Single-cylinder multi-point hot runner system

A hot runner and multi-point technology, applied in the field of single-cylinder multi-point hot runner system, can solve the problems of poor blade rotation balance, affecting the overall structure of the fan blade, and unable to ensure synchronization, etc., to achieve high de-balancing requirements, uniform quality, The effect of uniform and fast feeding speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

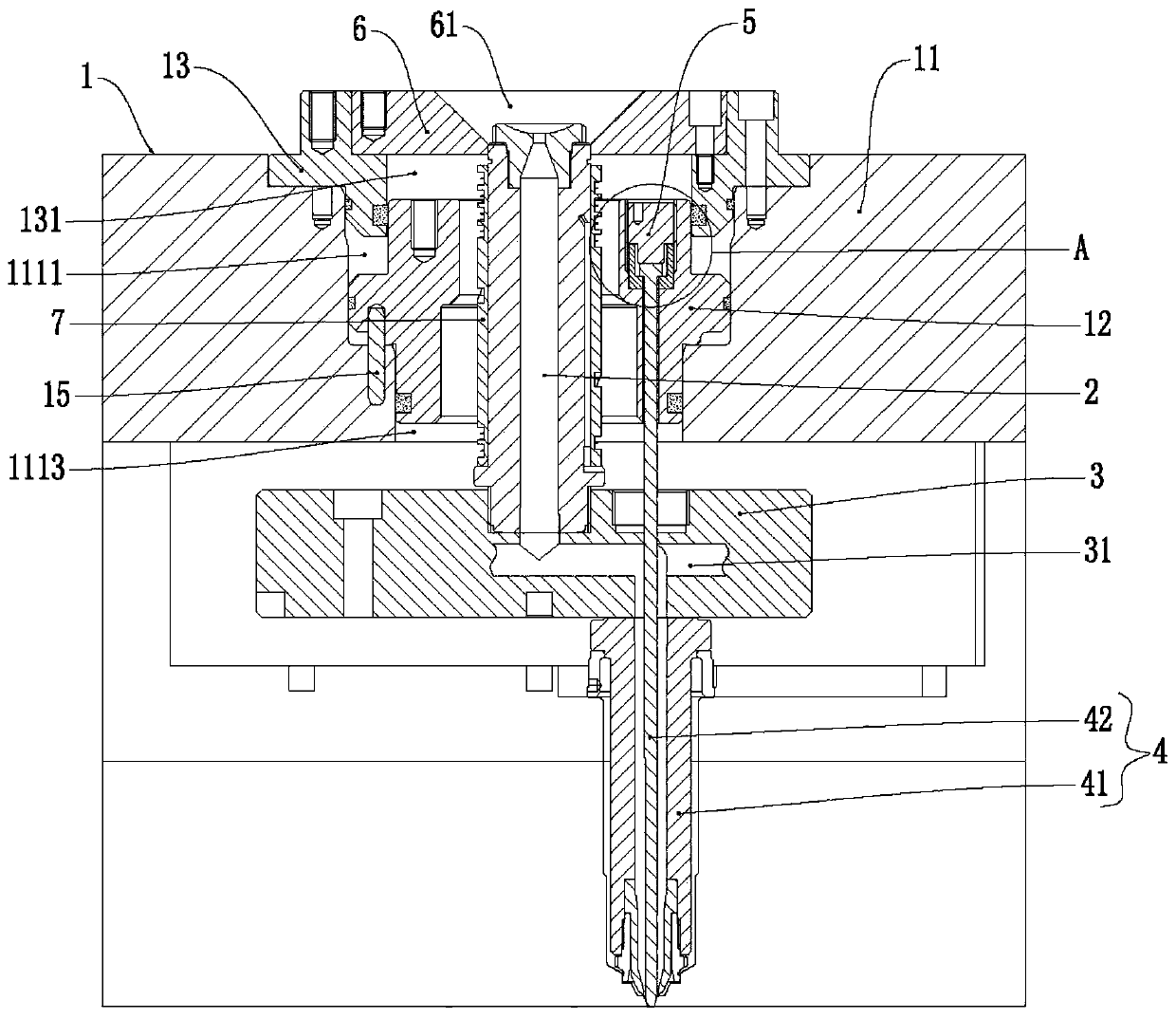

[0027] The technical solutions of the present invention will be further described below in conjunction with the accompanying drawings and through specific implementation methods.

