Air cylinder cover mold spraying method capable of achieving uniform spraying

A technology of mold and cylinder, which is applied in the field of cylinder head mold spraying, can solve the problem of no fixture, etc., and achieve the effect of wide application range and uniform spraying

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

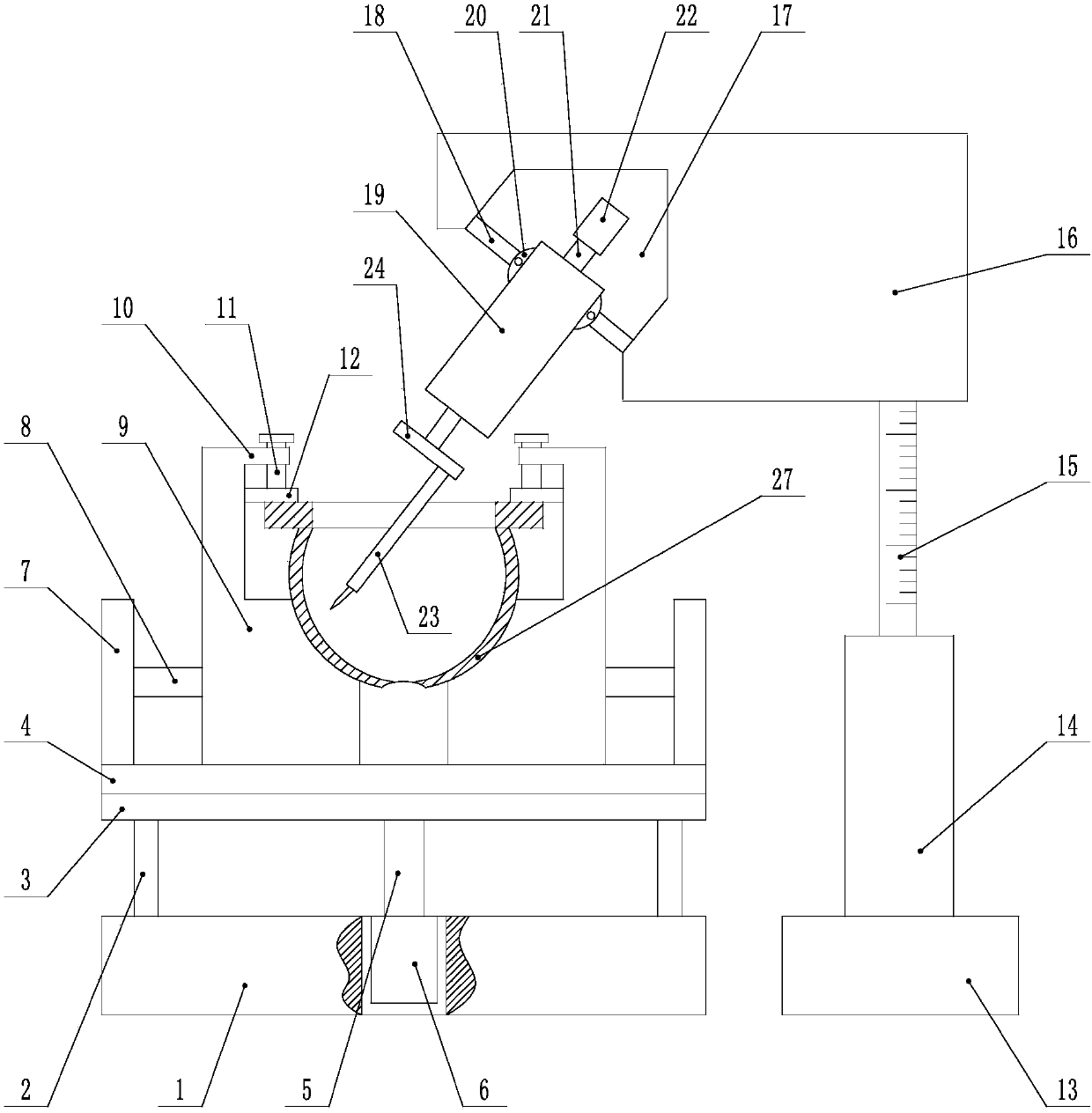

[0034] Such as figure 1 , figure 2 Shown, the cylinder head mold spraying method that the present invention can spray evenly comprises the following steps:

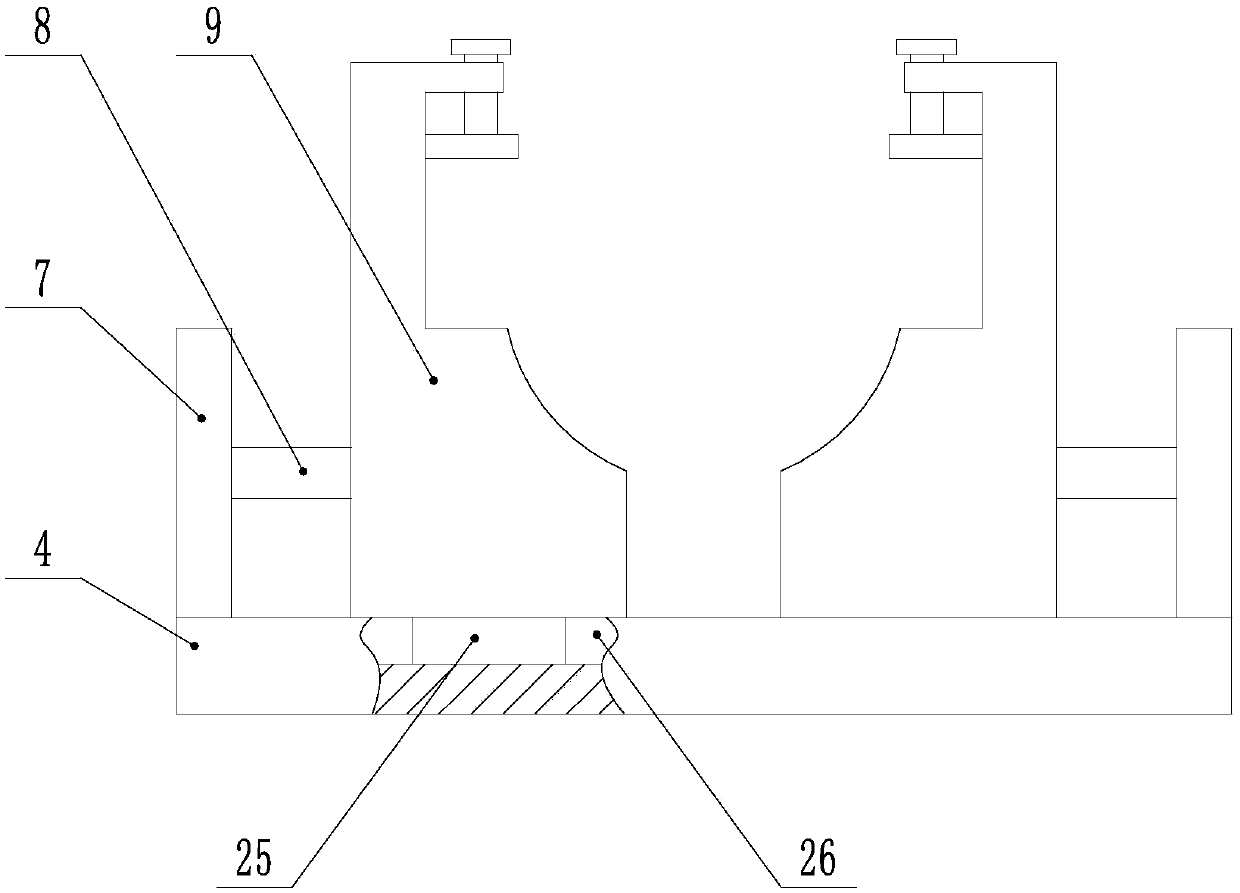

[0035] Step A: adjust the position of the sliding block 9 through the expansion and contraction of the hydraulic telescopic rod 8, and place the spherical mold 27 on the arc-shaped groove of the sliding block 9;

[0036] Step B: Rotate the screw rod 11, so that the pressing plate 12 fixes the spherical mold 27 on the sliding block 9;

[0037] Step C: adjust the height of the mounting seat 16 through the piston rod 15, adjust the angle of the nozzle 23 through the universal joint 20, and extend the nozzle 23 into the inner concave surface of the spherical mold 27;

[0038] Step D: Turn on the first motor 6 to rotate the first rotating shaft 5, turn on the second motor 22 to rotate the second rotating shaft 21, turn on the pump, and make the nozzle 23 spray the inner concave surface of the spherical mold 27;

[0039] In...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com