Movable low-speed bench drill

A mobile, low-speed technology, applied in the field of mechanical processing, can solve the problems of large drilling resistance, poor drilling accuracy of magnetic base drills, poor mobility of bench drills and radial drills, etc., to achieve good mobility and high drilling accuracy Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

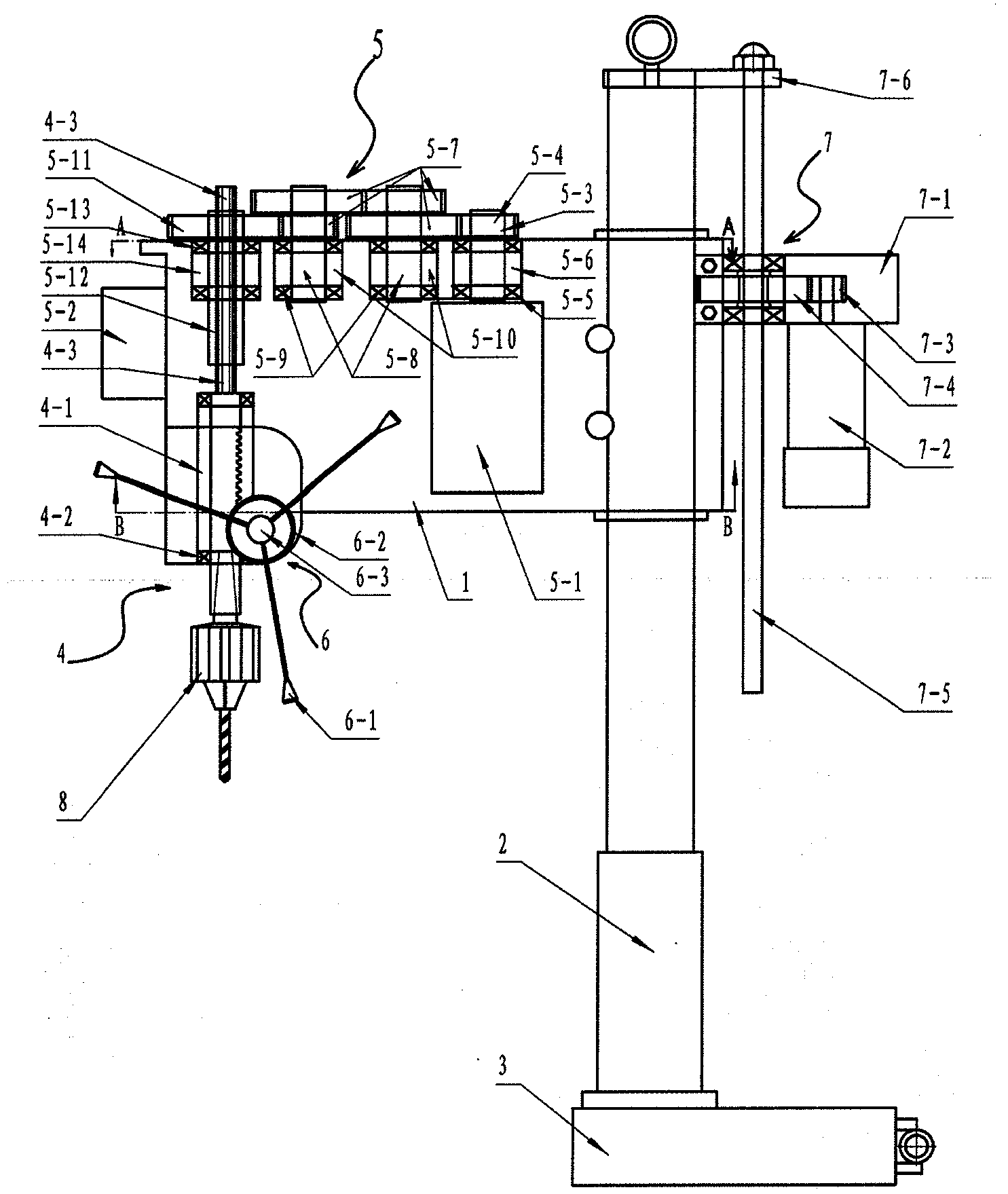

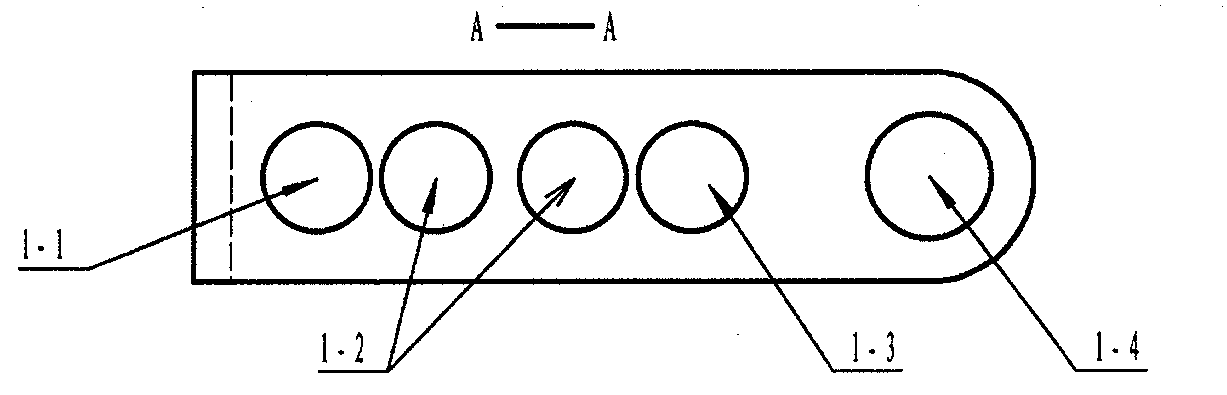

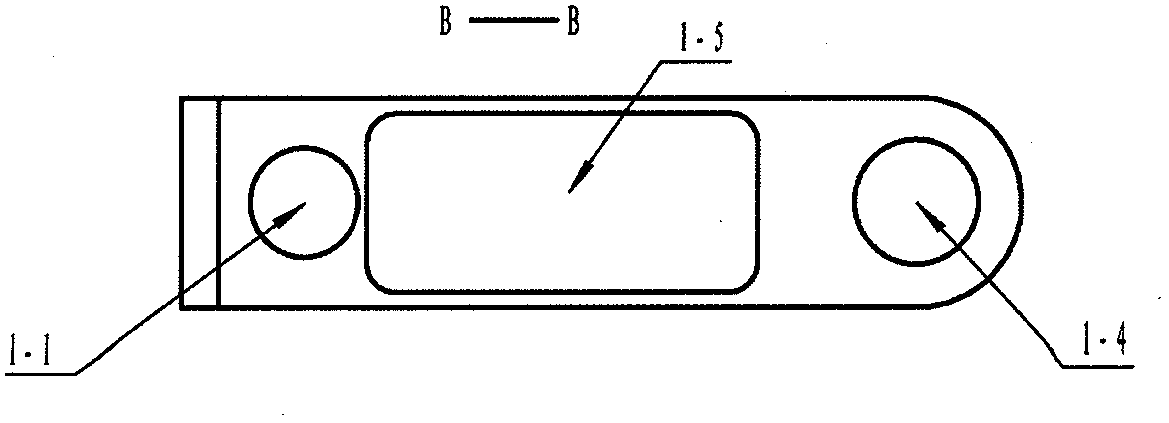

[0045] Below in conjunction with accompanying drawing, the present invention will be further described, as figure 1 one image 3 Shown: a mobile low-speed bench drill, including a drill body shell 1, a column 2, a magnetic base 3, a central drill rod device 4, a central drill rod drive reduction device 5, a central drill rod feeding device 6, and a drill body lifting device 7. Drill chuck 8; the center drill pipe device 4 includes: a center drill pipe guide column barrel 4-1 with a rack on the outer wall, a bearing 4-2, a center drill pipe 4-3, and the center drill The lower end of the rod 4-3 is provided with a Morse taper hole, and the upper end is provided with a spline shaft, and the central drill rod 4-3 is installed on the central drill rod guide cylinder 4- with a rack on the outer wall through the bearings 4-2 at both ends 1, an overall structure that moves up and down is formed; the central drill pipe feeding device 6 includes: a feed handle 6-1, a handle seat 6-2, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com