Patents

Literature

66results about How to "Guarantee the quality of injection molding" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

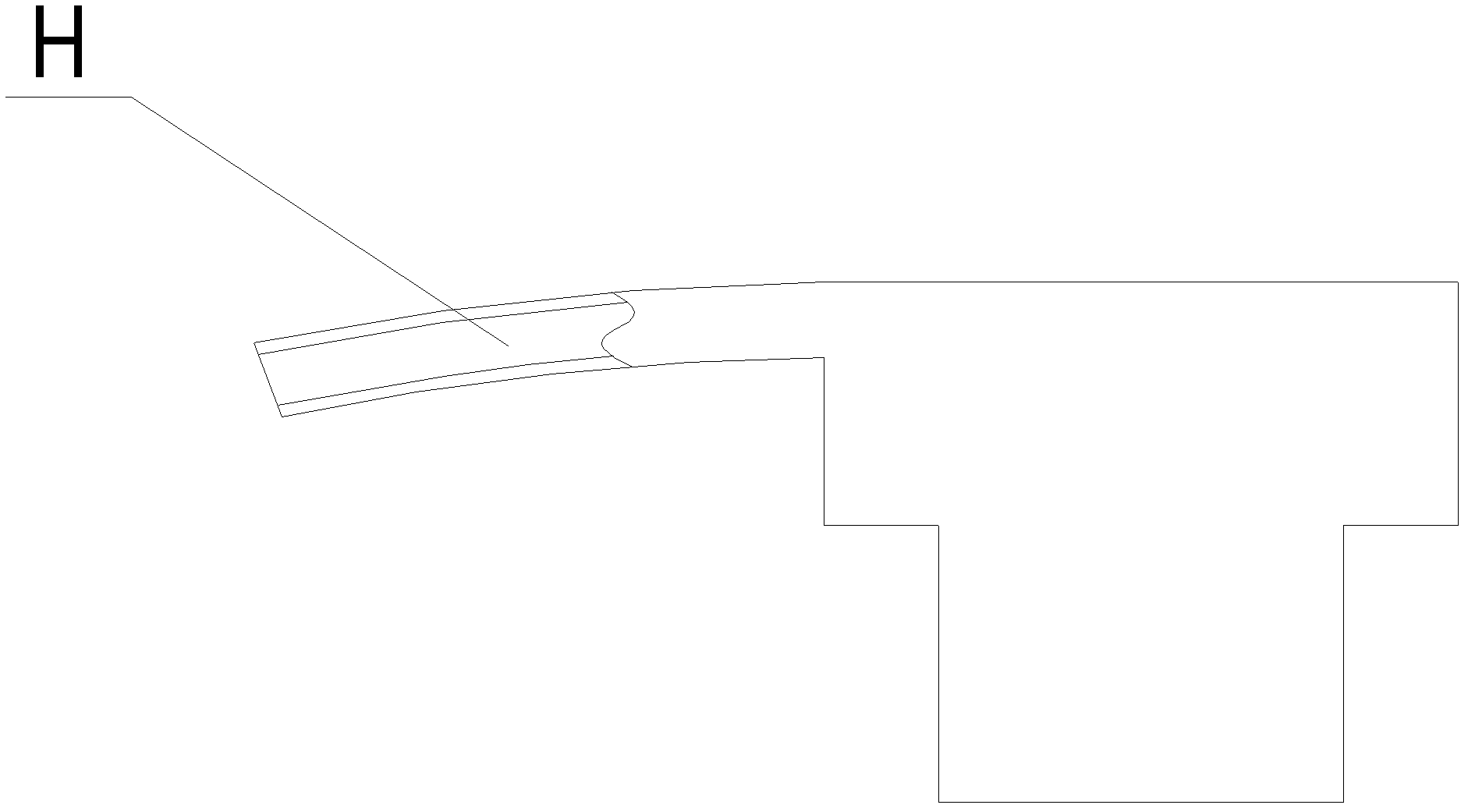

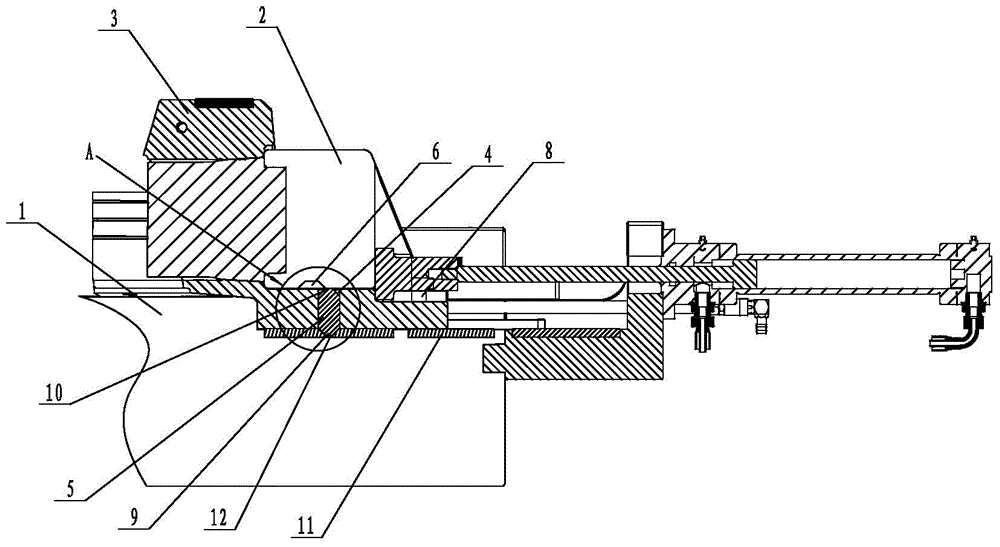

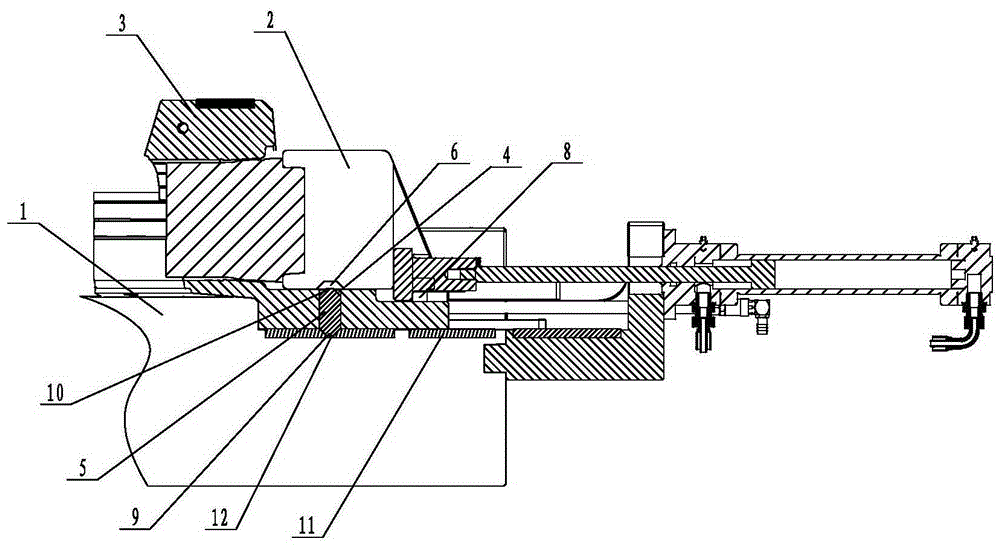

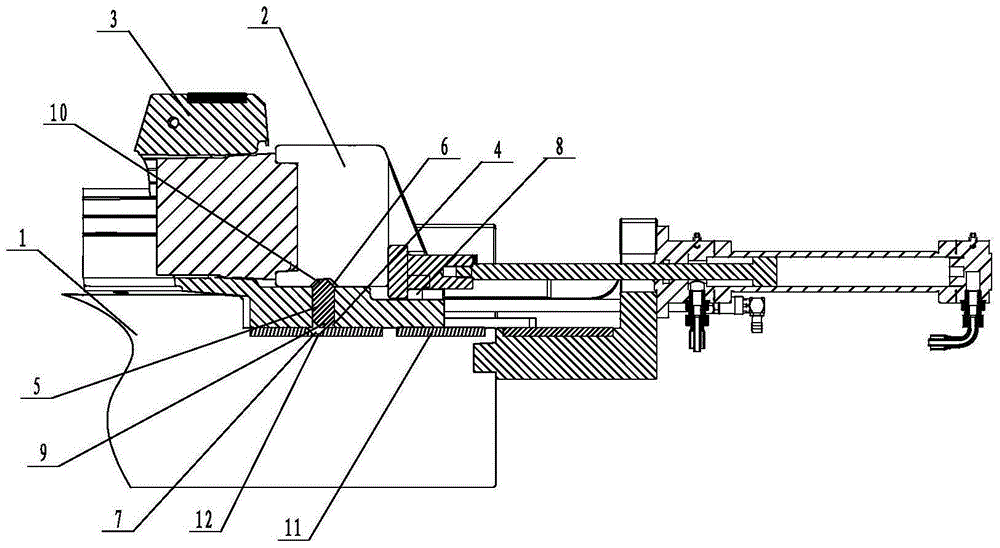

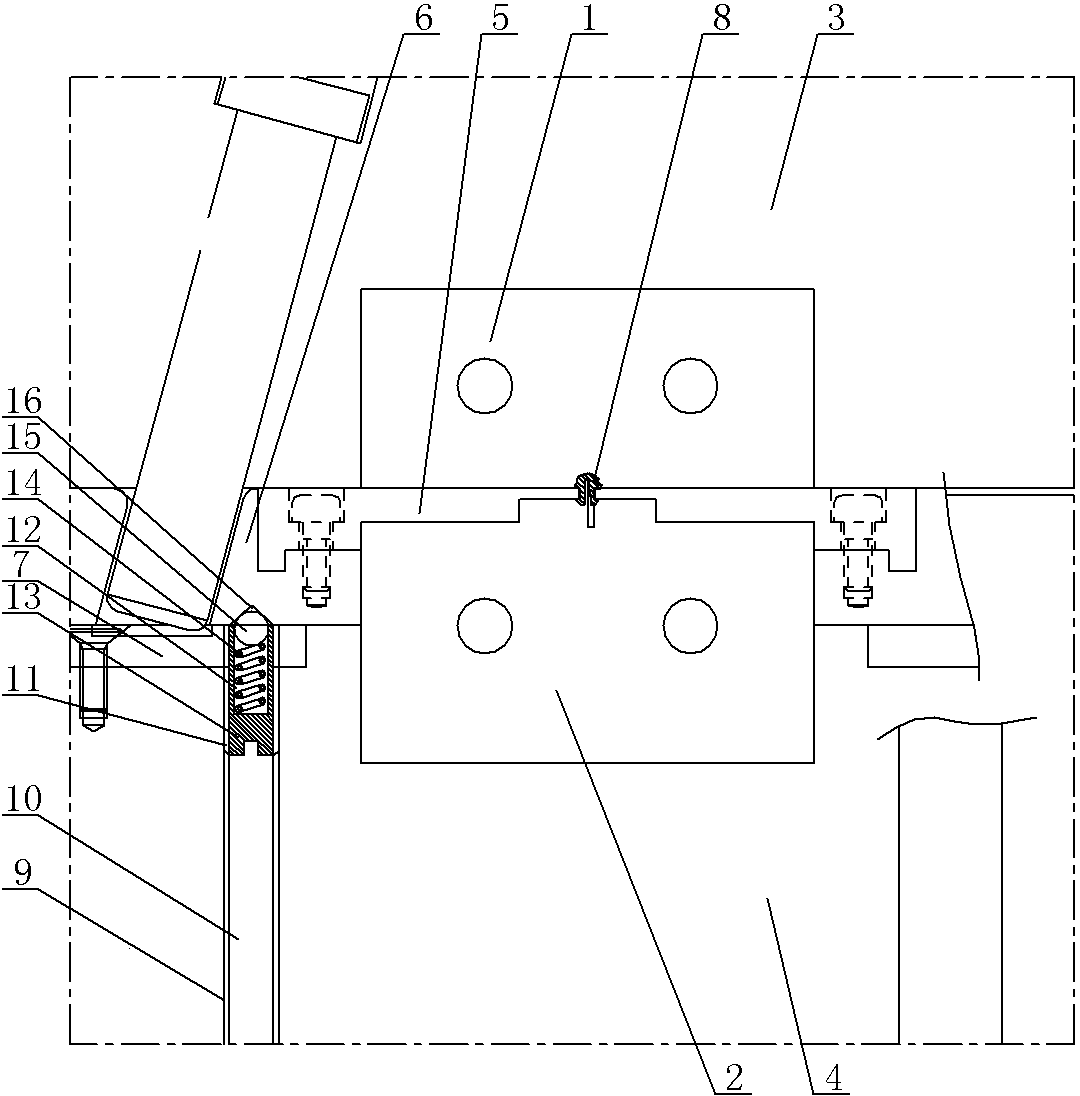

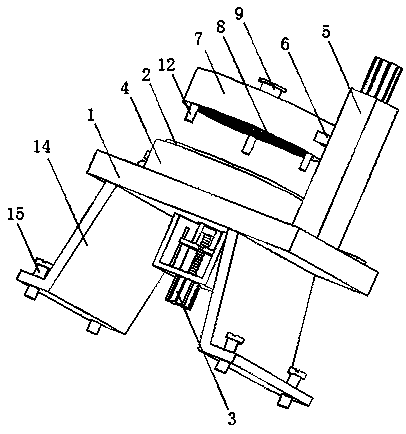

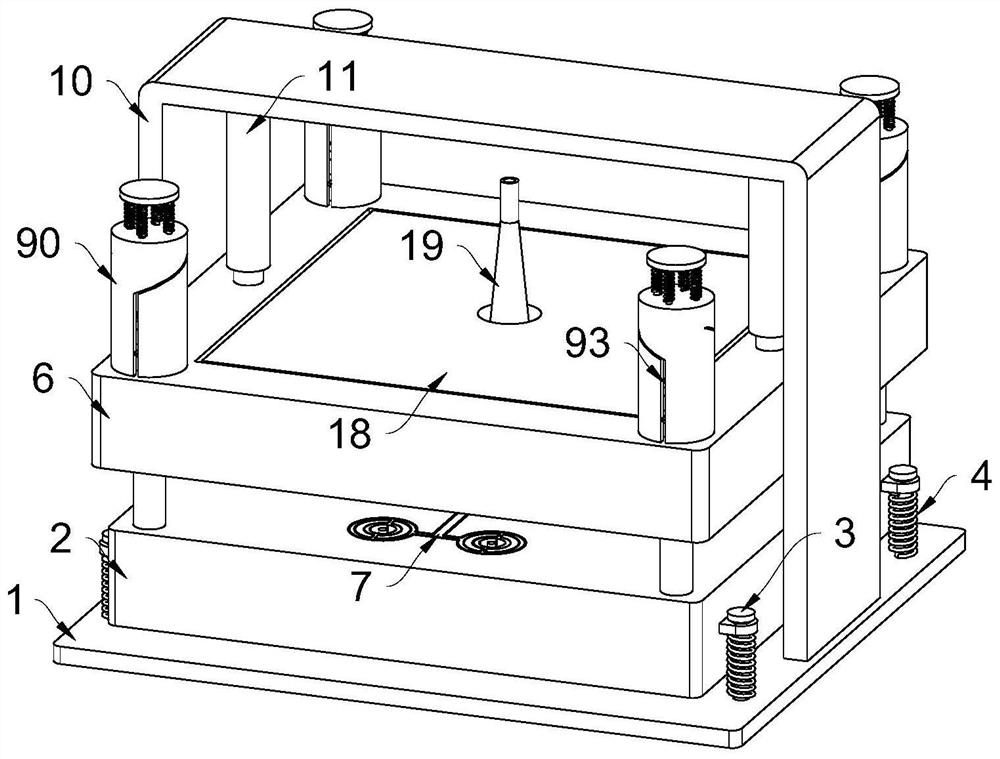

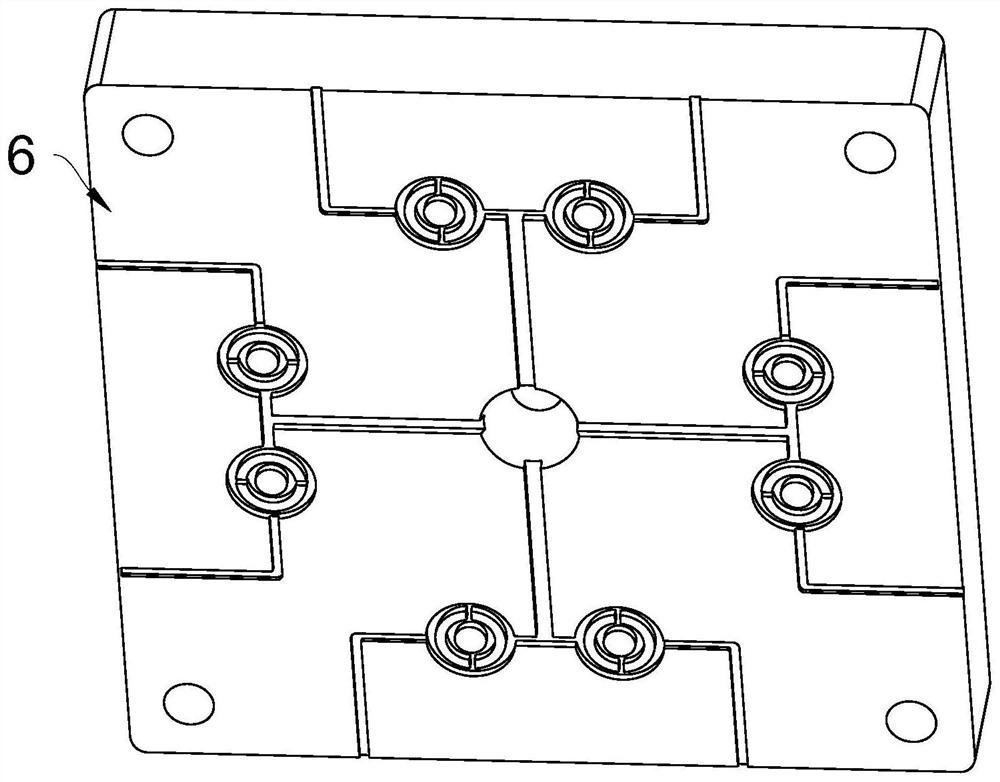

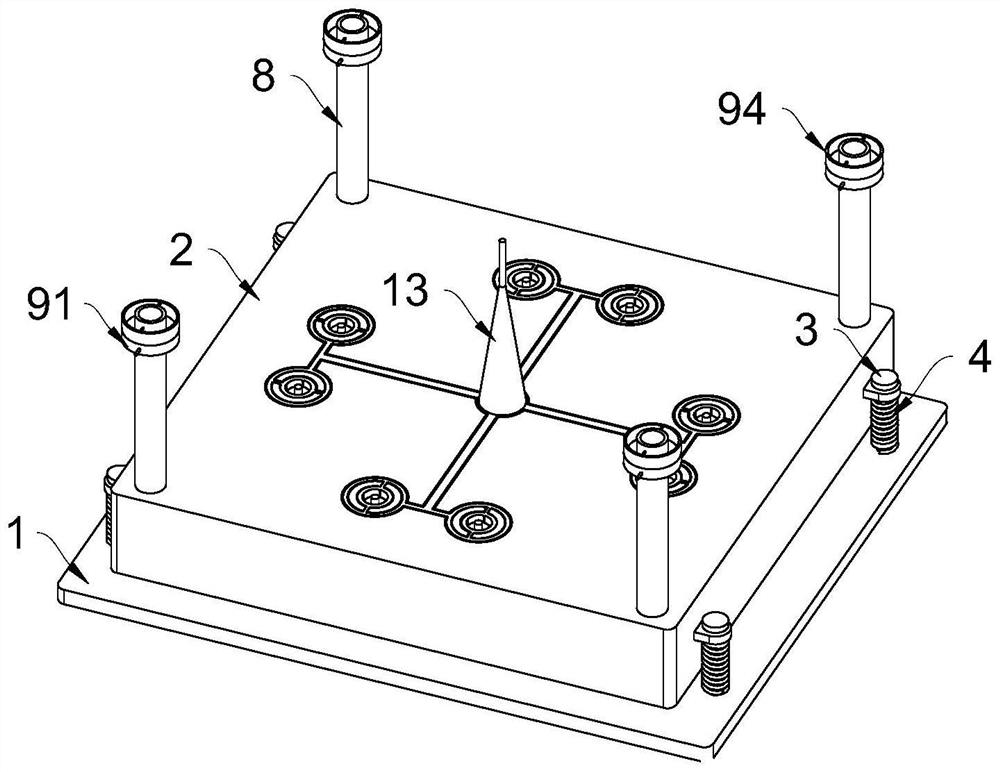

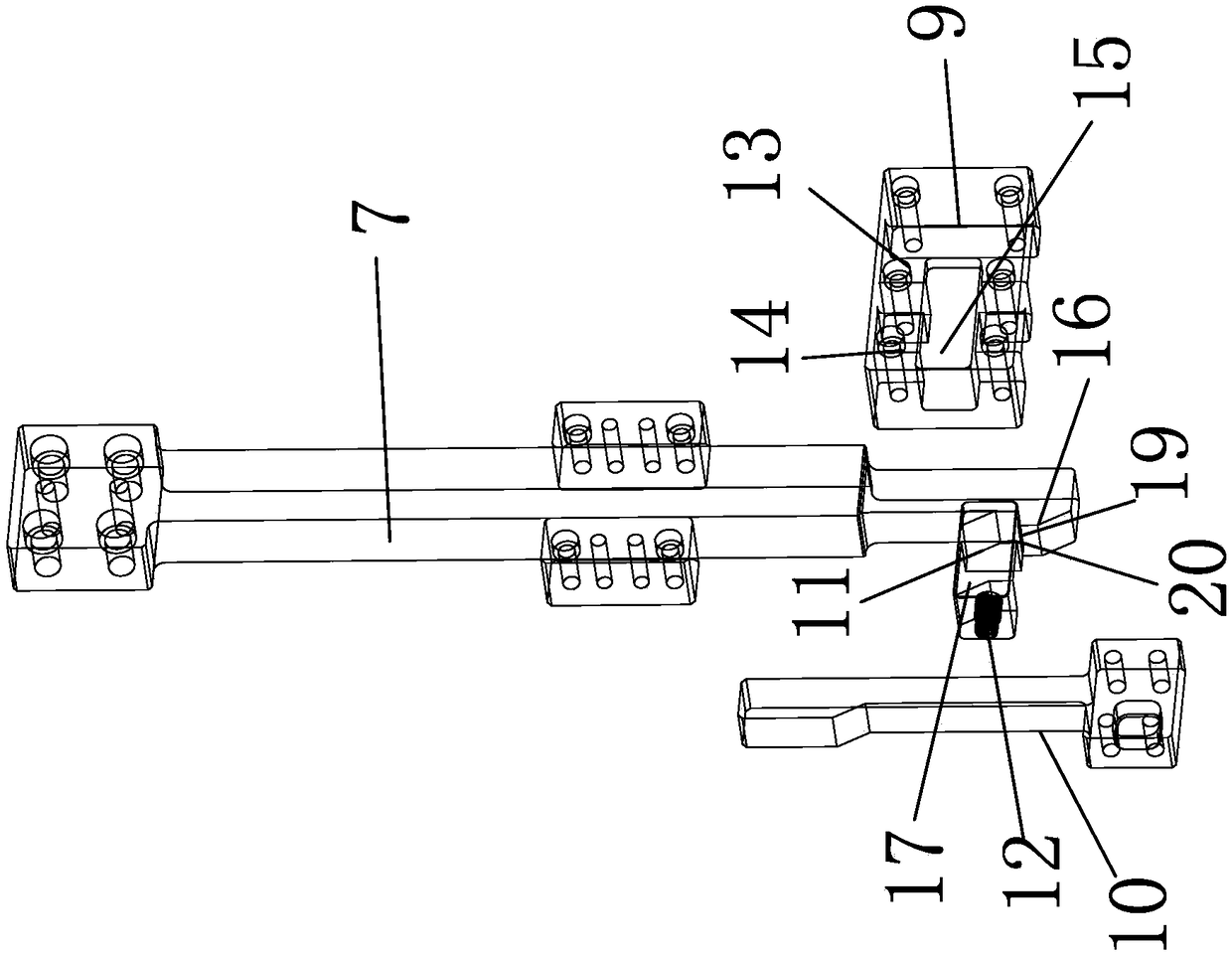

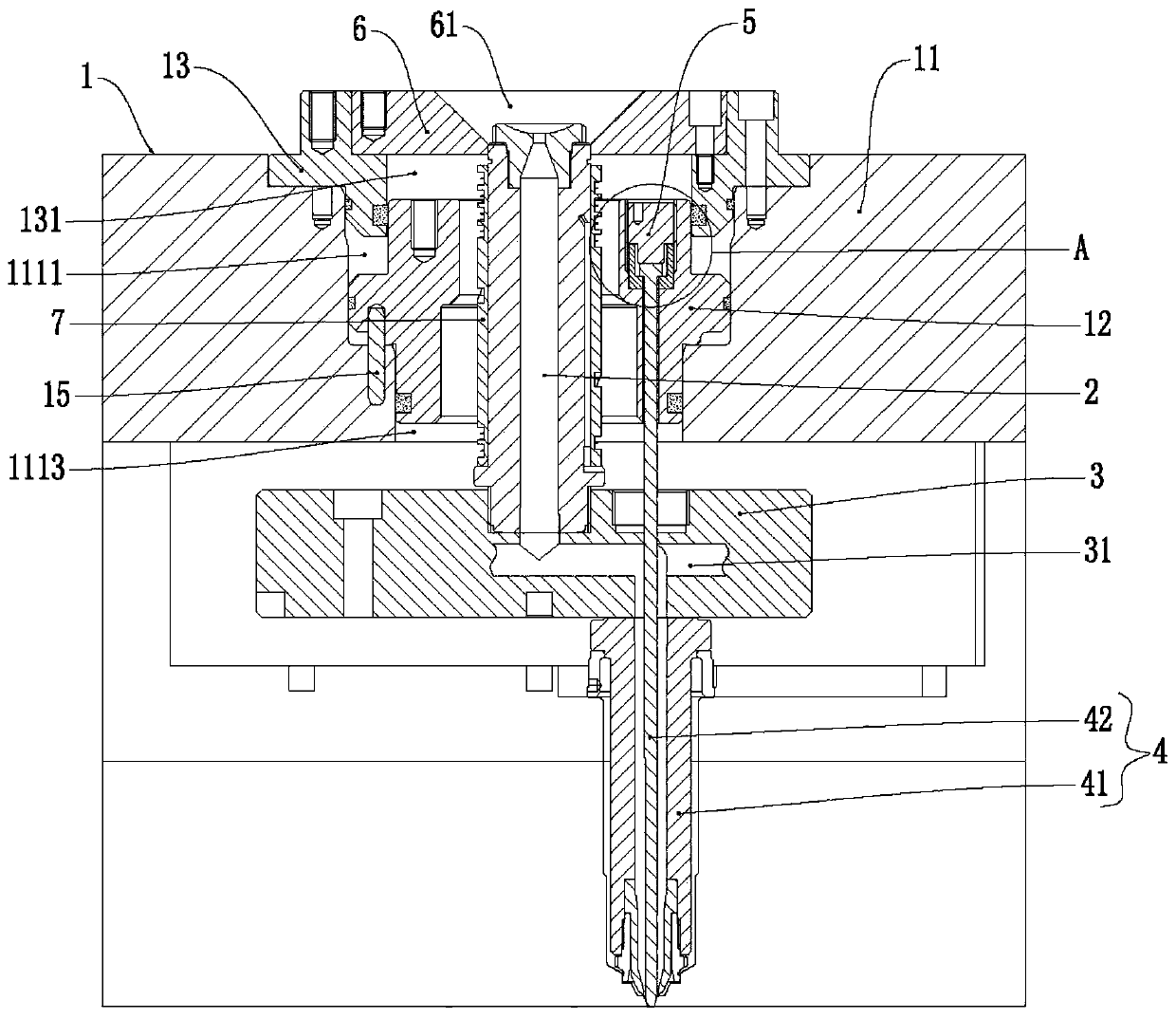

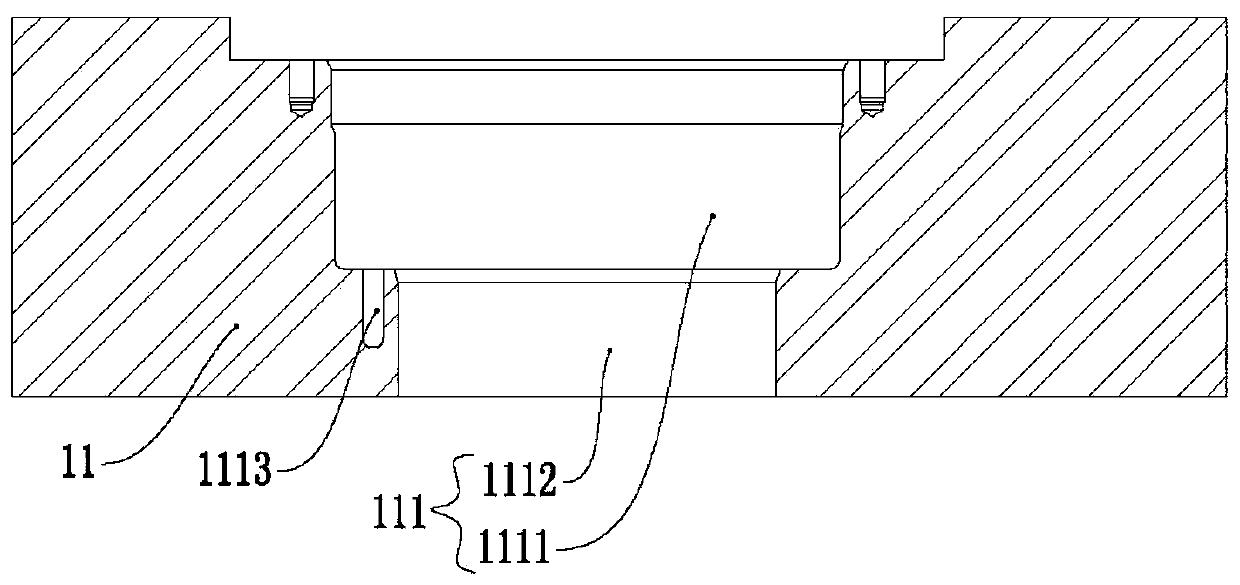