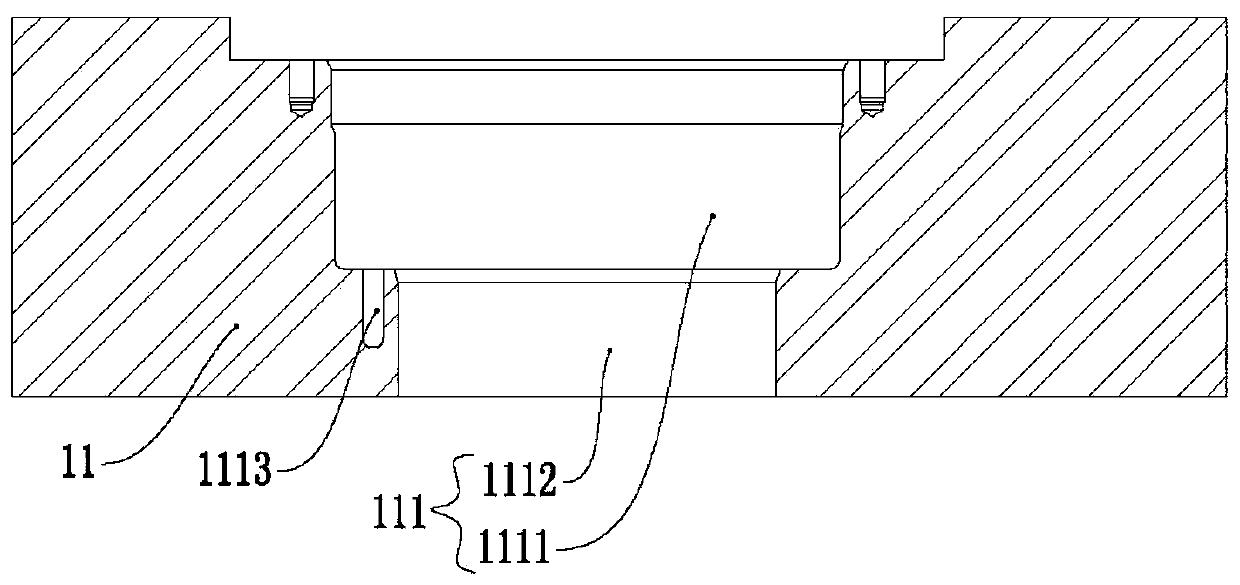

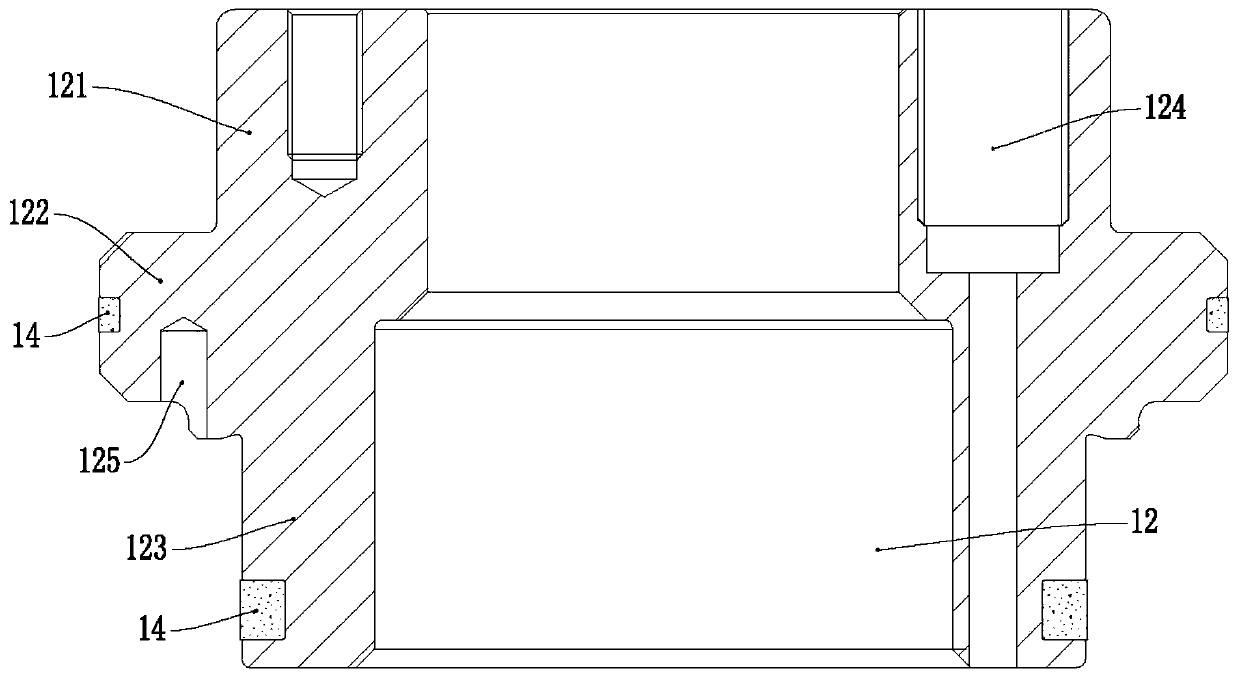

[0028] A single-cylinder multi-point hot runner system in this embodiment is used for injection molding of products with a circular or centrally symmetrical structure that diverges outward, such as figure 1 As shown, it includes an annular cylinder 1, a feed nozzle 2, a splitter plate 3 and a needle valve 4; the annular cylinder 1 includes a cylinder body 11, an annular piston 12, and an end cover 13, wherein:

[0029] A cavity 111 is provided inside the cylinder body 11, and the annular piston 12 is disposed in the cavity 111;

[0030] The annular piston 12 is slidingly fitted with the inner wall of the cavity, and the annular piston 12 divides the cavity into two upper and lower airtight air cavities;

[0031] The end cover 13 is provided at the opening of the cavity 111, and the end cover 13 is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com