An Air Buffer Device Used for Oil Pressure Dismounting of Conical Surface Interference Coupling

A buffer device and conical surface technology, which is applied in the direction of gas shock absorbers, springs, shock absorbers, etc., can solve the problems of tooling or ground damage, large vibration and noise, etc., and achieve extended service life, increased volume, and low vibration Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

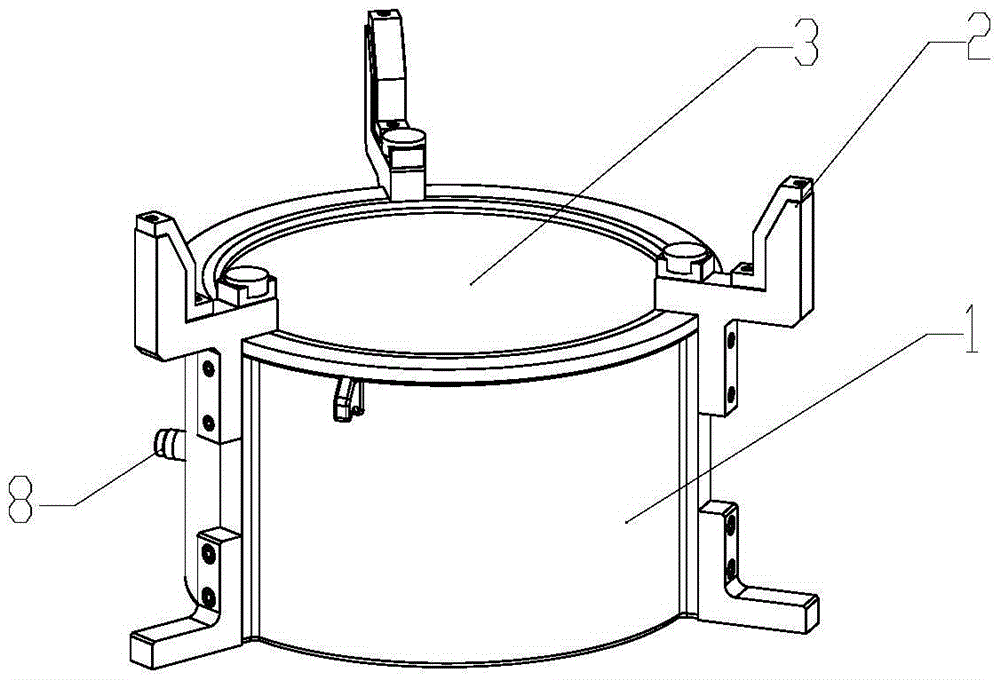

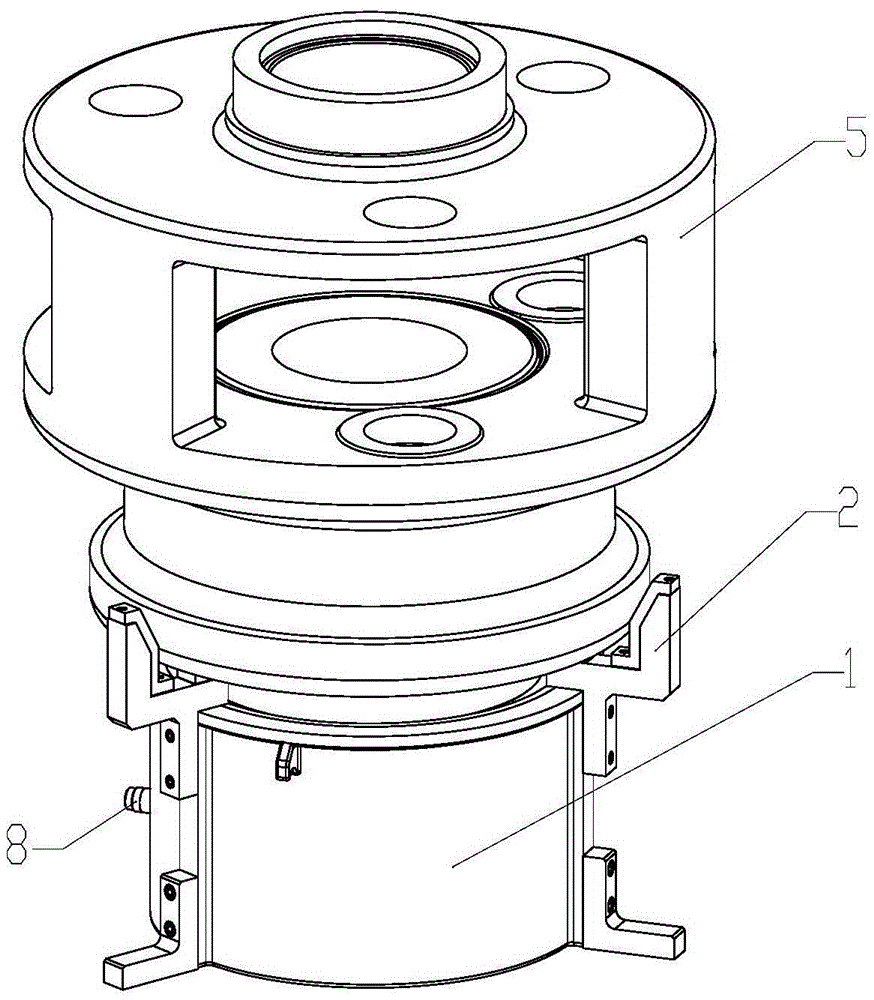

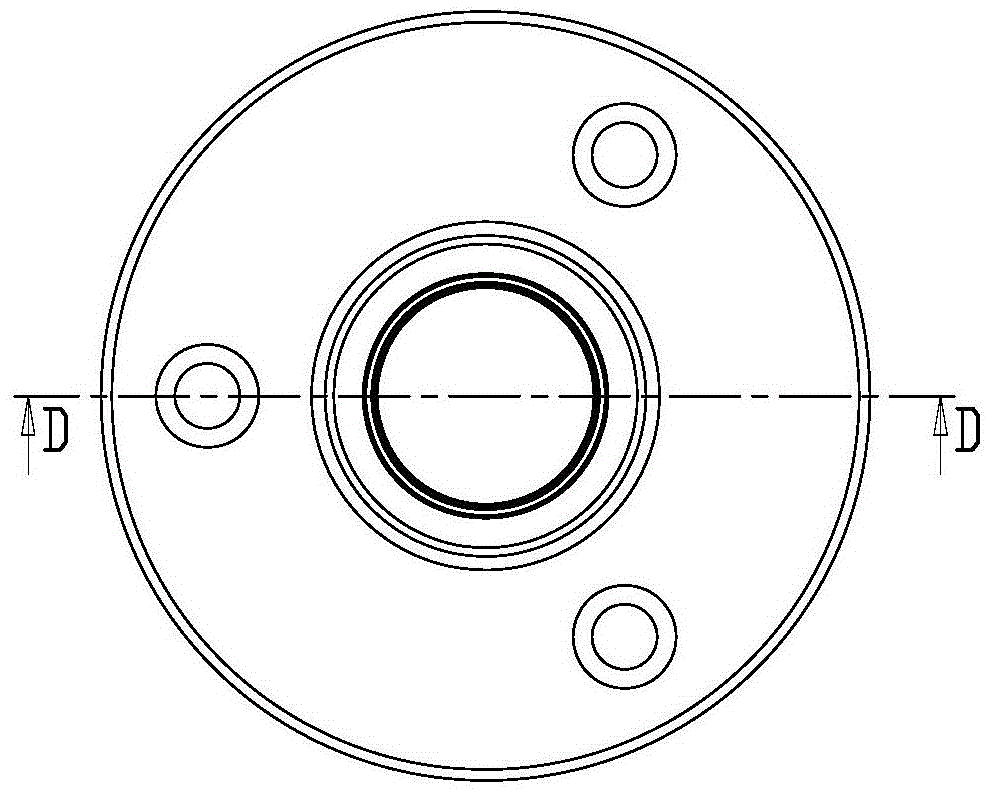

[0023] Such as Figure 1 to Figure 6 As shown, an air buffer device for oil pressure dismounting of the conical surface interference coupling, including a cylinder 1, a piston 3 arranged in the cylinder 1 and a spring 6 capable of restoring the piston 3, the spring 6 is at the same time There is a certain buffering effect during the disengagement process of the contained part. The piston 3 slides in the cylinder body 1 to form an air chamber 13 with the cylinder body 1. The spring 6 is arranged between the bottom of the cylinder body 1 and the piston 3. A throttling valve 8 is arranged on the side wall of the cylinder body outside the lower side of the stroke range of the piston 3, which acts as a buffer by throttling the air.

[0024] The side wall of the cylinder block 1 within the stroke range of the piston 3 is provided with an exhaust port 7, and the position of the exhaust port 7 determines the distance that the contained part and the containing part are quickly disengag...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com