Fire extinguisher dry powder recycling processing system

A processing system and fire extinguisher technology, applied in drying, fire rescue, drying solid materials, etc., can solve problems such as dust and soil pollution, and achieve the effects of increasing service life, avoiding filter clogging, and uniform feeding speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

[0021] The subject of protection of the present invention and embodiment are as follows:

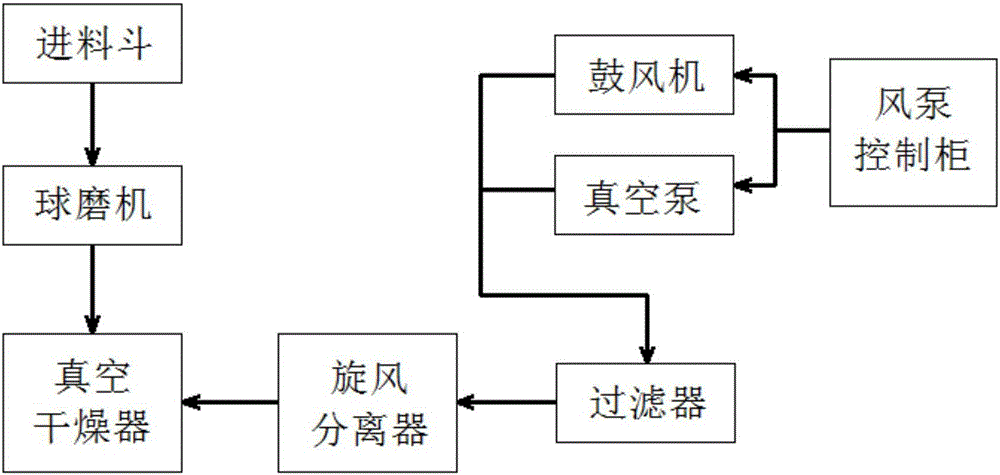

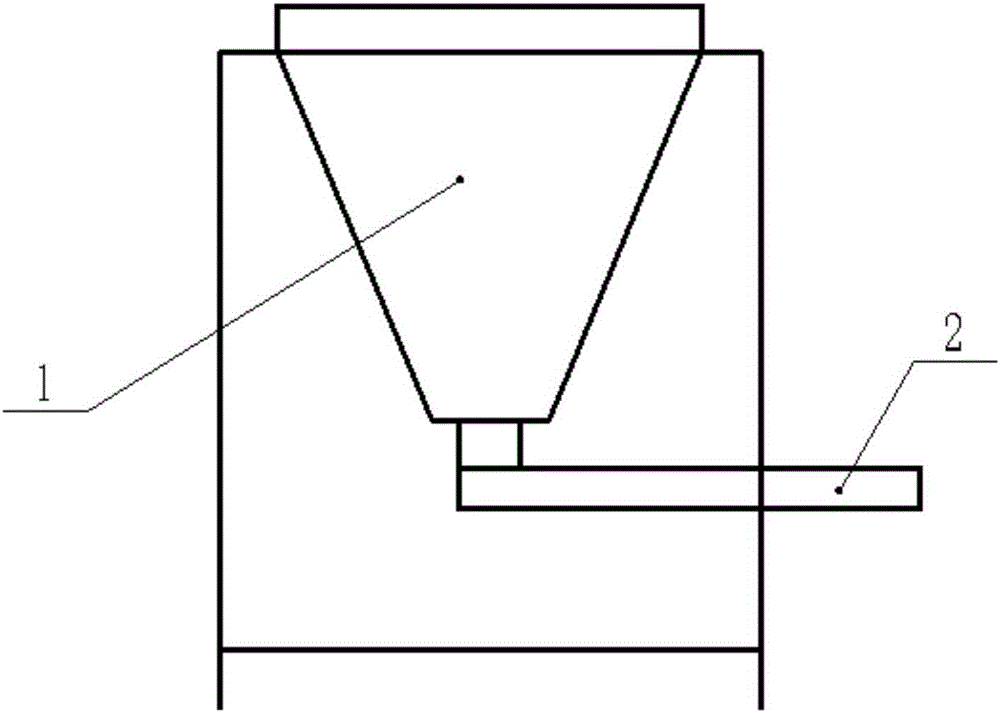

[0022] The fire extinguisher dry powder recycling processing system provided by the present invention includes a feed hopper 1, a ball mill, a vacuum dryer, an air pump control cabinet, a blower 25, a vacuum pump 24, a