Automatic traction device of coal charging train

A traction device and coal loading technology, which is applied in the direction of measuring device, hoisting device, clockwork mechanism, etc., can solve many safety hazards of tensioning device counterweight and iron tower, limit switch can not play a locking role, replacement and transformation Problems such as complicated procedures, to achieve the effect of small maintenance work, safety improvement, and safe operation performance improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

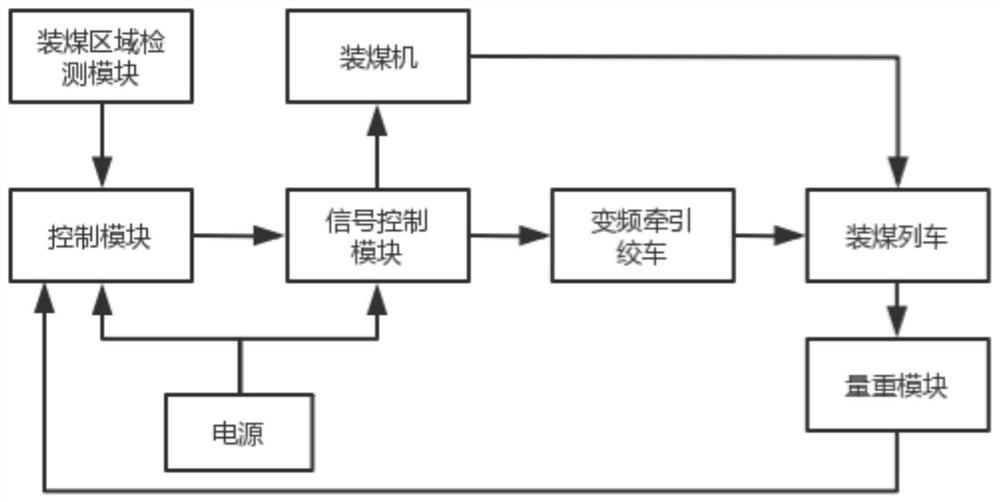

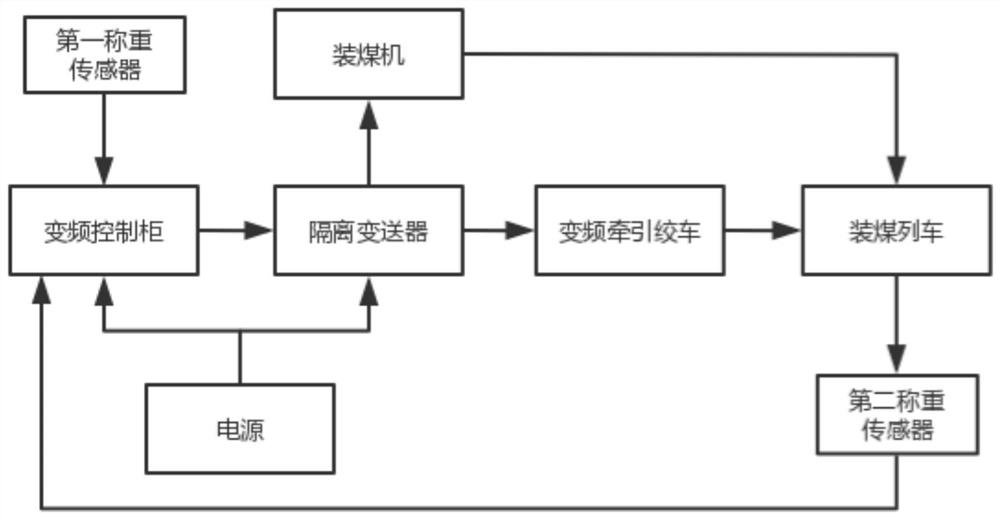

[0020] Example: figure 1 The shown automatic traction device for a coal-charging train includes a coal-charging train and a coal-charging machine located in a coal-charging area, and is characterized in that it includes a frequency-variable traction winch for pulling the coal-loading train, a control module for a variable-frequency traction winch, and a control module. The signal module, the coal loading area detection module and the weighing module of the coal loading train for detecting whether the coal loading train is located in the coal loading area, the signal output end of the coal loading area detection module is connected with the signal input end of the control module, and the signal of the control module The output end is respectively connected to the signal input end of the frequency conversion traction winch and the coal loader through the control signal module, and the frequency conversion traction winch is fixedly connected with the coal loading train through the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com