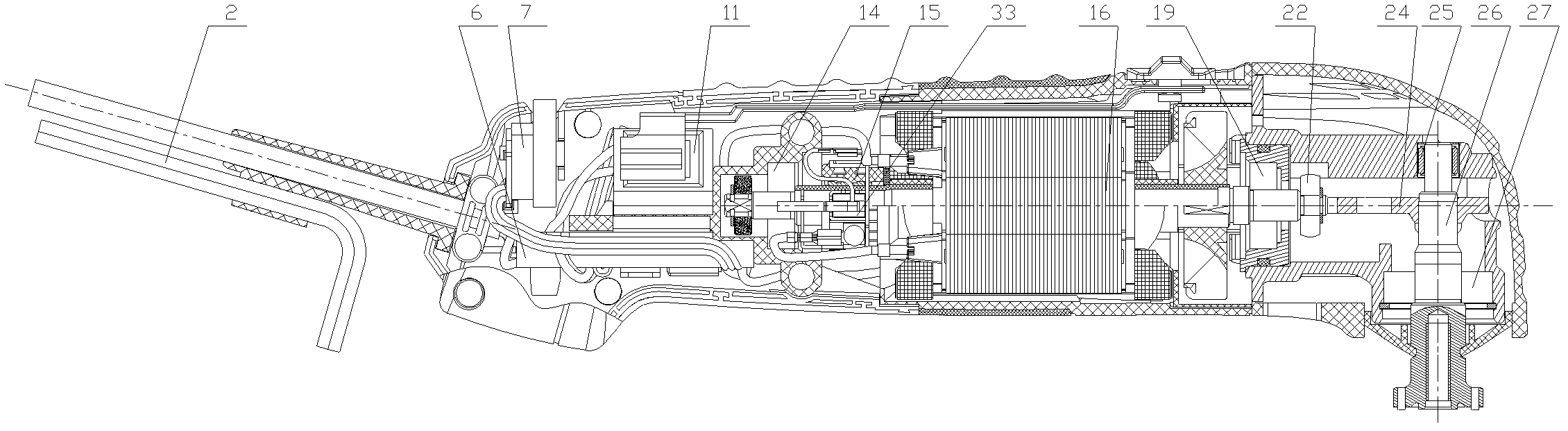

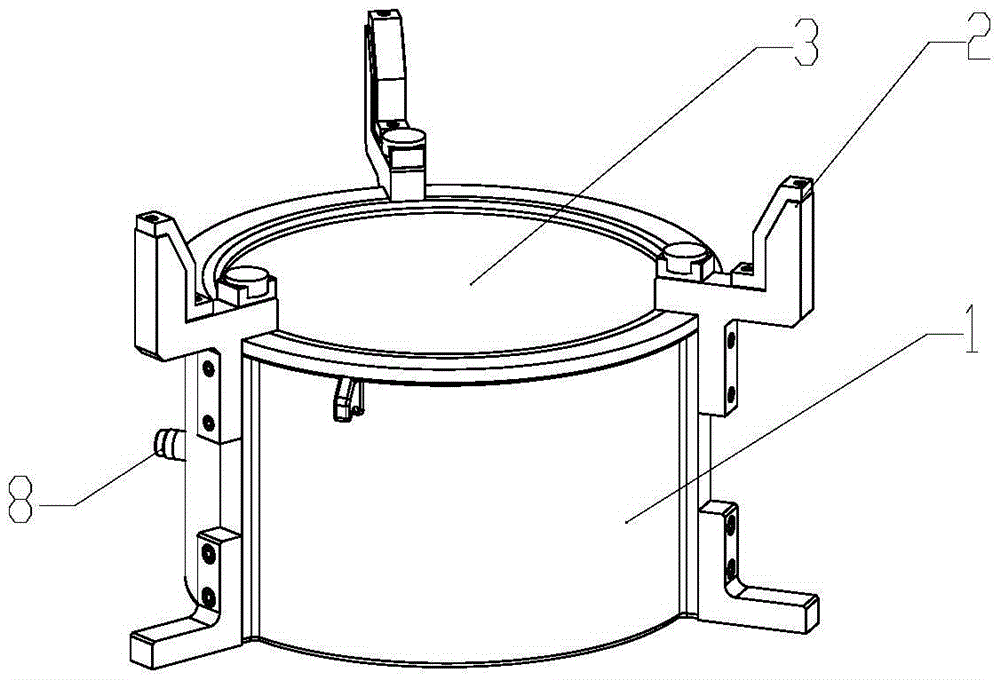

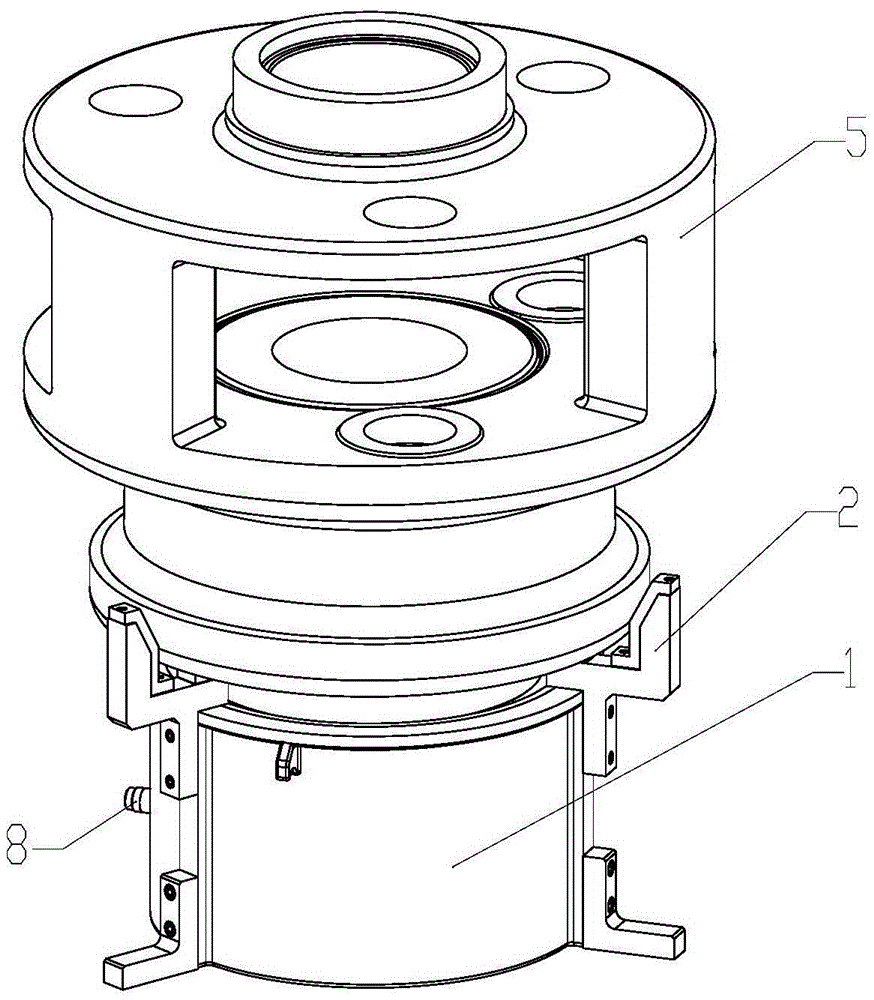

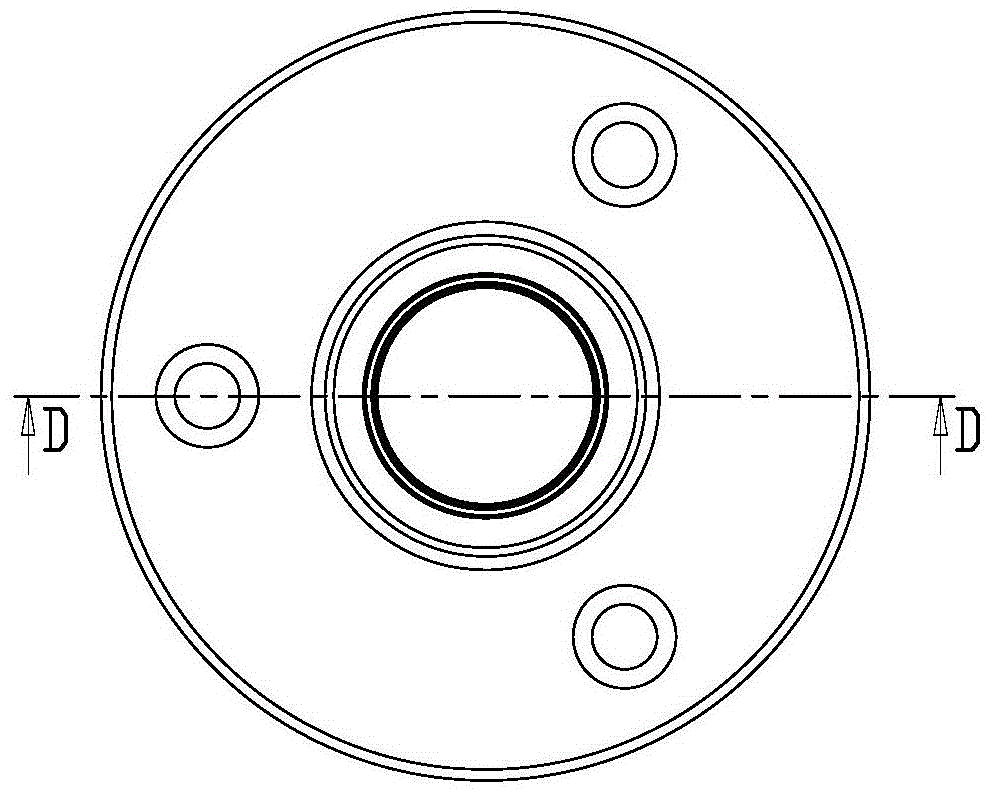

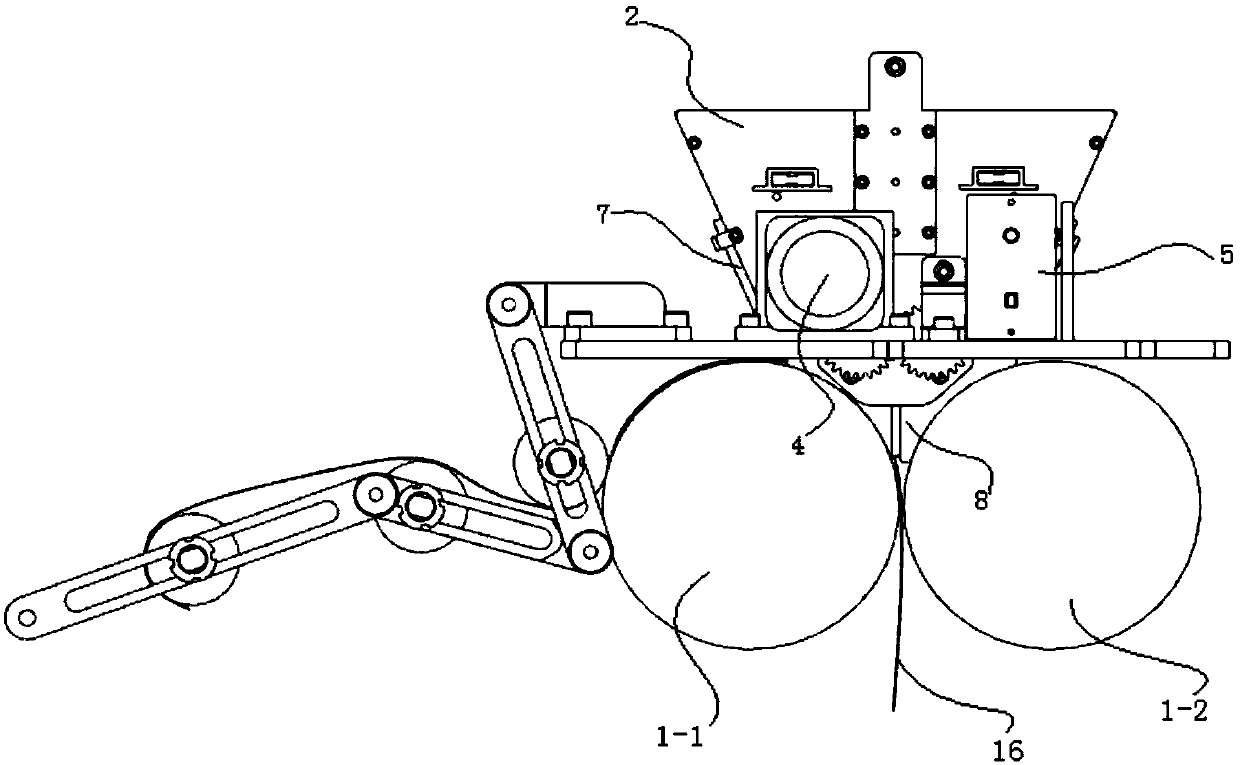

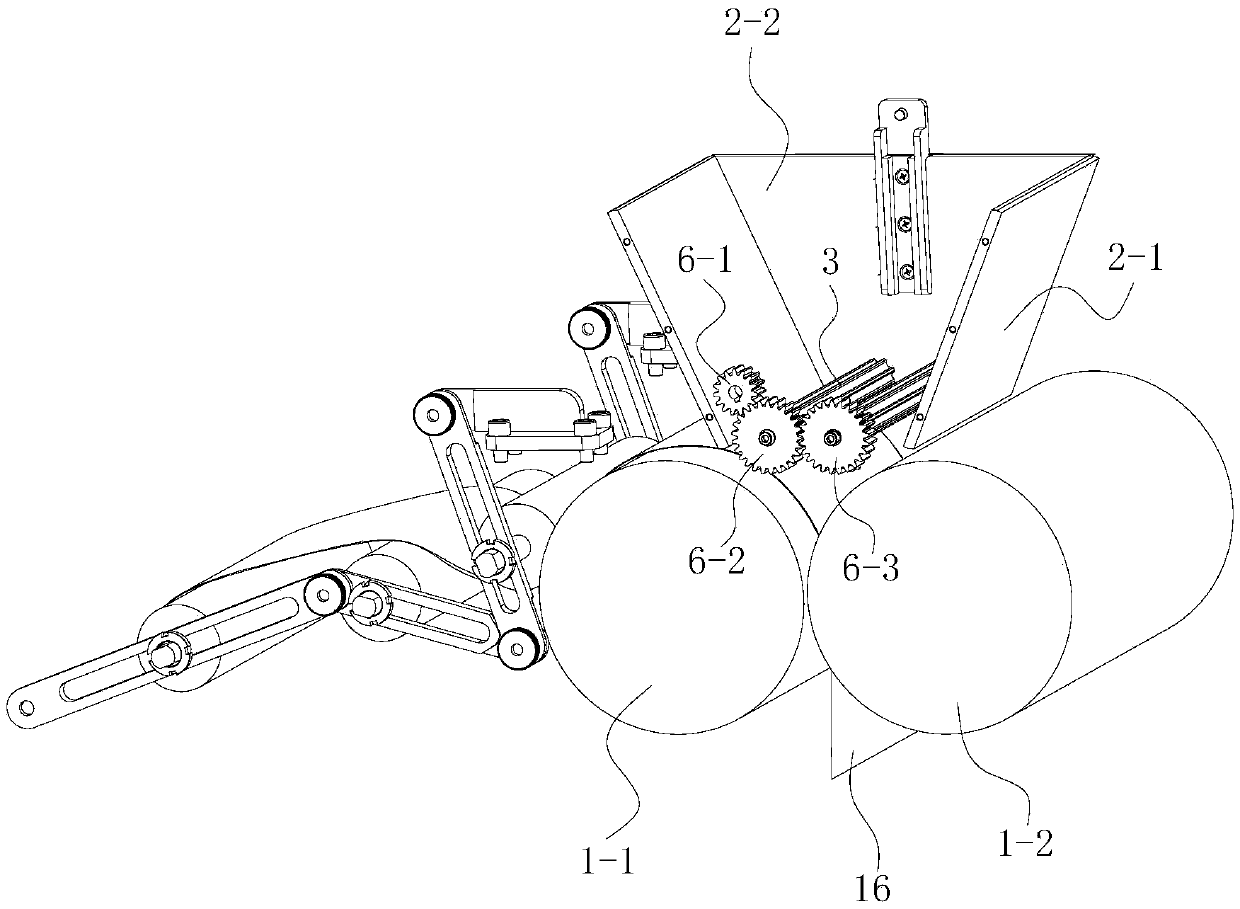

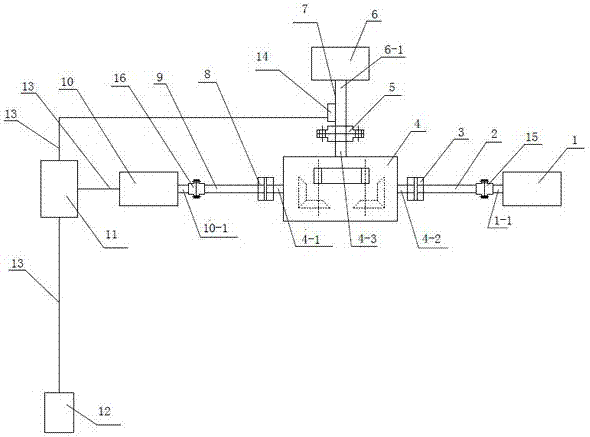

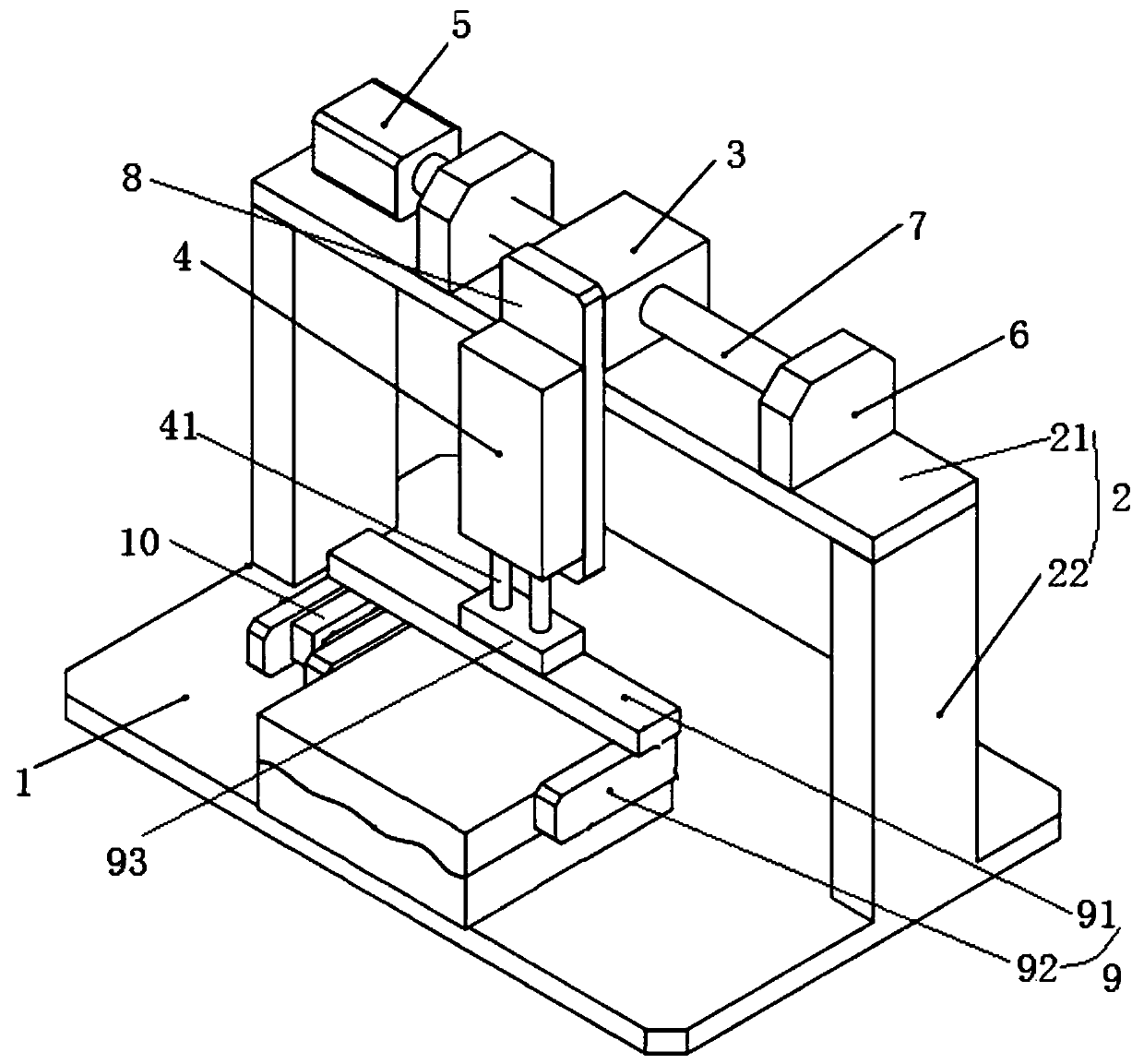

Rotating speed adjustable water power driving rotary spraying nozzle and speed adjusting method

ActiveCN103736609ASpeed can be adjustedGuaranteed uptimeMovable spraying apparatusWater savingImpeller

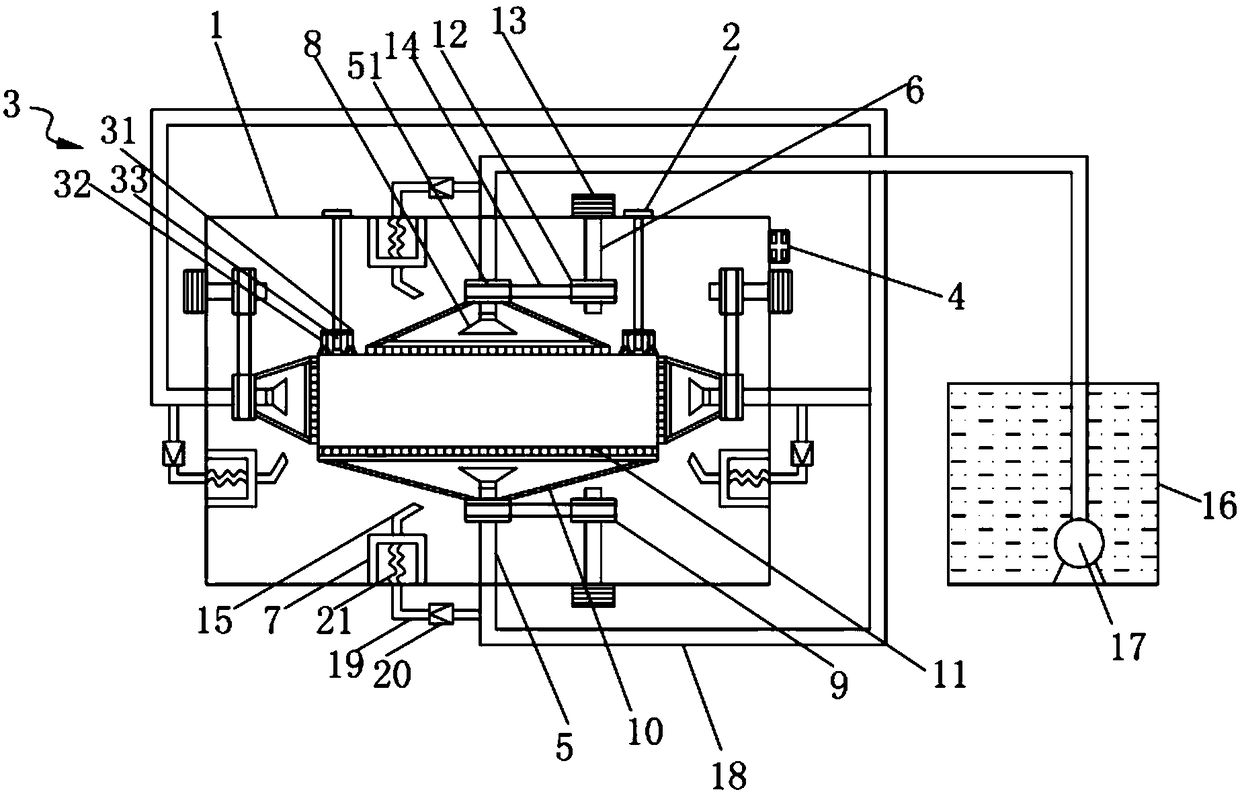

The invention relates to a key device in a water-saving sprinkling irrigation system and particularly to a rotating speed adjustable water power driving rotary spraying nozzle and a speed adjusting method. Water currents enter into a channel to impact an impeller, the impeller generates driving force to drive a shaft A to rotate, the shaft A and a back taper gear belt rotate together, a belt drives a taper gear belt to rotate, and the tapered gear belt and a shaft B rotate together. After the water currents pass through the impeller, the shaft B section which enters into the channel enters into an interior channel of the shaft B through a water inlet hole in the wall of the shaft B, the tail end of the shaft B is connected with the spraying nozzle, and the water currents enter into a spraying nozzle channel after passing through the shaft B to spray to the exterior. According to the speed changing method, a rotating speed ratio of the back tapered gear belt and the tapered gear belt is changed due to the fact that the belt positions in the back tapered gear belt and the tapered belt are changed and accordingly the rotating speed of the spraying nozzle is changed.

