A roller feeding device for powder

A feeding device and rolling technology, applied in the field of powder rolling feeding device, can solve the problems of inconsistent distribution of silver powder, uneven feeding speed of silver powder, slag drop, etc., and achieve uniform feeding speed and reduce cost. The effect of spending and saving silver powder

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

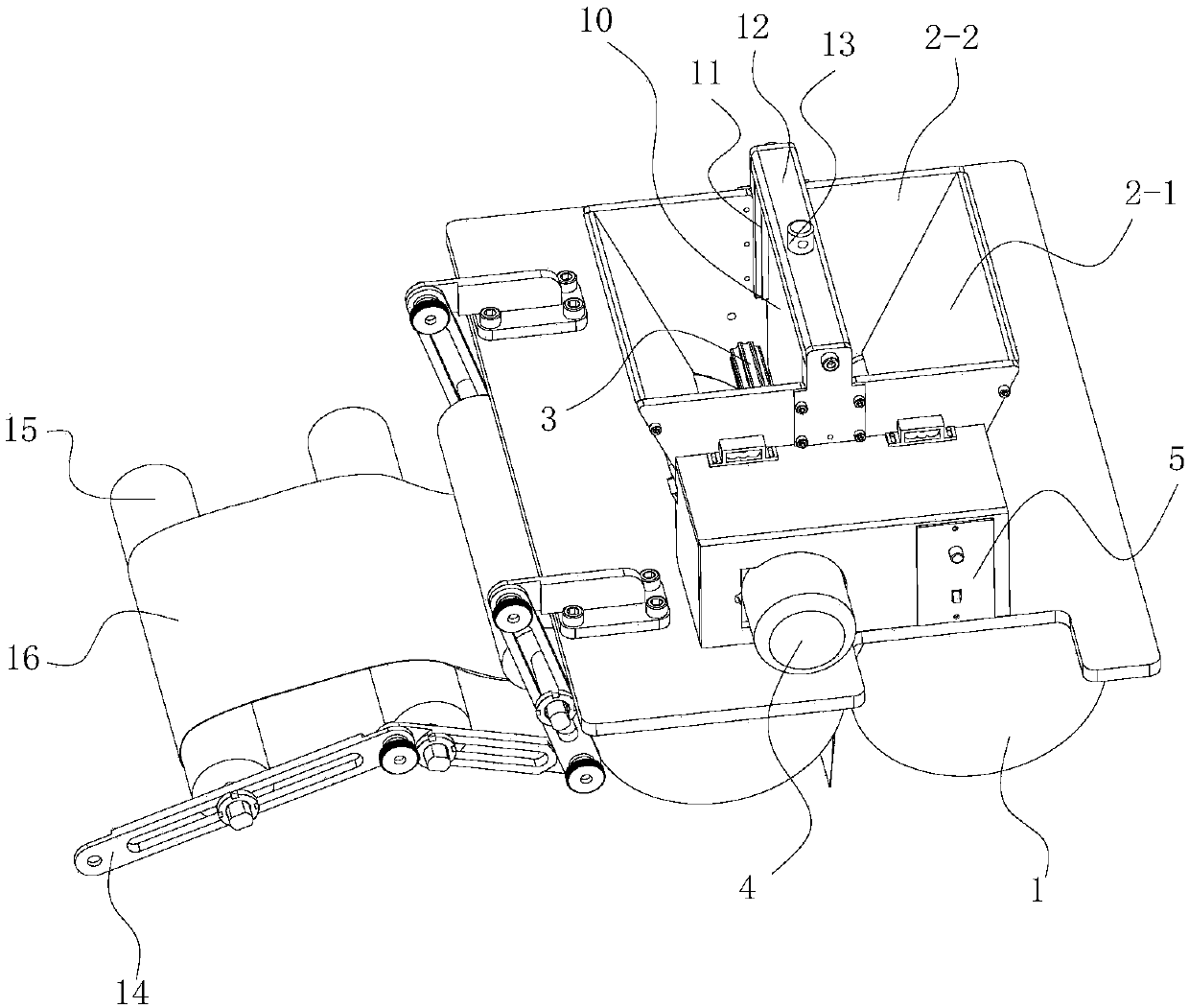

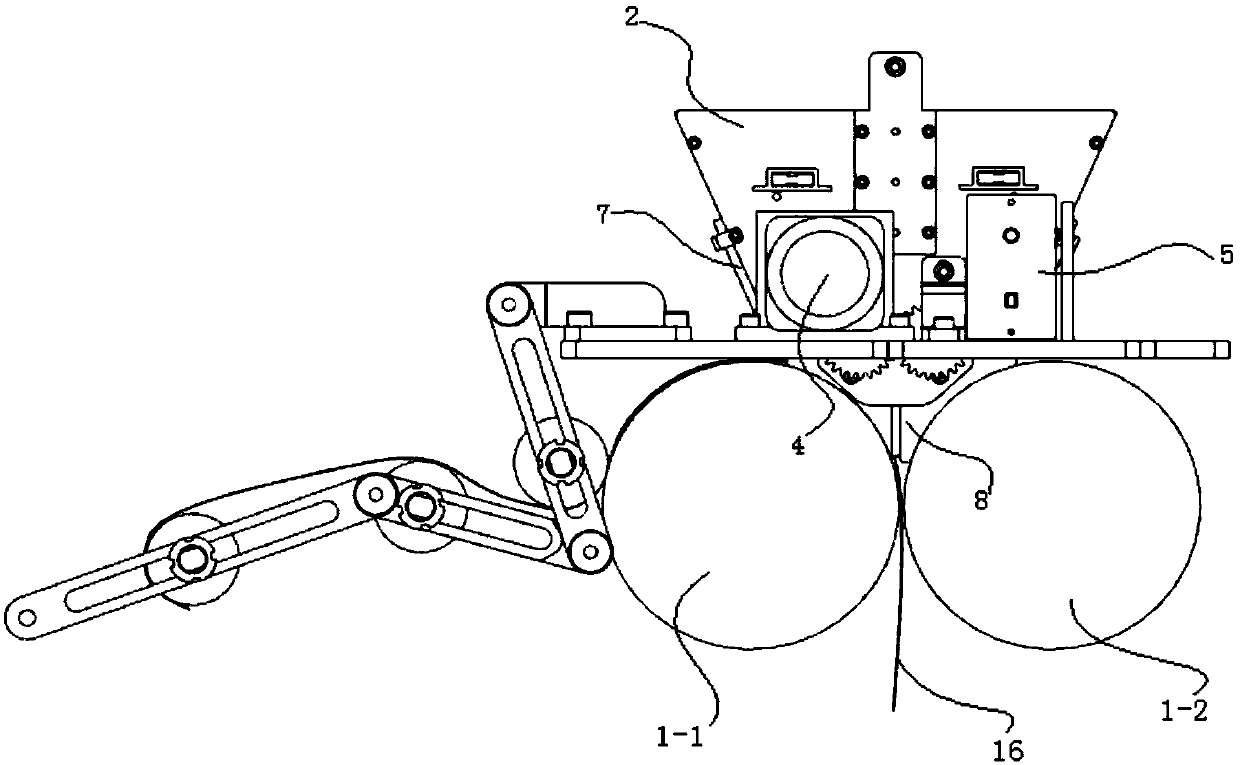

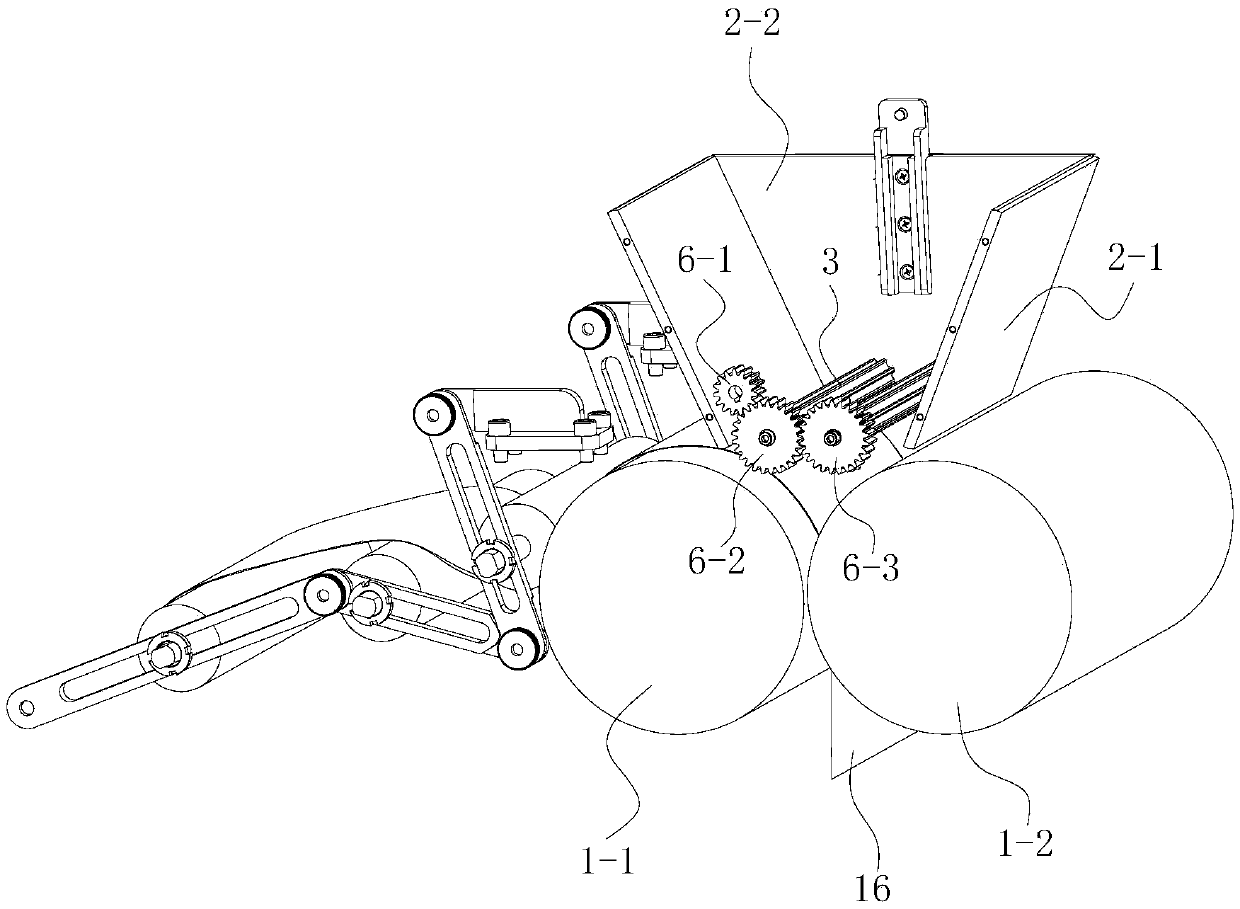

[0034] A rolling feeding device for powder, comprising a feeding hopper 2, the feeding hopper 2 is located directly above the two pressing rollers 1 of the rolling press; the two pressing rollers 1 are used for rolling on the rolling press The part of the silver stretch net 16 is driven to rotate by the roller press motor. These two pressing rollers 1 comprise the driving wheel pressing roller 1-1 of the side where the silver stretching net enters and the driven wheel pressing roller 1-2 that cooperates with the driving wheel pressing roller 1-1 to carry out rolling, and the driving wheel pressing roller 1-1 follows Clockwise rotation, driven wheel pressure