Pressure adjustment type abrasive belt grinding device

A technology of abrasive belt grinding and pressure regulating device, which is used in abrasive belt grinders, grinders, grinding/polishing equipment, etc., can solve the problem that the micro-grinding device cannot adapt to the pressure grinding requirements of curved surfaces, etc., and achieves a uniform removal of the surface allowance. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

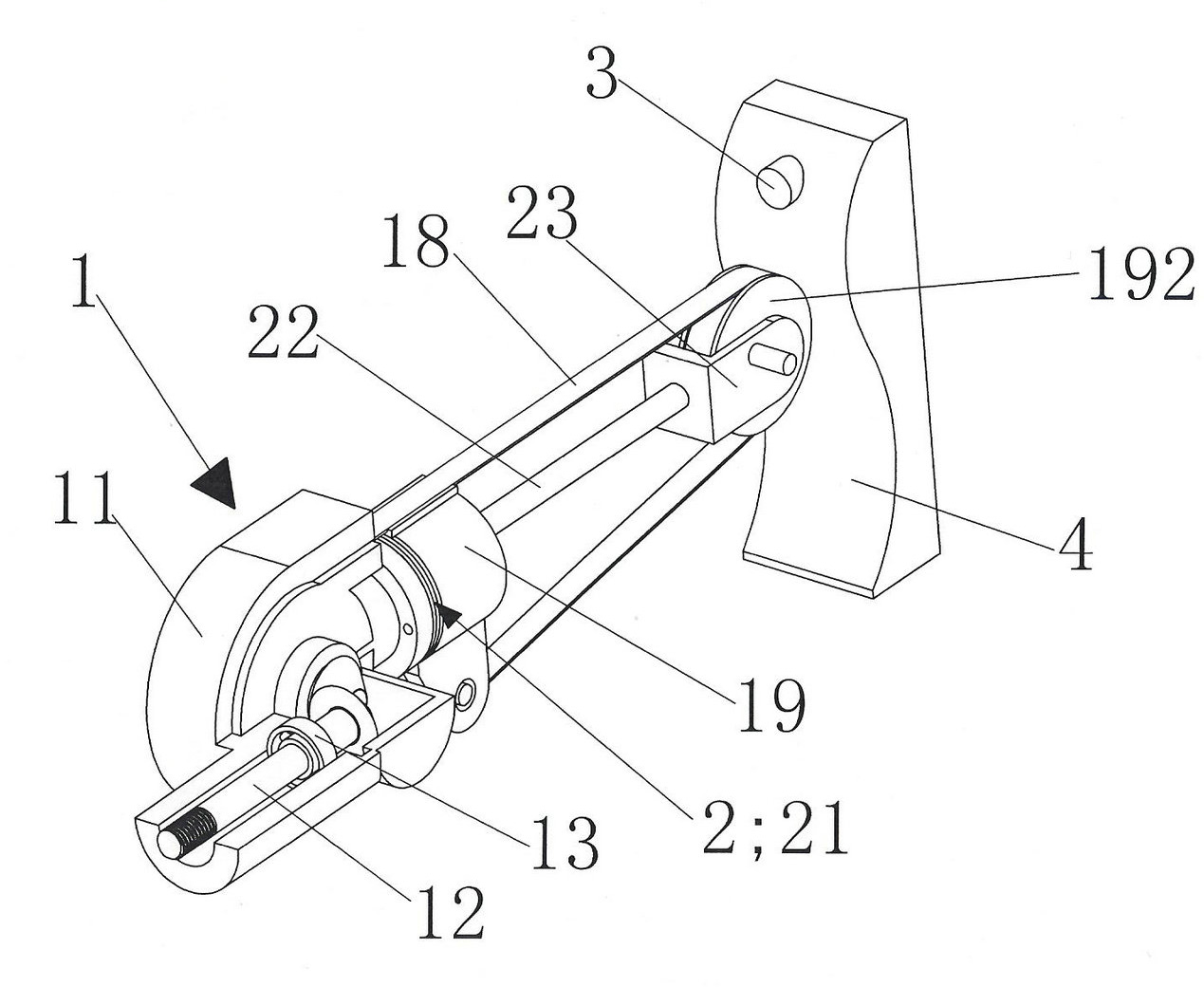

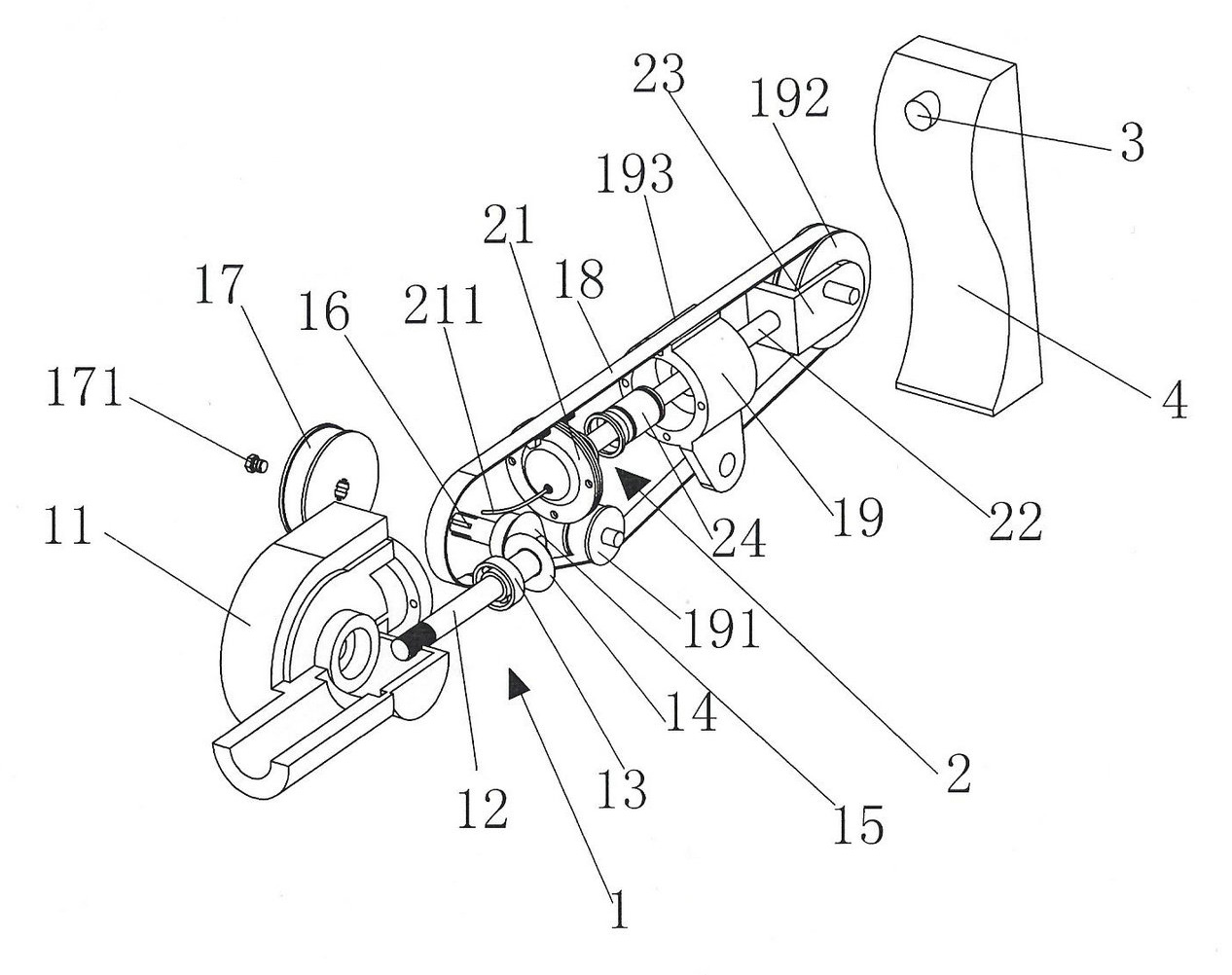