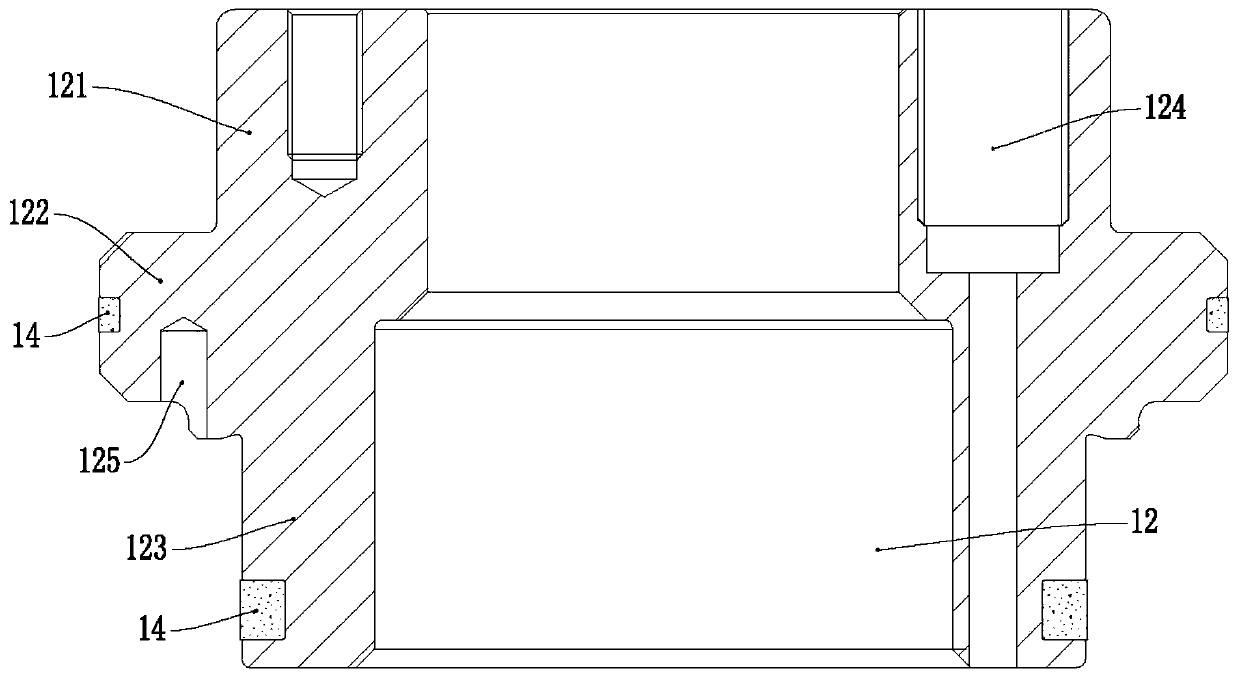

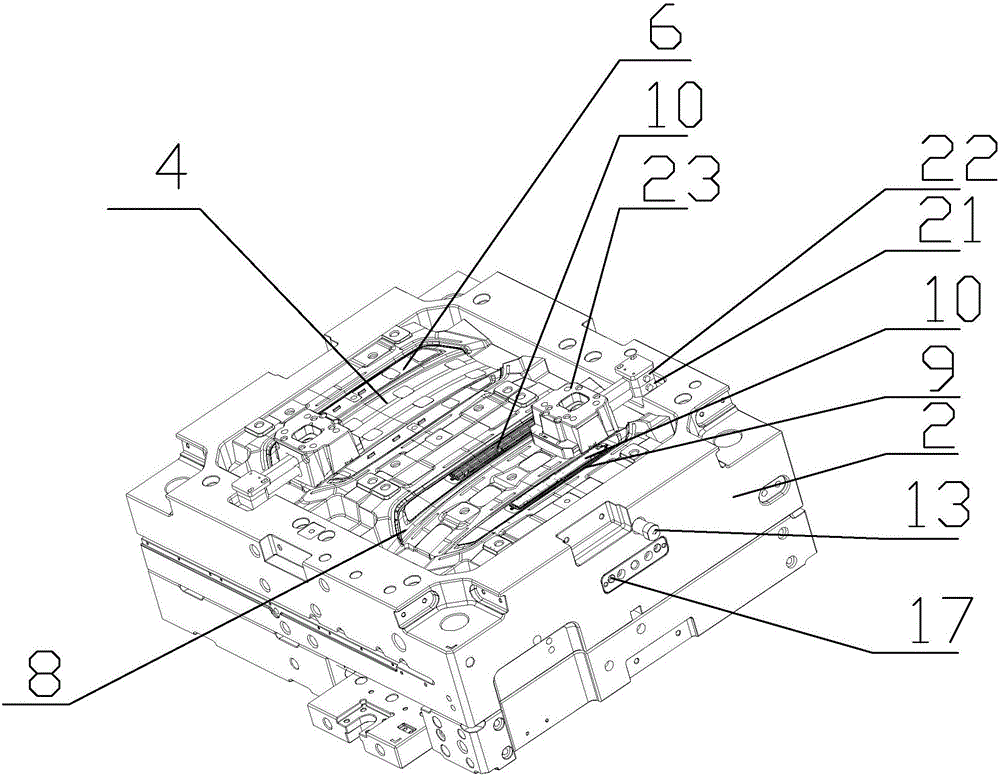

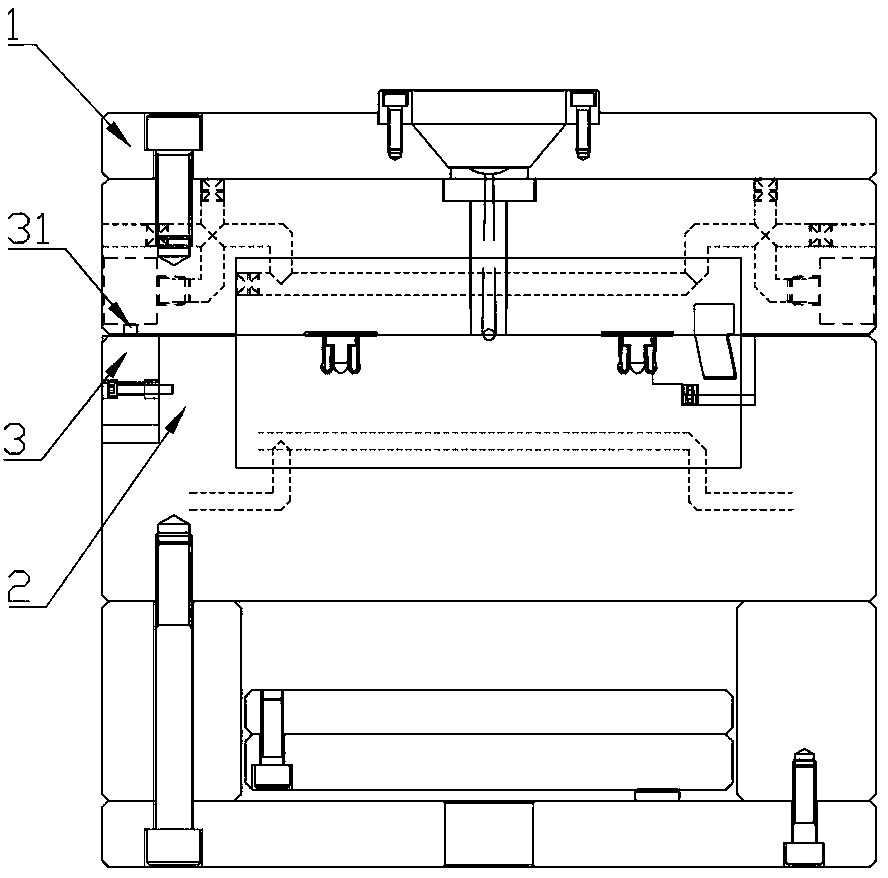

External gas assisted injection mould

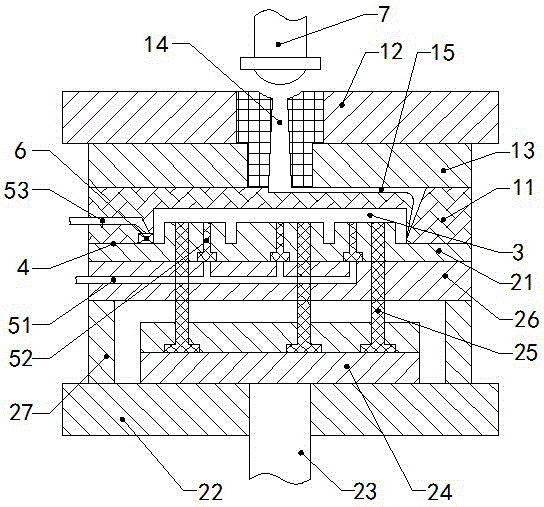

The invention provides an external gas assisted injection mould, and relates to the technical field of injection mould. The injection mould comprises an upper mould and a lower mould which cooperate with each other. A cavity having the same shape as an injection moulding is cooperatively arranged between the upper mould and the lower mould. The surface where the upper mould and the lower mould contact is the mould joint. The injection mould is characterized in that: the upper mould and the lower mould are respectively cooperatively provided with an air inlet duct and an air outlet duct; one end of the air inlet duct is connected to a gas pipe, the other end of the air inlet duct is communicated with the cavity through evenly arranged gas pins; one end of the air outlet duct is connected to the cavity, and the other end of the air outlet duct is communicated with the external space. The provided external gas assisted injection mould has a simple structure, is convenient for processing, can effectively solve the problem of gas sealing between the injection moulding and the surface of the mould joint during the pressure maintaining process of an external assistant gas, and is capable of maintaining the gas sealing during the pressure maintaining process and achieving a very good gas discharging effect during the injection mould filling process. The injection moulding quality of injection moulding is guaranteed, and the injection moulding is easy to demould.

Owner:ZHEJIANG UNIV OF TECH

Injection mold and injection molding process thereof

PendingCN111873302AIncrease production typeReduce manufacturing costInjection molding processEngineering

