Winding machine and method for controlling the same

A technology for controlling coils and winding machines, applied in the direction of transportation and packaging, tension measurement, conveying filamentous materials, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

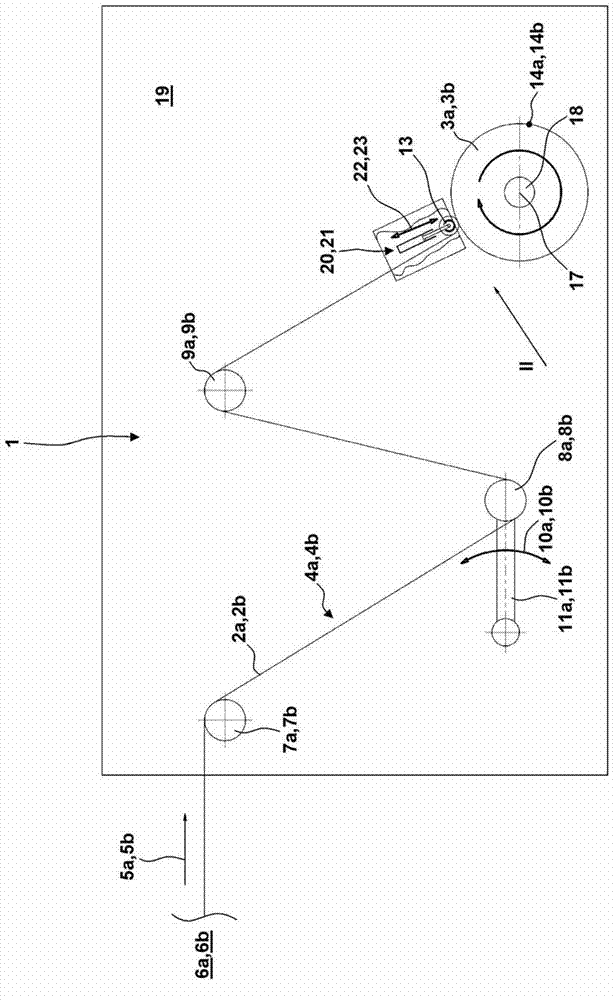

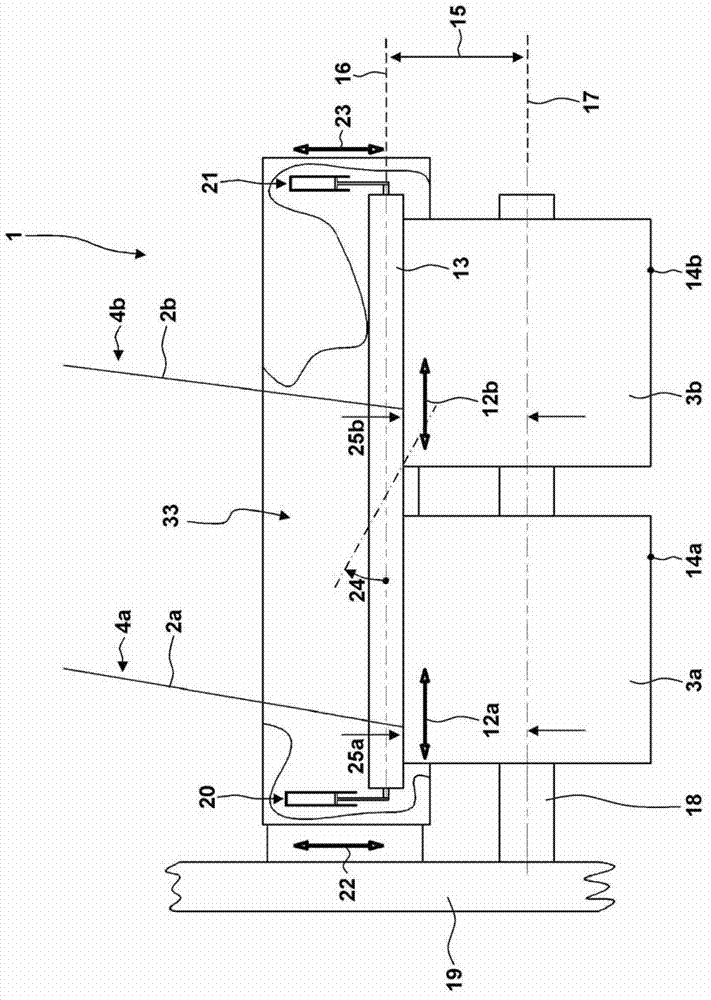

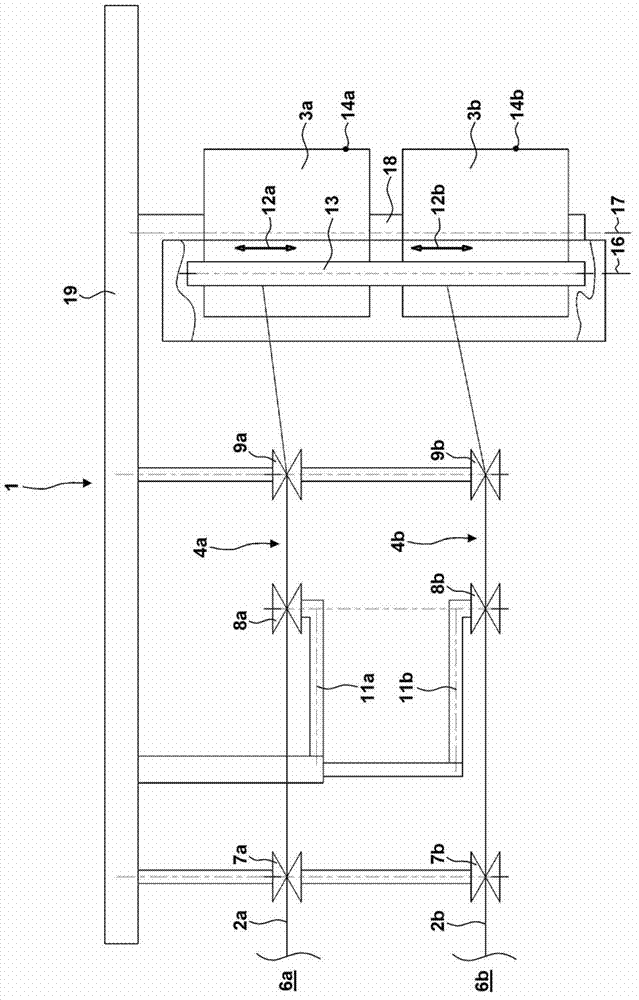

[0045] figure 1 A winder 1 is shown. as in figure 2 with 3 As seen in more detail in Winder 1, windings 2a, 2b are conveyed in parallel to mandrels 3a, 3b via input paths 4a, 4b which run perpendicular to figure 1 staggered in the direction of the drawing. Similar components in the supply path 4 a , 4 b are denoted in parts in the description with the same reference numerals and the additional letter a or b. Of course, it is also possible to use more than the two shown parallel input paths 4 a , 4 b on the winder 1 .

[0046] The path of the windings 2a, 2b through the feeding paths 4a, 4b is firstly explained below with the aid of the winding 2a via the feeding path 4a, wherein the same applies for the winding 2b in the parallel feeding path 4b:

[0047] The windings 2a leave a supply station 6, not shown in detail in the drawing, at a feed speed 5a, 5b. The winding 2 a is deflected in the direction of the movable dancer roller 8 a by means of the stationary first defl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com