roller 1-2 counterclockwise rotation. There is a certain gap between the driving wheel pressing roller 1-1 and the driven wheel pressing roller 1-2 according to the thickness of the silver expanded mesh 16 to be rolled. The position where the powder enters between the driving wheel pressing roller 1-1 and the driven wheel ...

Embodiment 2

[0041] Since there is a gap between the bottom of the feed hopper 2 and the pressure roller 1, after the powder is filled, the powder will leak. Therefore, the difference between the second embodiment of the present invention and the first embodiment is that: On the basis, the automatic anti-leakage powder structure design is added, and it can adapt to the positive roll pressure under any roll spacing, saving silver powder and reducing costs.

[0042]The automatic anti-leakage powder structure includes two axial baffles 7 arranged along the roller axis and a radial baffle 8 perpendicular to the roller axis; the two axial baffles 7 are attached to the axial On the outer side of the baffle plate 2-1, the axial baffle plate 7 can slide downwards along the positioning fixtures arranged on the left and right sides of the axial baffle plate 2-1 until it fits with the silver net 16; The baffle plate 7 is a metal plate such as an iron plate or a steel plate. When placing the silver n...

Embodiment 3

[0045] In order to conveniently adjust the feeding amount of the powder, and roll out positive electrodes with different thicknesses, the third embodiment of the present invention is based on the first or second embodiment, adding the thickness of the positive electrode according to the thickness of the positive electrode in the feeding hopper 2. Feed adjustment mechanism to adjust the size of powder feed.

[0046] The feed adjustment mechanism is arranged above the roller nip, and the feed adjustment mechanism includes a slide rail 11 arranged inside two radial baffle plates 2-2 and an adjustment plate 10 that slides up and down along the slide rail 11 ; Preferably, the slide rail 11 uses polytetrafluoroethylene with self-lubricating effect. The thickness of the adjusting plate 10 is equal to or slightly larger than the gap between the driving wheel pressing roller 1-1 and the driven wheel pressing roller 1-2, so as the adjusting plate 10 moves up or down, the powder that can...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com