Full-automatic efficient sanding machine

A fully automatic, sanding machine technology, used in surface polishing machine tools, grinding frames, grinding drives, etc., can solve the problems of uneven grinding quality, uneven quality of finished products, low efficiency, etc. The effect of uniform, stable rotation speed and uniform feeding speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

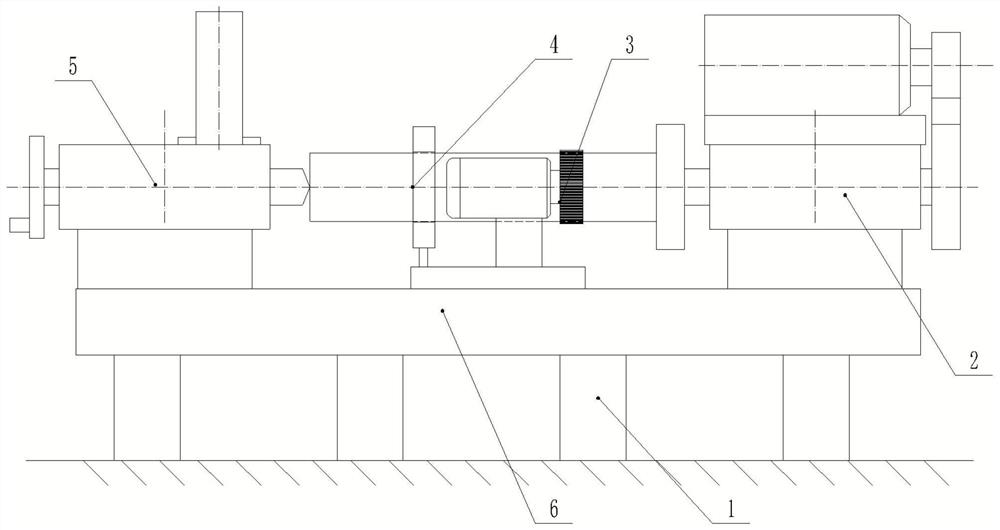

[0019] Below, the present invention will be further described in conjunction with the accompanying drawings and specific implementation methods. It should be noted that, under the premise of not conflicting, the various embodiments described below or the technical features can be combined arbitrarily to form new embodiments. .

[0020] Such as figure 1 As shown, the fully automatic high-efficiency sanding machine includes a track 6 arranged on the frame 1, and the track 6 is provided with a clamping part and a sanding part sliding along the track 6, and the clamping part includes a The fixed clamping assembly on the frame 1 and the dynamic clamping assembly 5 placed on the track 6 and sliding along the track 6, the metal rod is clamped between the fixed clamping assembly and the moving clamping assembly 5 , the fixed clamping assembly is driven to rotate by the first motor provided on the frame 1;

[0021] The sanding part is placed between the fixed clamping assembly and th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com