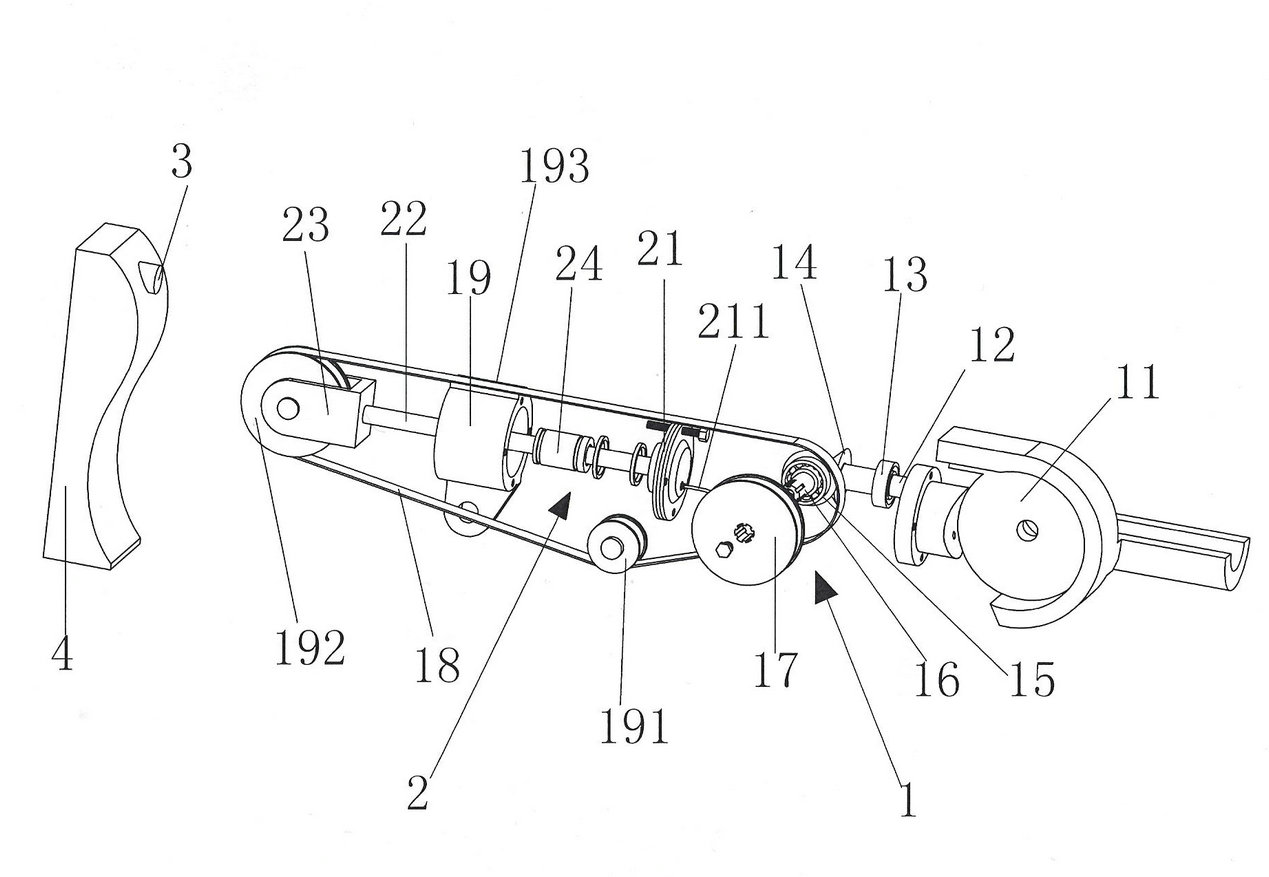

[0009] see figure 1 , figure 2 and image 3 As shown, the present embodiment is composed of a transmission device 1, a pressure regulating device 2 and a polishing pressure control system. The transmission device 1 is composed of a body 11, a power input shaft 12, a bearing 13, a first bevel gear 14, a second bevel gear 15. The gear shaft 16, the driving wheel 17, the abrasive belt 18, the second body 19, the abrasive belt supporting wheel 191, and the abrasive belt grinding and polishing wheel 192 are composed of a film cylinder 21, the abrasive belt small main shaft 22 and the support Wheel frame 23 is formed, and polishing pressure control system is made up of force sensor 3, pressure servo valve and air source, because pressure servo valve and air source are common technology, so, not shown in the figure, power input shaft 12, bearing 13, The first bevel gear 14, the second bevel gear 15, the gear shaft 16 and the driving wheel 17 are arranged in the body 11, the power ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com