Oscillating shaft heading machine by sinking method

A roadheader and swing-type technology, which is applied in the field of sinking swing-type shaft roadheaders, can solve the problems of low safety of construction personnel, low degree of mechanization, and high construction costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

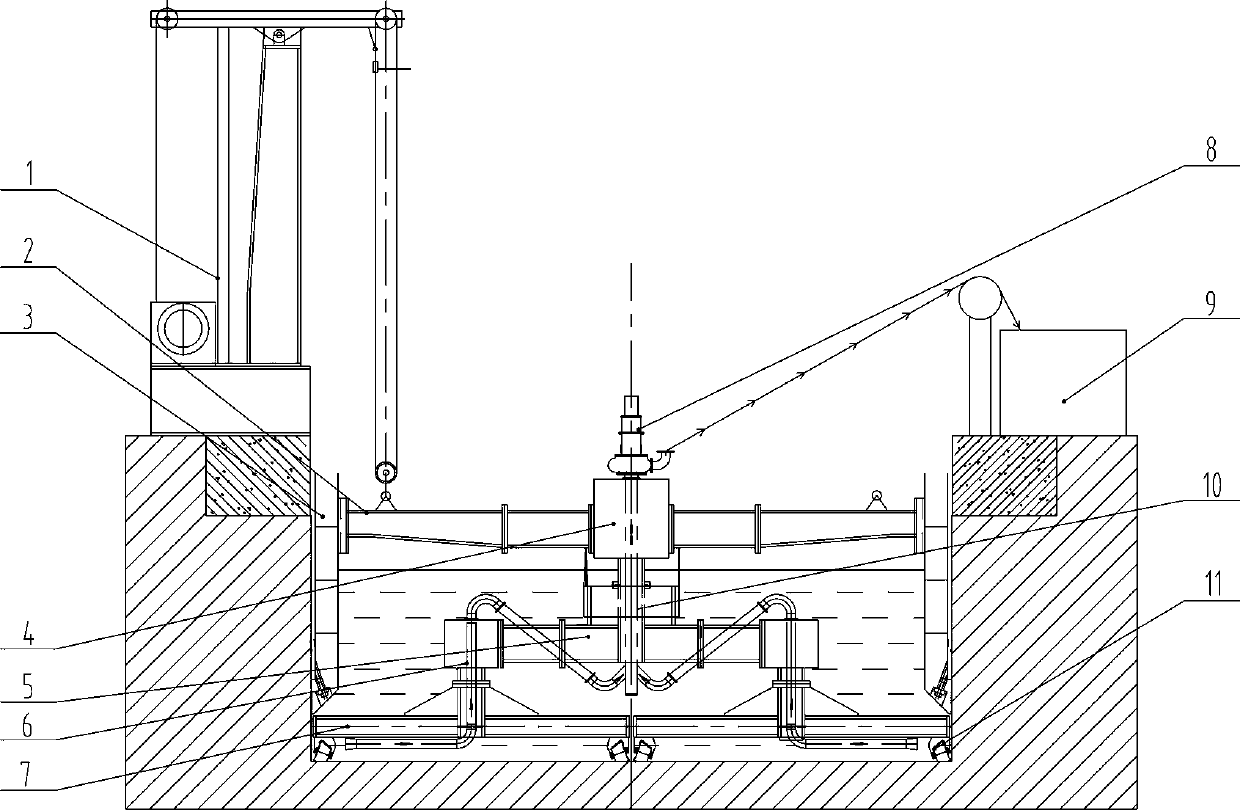

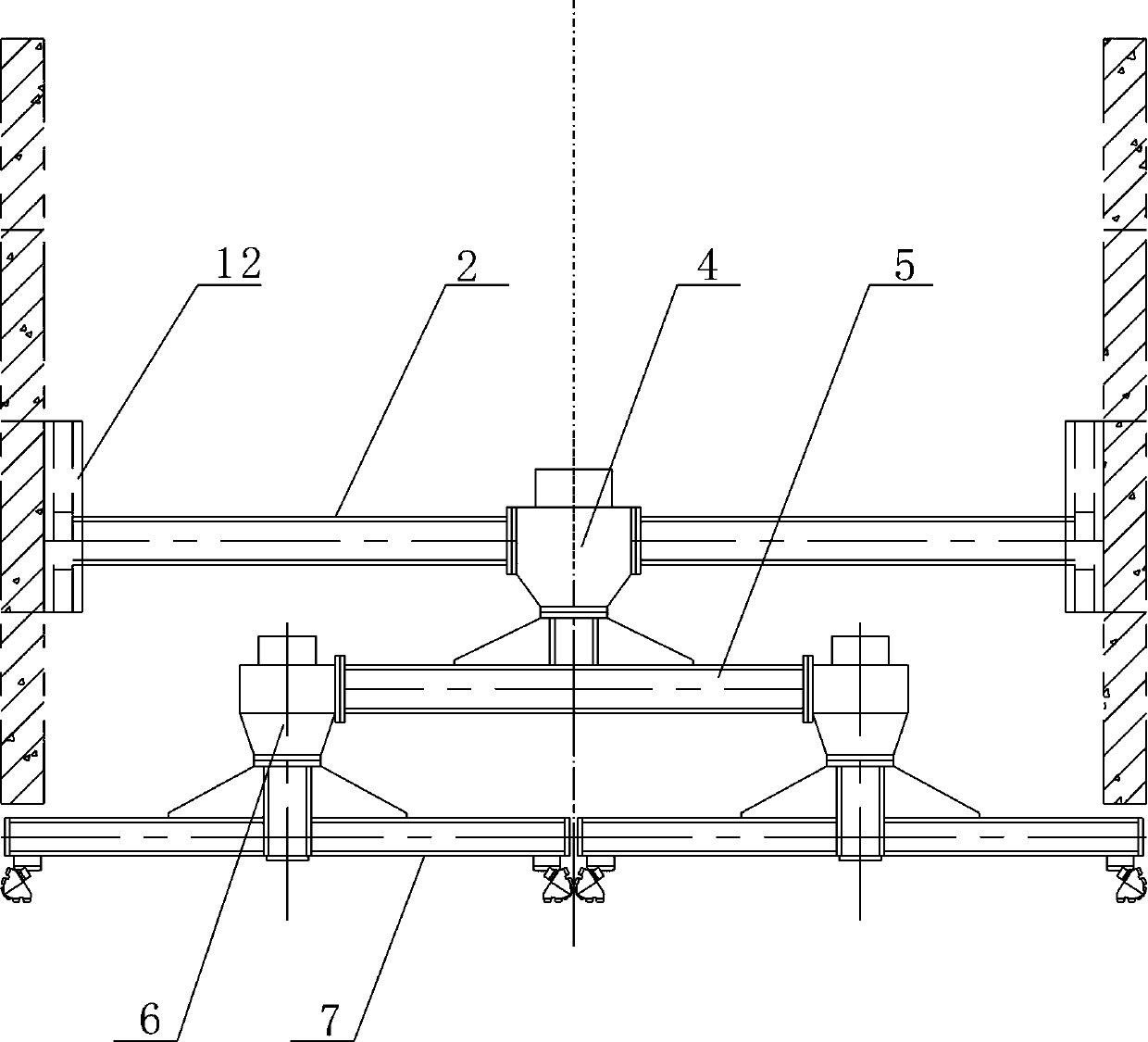

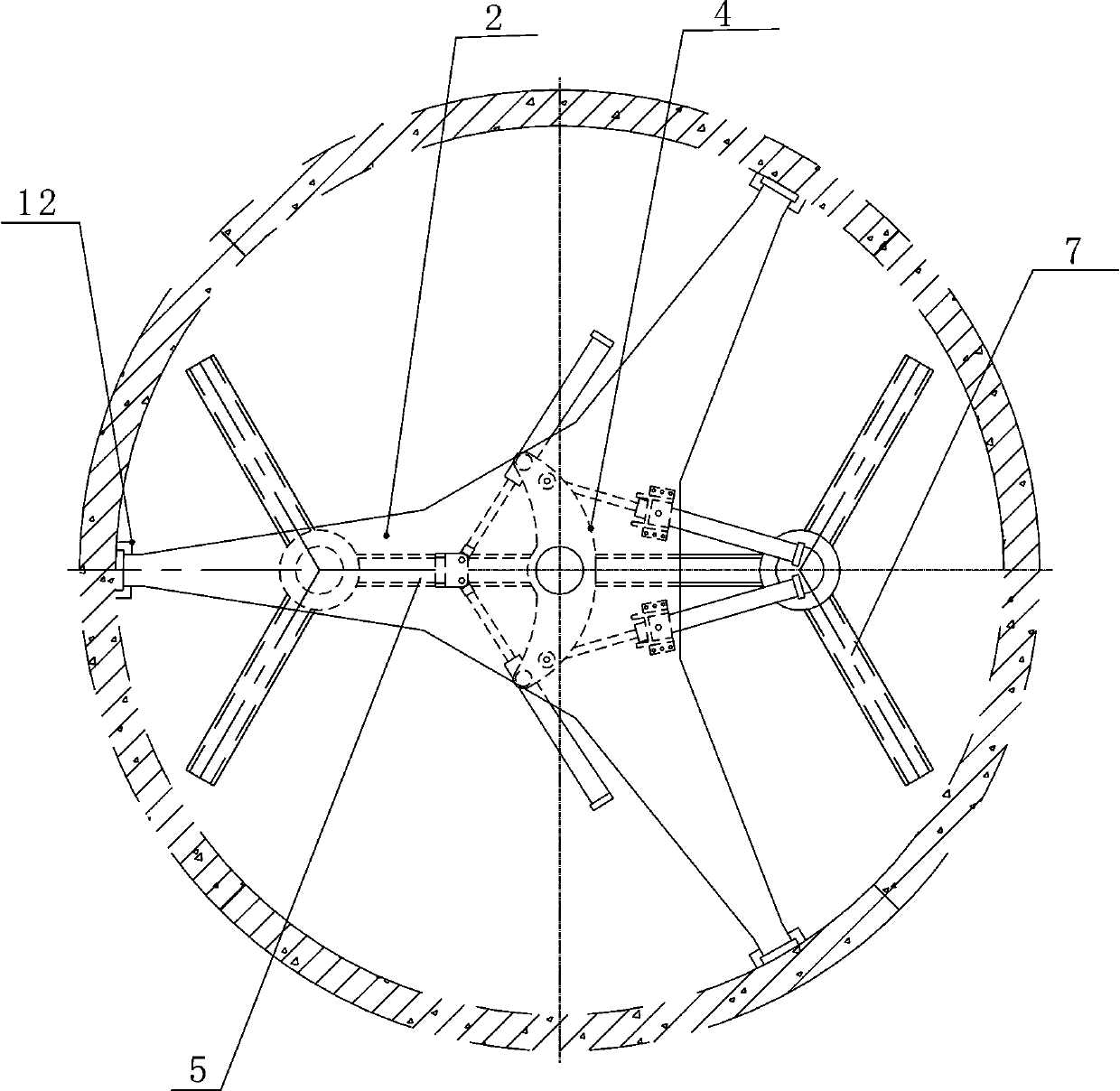

[0049] The technical scheme of the present invention will be further described in detail below in conjunction with the drawings and embodiments.

[0050] Such as Figure 1-23 As shown, the sinking method swing-type shaft tunneling machine includes a tunneling mechanism and a power lifting mechanism set on the ground for lifting the tunneling mechanism 1. It is used for lifting and discharging the mud in the shaft after the tunneling mechanism breaks. The processed slurry separation mechanism and an operation control system for controlling the operation of the above-mentioned mechanism; the tunneling mechanism includes a tunneling frame 2, a drill arm 5, a main driving device 4 for driving the drill arm to rotate, and a drill tool 7 , The auxiliary driving device 6 that drives the drilling tool to rotate. The main driving device includes an outer shell 16, a first hydraulic cylinder 17, a second hydraulic cylinder 18, a third hydraulic cylinder 19, and a fourth hydraulic cylinder ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com