Owner:JIANGSU UNIV

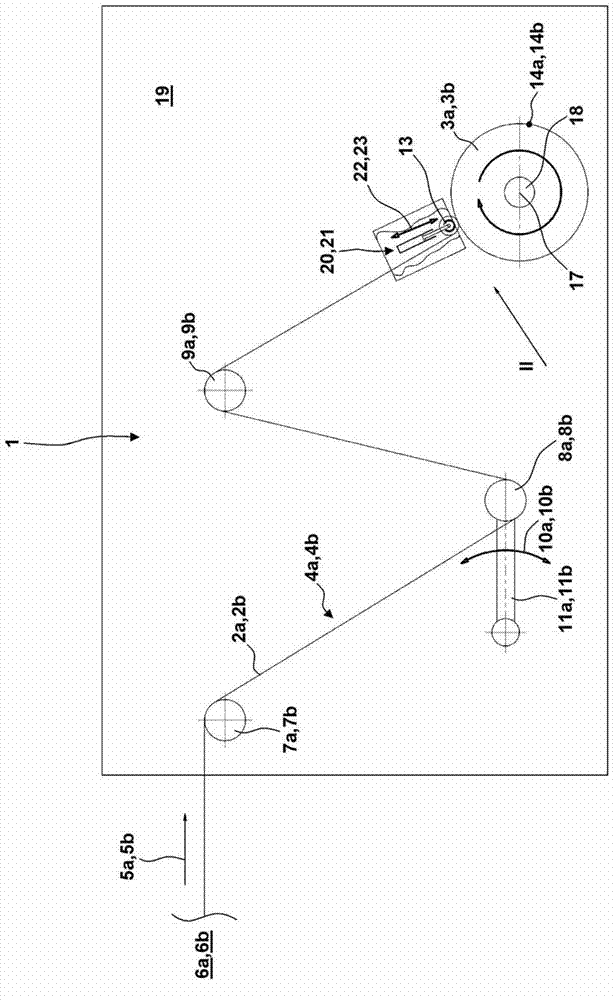

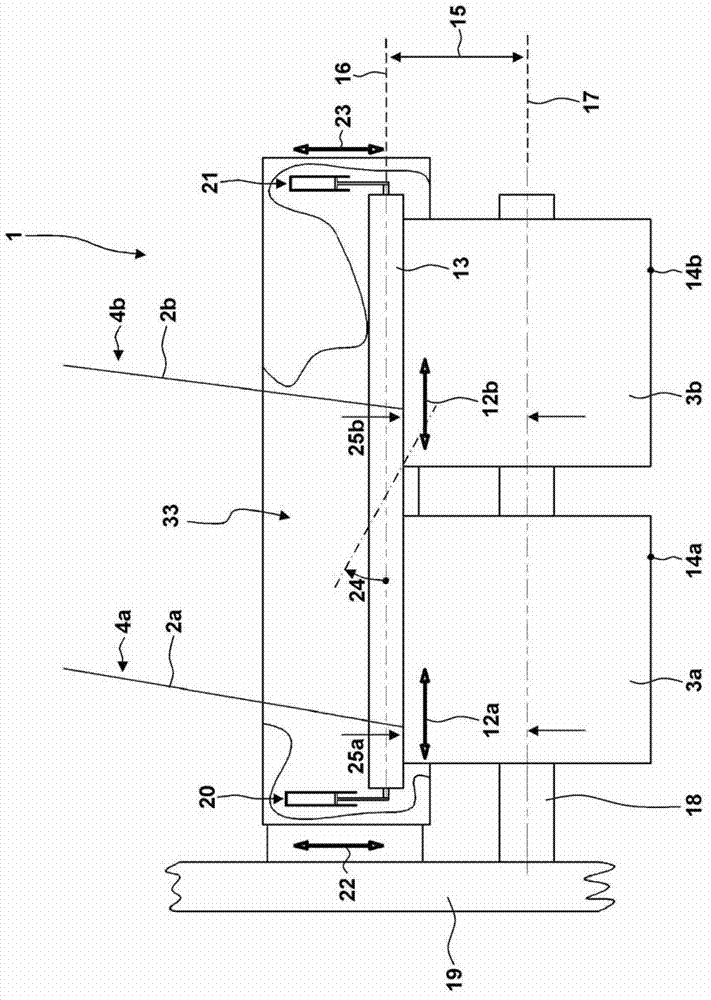

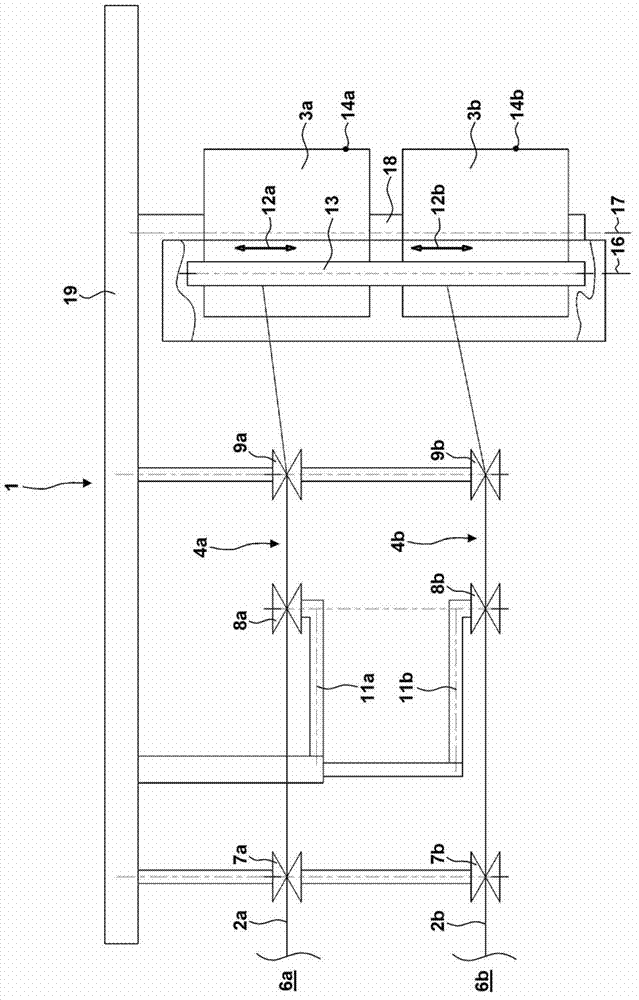

Winding machine and method for controlling the same

InactiveCN102951494AResistance to changes in relative tensionChange the tensionFilament handlingTension measurementWinding machineControl signal

The invention relates to a method for controlling a winding machine (1). The method involves performing parallel winding of continuously running goods (2a, 2b) to be wound to coils (3a, 3b) that are supported on a common spindle (18). Control signals are produced, and actuators (20, 21) are subjected with the signals, where the actuator changes contact force of a pressure roller (13) at the coils depending on the signals. The signals are provided depending on voltage of the goods to be wound and / or deflection of dancer rollers (8a, 8b). Rotational speed of the coils is controlled depending on the voltage of the goods and / or the deflection of the dancer rollers.

Owner:GEORG SAHM GMBH & CO KG

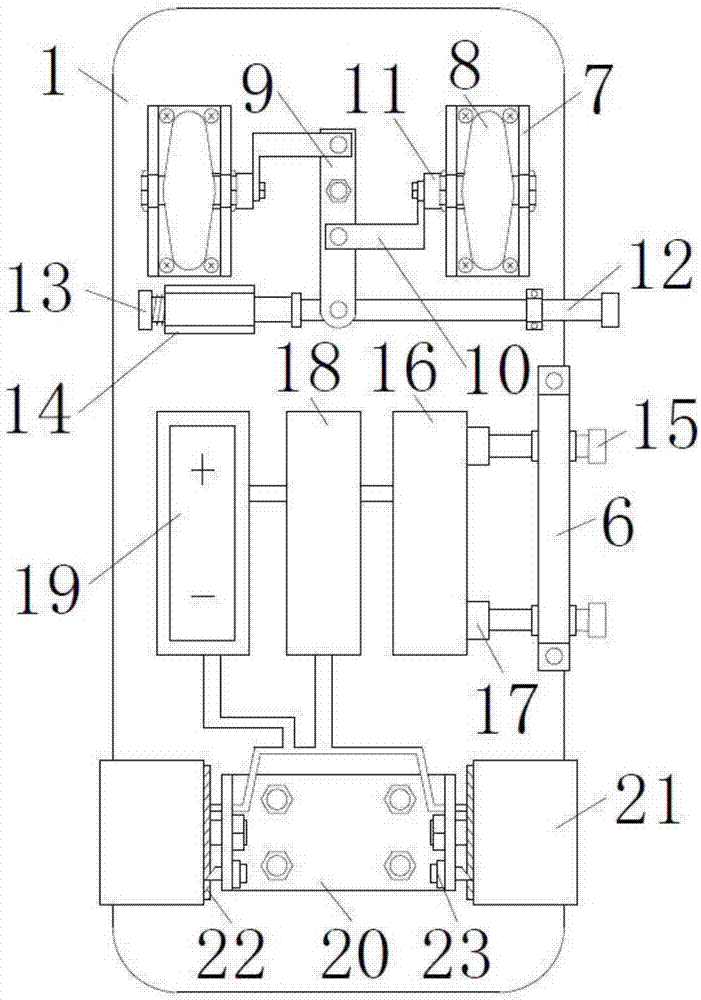

Electric shoes

ActiveCN106984033AAdjustable speedSpeed can be adjustedSkate-boardsRoller skatesElectricityDrive wheel

The invention discloses an electric shoe in the technical field of wearing devices. A driving wheel set, a driven wheel set, a driving assembly and a braking device are respectively arranged on a sole, wherein the driving assembly comprises a power supply, a driving motor and a driving controller, the driving controller is electrically connected with the power supply and the driving motor, respectively, and the driving motor is used for supplying a driving force to the driving wheel set. The speed of the electric shoe can be adjusted, so that a user can conveniently adjust the different speeds in use environments; and by setting wheel locking and anti-reversion modes, a user dost not fall due to wheel locking and reversion in a non-electric normal walking process, so that the safety is improved.

Owner:SICHUAN YUNXIAOBAO TECH CO LTD

Automatic-turning pot

The invention discloses an automatic-turning pot. The automatic-turning pot comprises a pot body, a pot handle and a supporting frame. One end of the supporting frame is connected with the pot handle, and the other end of the supporting frame is connected with a rotating base. The bottom of the pot body is connected with the rotating base. A drive motor A and a drive motor B are arranged in the pot handle. The drive motor A is connected with a pot turner and drives the pot turner to rotate vertically. The drive motor B is used for driving the pot body to horizontally rotate on the rotating base. By the adoption of the automatic-turning pot, manual turning is not needed, when food is cooked, full automation is achieved, the turning speed can be adjusted, the labor intensity is lowered, and great convenient is brought to a user.

