Polar coordinate numerical control fused deposition rapid prototyping machine and its forming method

A technology of fused deposition and polar coordinates, applied in processing data acquisition/processing, manufacturing tools, coating devices, etc., can solve problems such as difficulty in maintaining consistency of extruded materials, uneven running speed of nozzles, troublesome operation, etc., to achieve Ingenious structural design, shortened molding cycle, and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

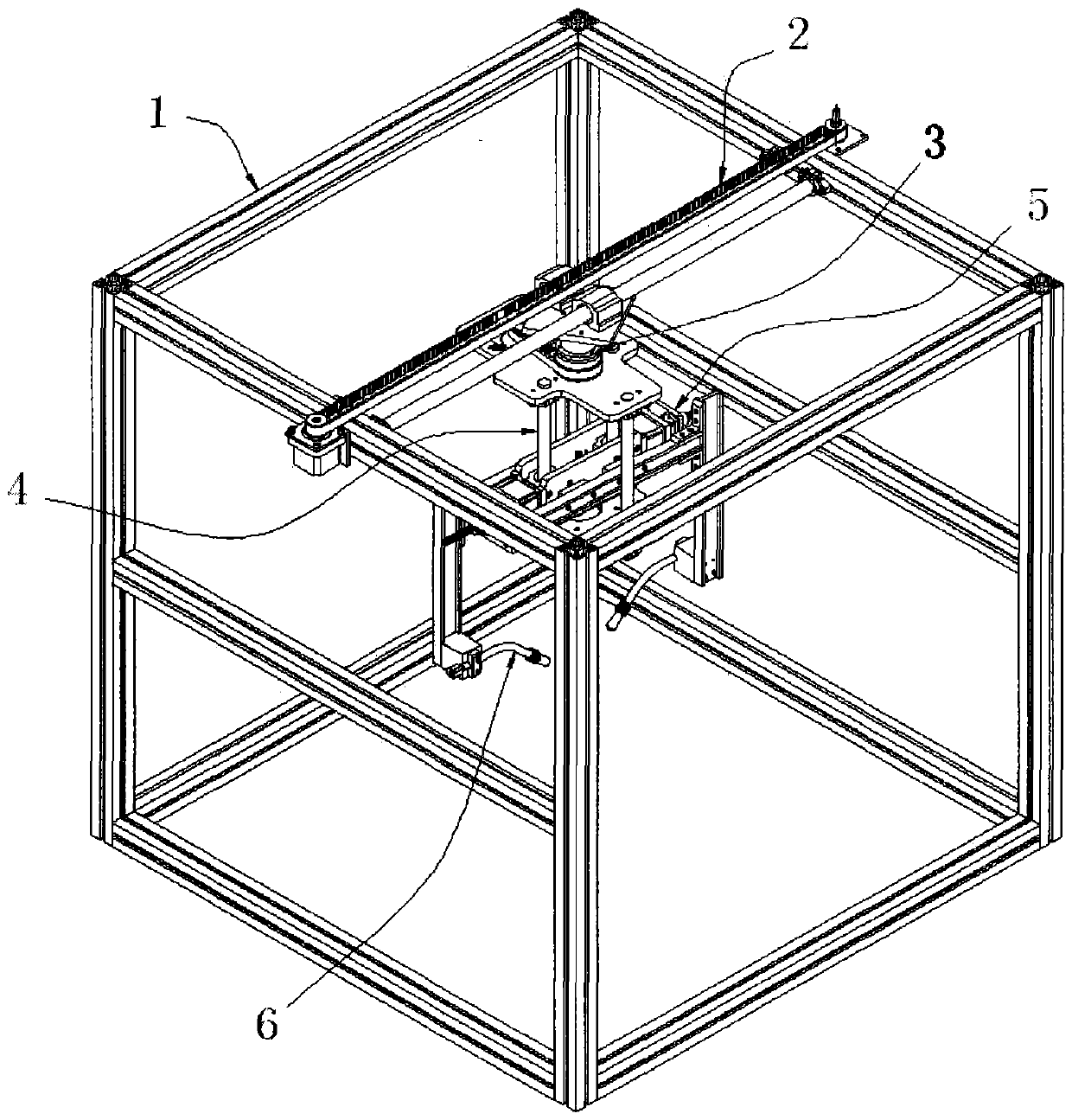

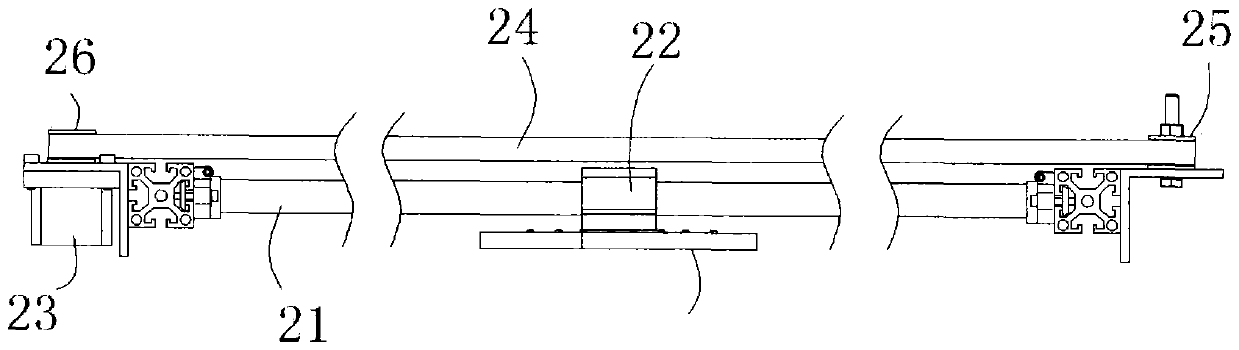

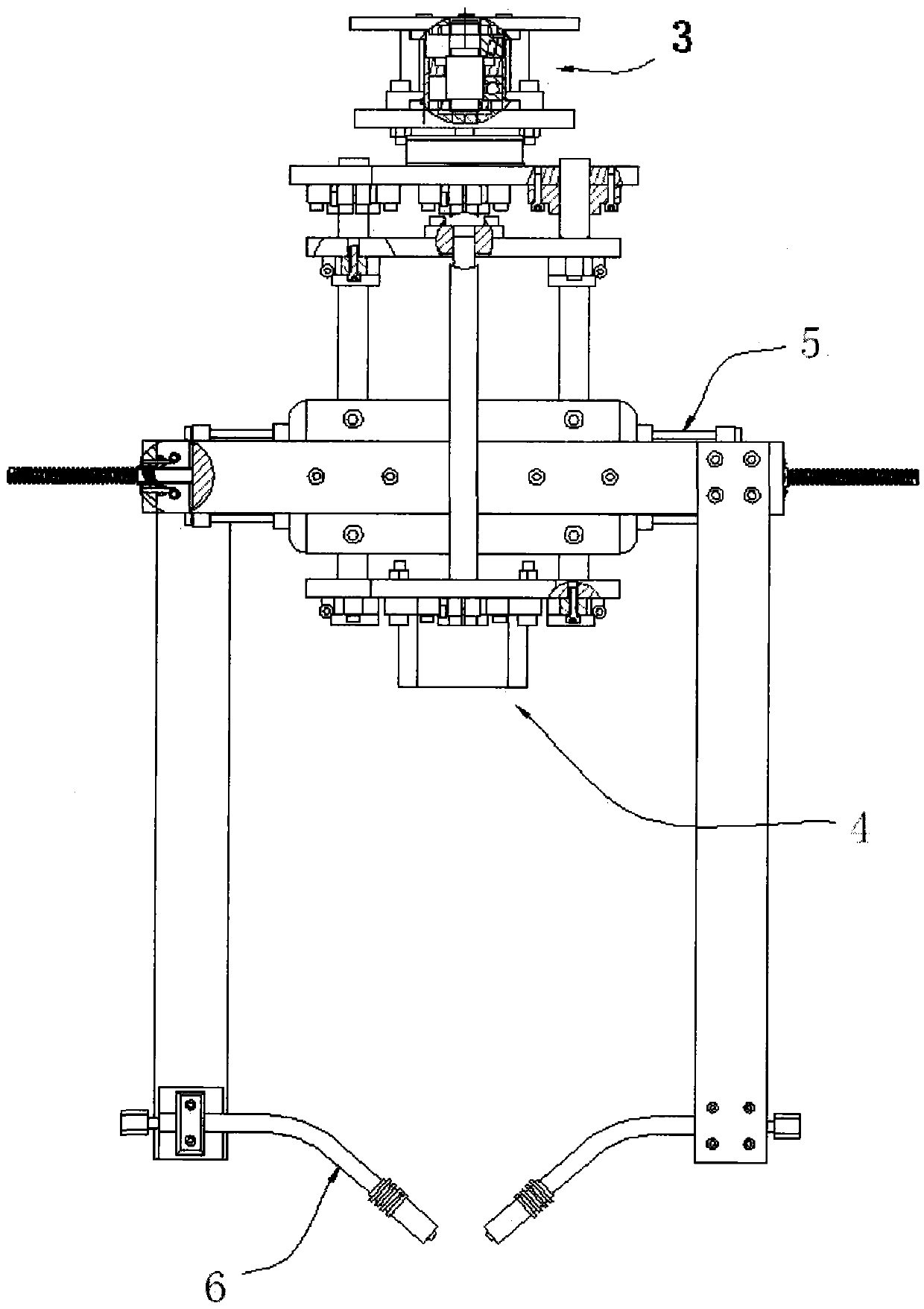

[0031] see Figure 1 to Figure 6 , a polar coordinate numerical control fused deposition rapid prototyping machine provided in this embodiment, which includes a support frame 1, a lateral movement device 2, a rotary device 3, a lifting device 4, a lateral adjustment device 5 and an extrusion nozzle 6, the lateral movement The device 2 is arranged laterally on the support frame 1, the slewing device 3 is arranged on the slewing device 2, and is driven by the slewing device 2 to move laterally, and the lifting device 4 is arranged on the slewing device 3, Driven by the rotary device 3, the horizontal adjustment device 5 is arranged on the lifting device 4, and is driven by the lifting device 4 to move up and down relative to the horizontal adjustment device 5. The extrusion nozzle 6 is arranged on the On the horizontal adjustment device 5, and driven by the horizontal adjustment device 5, it moves closer to or away from the rotation axis of the rotary device 3.

[0032] see fi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com