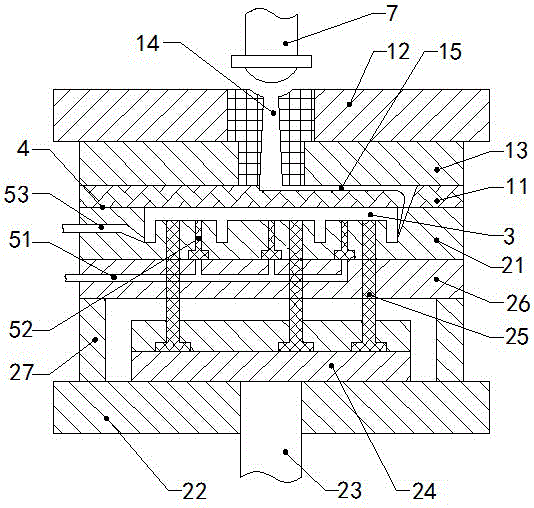

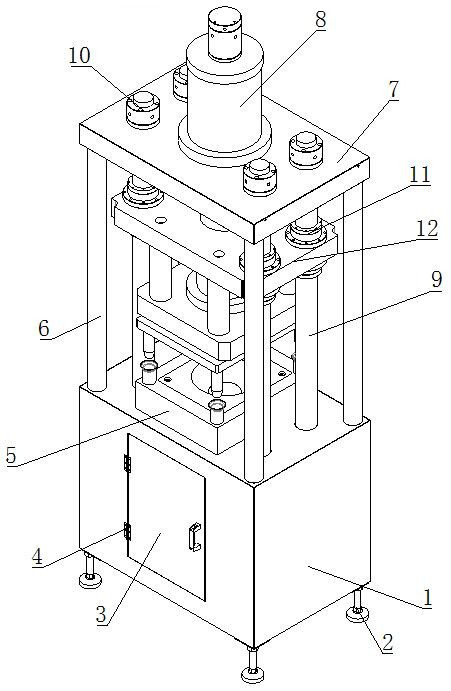

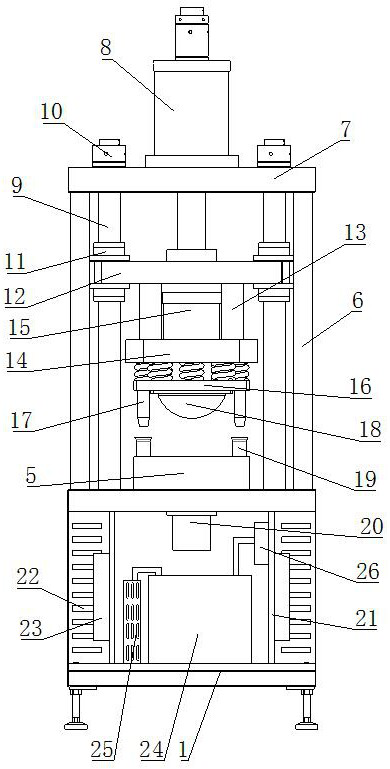

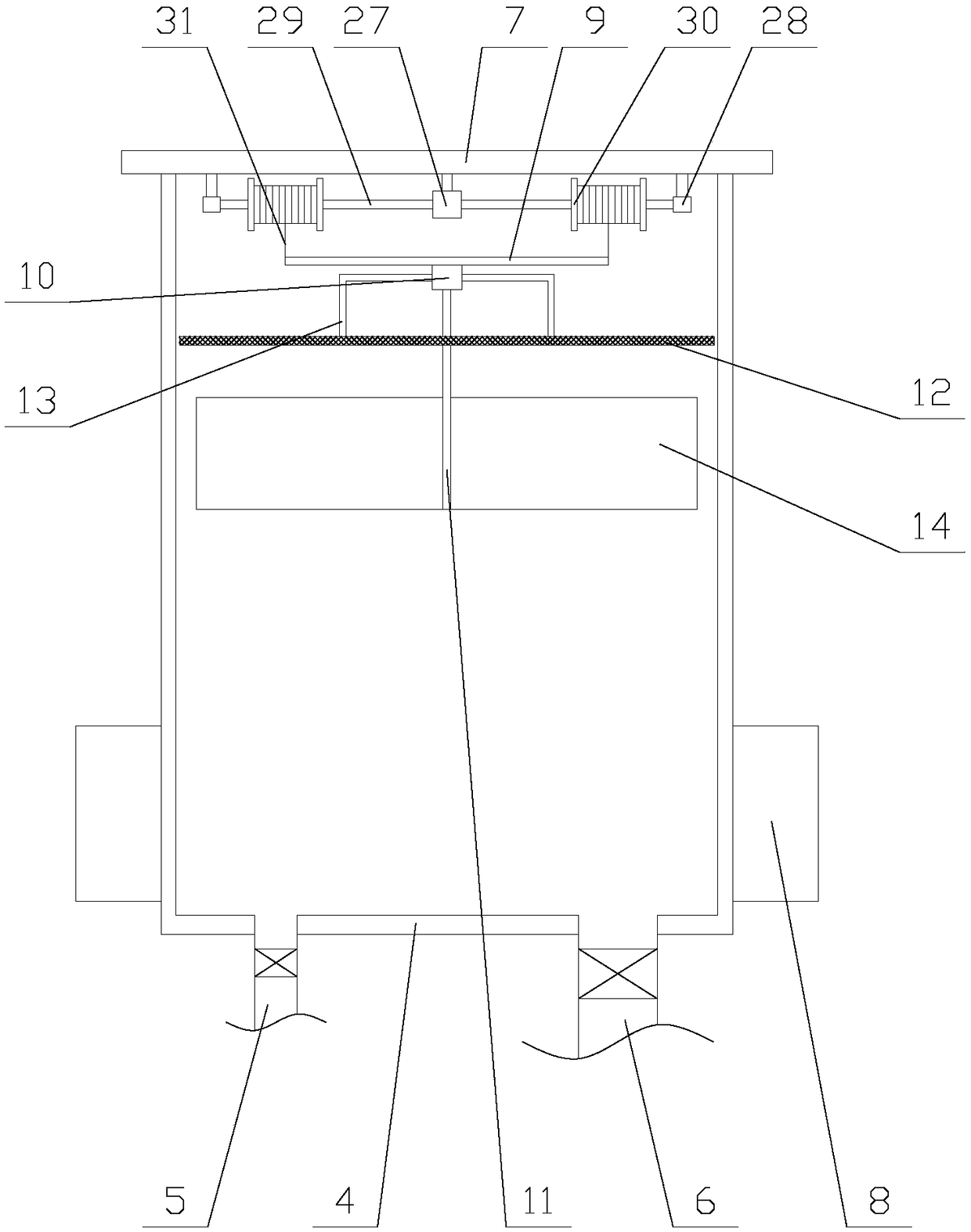

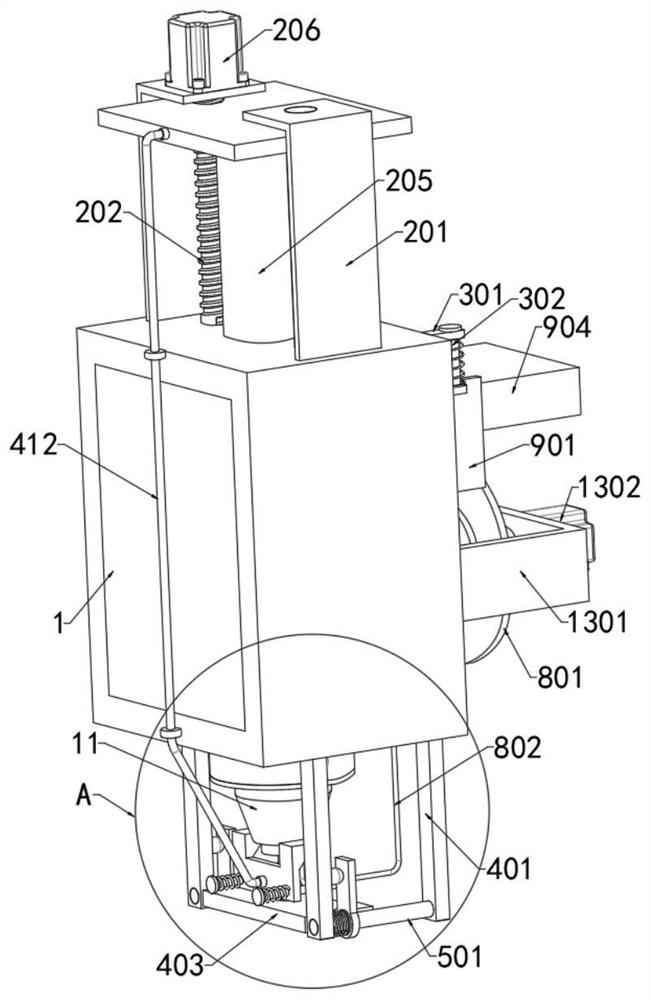

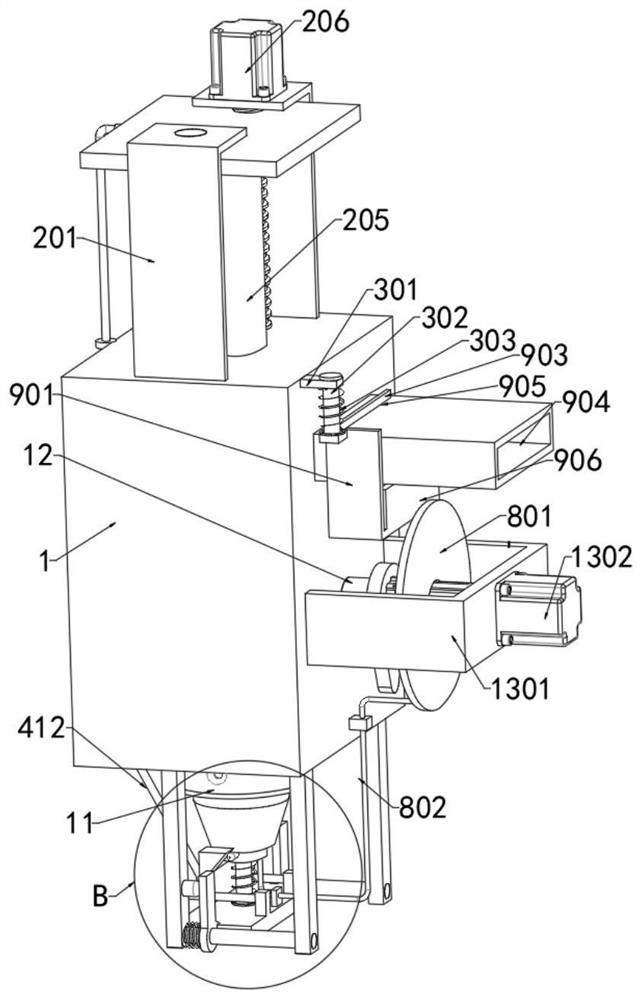

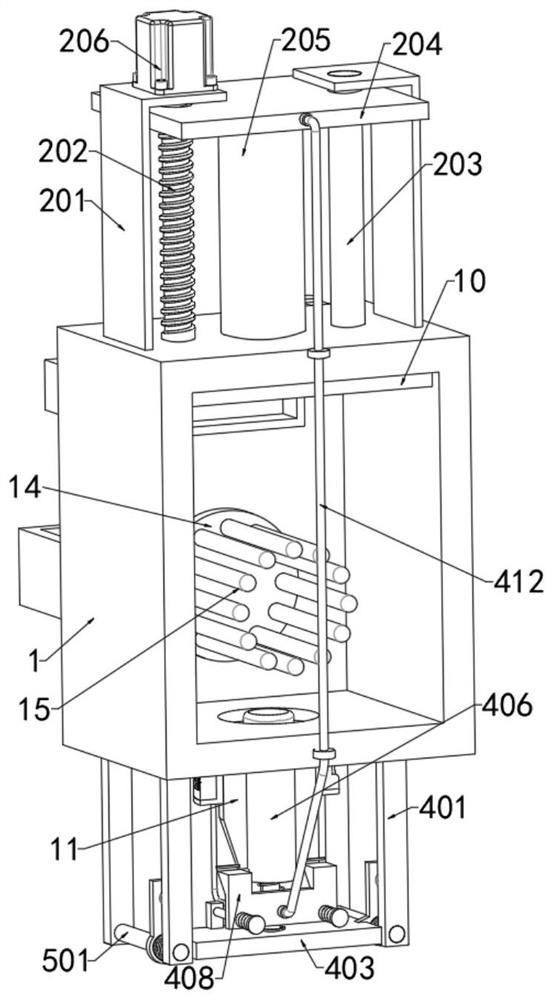

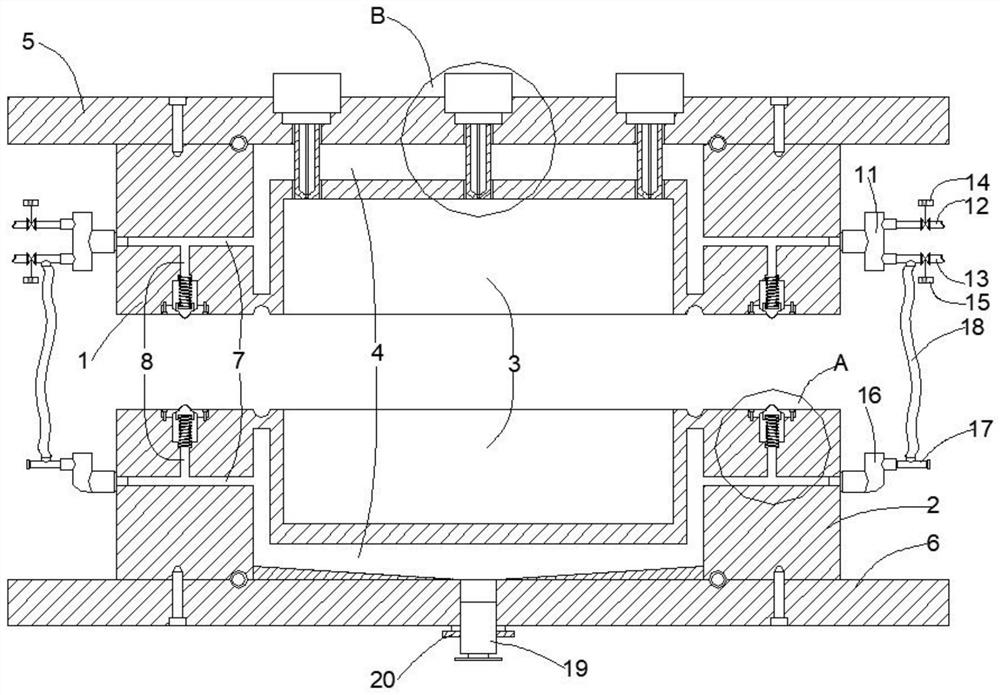

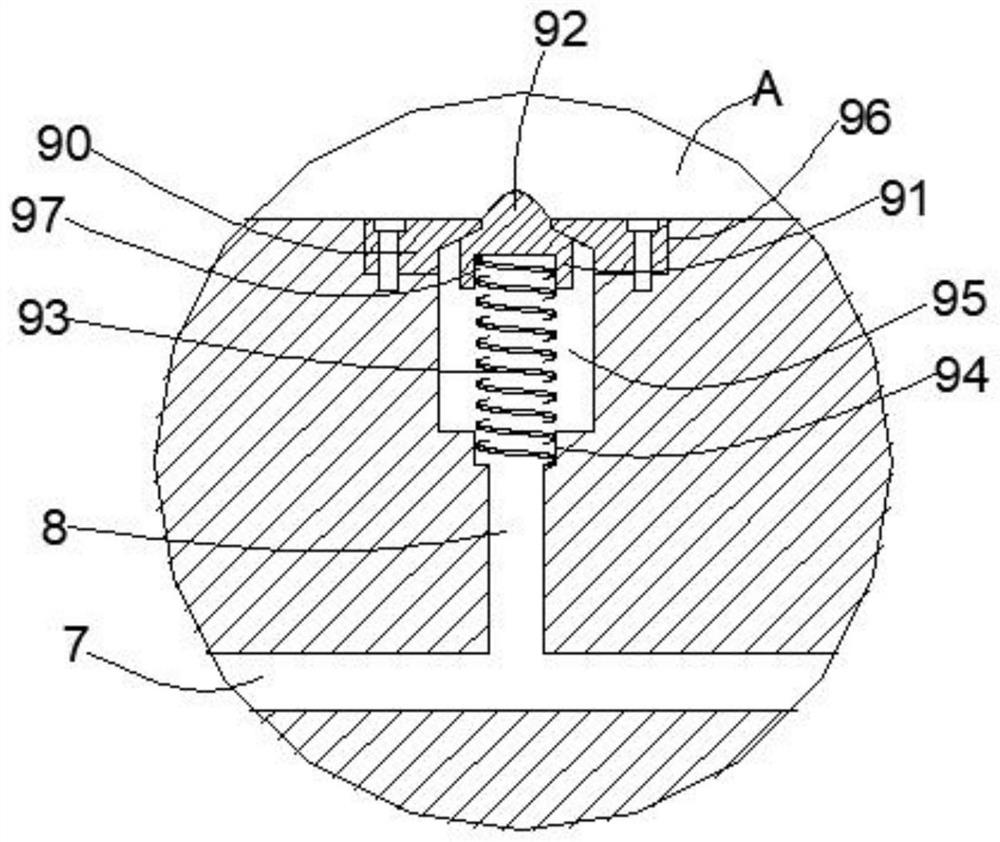

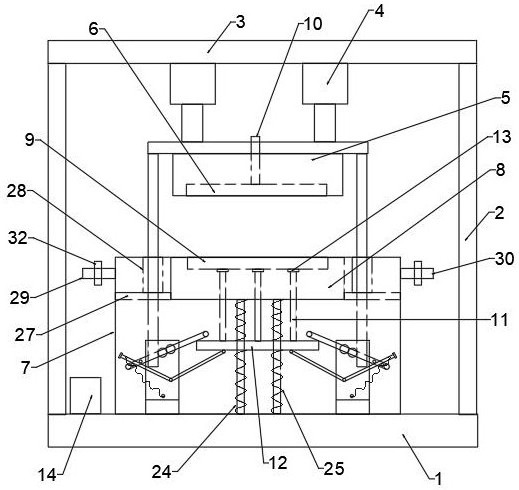

The invention discloses an injection mold and an injection molding process thereof. A lower mold base is fixedly arranged in the center of the upper end of an injection molding bottom cabinet, a mounting groove matched with an injection molding lower mold is formed in the lower mold base, and the injection molding lower mold is detachably mounted on the lower mold base through bolts; and vertically upward supporting columns are fixedly connected to the four corners of the upper end of the injection molding bottom cabinet correspondingly, a top plate is fixedly connected to the upper ends of the supporting columns, and a vertically downward first driving hydraulic cylinder is fixedly installed at the center position of the