Owner:NINGBO SKL INT

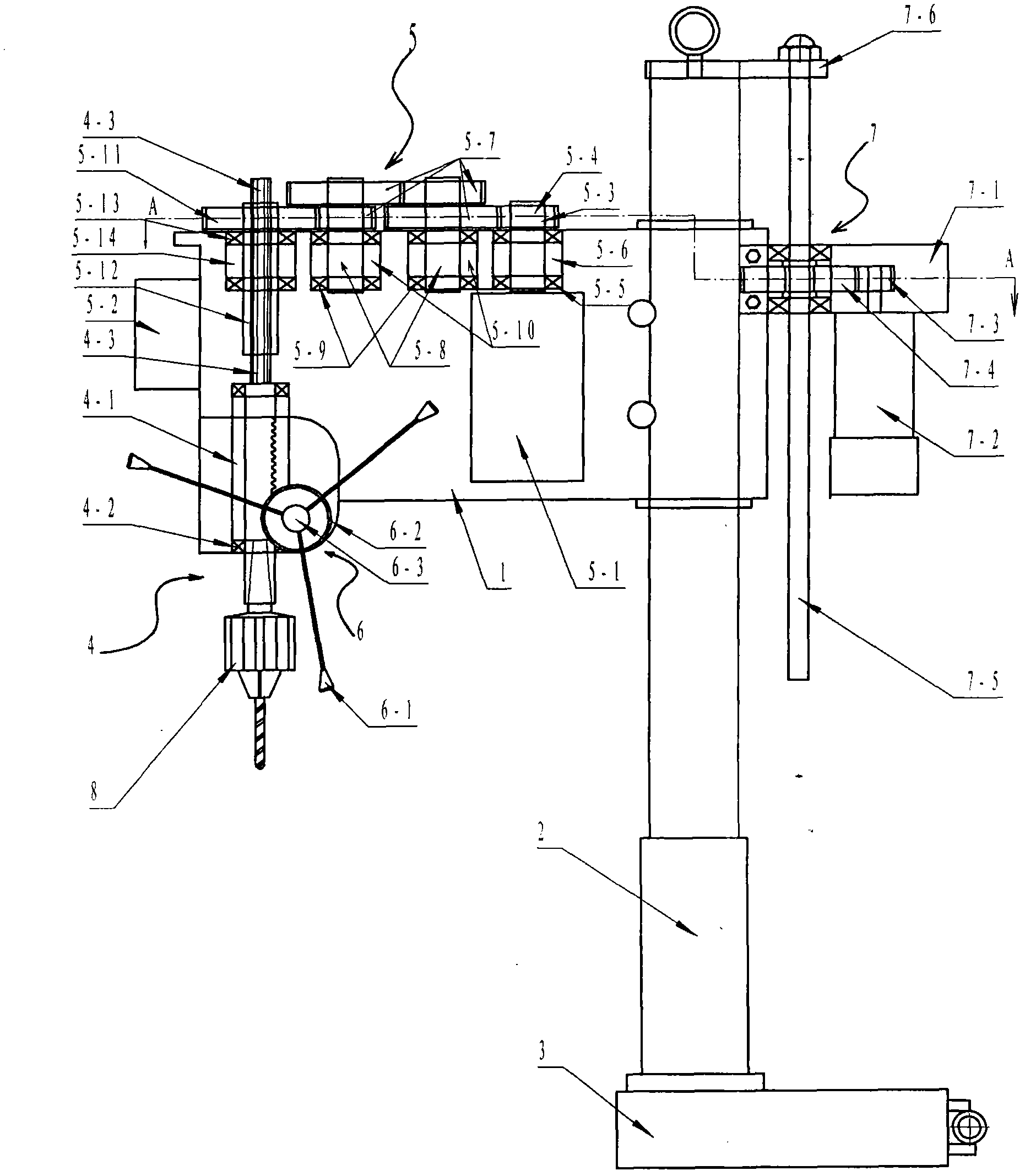

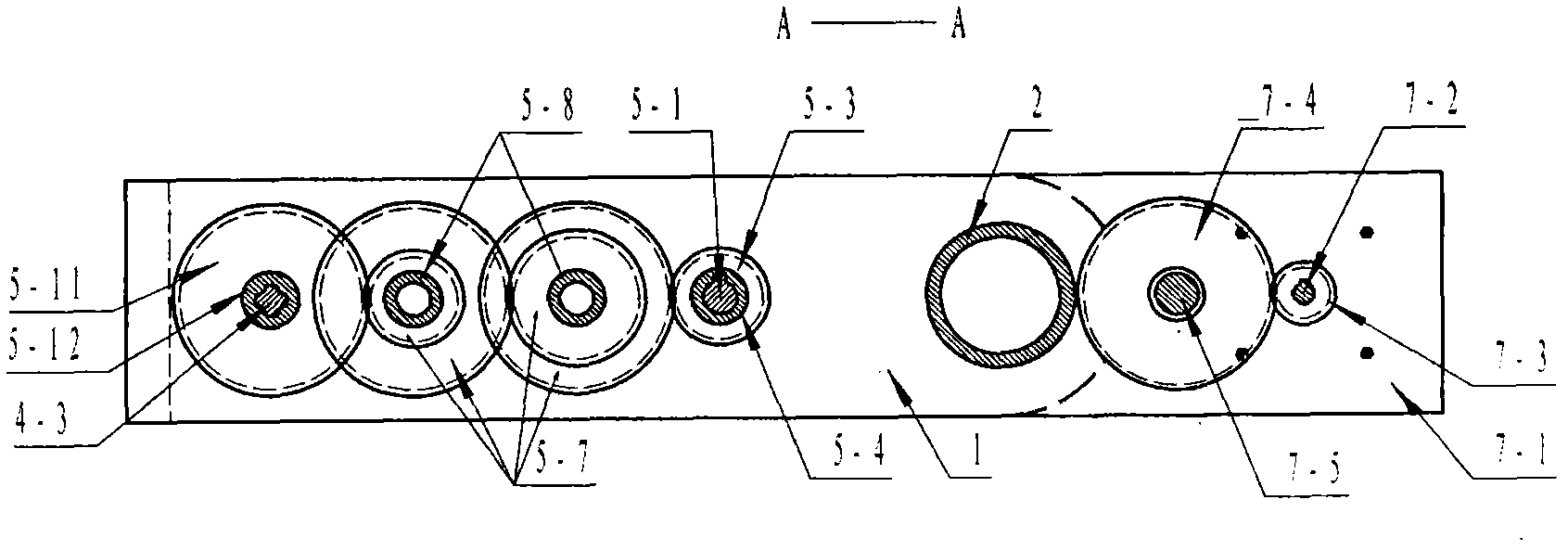

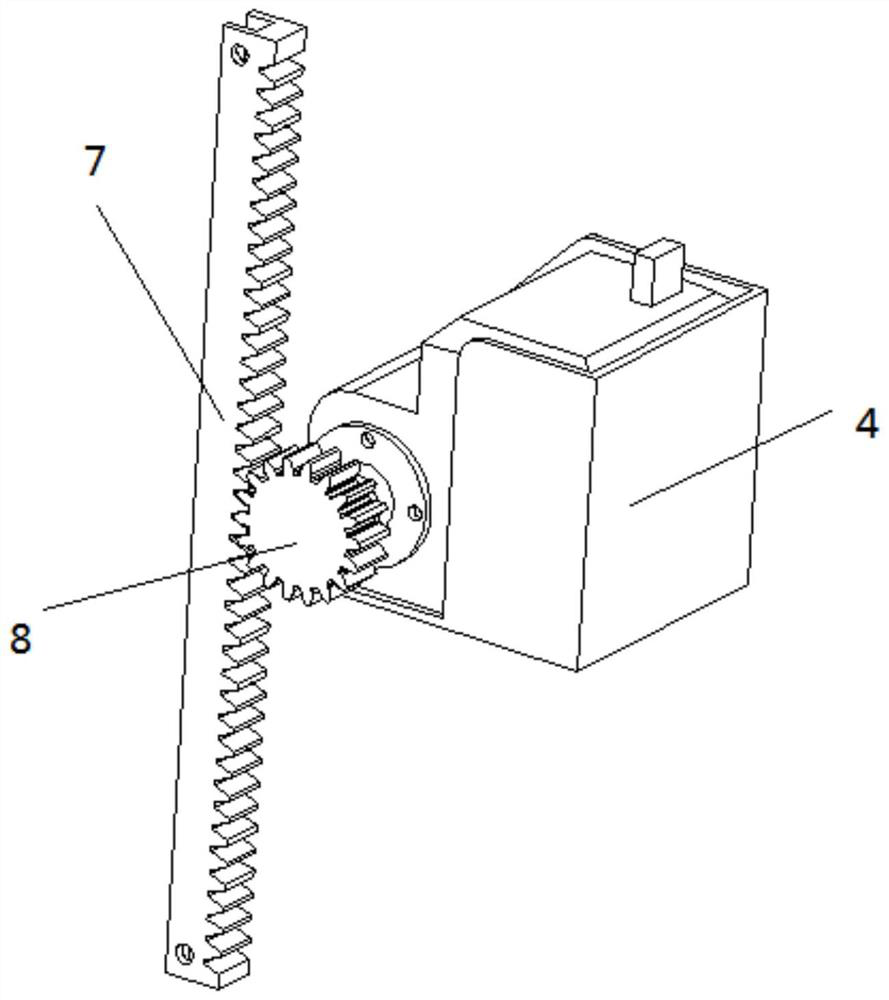

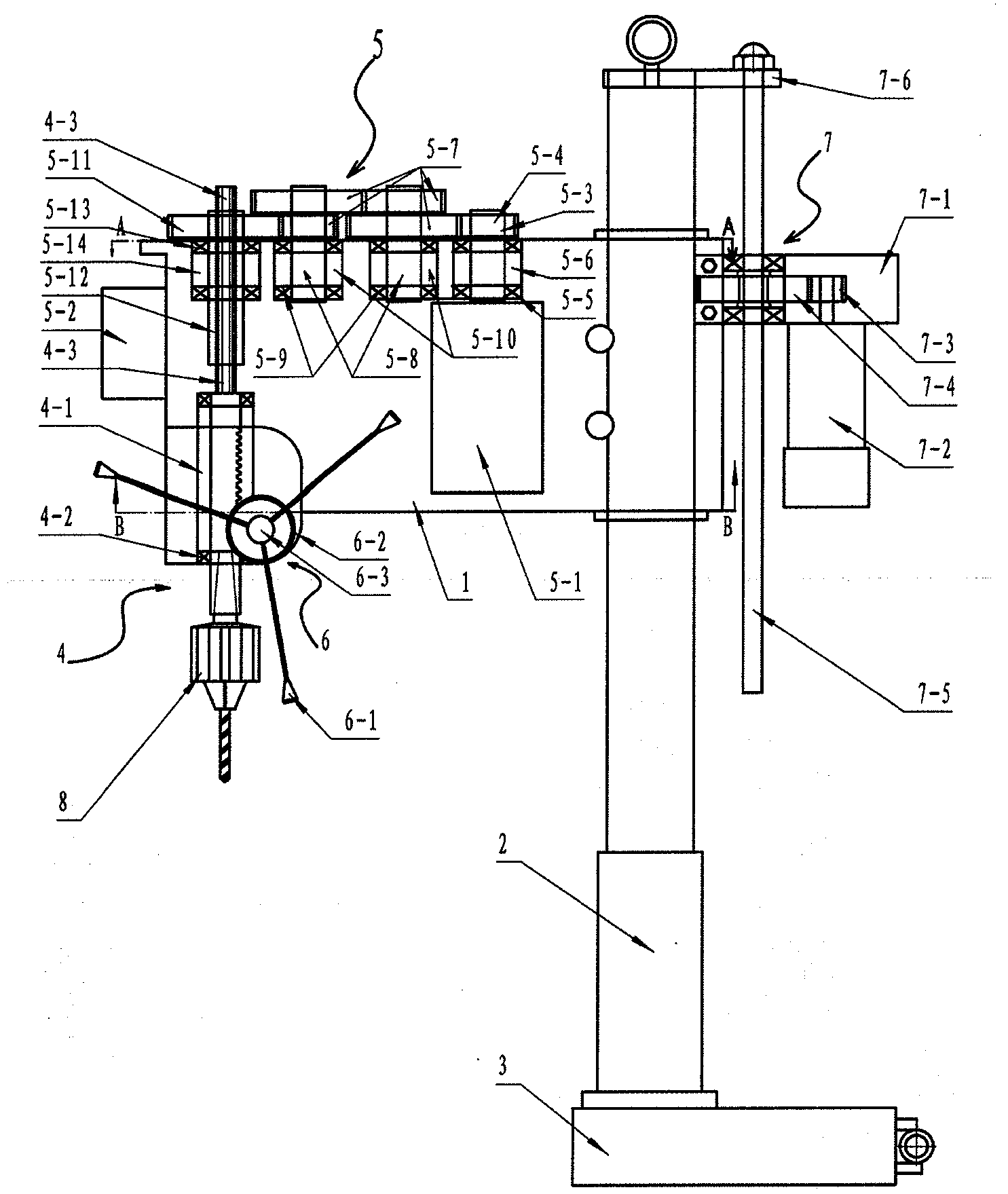

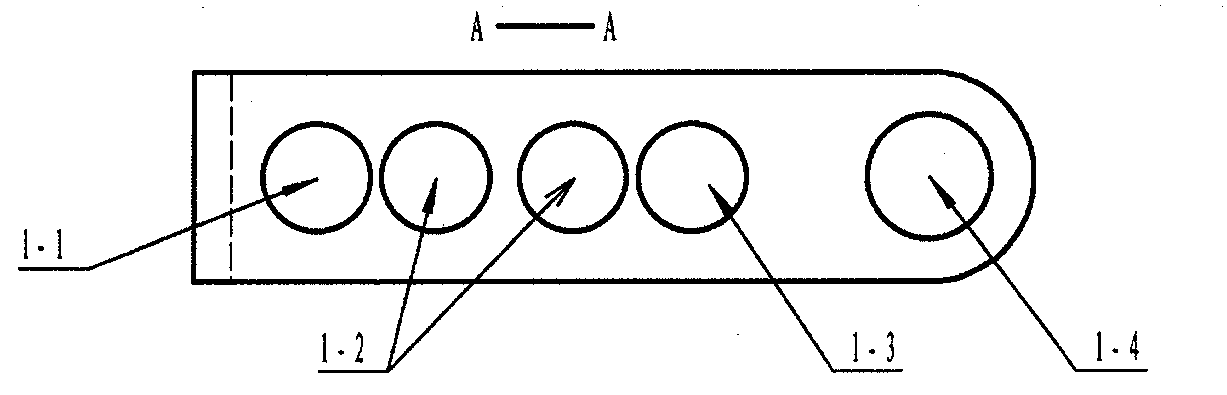

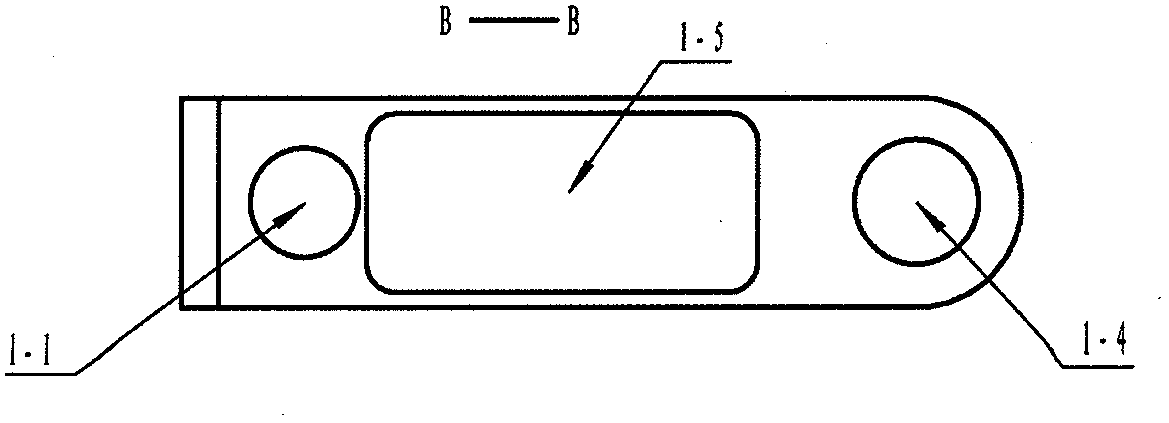

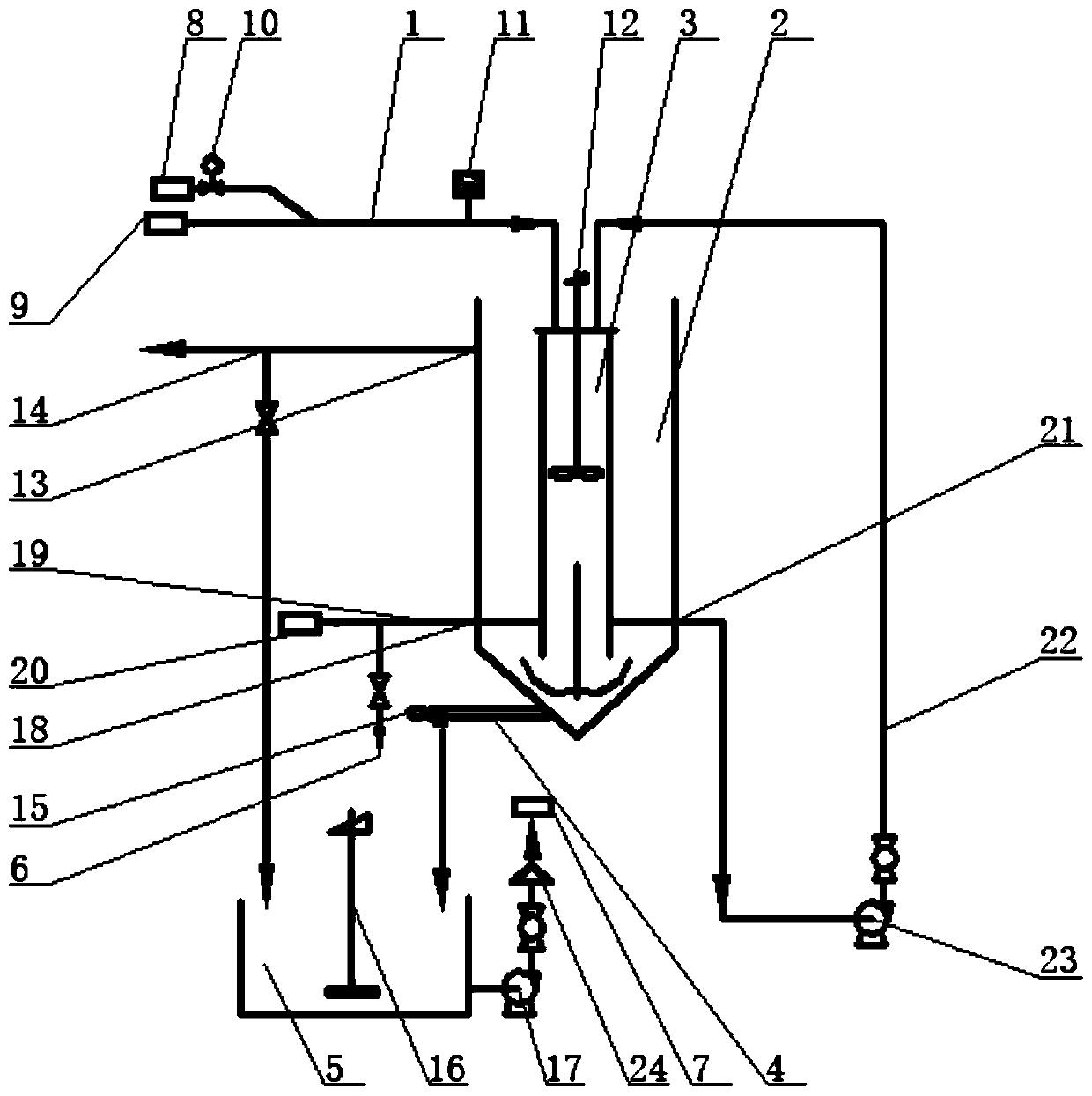

Movable low-speed driller

InactiveCN103223508AImprove drilling accuracyEasy to moveBoring/drilling componentsBoring/drilling machinesLow speedEngineering

The invention belongs to the field of machining, and relates to a driller, in particular to a movable low-speed driller. A center drill rod driving reduction device (5) comprises a driving motor (5-1), a driving motor controller (5-2), a driving gear (5-3), a driving gear shaft (5-4), a driving gear bearing (5-5), a driving gear bearing pedestal (5-6), middle gears (5-7), middle gear shafts (5-8), middle gear bearings (5-9), middle gear bearing pedestals (5-10), a driven gear (5-11), a driven gear shaft (5-12), a driven gear bearing (5-13) and a driven gear bearing pedestal (5-14), and is characterized in that the driven gear shaft (5-12) is a hollow shaft; an inner hole of the driven gear shaft (5-12) is provided with a spline; and the spline inner hole is in sliding fit with a spline shaft at the upper end of a center drill rod. The movable low-speed driller has the benefits that the movable low-speed driller is high in drilling accuracy, good in movability and adjustable in rotating speed, and can be absorbed on a large workpiece for use.

Owner:王志生

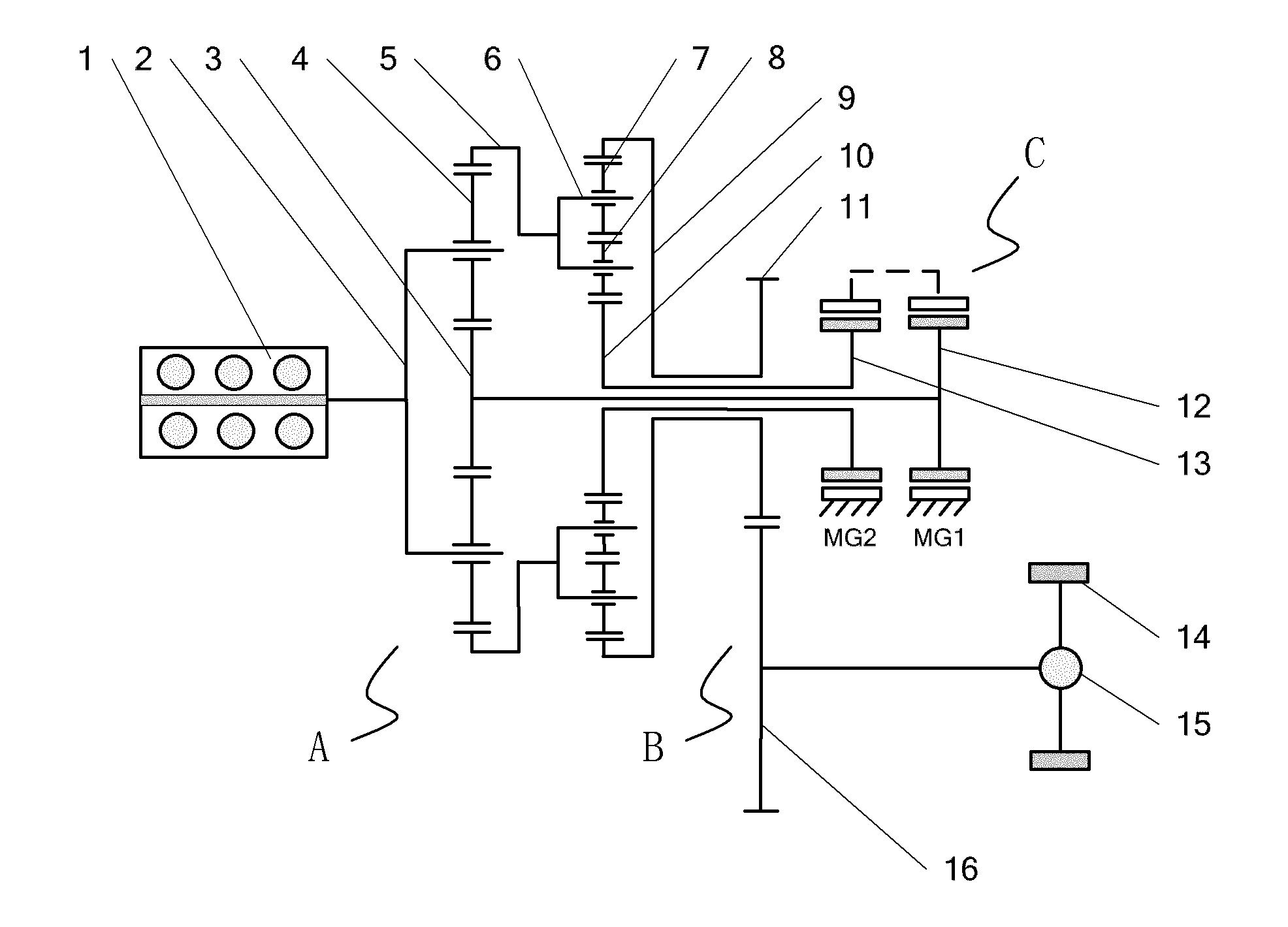

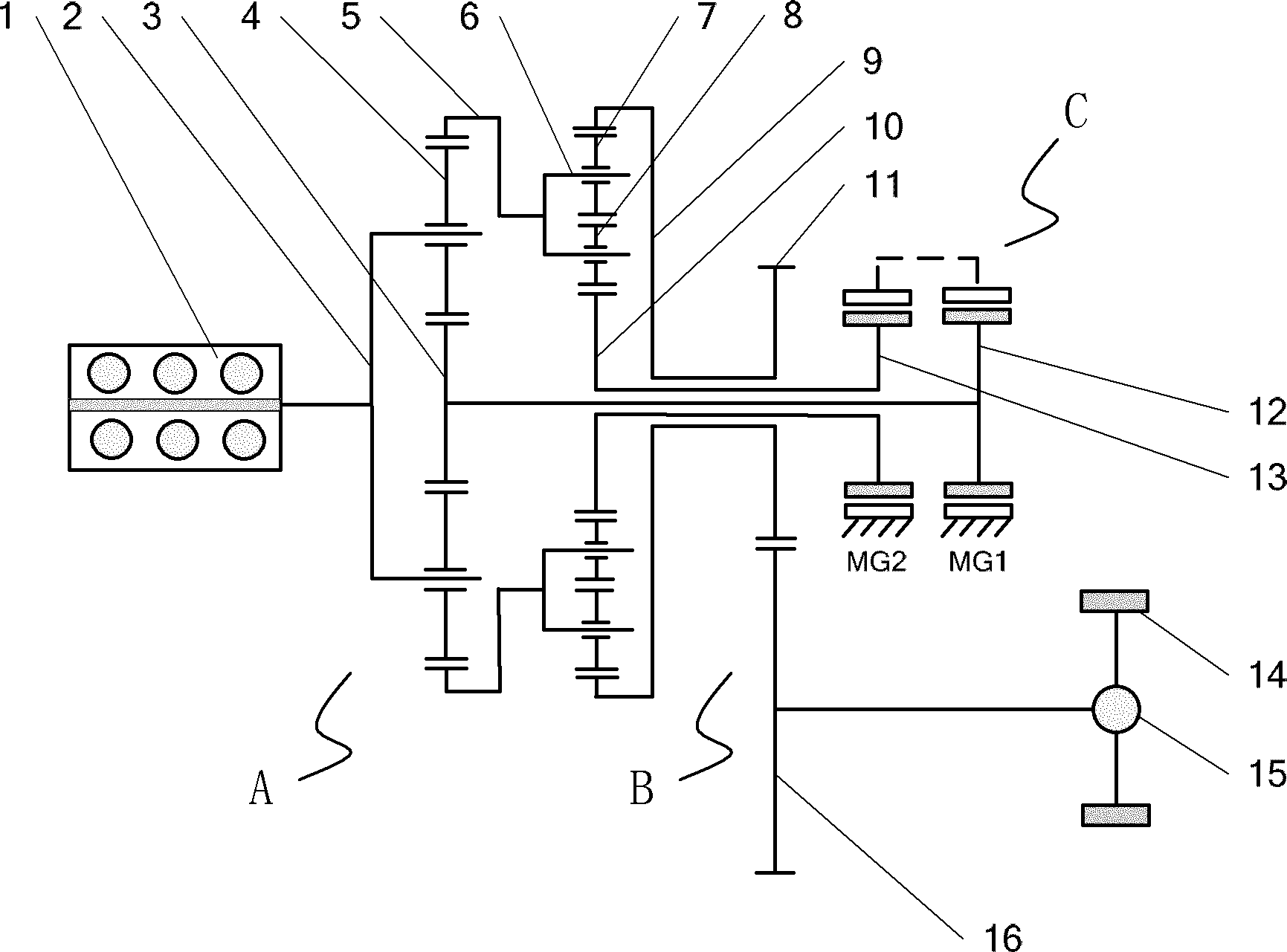

Electromechanical power coupling device for hybrid vehicle

InactiveCN102582414AControl speedControl torqueGas pressure propulsion mountingPlural diverse prime-mover propulsion mountingPower couplingHybrid electrical vehicle

An electromechanical power coupling device for a hybrid vehicle comprises an engine, a power transmission mechanism, a power output mechanism and an electric mechanism, wherein the engine is connected with both the power output mechanism and the electric mechanism through the power transmission mechanism, the electric mechanism is connected with the power output mechanism through the power transmission mechanism, and the electromechanical power coupling device can operate in different transmission working modes by controlling the engine and the electric mechanism. According to the electromechanical power coupling device, the engine, a power generator and an electromotor are reasonably configured by utilizing a planetary gear mechanism, and the whole power system can realize the function of stepless speed change, so that the overall oil consumption of the hybrid vehicle is better improved.

