Leftover material transmitting device for paper product processing

A technology of conveying device and scraps, applied in transportation and packaging, loading/unloading, grain handling, etc., can solve problems such as low work efficiency, easy pollution of workshop environment, loss of equipment, etc., and achieve the effect of easy observation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

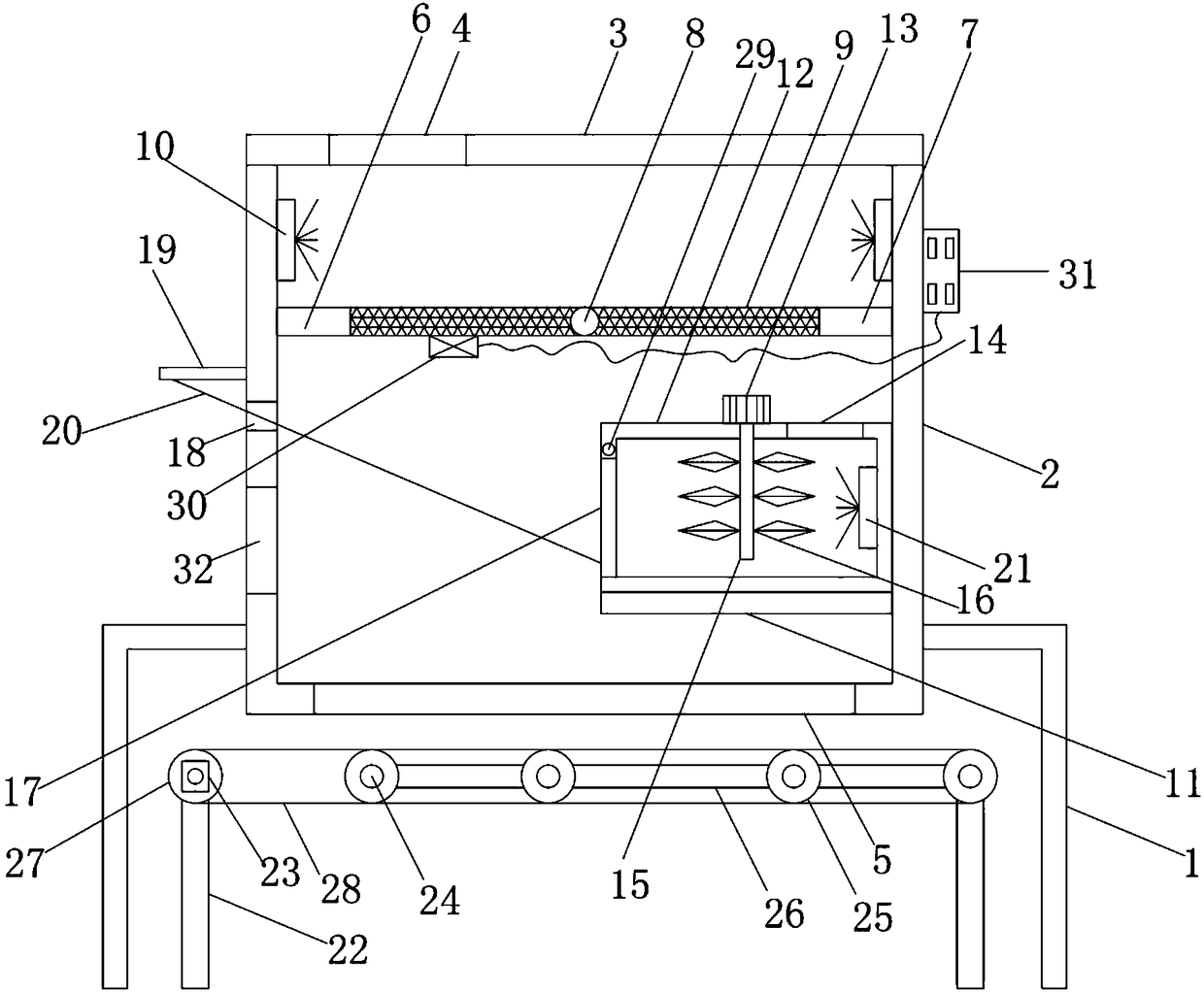

[0023] Such as figure 1 As shown, a scrap conveying device for paper product processing includes a support frame 1, a processing box 2 is provided on the support frame 1, and a box cover 3 is provided on the top surface of the processing box 2.

[0024] The top surface of the box cover 3 is provided with a feed port 4, the bottom surface of the processing box 2 is provided with a discharge port 5, and the inner side wall of the processing box 2 is provided with a first partition 6 and a second partition at the same height and parallel to each other. Partition 7, a round shaft 8 is installed on the side wall of the processing box 2, and a first screen 9 is mounted on the round shaft 8. The first screen 9 is located between the first partition 6 and the second partition 7 and A screen 9 is in contact with the first partition 6 and the second partition 7, and a first fan 10 located above the first screen 9 is installed on the left and right inner walls of the processing box 2. Ente...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com