upper end of the top plate. According to the injection mold, the upper surface and the lower surface of an injection molding part are cooled at the same time, uniform cooling of the upper surface and the lower surface of the injection molding part is guaranteed, the forming quality of the injection molding part is guaranteed while rapid cooling and shaping of the injection molding part are improved, the injection molding part obtained after injection molding is completed is ejected out of a female mold on the injection molding lower mold through a demolding ejection plate, rapid demolding of the injection molding part is achieved, and the injection molding part machining efficiency is improved.

Owner:金华观瑞科技有限公司

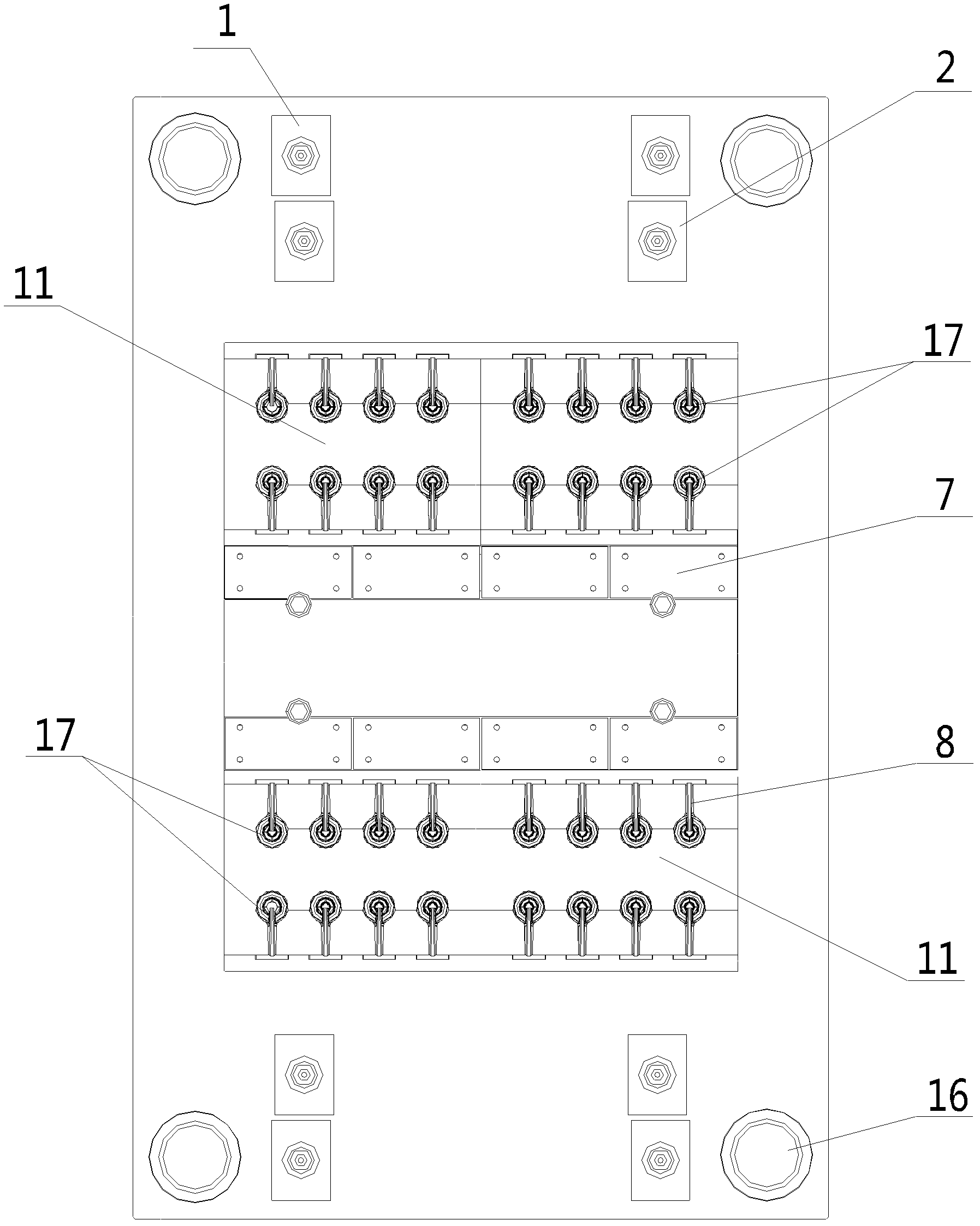

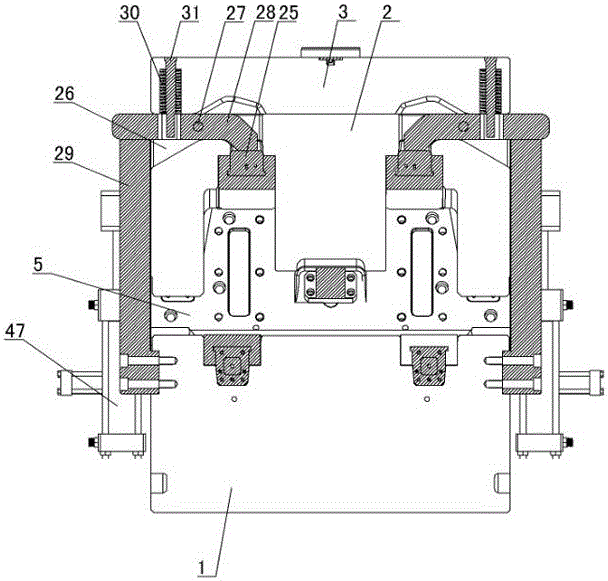

Injection mold

InactiveCN102601930AGuarantee the quality of injection moldingGuaranteed YieldEconomic benefitsMaterials science

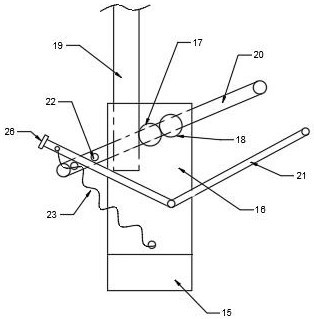

The invention discloses an injection mold. The injection mold comprises a fixed mold plate, fixed mold kernels, a movable mold plate, movable mold kernels, a mold core, an ejector sleeve, oil cylinders, a push plate, a bottom needle plate, a surface needle plate, a sliding block insert, a sliding block seat and a connecting rod mechanism, wherein a plurality of pairs of the fixed mold kernels and the movable mold kernels are arranged on the fixed mold plate and the movable mold plate, and a plurality of mold cavities are formed between each pair of the fixed mold kernel and the movable mold kernel; and actions of core pulling and pushing out of the mold are respectively controlled through the two groups of the oil cylinders, and the sliding block insert can slide out of the mold cavities like arcs through arc-shaped fit of the sliding block seat, the sliding block insert and the movable mold kernels during core pulling. By adopting the injection mold disclosed by the invention, injection molding of a plurality of products can be completed by closing the mold once while the finished product rate of the products is ensured, the production efficiency is greatly improved, market and production requirements are met, and the injection mold further brings a great deal of economic benefits to manufacturers.