Owner:BEIQI FOTON MOTOR CO LTD

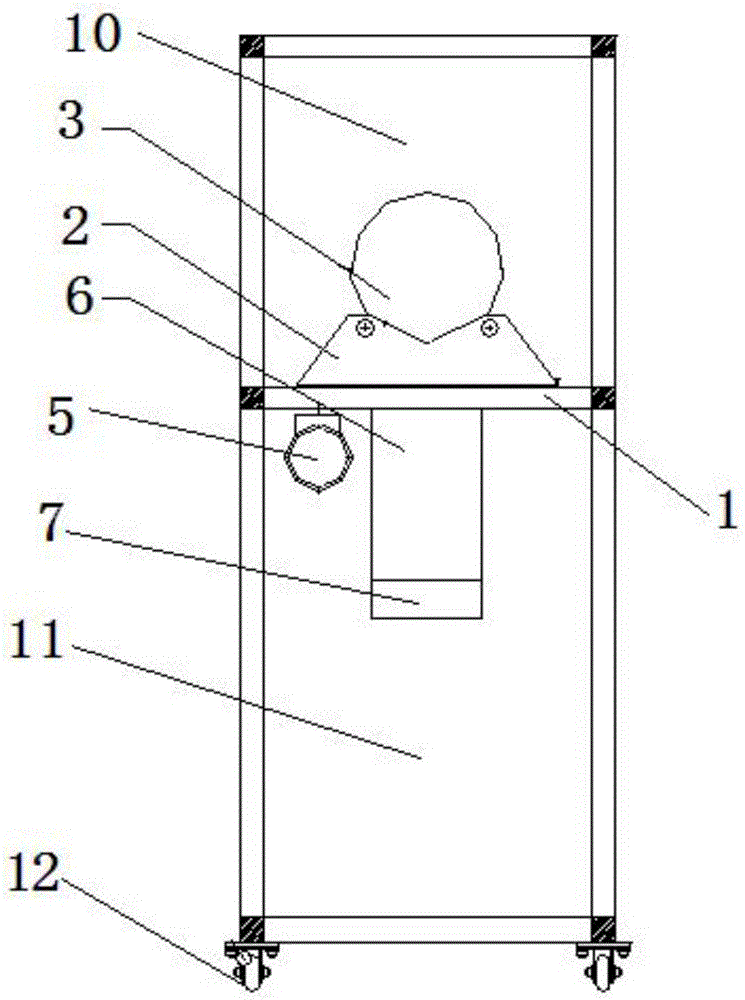

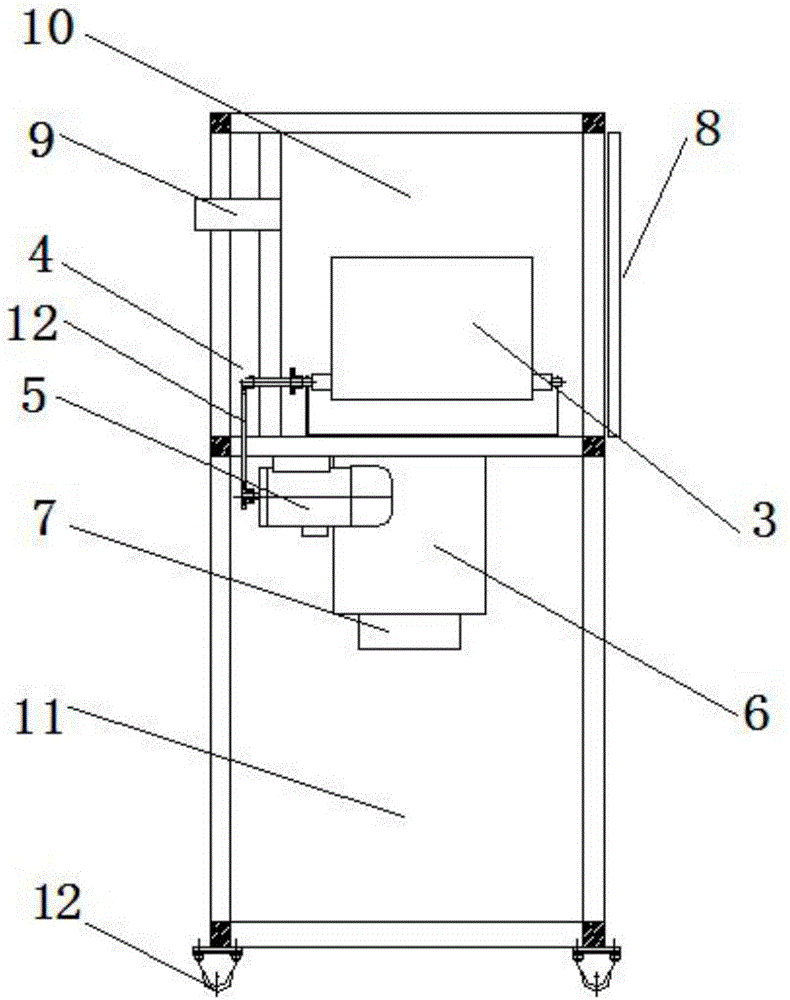

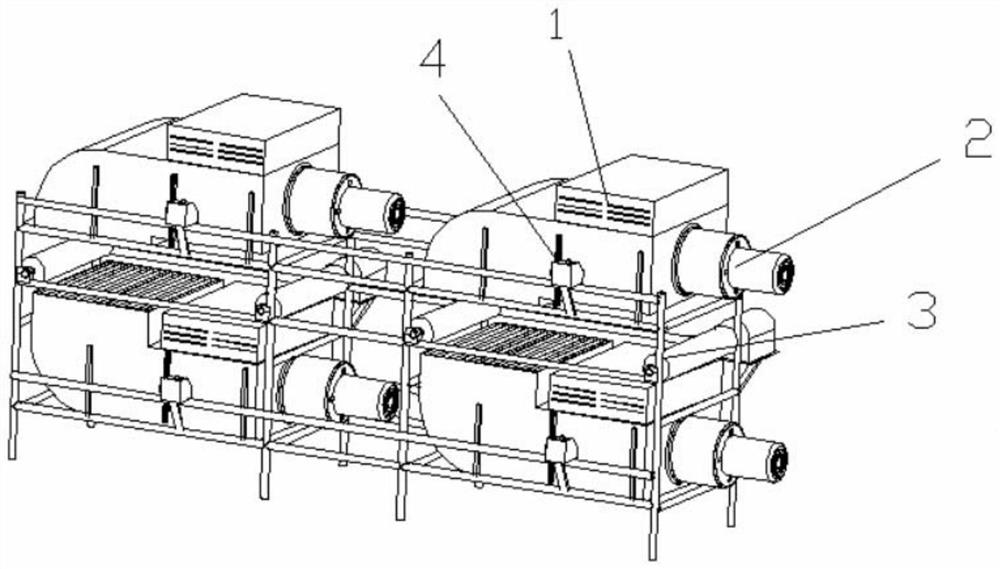

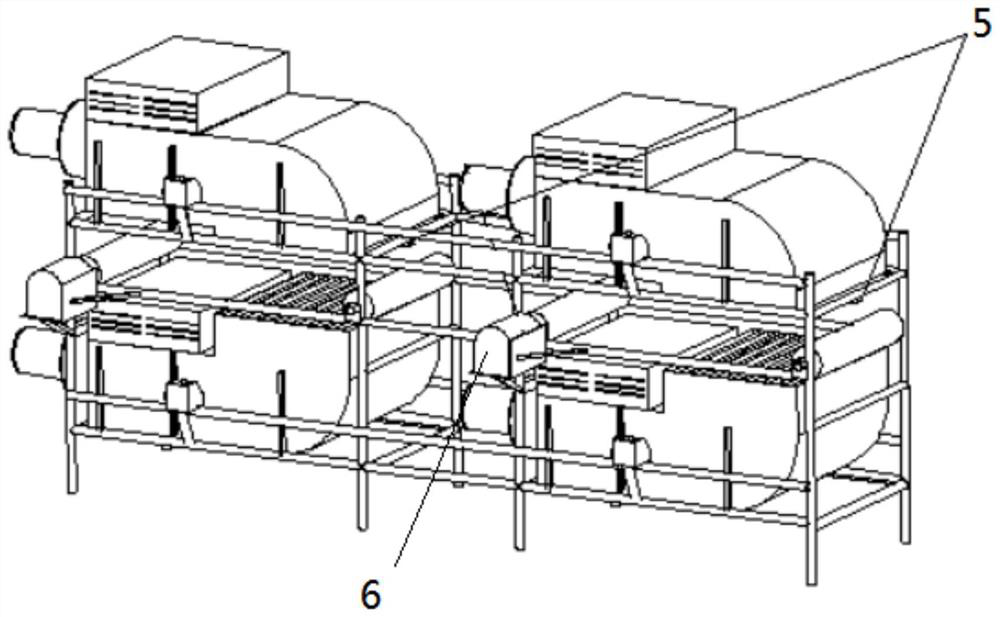

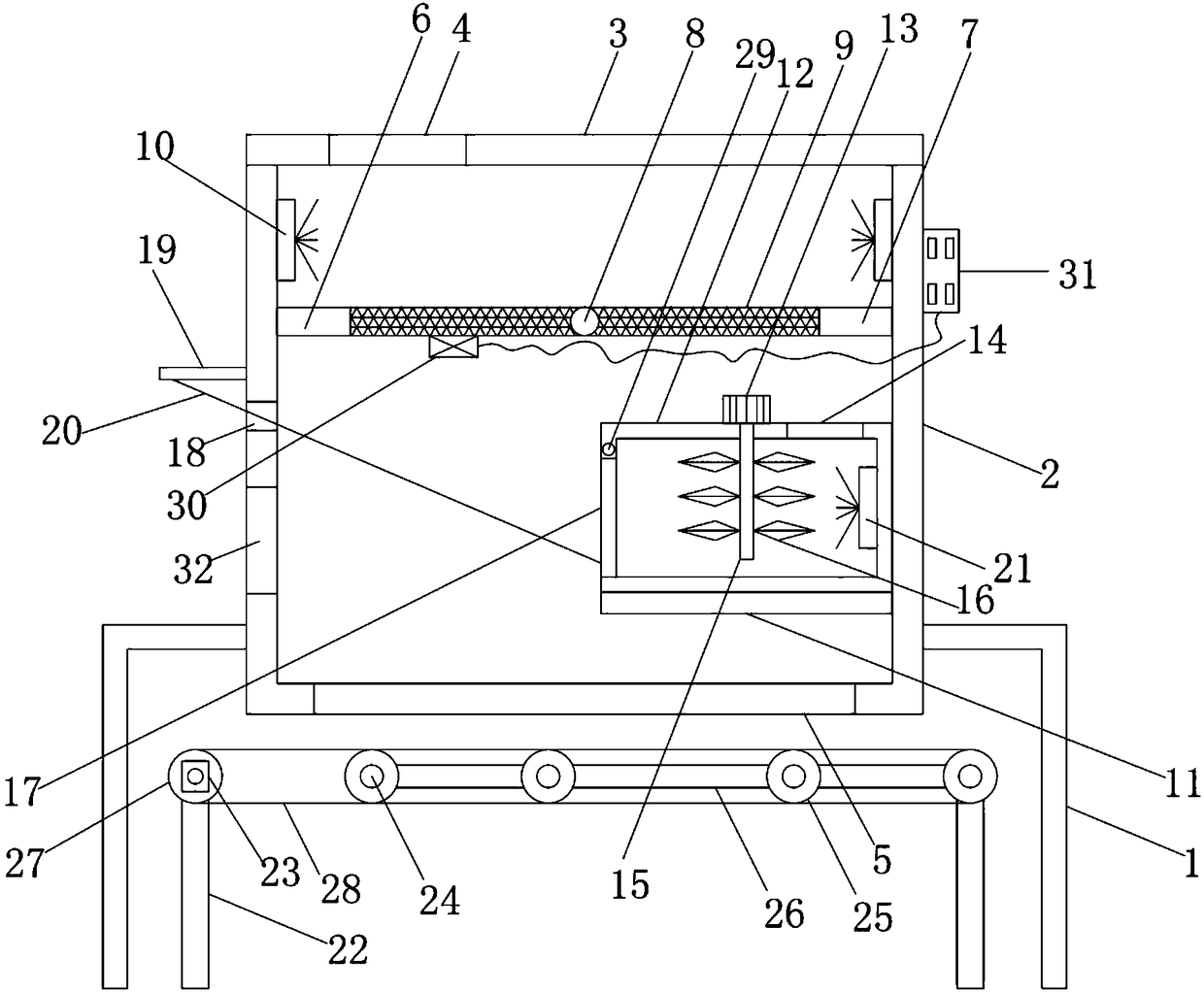

Vegetable seed drying box

InactiveCN106766756ASpeed can be adjustedSatisfy drying characteristicsSeed and root treatmentGranular material dryingAgricultural engineeringMoisture

The invention relates to a vegetable seed drying box. The vegetable seed drying box comprises a supporting frame, a drying drum bracket, a drying drum, a rolling shaft, a motor, an electric heater, a draught fan, a controller, a moisture eliminating opening and a monitoring device. The drying box is divided into a drying oven located on the upper portion and an instrument container located on the lower portion through the supporting frame. The drying drum bracket is fixedly arranged on the supporting frame. The drying drum is arranged on the drying drum bracket. The two ends of the drying drum are both connected with the rolling shaft. The rolling shaft is arranged on the drying drum bracket. One end of the rolling shaft is connected with the motor through a chain. The motor is fixedly arranged on the lower portion of the supporting frame. The electric heater is arranged under the drying drum. The draught fan is arranged under the electric heater. The motor and the draught fan are both electrically connected with the controller. The moisture eliminating opening is formed in the upper portion of one side of the drying oven and provided with the monitoring device. Through the vegetable seed drying box, drying states of different seeds can be achieved according to various storage conditions of the different seeds.

Owner:CHINA AGRI UNIV

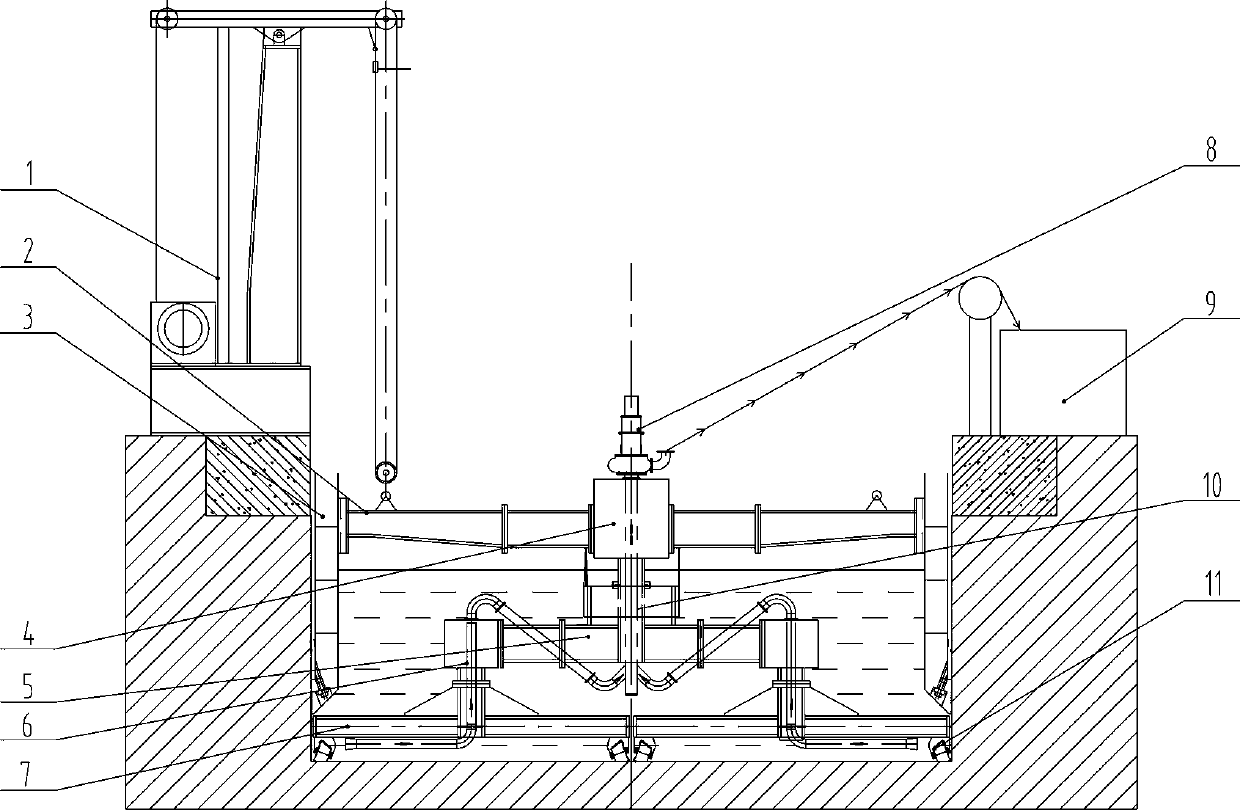

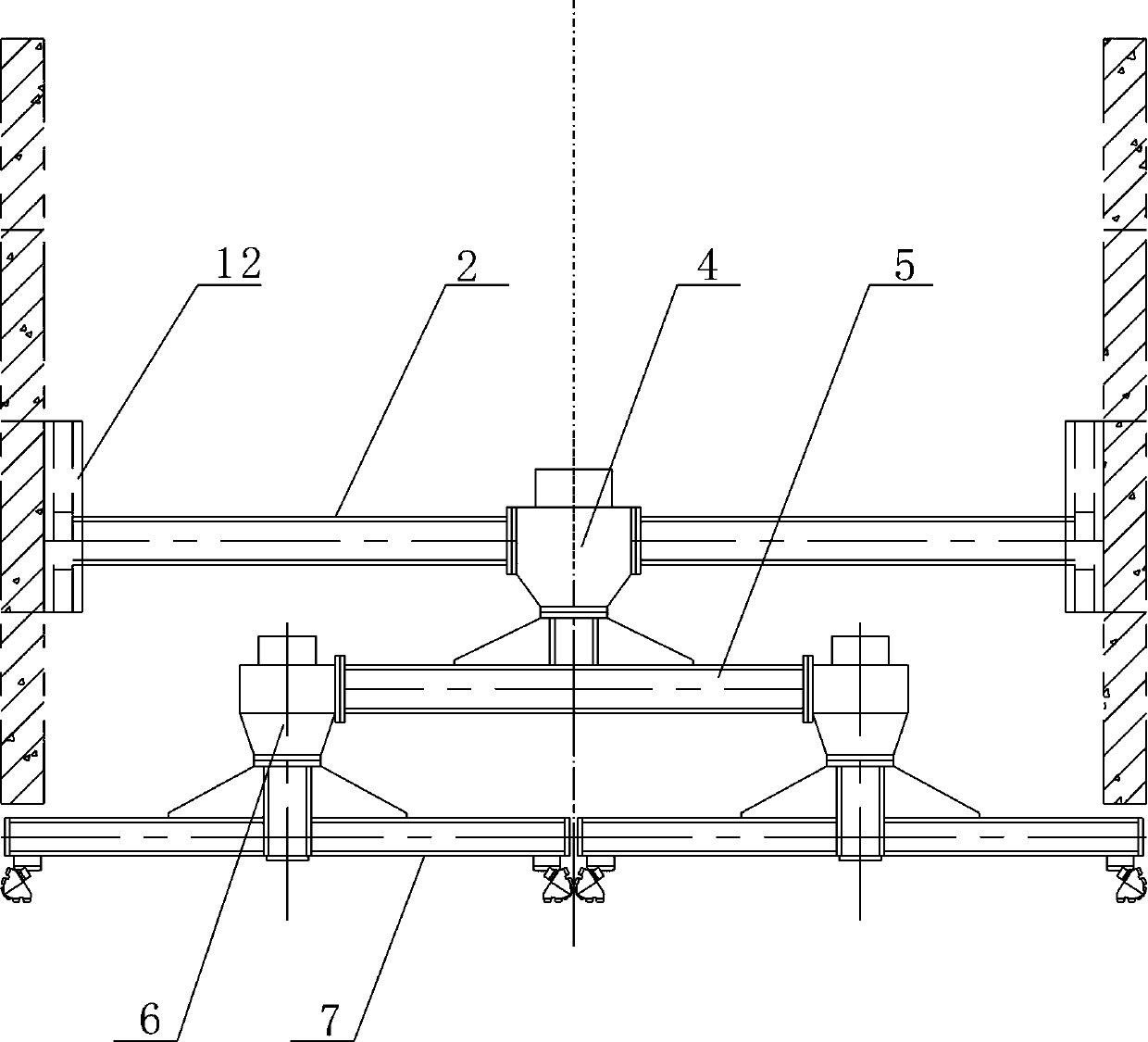

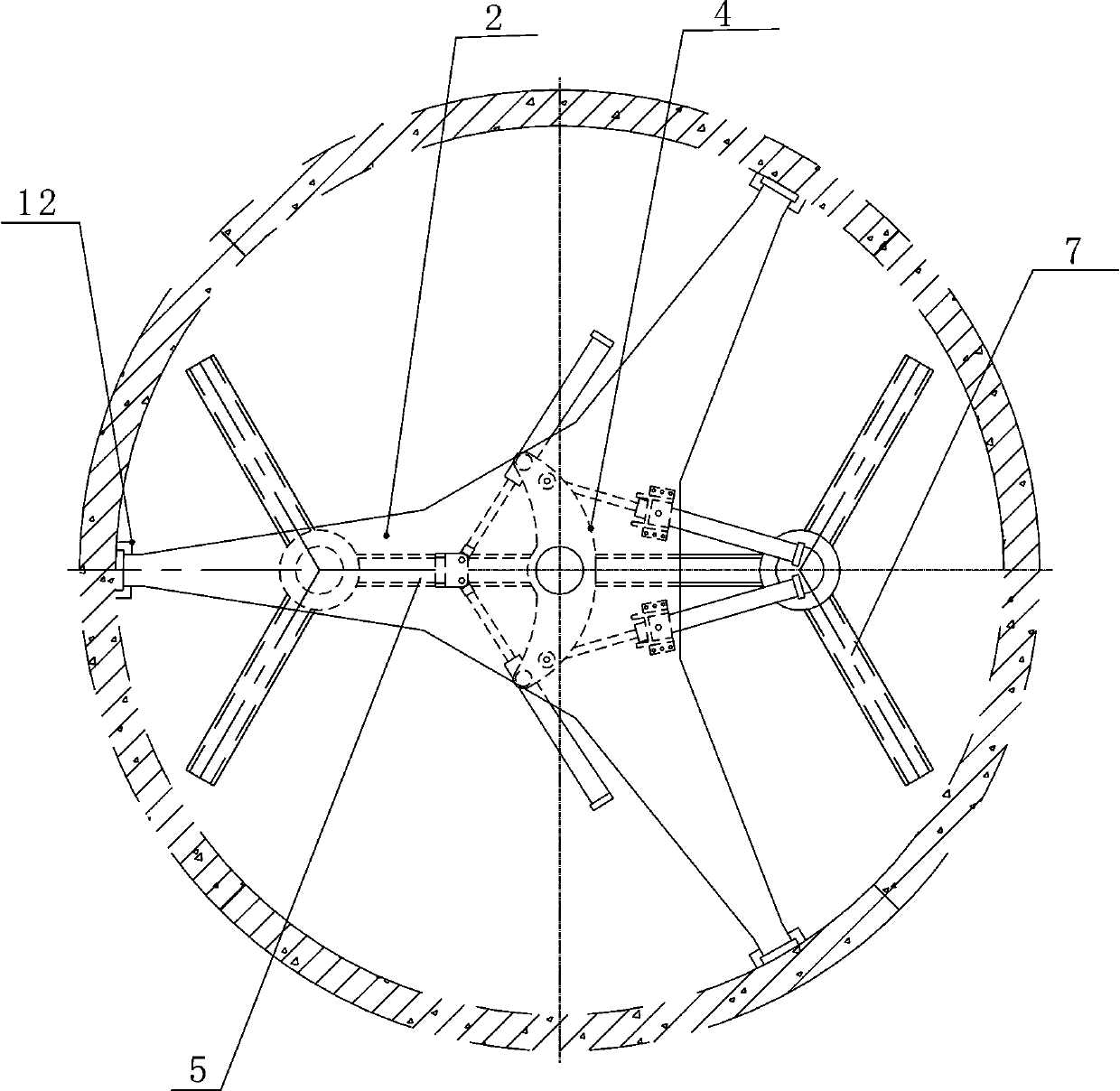

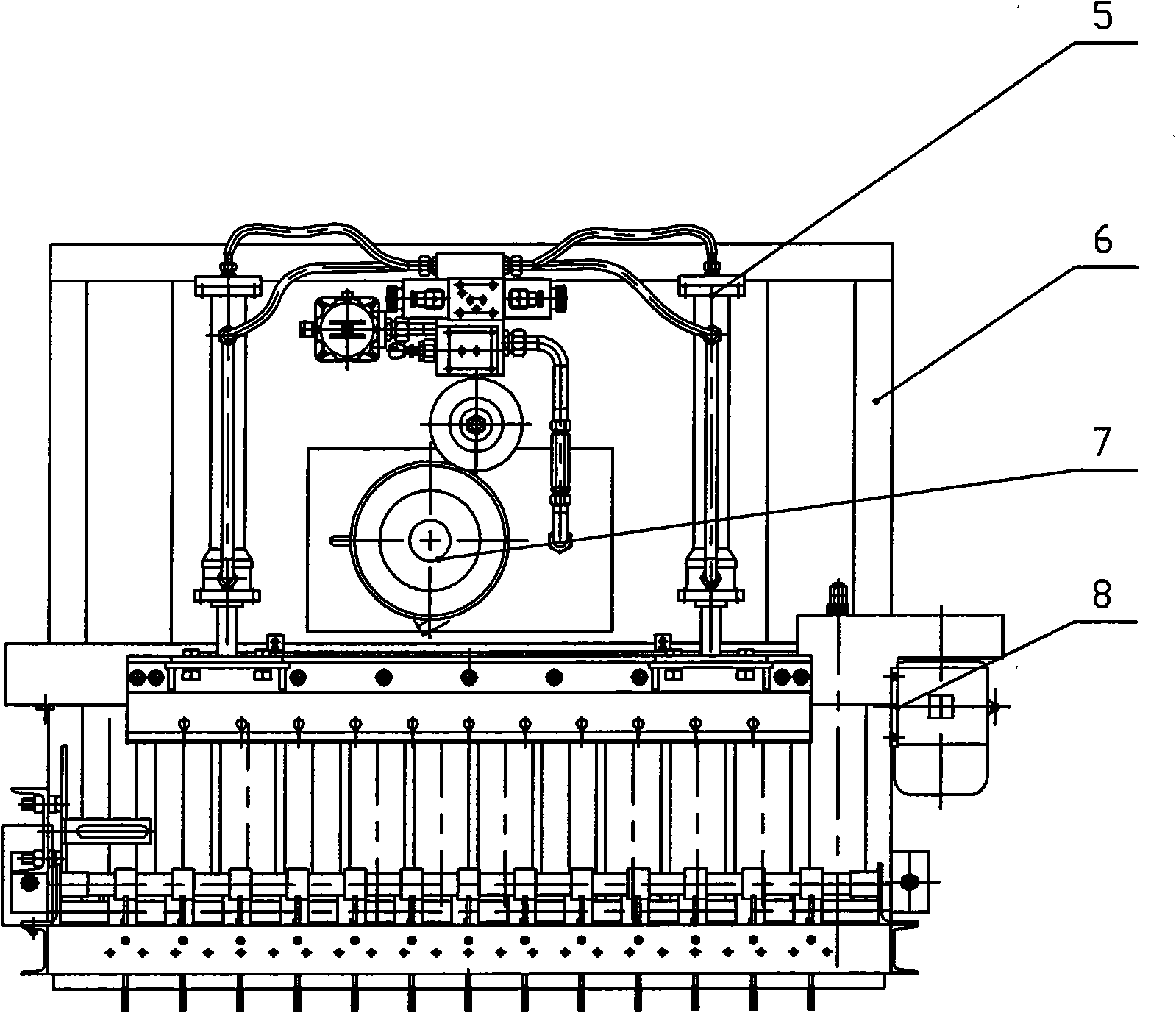

Oscillating shaft heading machine by sinking method

PendingCN109763765ASimple structureReasonable designEarth drilling toolsDerricks/mastsSlagEngineering