filter 23, and a cyclone separator 20, and its connection relationship is as follows: figure 1 As shown, the dry powder primary material enters the ball mill through the feeding hopper 1 for pulverization and refinement, and then enters the vacuum dryer for drying. At the same time, the air pump control cabinet controls the blower 25 and the vacuum pump 24 to suck the air in the processing system. The air in the processing system is discharged after being separated and filtered by the cyclone separator 20 and the filter 23 to form a vacuum environment required by the processing system.

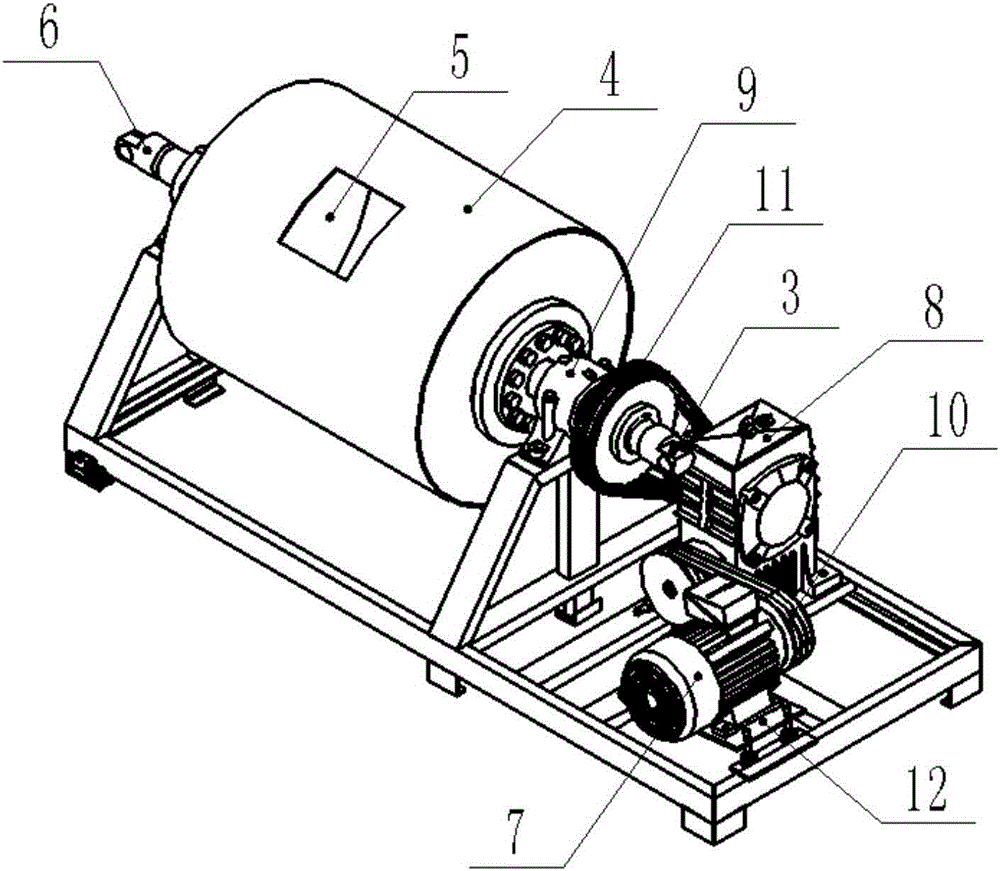

[0023] Such as image 3 As shown, the ball mill includes a feed joint 3, a vacuum joi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com