Manufacturing apparatus of prefabricated rod for optical element blank, and method for manufacturing element blank

A technology for optical components and manufacturing devices, which is applied in the direction of manufacturing tools, glass manufacturing equipment, glass cutting devices, etc., can solve the problems of difficult reduction of manufacturing costs, low material utilization rate, and complicated equipment, so as to improve material utilization rate and save Effects of processing steps and small diameter tolerances

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

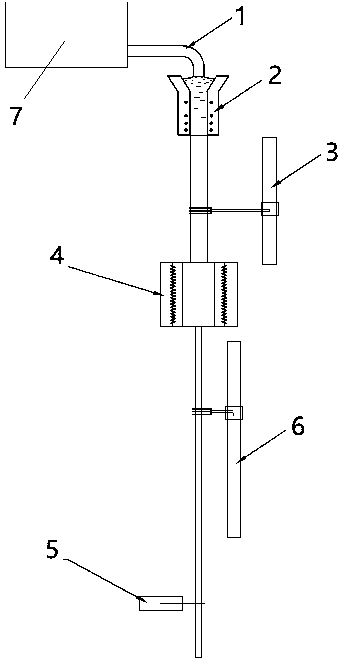

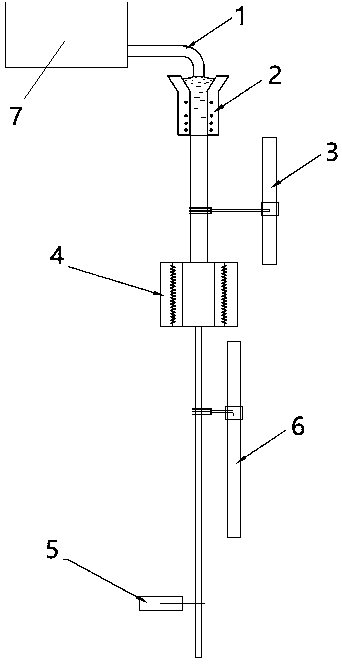

[0022] Example figure 1 shown. The device for manufacturing a preform for an optical element blank provided by the present invention includes a molding die 2 , a first drawing device 3 , a heating device 4 , a second drawing device 6 and a cutting device 5 . Wherein, the first drawing device 3 is located below the molding die 2, and the molding die 2 has a local cooling mechanism, a heating mechanism, and a temperature control device thereof, and the first drawing device 3 is equipped with a grip that can firmly hold the glass rod. device, power equipment and speed adjustment equipment, the molten glass is hardened and shaped into a solid round thick rod with a diameter of 25~45mm after passing through the mold. The heating device 4 is located below the first drawing device 3, and the heating elements of the heating device 4 are evenly distributed alo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com