Owner:LUOYANG MINING MACHINERY ENG DESIGN & RES INST +1

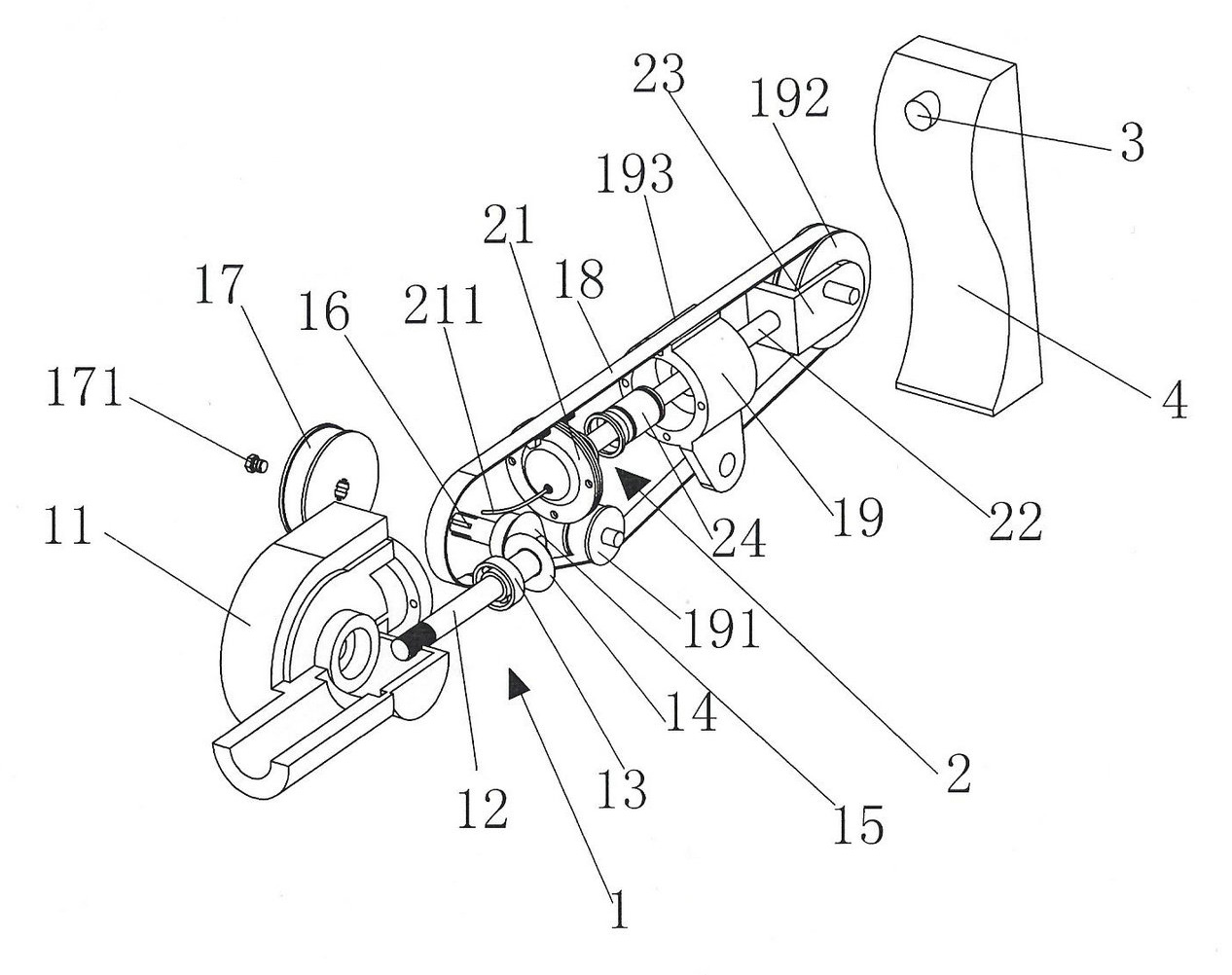

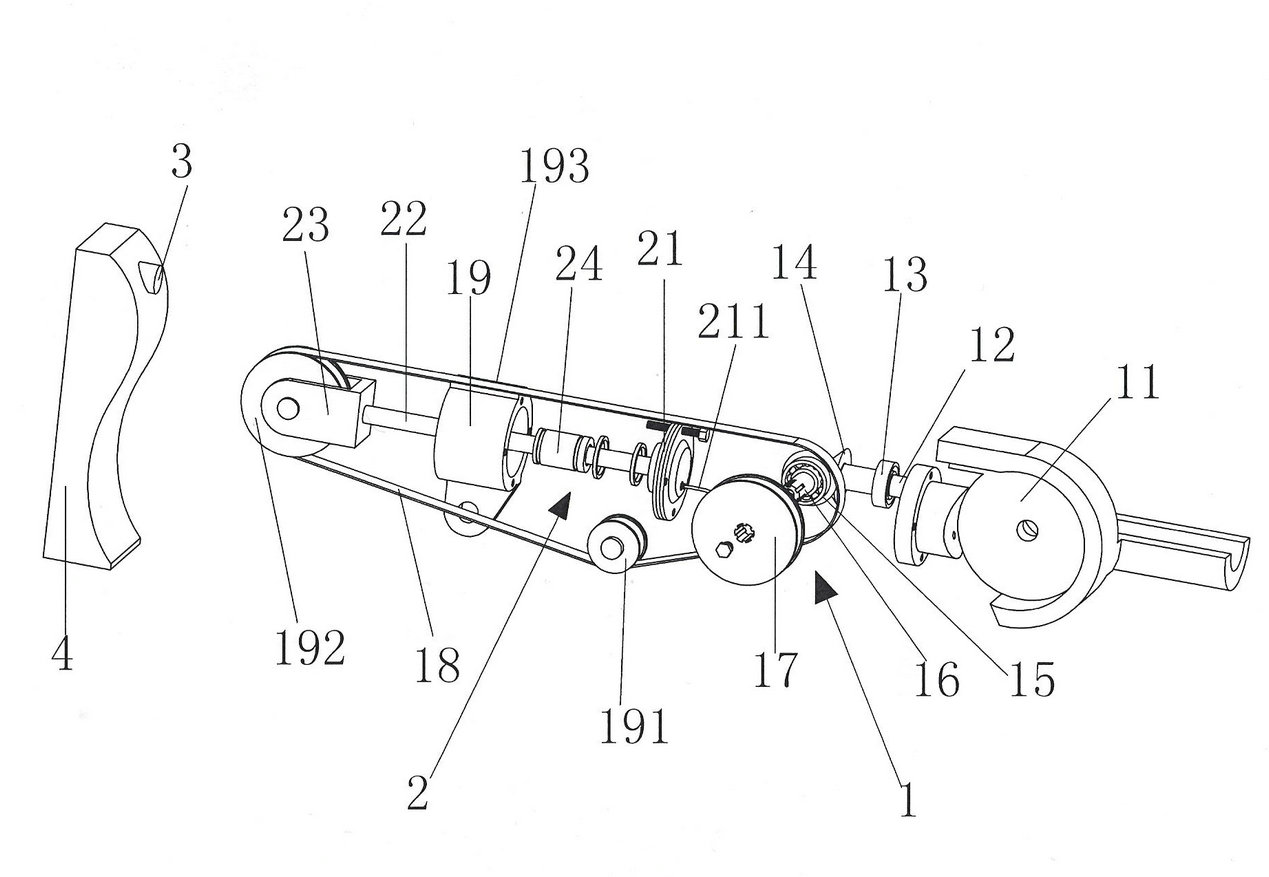

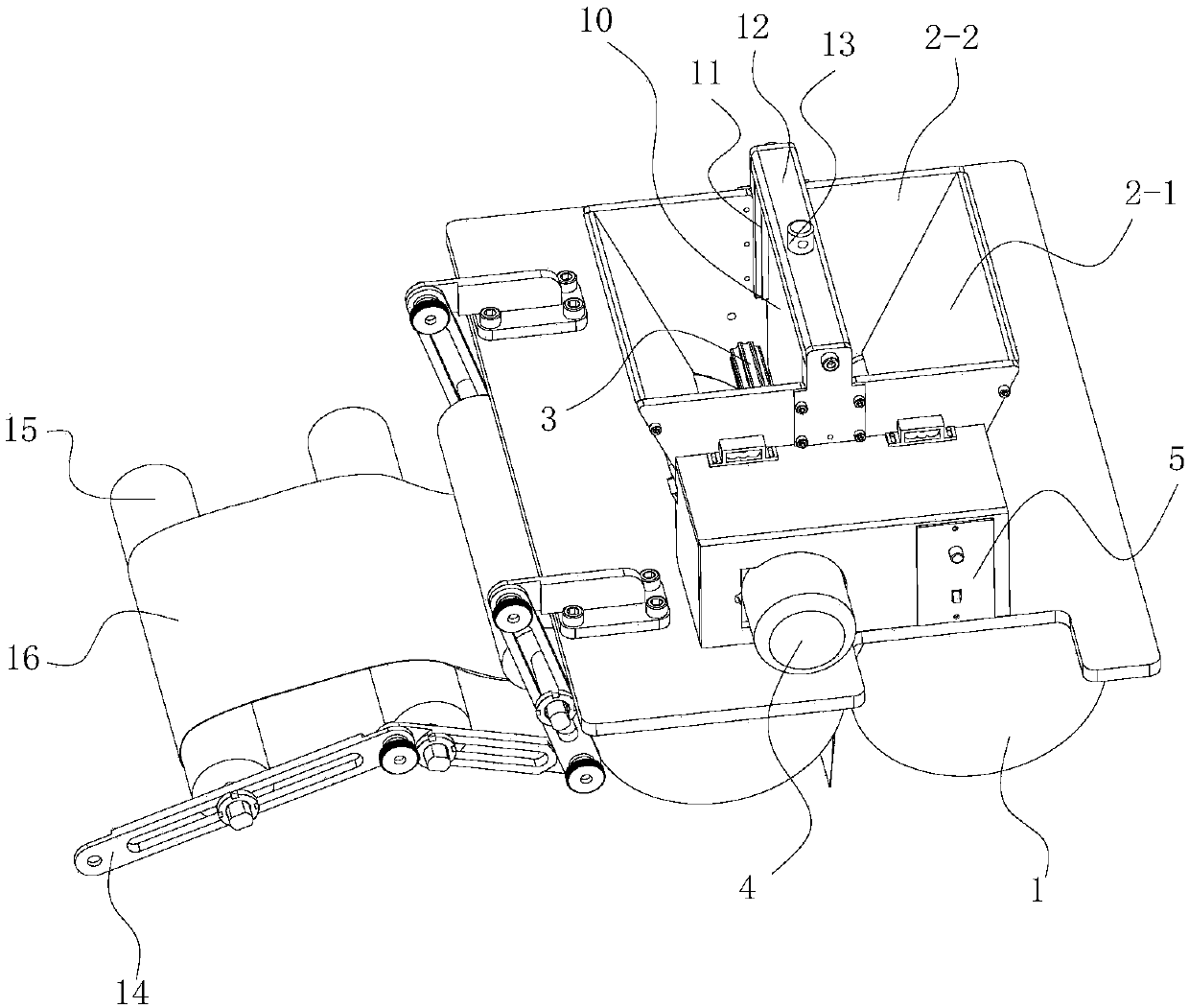

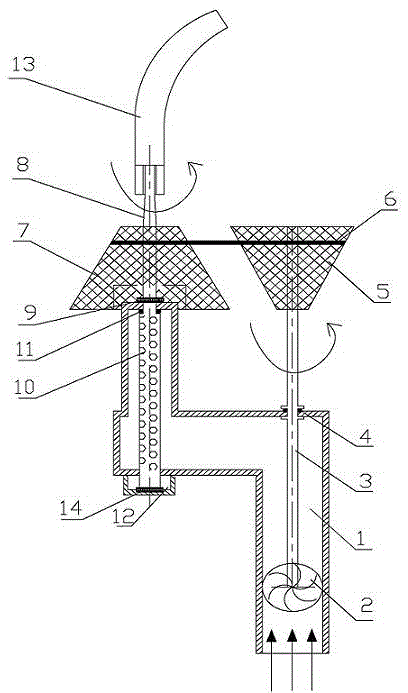

Pressure adjustment type abrasive belt grinding device

InactiveCN102501157ASpeed can be adjustedUniform Surface AllowanceBelt grinding machinesDrive wheelControl system

The invention discloses a pressure adjustment type abrasive belt grinding device which consists of a transmission device, a pressure adjustment device and a grinding and polishing pressure control system, wherein the transmission device consists of a body, a power input shaft, a bearing, a first bevel gear, a second bevel gear, a gear shaft, a drive wheel, an abrasive belt, a second body, an abrasive belt supporting wheel and an abrasive belt grinding and polishing wheel, wherein the pressure adjustment device consists of a thin film air cylinder, an abrasive belt small main shaft and a supporting wheel frame; the grinding and polishing pressure control system consists of a force sensor, a pressure servo valve and an air source; an external electric motor is connected with the power input shaft and drives the drive wheel of the transmission device to rotate, so that the abrasive belt moves to grind and process a curved surface of a workpiece; the thin film air cylinder of the pressure adjustment device can drive the abrasive belt small main shaft to move forwards and backwards; and when the grinding pressure is changed, the force sensor transmits a pressure signal to the pressure servo valve, successively pushes the thin film air cylinder to act and drives abrasive belt small main shaft to move forwards and backwards so as to realize the pressure adjustment control. With the adoption of the pressure adjustment type abrasive belt grinding device, the isopiestic grinding and processing of the curved surface can be realized while the speed is adjusted.

Owner:CHANGCHUN UNIV

Manufacturing apparatus of prefabricated rod for optical element blank, and method for manufacturing element blank

ActiveCN109704544ASpeed can be adjustedTight diameter toleranceGlass drawing apparatusGlass reforming apparatusManufactured apparatusOptical glass

The invention relates to a manufacturing apparatus of a prefabricated rod for an optical element blank, and a method for manufacturing the element blank, and belongs to the technical field of opticalglasses. The problem of restriction of the shape of a raw material in the processing process of the optical element is mainly solved in the invention. The apparatus is mainly characterized in that theapparatus comprises a molding die, a first drawing device, a second drawing device, a heating device and a cutting device; the first drawing device is located below the molding device, and is used for molding glass to form a circular thick rod; the heating device is located below the first drawing device, and is used for heating and softening the circular thick rod; the second drawing device is located below the heating device, and is used for drawing the circular thick rod to form a circular thin rod; and the cutting device is located below the second drawing device, and is used for cuttingthe circular thin rod. The circular rod can be directly manufactured during manufacturing of the optical glass, and the shape of the cross section of the circular rod approaches the needed shape of the cross section of the optical element, so the circular rod can be directly sliced to manufacture the optical element blank.

