Integrated neon refrigerating machine and refrigerating method

An integrated and refrigerator technology, applied in the field of neon gas refrigerators and integrated neon gas refrigerators, can solve the problems of complex preparation process and low efficiency, and achieve the effect of solving heat dissipation problems and improving maintenance-free time.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be further described below in conjunction with the accompanying drawings, but the present invention is not limited to the following examples.

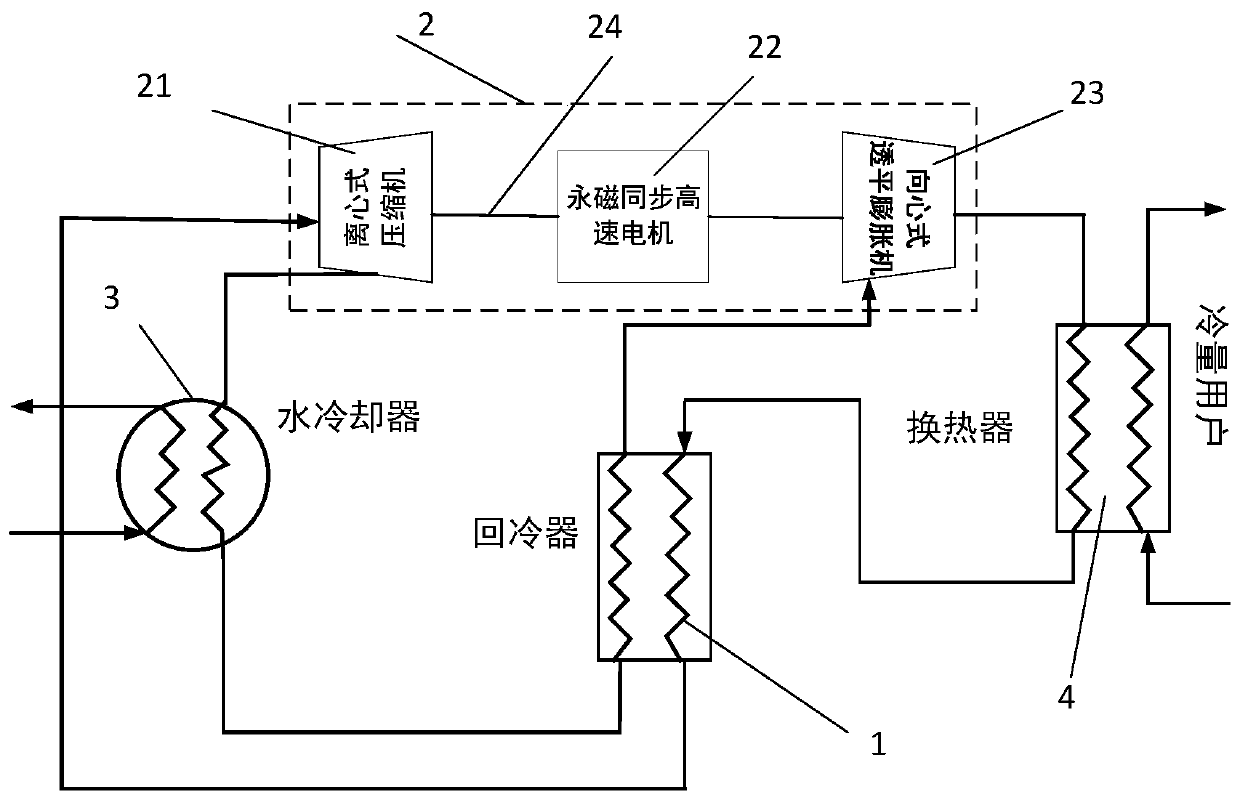

[0024] according to figure 1 The shown integrated neon gas refrigerator includes an expansion work recovery device 2, and the expansion work recovery device 2 includes a centrifugal compressor 21, a permanent magnet high-speed synchronous motor 22, and a radial turbo expander 23 And the main shaft 24; the recooler 1 for recovering cold capacity, the water cooler 3 for cooling the outlet gas temperature of the compressor, and the plate-fin heat exchanger 4 for exchanging cold capacity with users. In addition, the entire refrigerator also includes an auxiliary control system for data acquisition at system measurement points and monitoring system operation. The auxiliary control system is equipped with a touch screen, which is convenient for the operator to operate and monitor the operating status of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com