Owner:HUBEI NEW HUAGUANG NEW INFORMATION MATERIALS CO LTD

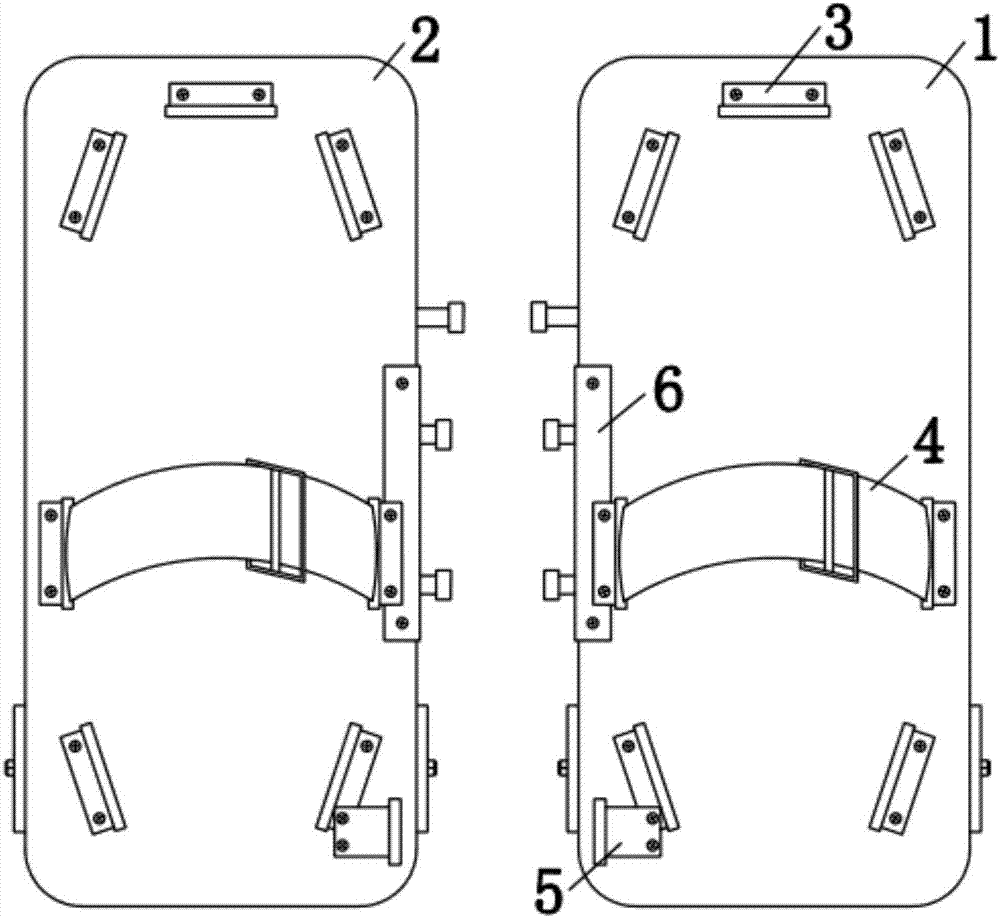

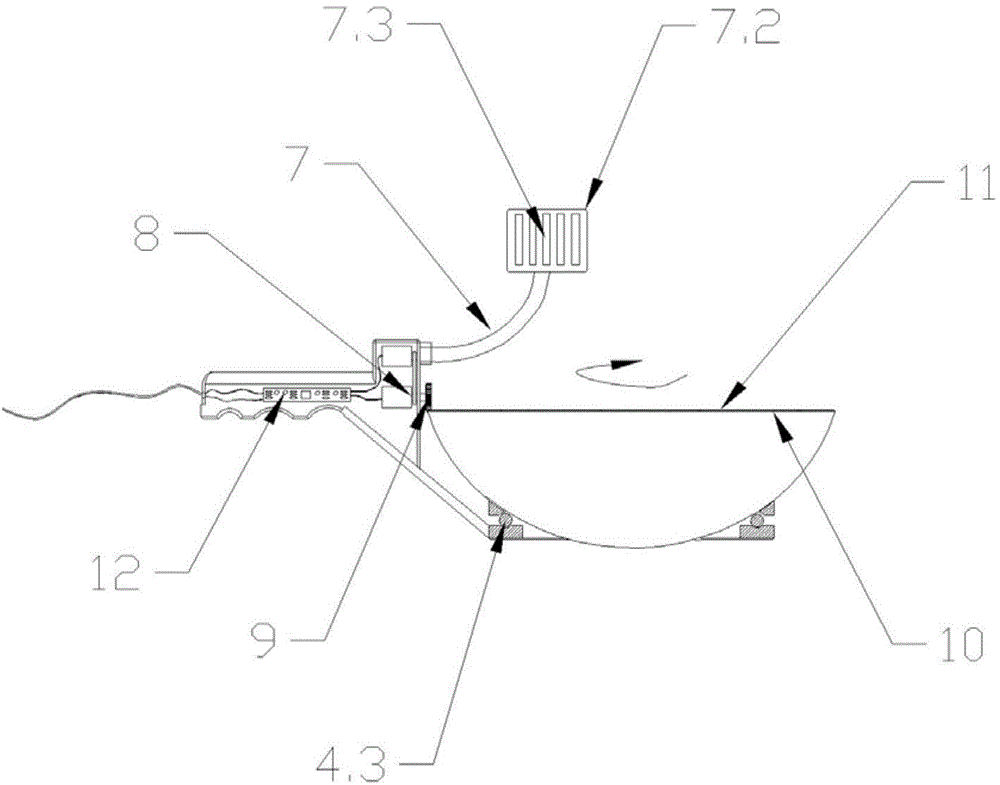

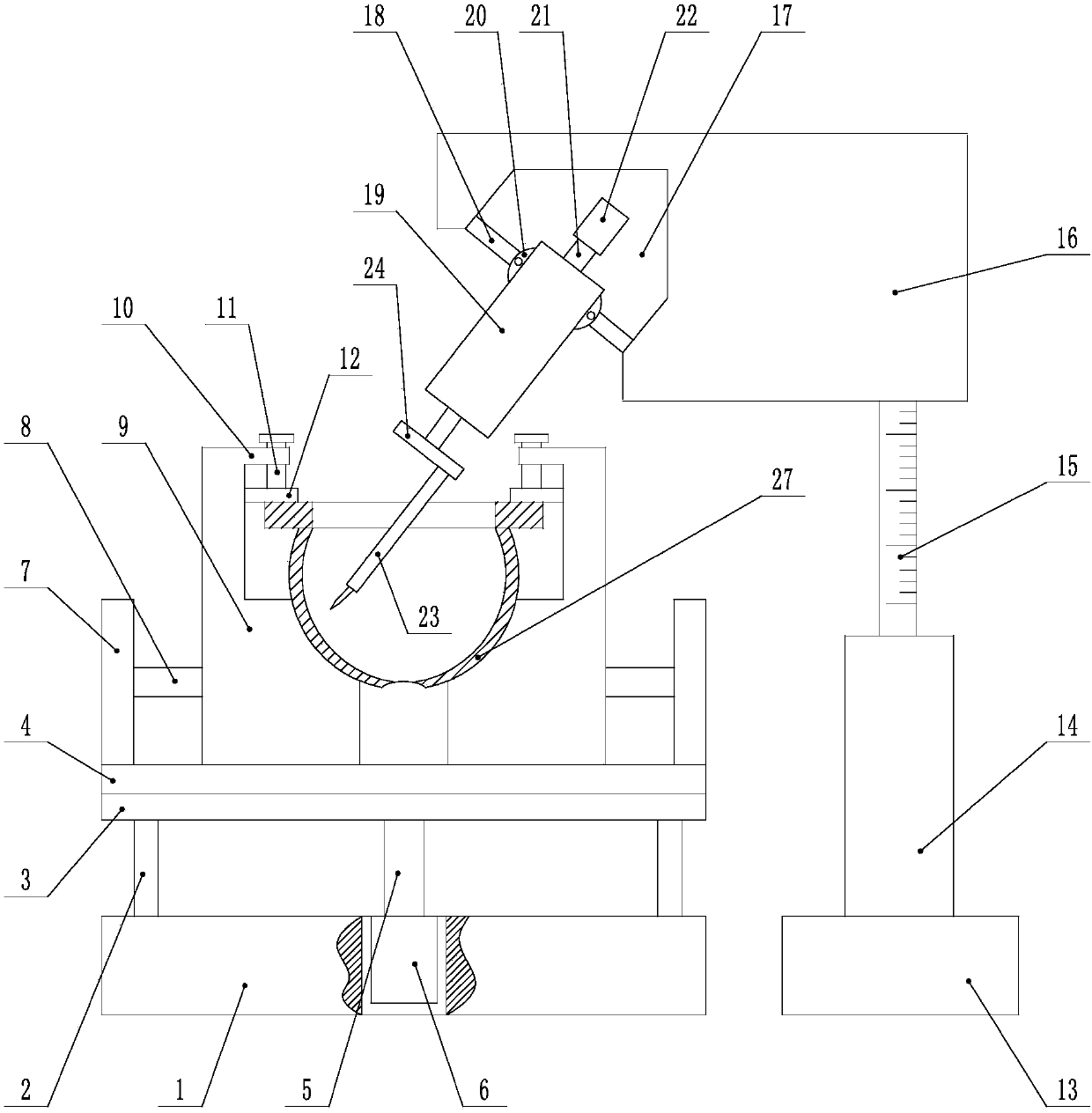

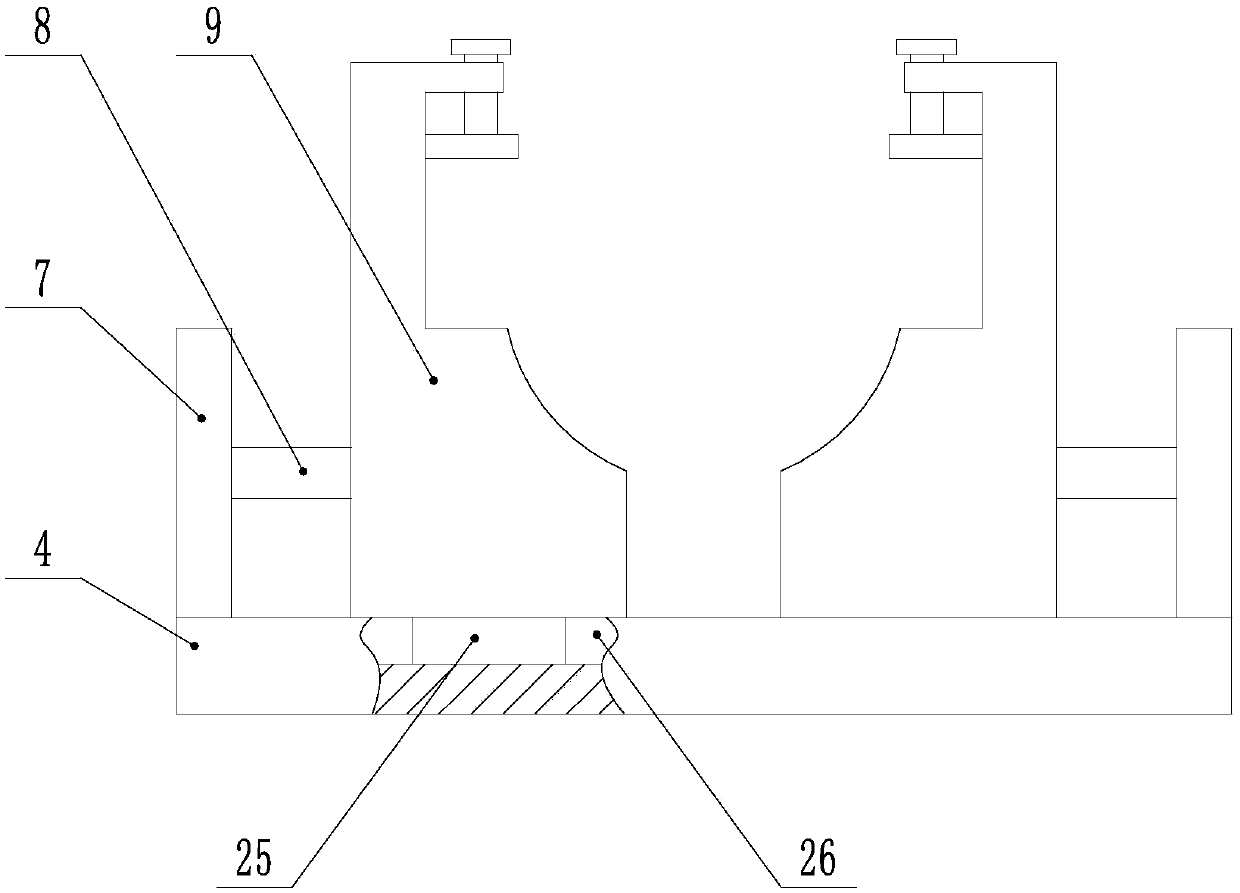

Air cylinder cover mold spraying method capable of achieving uniform spraying

ActiveCN109604537ASpeed can be adjustedSpray evenlyMoulding toolsFoundry mouldsMechanical engineeringPiston rod

The invention discloses an air cylinder cover mold spraying method capable of achieving uniform spraying. The air cylinder cover mold spraying method comprises the following steps that A, the positions of sliding blocks are adjusted through extending and retracting of hydraulic telescopic rods, a spherical mold is placed on circular-arc-shaped grooves of the sliding blocks; B, screw rods are rotated, so that the spherical mold is fixed to the sliding blocks by compressing plates; C, the height of a mounting seat is adjusted through a piston rod, the angle of a spray head is adjusted through auniversal joint, and the spray head extends into the inner concave face of the spherical mold; and D, a first motor is started to enable a first rotating shaft to rotate, a second motor is started toenable a second rotating shaft to rotate, and a pump is started to enable the spray head to spray the inner concave face of the spherical mold. Spraying is more uniform, the time and labor are saved,and the air cylinder cover mold spraying method is suitable for spherical molds of different specifications and sizes and wide in application range.

Owner:ANHUI HIGH TECH POWER TECH

Temperature control system with controllable condensation distance for tire tread and sidewall production

PendingCN112140419AWide cooling coverageImprove cooling efficiencyTyresTemperature controlEngineering

The invention discloses a temperature control system with a controllable condensation distance for tire tread and sidewall production. The temperature control system comprises a support and a conveying mechanism which is arranged on the support and used for transporting tires, wherein a plurality of temperature sensors used for detecting the temperature of the tires are arranged on the support inthe conveying direction of the conveying mechanism, each temperature sensor is at least provided with two sets of cooling assemblies used for cooling the tires, each set of cooling assembly comprisestwo air cooling units which are symmetrical about a tire conveying face, the air spraying ends of every two corresponding air cooling units face the upper side face and the lower side face of the conveying mechanism respectively, each air cooling unit comprises an installation base, and an air blower is arranged on each installation base. Experiments prove that a cooling device is wide in coolingcoverage area, high in cooling efficiency, high in precision, capable of saving cooling liquid and high in energy-saving efficiency, and meanwhile the manufacturing process and cost of a whole experimental device are effectively controlled.

Owner:山东玲珑橡胶科技有限公司

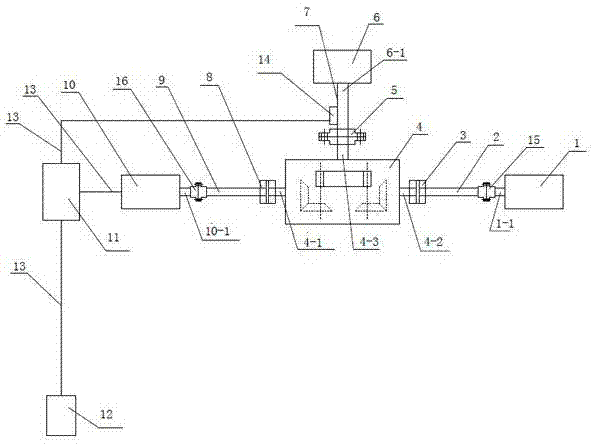

Movable low-speed bench drill

InactiveCN103223510AImprove drilling accuracyEasy to movePortable power-driven toolsPortable drilling machinesLow speedDrive shaft

The invention relates to a movable low-speed bench drill, and belongs to the field of mechanical processing. A center drill rod drive speed reducer (5) comprises a drive motor (5-1), a controller (5-2), a driving gear (5-3), a driving gear shaft (5-4), a driving gear bearing (5-5), a driving gear bearing support (5-6), an intermediate gear (5-7), an intermediate gear shaft (5-8), an intermediate gear bearing (5-9), an intermediate gear support (5-10), a driven gear (5-11) and a driven gear shaft (5-12). The movable low-speed bench drill is characterized in that the center drill rod drive speed reducer (5) is arranged in a drill casing (1) between an stand column (2) and a center drill rod device (4); and a central axis of the drive motor (5-1) is parallel to the central axes of a center drill rod (4-3) and the stand column (2). The movable low-speed bench drill has the benefits that the drilling accuracy is high, the mobility performance is good, the rotating speed is adjustable, and the bench drill can be directly absorbed on a large workpiece for use.

Owner:王志生

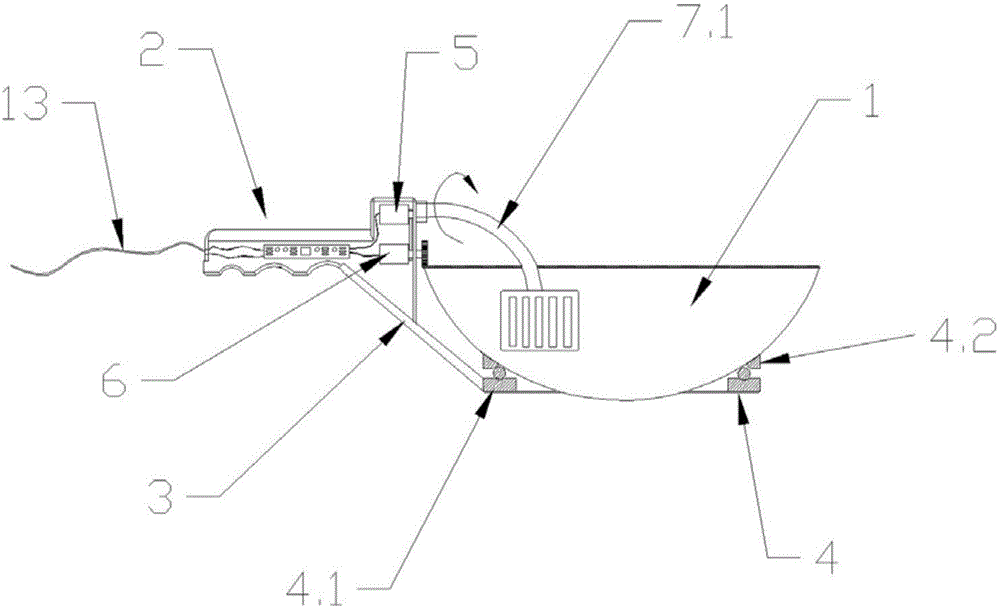

Portable core sampling drill

The invention discloses a portable core sampling drill. The portable core sampling drill comprises a handle, wherein a power supply device is mounted in the handle and electrically connected with a transmission clutch through a wire, a power switch is arranged below the right side of the handle, a power head is mounted on the right side of the transmission clutch, a drill pipe is arranged on the right side of the power head, a bellows is mounted on the right side of the drill pipe, vent holes are formed in the right side in the bellows which is fixedly connected with a core barrel, dust removal holes are formed above and below the core barrel, a rock breaking drill bit is mounted on the right side of the core barrel and movably connected with the core barrel, and a chromium-manganese tooth head is arranged on the right side of the rock breaking drill bit. The portable core sampling drill is reasonable in structure, easy to operate, small in size, portable, high in drilling efficiency and suitable for field work, guarantees high rock pillar forming rate and has good marketing value.

Owner:GUANGZHOU CHANXIN BIOTECH CO LTD

Dual-power driven superposed output power device

ActiveCN104753314ASo as not to damageSimple structural designDynamo-electric gearsCooling towerDrive shaft

The invention relates to a dual-power driven superposed output power device which is mainly used for comprehensive utilization of power equipment and belongs to the field of cooling towers. The dual-power driven superposed output power device comprises a motor, a motor output transmission shaft, power output equipment, a power output transmission shaft, a dual-power input gear box, a transmission shaft, a controller circuit device and at least one clutch; an output shaft of a motor is connected with an input shaft I of the dual-power input gear box through the motor output transmission shaft; an output shaft of the power output equipment is connected with an input shaft II of the dual-power input gear box through the power output transmission shaft; the number of the clutches is two; the two clutches comprise a motor output clutch and a power output clutch; the motor output clutch is arranged one side of a motor; the power output clutch is arranged on one side of the power output equipment; the controller circuit device is connected with the motor. The dual-power driven superposed output power device is simple and reasonable in structural design, convenient to install and maintain and efficient and energy-saving and can be applied to energy-saving comprehensive utilization of the power equipment.

Owner:HANGZHOU FUDING ENERGY SAVING TECH SERVICE

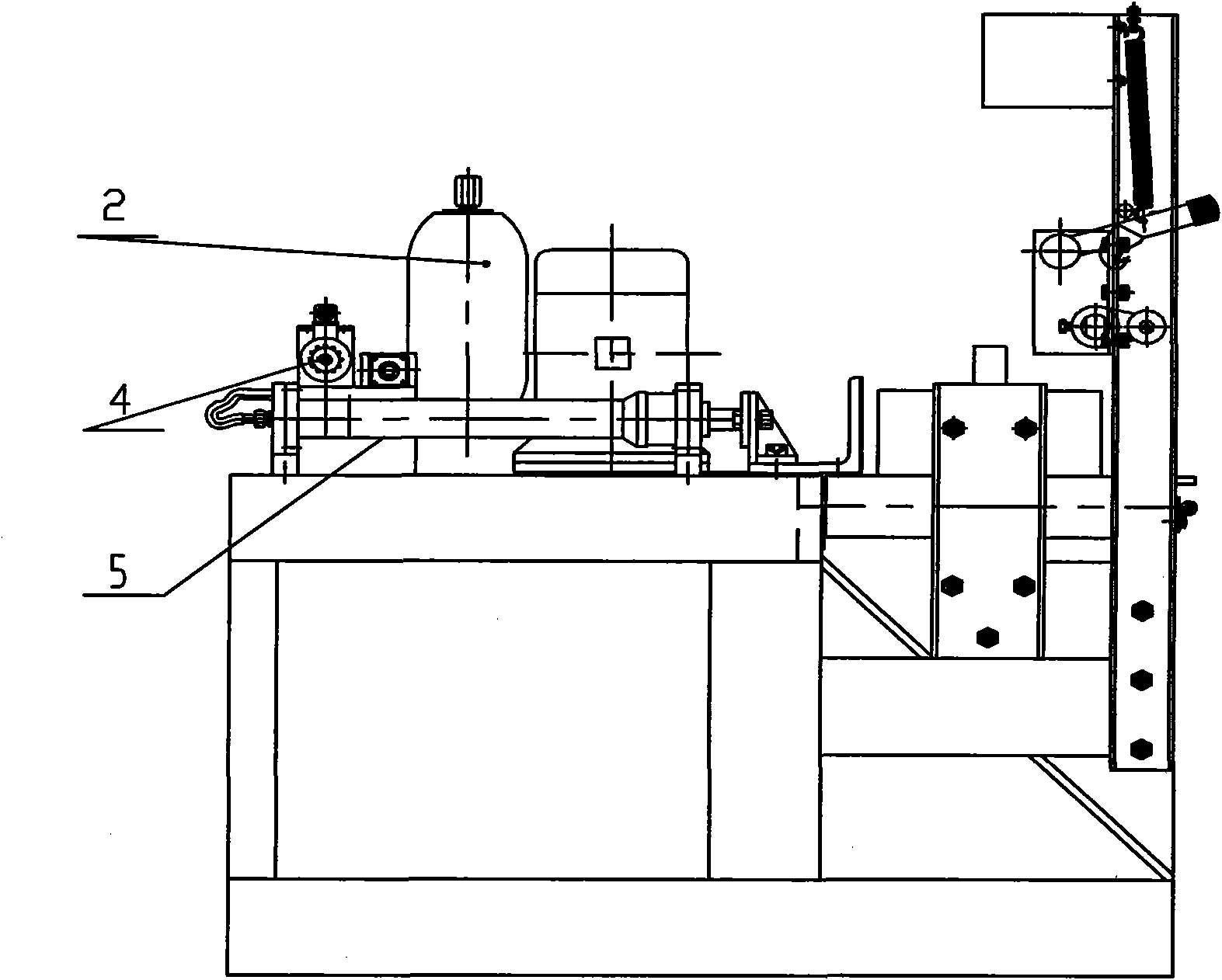

Hydraulic blank cutting machine

The invention provides a hydraulic blank cutting machine belonging to the technical field of brick making mechanical equipment. A hydraulic device is used for replacing a crank connecting rod mechanism of the prior blank cutting machine, and is provided with a power element, a control element and two hydraulic cylinders which synchronously work; the hydraulic cylinders are installed on a stand ofthe blank cutting machine, are in rigid connection with the stand, and are connected with the control element and an oil tank through pipelines; a piston rod of each hydraulic cylinder is connected with a pushing head of the blank cutting machine; an accumulator is arranged on the pipeline between the hydraulic cylinder and the oil tank; an oil absorption pipeline and an oil return pipeline are both provided with filters; the power element of the hydraulic device is a gear pump; and the control element comprises a check valve, an overflow valve, a one-way throttle valve, an electromagnetic directional valve and a ball valve. The invention has the advantages of reasonable design, simple structure, energy-saving system, higher synchronous accuracy, convenient control and safe use.

Owner:SHANDONG JUXIANG MACHINERY

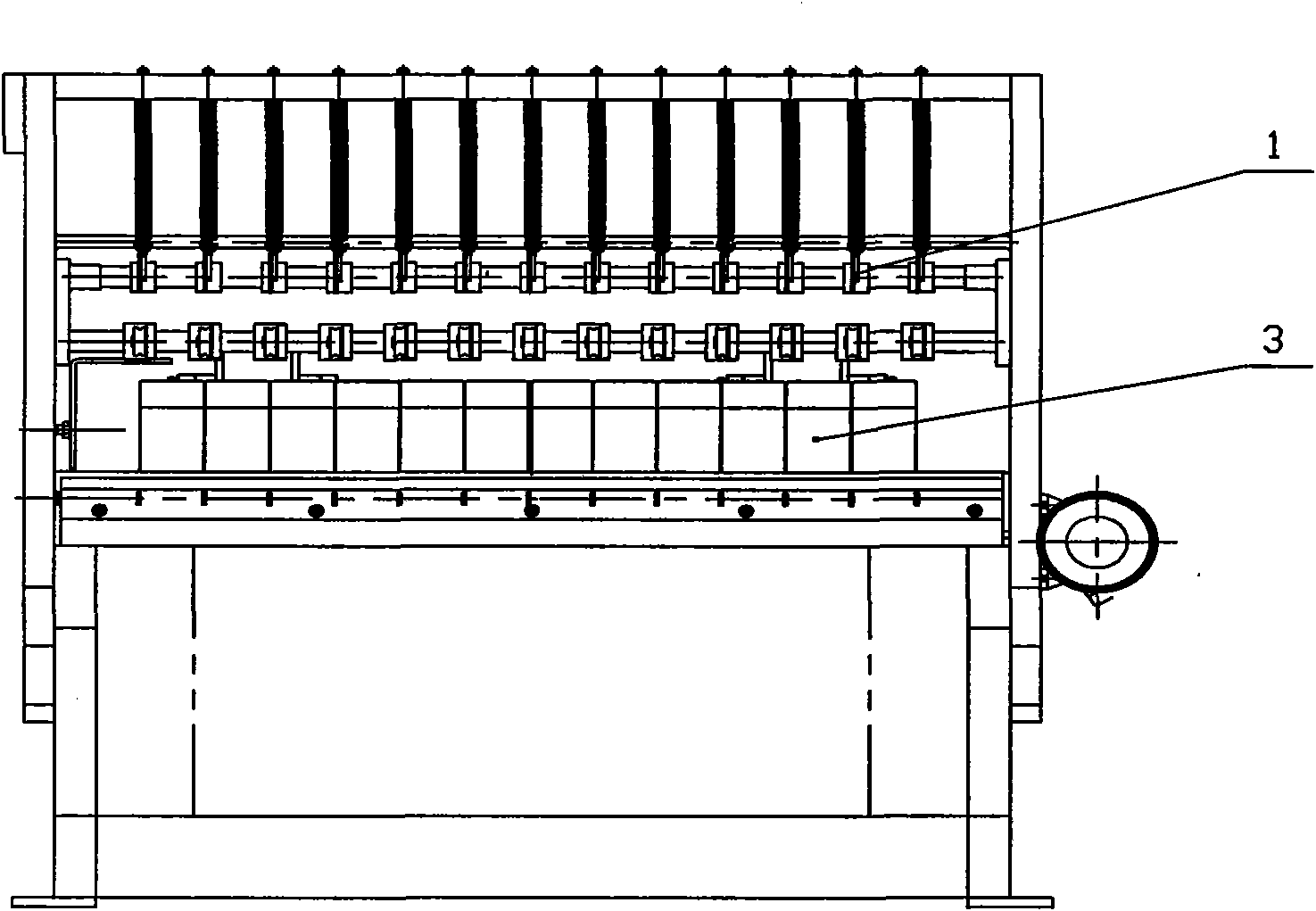

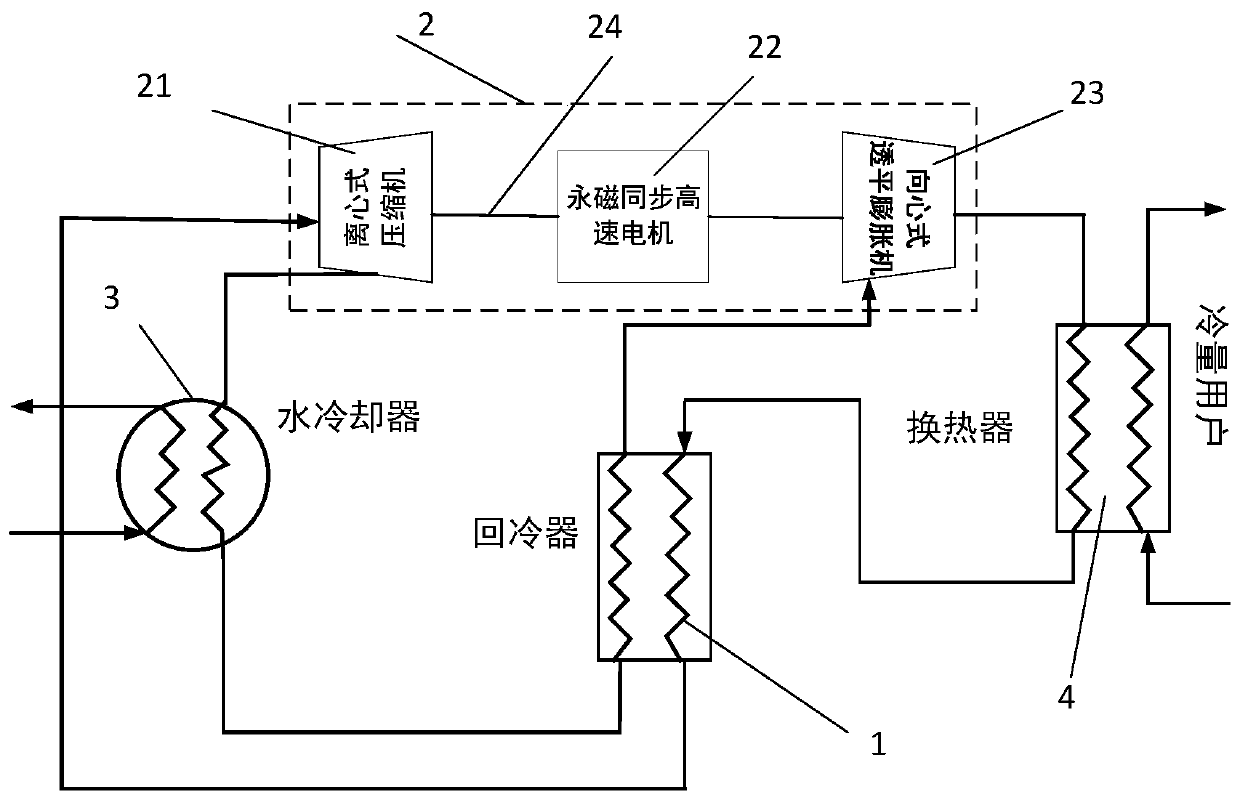

Integrated neon refrigerating machine and refrigerating method

InactiveCN110986408ASolve the cooling problemExtend maintenance-free timeMechanical apparatusCompression machines with non-reversible cycleElectric machineEngineering

The invention discloses an integrated neon refrigerating machine and a refrigerating method. The integrated neon refrigerating machine comprises a centrifugal compressor, a permanent magnet synchronous high-speed motor, a centripetal expansion turbine, a water cooler, a recooler and a heat exchanger. The centrifugal compressor, the permanent magnet synchronous high-speed motor and the centripetalexpansion turbine are manufactured on the same axis in an integrated mode. The water cooler is used for achieving exchange cooling with neon at an outlet of the centrifugal compressor, and the cooledneon enters the centripetal expansion turbine after passing the recooler. After the centripetal expansion turbine acts, low-temperature neon can be obtained, the obtained low-temperature neon conductsheat exchange with coolants of cold users through a plate-fin heat exchanger, and then the low-temperature neon returns to the inlet end of the centrifugal compressor after passing the recooler to form closed-loop circulating. According to the integrated neon refrigerating machine and the refrigerating method, the circulating neon is used for achieving compressed expansion refrigeration, the neonin different low-temperature sequences can be obtained and different needs of the cold users can be met. The integrated neon refrigerating machine is high in efficiency, good in stability, easy to operate and capable of providing preparation cold sources for nitrogen supercooling, plasma nitridation, natural gas liquefaction and the like.

Owner:HEFEI INSTITUTES OF PHYSICAL SCIENCE - CHINESE ACAD OF SCI

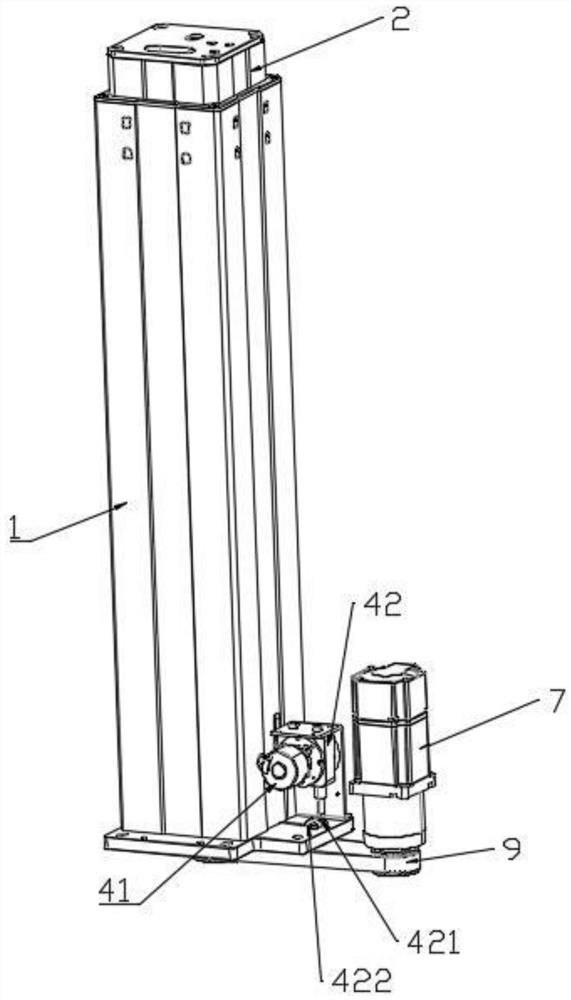

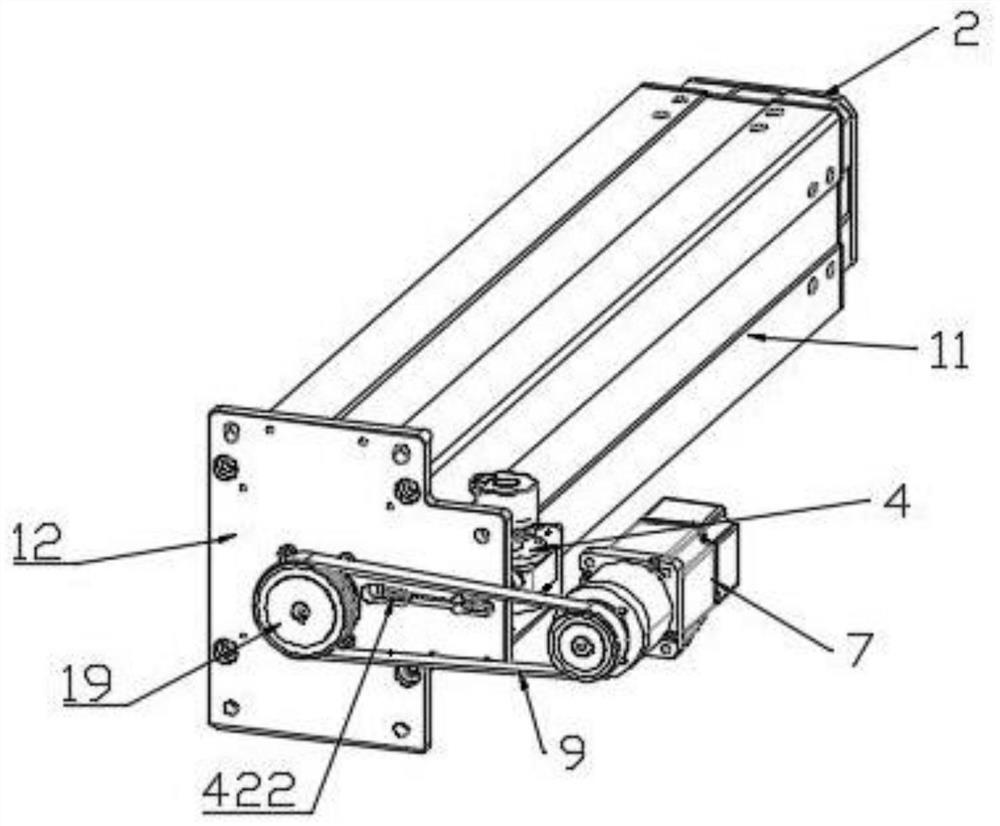

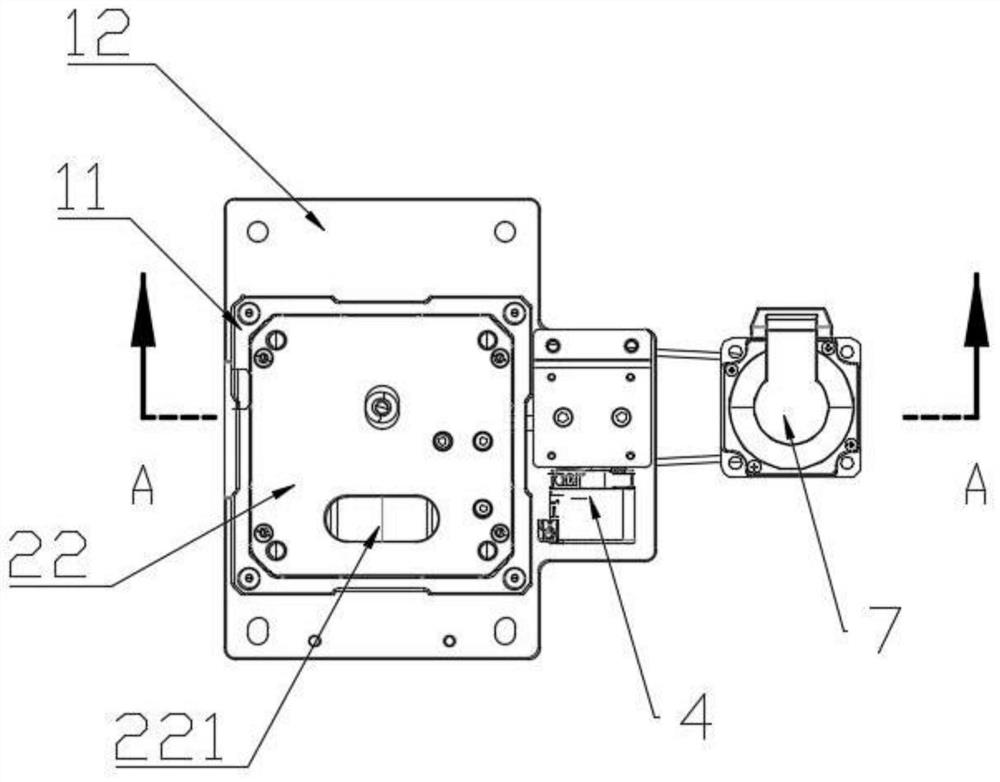

Lifting stand column device

PendingCN113357509AA large amountRealize self-lockingHauling chainsHoisting chainsStructural engineeringControl theory

Owner:上海追术科技有限公司

Leftover material transmitting device for paper product processing

PendingCN109051865AAvoid cloggingEasy to pourGrain treatmentsLoading/unloadingSize differenceDrive wheel

The invention provides a leftover material transmitting device for paper product processing, and belongs to the field of transmitting devices. The leftover material transmitting device comprises a supporting frame, wherein a processing box is arranged on the supporting frame; a charge hole is formed in the top surface of a box cover; a discharge hole is formed in the bottom surface of the processing box; a first screen is mounted on a circular shaft; the first screen is positioned between a first partition and a second partition; the lower end of a crushing motor is connected with a rotary shaft; crushing blades are connected on the rotary shaft; a rope hole is formed in the left side wall of the processing box; a fixed ring is arranged on the outer wall of the left side of the processingbox; a fine rope is connected on the fixed ring; one end of the fine rope passes through the rope hole and is connected with a rotary door; driven wheels are mounted on the rotary shaft; a conveyor belt is connected on the rotary shaft; a drive wheel is connected with the driven wheels through a belt, and the driven wheels are connected through the belt; first fans are mounted on the inner wall ofthe left side of the processing box and the inner wall of the right side of the processing box; and a second fan is mounted on the inner wall of the right side of a crushing box. The leftover material transmitting device has the advantages of being relatively small in leftover material size difference, and convenient in transmission.

Owner:盐城名杰纸品包装有限公司

Speed-adjustable swinging shovel

InactiveCN103158116ASpeed can be adjustedSimple structurePortable power-driven toolsMechanical energy handlingStatorEngineering

The invention relates to a speed-adjustable swinging shovel which comprises a machine shell, a circuit board box, a rotor, a stator, a carbon brush assembly and a switch, wherein a first bearing, a second bearing, a third bearing, a fourth bearing and a fifth bearing are installed in the machine shell, the first bearing is connected with the second bearing through an output shaft, a shifting fork is installed between the output shaft and the third bearing, the third bearing, the fourth bearing and the fifth bearing are connected with each other through an input shaft, and a speed adjusting circuit board is installed in the circuit board box. The speed-adjustable swinging shovel has the advantages of being capable of adjusting speed, simple in structure, and capable of having functions of being capable of grinding, sawing, shoveling and the like.

Owner:鲁仲清

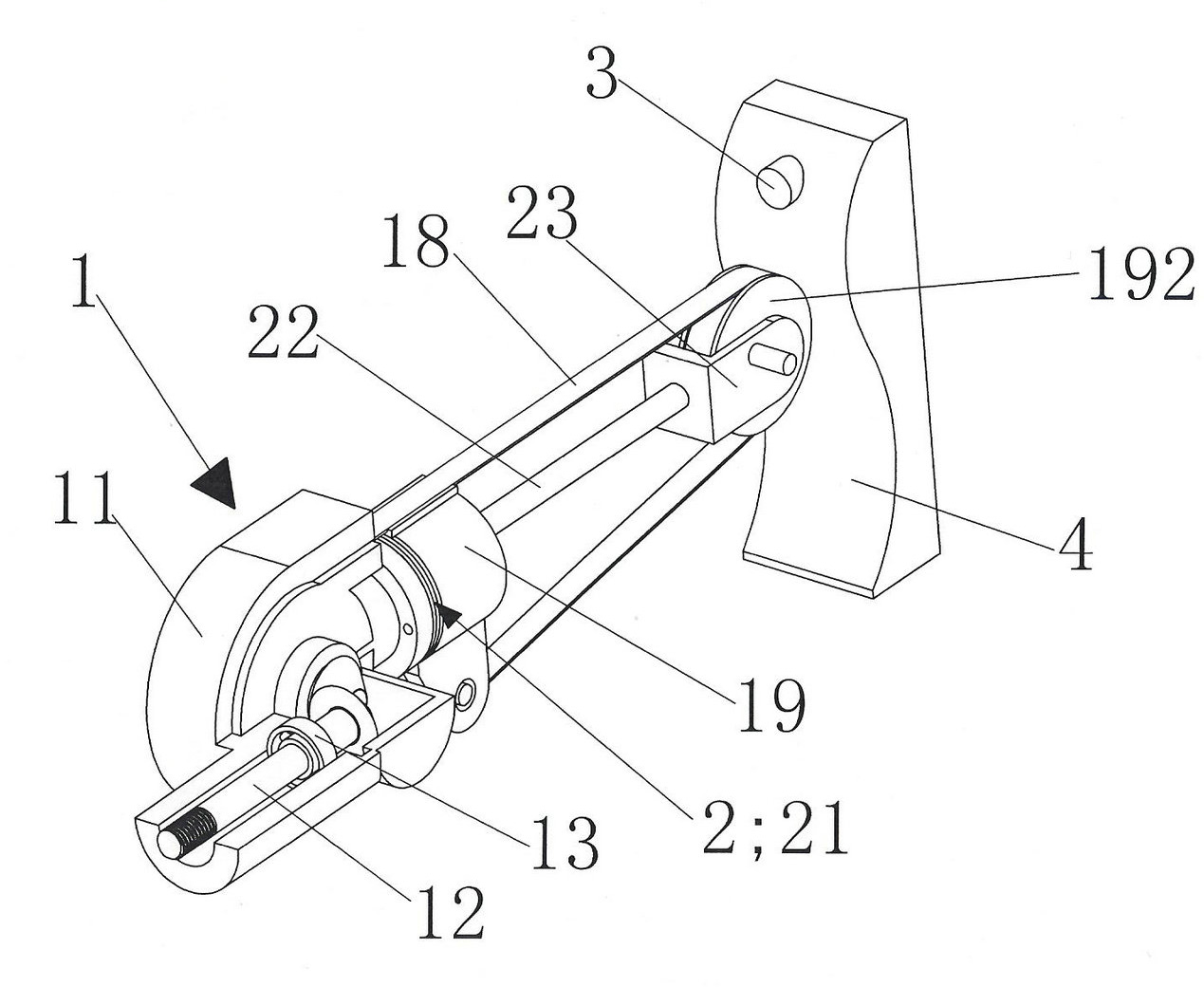

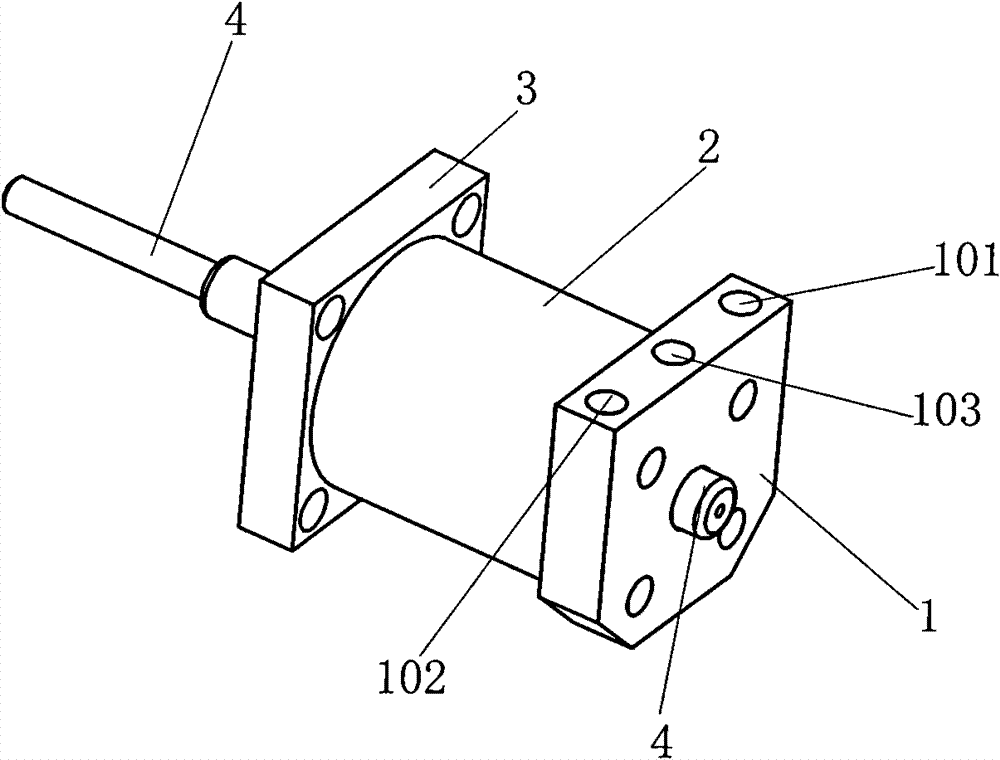

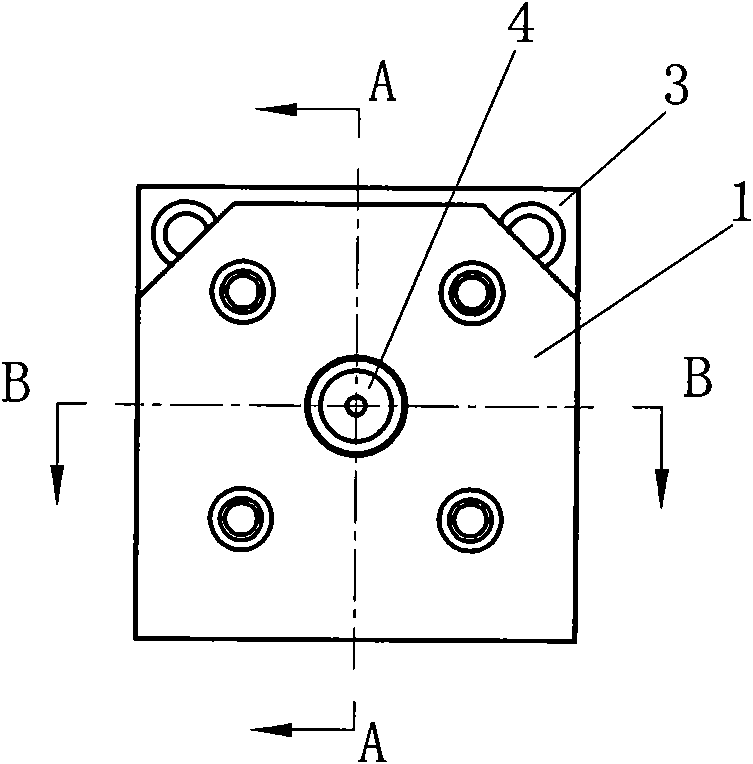

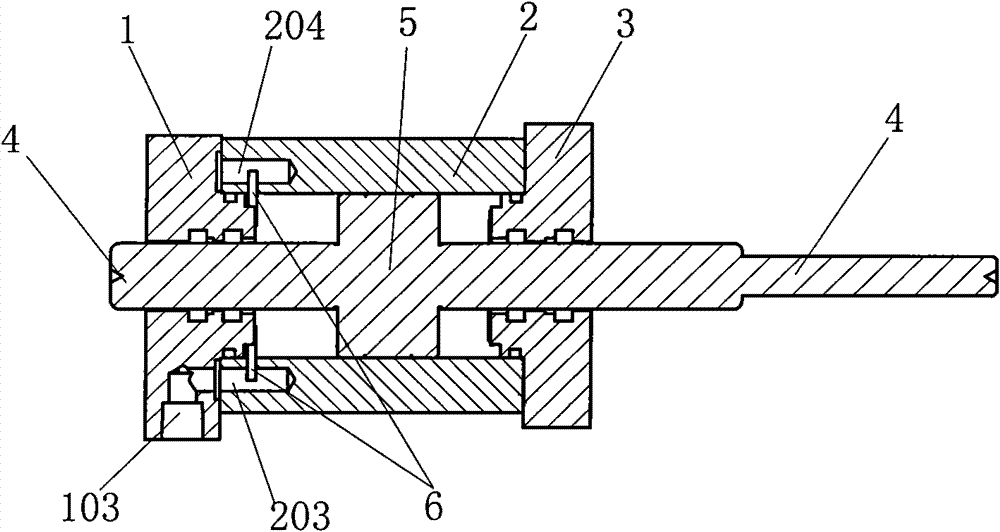

An Air Buffer Device Used for Oil Pressure Dismounting of Conical Surface Interference Coupling

ActiveCN104196943BIncrease in sizeImprove buffering effectSpringsGas based dampersInterference fitLow noise

The invention discloses an air buffer device for oil pressure removal of conical surface interference coupling, which belongs to the field of buffer devices. The air buffer device for oil pressure removal of conical surface interference connection includes a cylinder body and a There is a piston in the cylinder that can slide in the cylinder and a spring that can reset the piston. The piston and the cylinder form an air chamber. The spring is arranged between the bottom of the cylinder and the piston. An exhaust port is provided on the side wall of the cylinder body, and a throttle valve is provided at the lower part of the side wall of the cylinder body outside the stroke range of the piston. The invention has the advantages of simple structure, good cushioning effect, low vibration, low noise, convenient manufacture, friendly environment, and prolongs the service life of the disassembly tooling at the same time.

Owner:DALIAN HUARUI HEAVY IND GRP CO LTD

A roller feeding device for powder

The invention discloses a powder rolling feeding device, and belongs to the field of chemical power supplies. The powder rolling feeding device comprises a feed hopper; the feed hopper is positioned rightly above two pressure rollers of a rolling machine; a position for feeding powder between the two pressure rollers is a rolling port; the feed hopper is of a funnel structure for feeding the powder in the rolling port; the feed hopper consists of four baffle plates; impeller shafts parallel to pressure roller shafts are respectively arranged on the left and right sides of the rolling port; two ends of each impeller shaft are connected with two baffle plates perpendicular to the pressing roller shafts; two impeller shafts are connected with a rotary driving mechanism, and are driven by the rotary driving mechanism to oppositely rotate; each impeller shaft and the pressure roller in the same side are oppositely rotated; and the impeller shafts and the pressure rollers therebelow are provided with gaps at least capable of enabling silver pull nets to pass through. The powder rolling feeding device has such characteristics as uniform powder feeding speed, adjustable feeding quantity, capability of preleveling the silver pull nets, capability of adjusting the lengths of the silver pull nets and possession of an automatic powder leakage preventing function.

Owner:CHINA ELECTRONIC TECH GRP CORP NO 18 RES INST

A dual power drive superimposed output power device

ActiveCN104753314BSpeed can be adjustedAdjustable speedDynamo-electric gearsDrive shaftElectric machine

The invention relates to a dual power drive superimposed output power device, which is mainly used for comprehensive utilization of power equipment and belongs to the field of cooling towers. The invention includes a motor, a motor output transmission shaft, a power output device, a power output transmission shaft, a dual power input gearbox, a transmission shaft, a controller circuit device and at least one clutch, and the output shaft of the motor is connected to the dual power input through the motor output transmission shaft. The first input shaft of the gearbox is connected, and the output shaft of the power output device is connected to the second input shaft of the dual power input gearbox through the power output transmission shaft. There are two clutches, the two clutches include the motor output clutch and the power output clutch, and the motor output The clutch is located at one side of the motor, the power output clutch is located at one side of the power output device, and the controller circuit device is connected with the motor. The invention has the advantages of simple and reasonable structural design, convenient installation, convenient maintenance, high efficiency and energy saving, and can also be used for energy-saving comprehensive utilization of power equipment.

Owner:HANGZHOU FUDING ENERGY SAVING TECH SERVICE

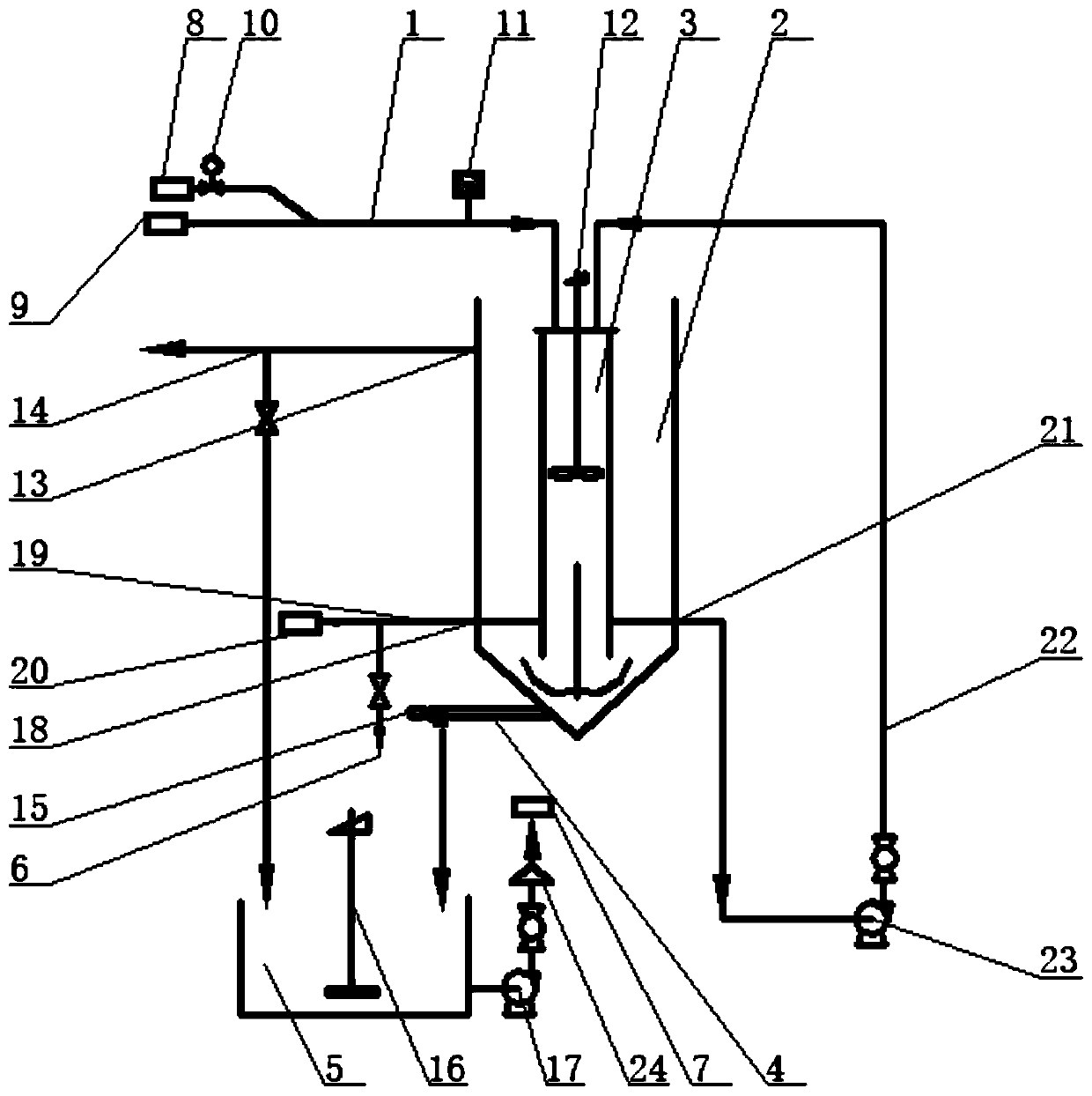

A kind of device and preparation method for preparing heavy magnesium carbonate with heavy magnesium water

ActiveCN108773848BSpeed can be adjustedAdjust the speedMagnesium carbonatesChemical industryInorganic saltsPhysical chemistry

The invention discloses a device for preparing heavy magnesium carbonate from heavy magnesium water and a preparation method, relating to the field of inorganic salt synthesis. The device comprises aheating pipe, a settling tank, a reaction tank, a discharging auger, a stirring tank, a sampling hole, filtering equipment and drying equipment, wherein a steam inlet and a heavy magnesium water inletare formed in one end of the heating pipe; a first reaction kettle stirrer is arranged in the reaction tank; a sampling pipeline is arranged on the left side of the lower end of the settling tank; and a reflux pipeline is arranged on the right side of the lower end of the settling tank. The preparation method comprises the following steps: heating heavy magnesium water with steam, carrying out adecomposition reaction in the reaction tank, entering the settling tank to settle, discharging large-particle materials by the discharging auger, pulping, filtering, and drying, thereby obtaining theheavy magnesium carbonate. The device disclosed by the invention has the beneficial effects that the device disclosed by the invention is simple and compact in equipment, the equipment is normal pressure equipment, and the pH value of the reaction is neutral; the equipment material requirement is low, and the cost is low; and in the preparation method, in addition to the heavy magnesium water andsteam, other extra materials are not added, and the product quality is easy to control.

Owner:青海美盛新材料科技有限公司

An automatic control device and method for realizing rock joint contact state

InactiveCN108762115BPrecise control of contact stateRealize automatic termination of testProgramme control in sequence/logic controllersAutomatic controlReciprocating motion

The invention discloses an automatic control device for realizing the rock joint contact state. The automatic control device comprises a base, rock joints are placed on the base, the support is erected on the base, two baffle boards are arranged above the support, a horizontal moving guide rail is fixed in the middle of the two baffle boards, a horizontal motor is arranged in the horizontal movingguide rail and performs reciprocating motion in the horizontal direction along the horizontal moving guide rail; the horizontal motor is vertically connected with a vertical moving guide rail, a lifting motor is arranged in the vertical moving guide rail, and can performs reciprocating motion in the vertical direction along the vertical moving guide rail, the horizontal motor and the lifting motor are connected with a digital display control box, and the digital display control box controls the motion postures of the horizontal motor and the lifting motor in the horizontal direction and the vertical direction, and the lower end of the lifting motor is connected with a clamp device. According to the invention, the contact state of the rock joints can be automatically realized, and the contact state of the rock joints can be accurately controlled.

Owner:CHINA UNIV OF GEOSCIENCES (WUHAN)

A hydraulically driven rotary sprinkler head with adjustable speed and its speed regulating method

ActiveCN103736609BSpeed can be adjustedGuaranteed uptimeMovable spraying apparatusImpellerWater saving

Owner:JIANGSU UNIV

Cleaning equipment for container packaging tank and using method

InactiveCN108856216AEasy to fixSpeed can be adjustedHollow article cleaningDrive wheelPackaging Tank

The invention provides cleaning equipment for a container packaging tank and a using method, and belongs to the technical field of cleaning. The cleaning equipment comprises a cleaning box, electric telescopic cylinders are arranged on the top face of the cleaning box, hanging fixing pieces are arranged on telescopic rods of the electric telescopic cylinders, nozzles are connected to one ends of water delivery pipes, and driven wheels are arranged on the pipe walls of the water delivery pipes. Connecting rods are arranged on the side faces of the driven wheel, a cleaning brush is arranged on the connecting rods, driving wheels are installed at one ends of rotating shafts, motors are installed at the other ends of the rotating shafts, belts are arranged between the driving wheels and the driven wheels, and high-pressure water guns are installed on installation frames. A water tank is arranged on one side of the cleaning box, and a water suction pump is arranged in the water tank. A first water pipe is connected between the water suction pump and the water delivery pipe, second water pipes are connected to the first water pipe, booster pumps are installed on the second water pipe, hoses are connected to the second water pipes, and the hoses are connected with the high-pressure water guns. The cleaning equipment for the container packaging tank has the advantages of good cleaningeffect and high working efficiency.

Owner:南京易洁环保科技有限公司

Steerable and differential hydraulic damping cylinder

InactiveCN102062131BCompact structureReduce manufacturing costFluid-pressure actuatorsCylinder blockPetroleum engineering

Owner:无锡迪奥数控科技有限公司

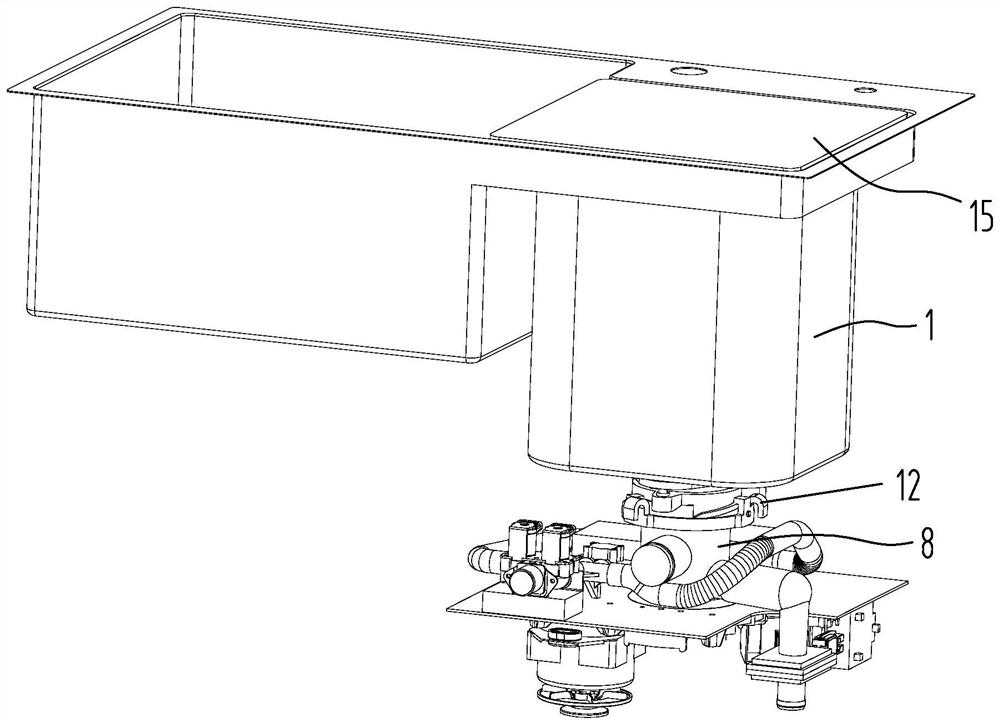

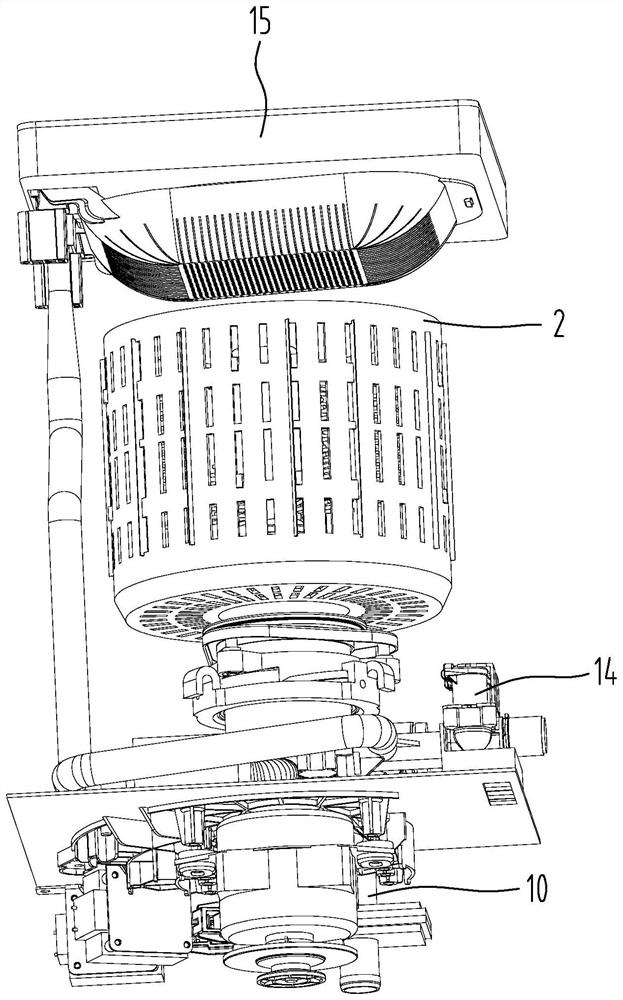

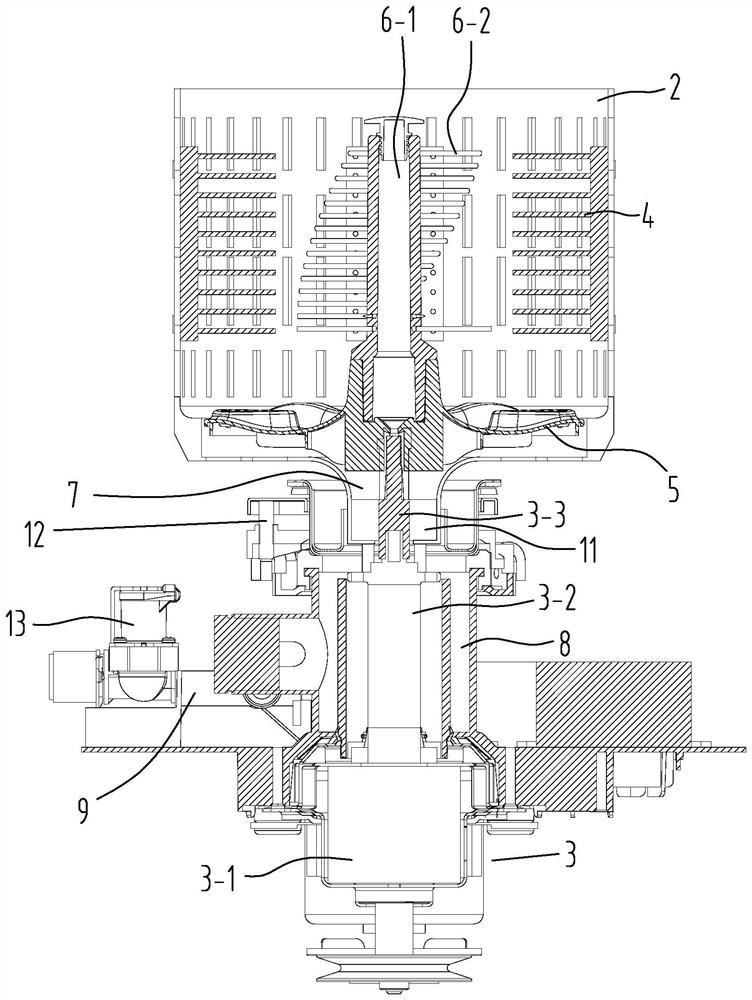

Hand washing imitating type fruit and vegetable cleaning machine

PendingCN114246499AFull relative motionEasy to cleanKitchen equipmentAgricultural engineeringWater flow

The invention discloses a hand-washing-imitating fruit and vegetable cleaning machine which comprises a tank body, a cleaning basket located in the tank body and a driving assembly located below the tank body, an impeller is arranged in the center of the bottom of the cleaning basket, the cleaning basket and the impeller rotate through the driving assembly, a plurality of first brushes are evenly arranged on the inner circumferential wall of the cleaning basket, and a plurality of second brushes are evenly arranged on the inner circumferential wall of the cleaning basket. A second brush is arranged in the center of the surface of the impeller, and the first brush and the second brush rotate along with the cleaning basket and the impeller respectively. The brush in the cleaning basket and the water flow move relatively to form a hand scrubbing simulation state, so that food materials and the water flow generate sufficient relative movement, and the cleaning effect is better.

Owner:宁波轻美电器科技有限公司

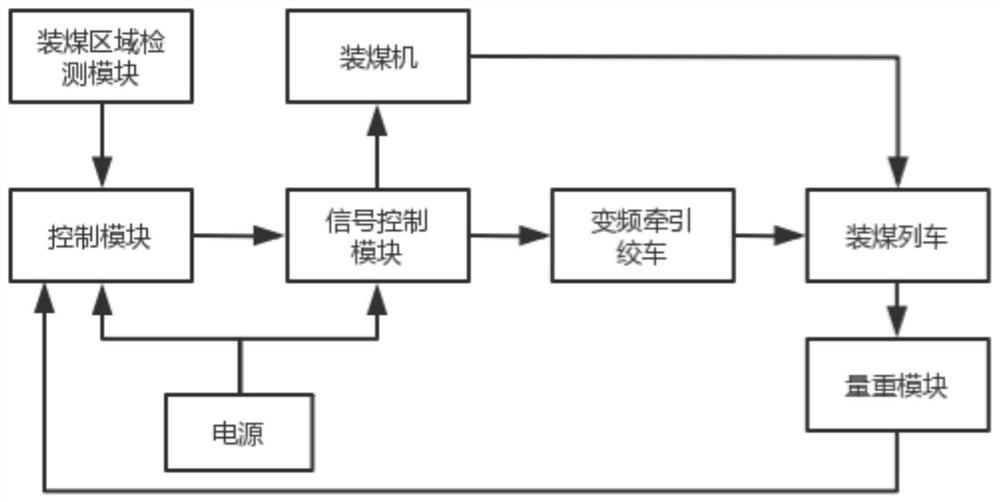

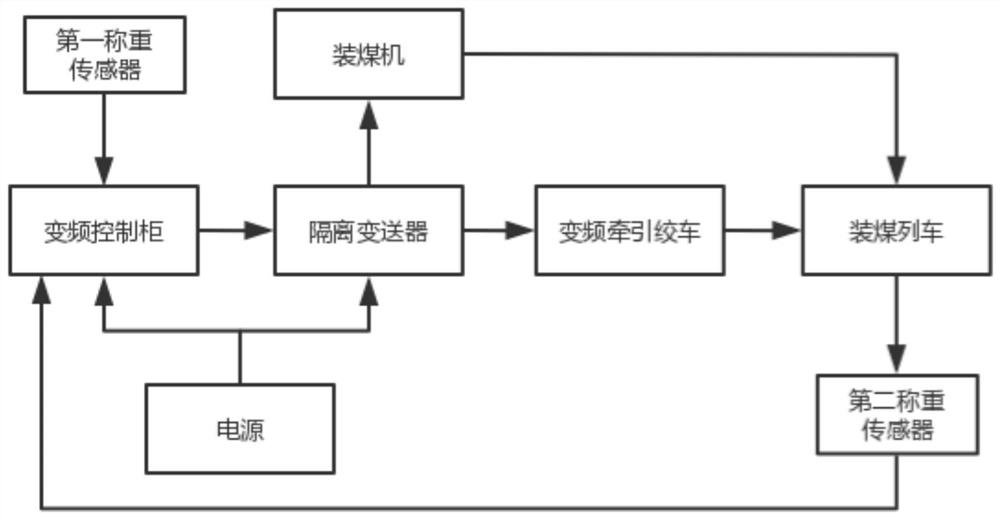

Automatic traction device of coal charging train

PendingCN112707326AReduce shockSpeed can be adjustedWinding mechanismsSpecial purpose weighing apparatusControl signalEngineering

The invention discloses an automatic traction device of a coal charging train. The automatic traction device comprises the coal charging train and a coal loader located in a coal charging area; a variable-frequency traction winch used for pulling the coal charging train, a control module of the variable-frequency traction winch, a control signal module of the variable-frequency traction winch, a coal charging area detection module used for detecting whether the coal charging train is located in the coal charging area or not, and a weight measuring module of the coal charging train are included; the signal output end of the coal charging area detection module is connected with the signal input end of the control module; the signal output end of the control module is connected with the signal input ends of the variable-frequency traction winch and the coal loader through the control signal module, the variable-frequency traction winch is fixedly connected with the coal charging train through a twisted rope, and the weight measuring module is arranged at the bottom, located in the coal charging area, of the coal charging train; and the signal output end of the weight measuring module is connected with the signal input end of the control module, and the power input ends of the control module and the control signal module are both connected with a power source. According to the scheme, coal charging automation is achieved, and economic benefits and safety are greatly improved.

Owner:HUAIBEI MINING IND

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com