Owner:SUZHOU YAER PLASTIC TECH

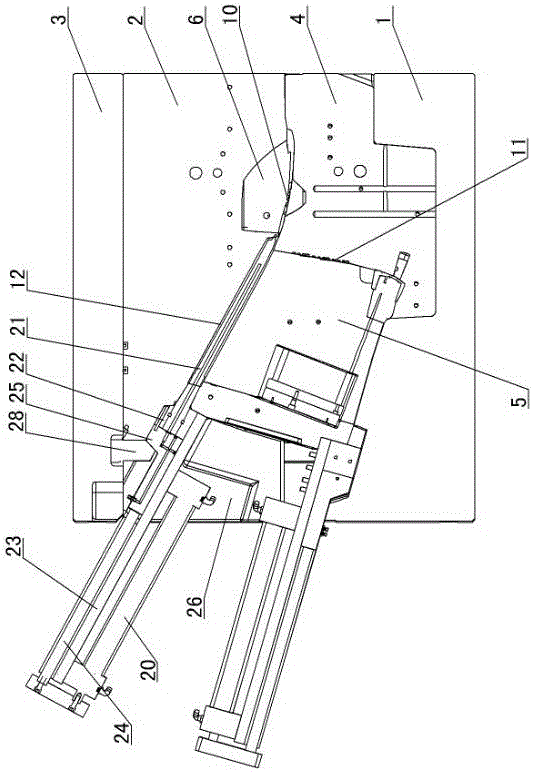

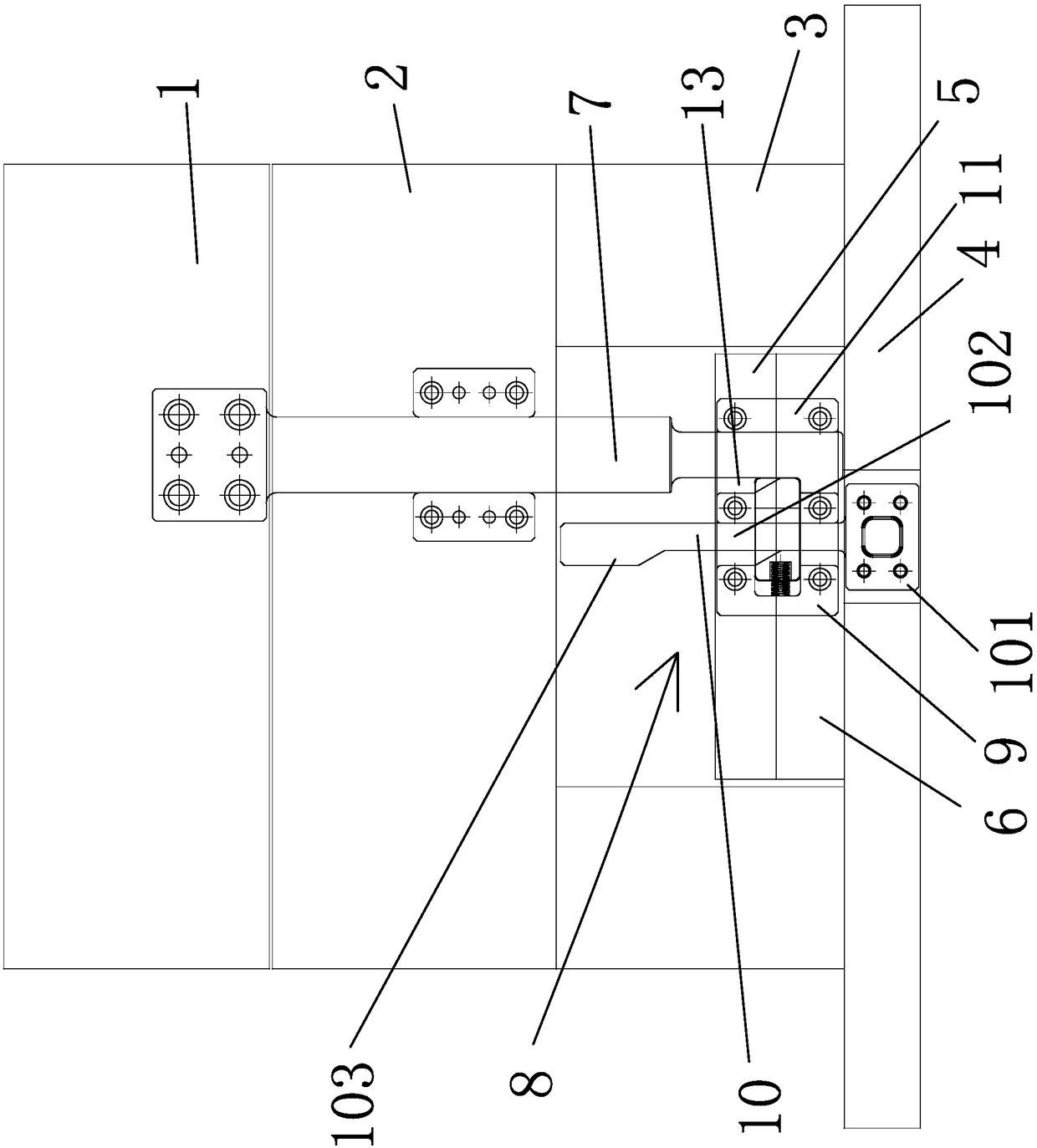

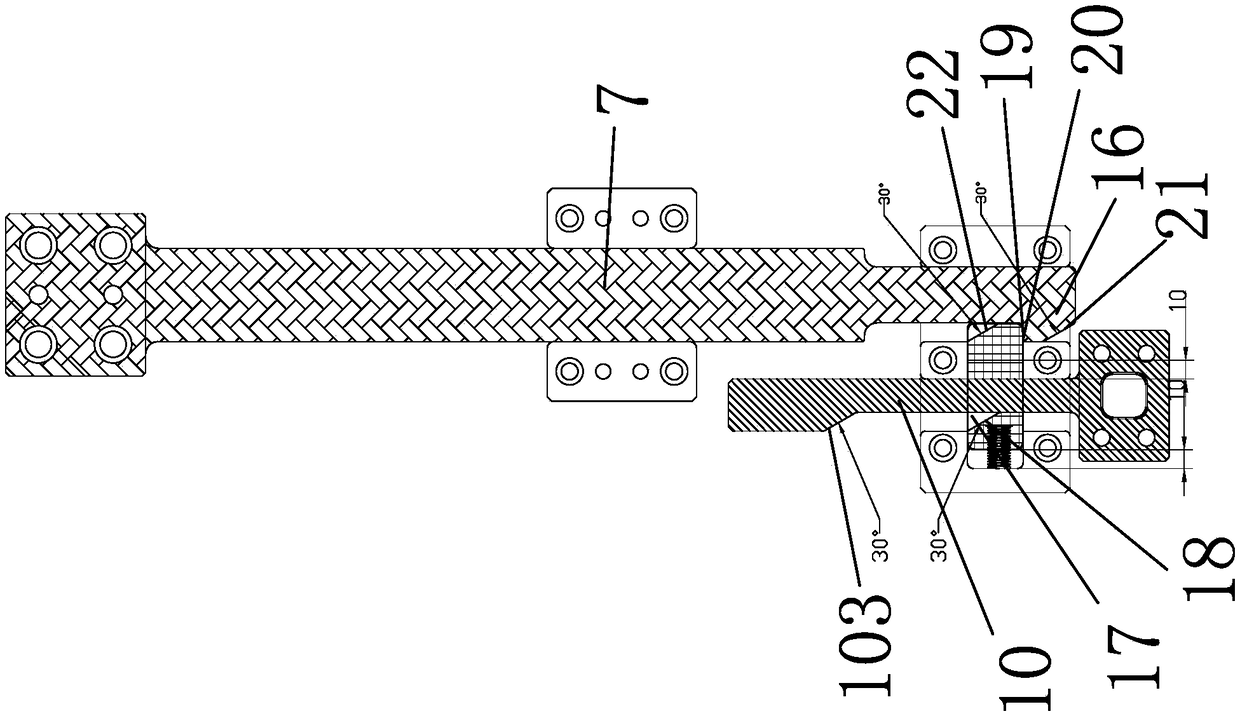

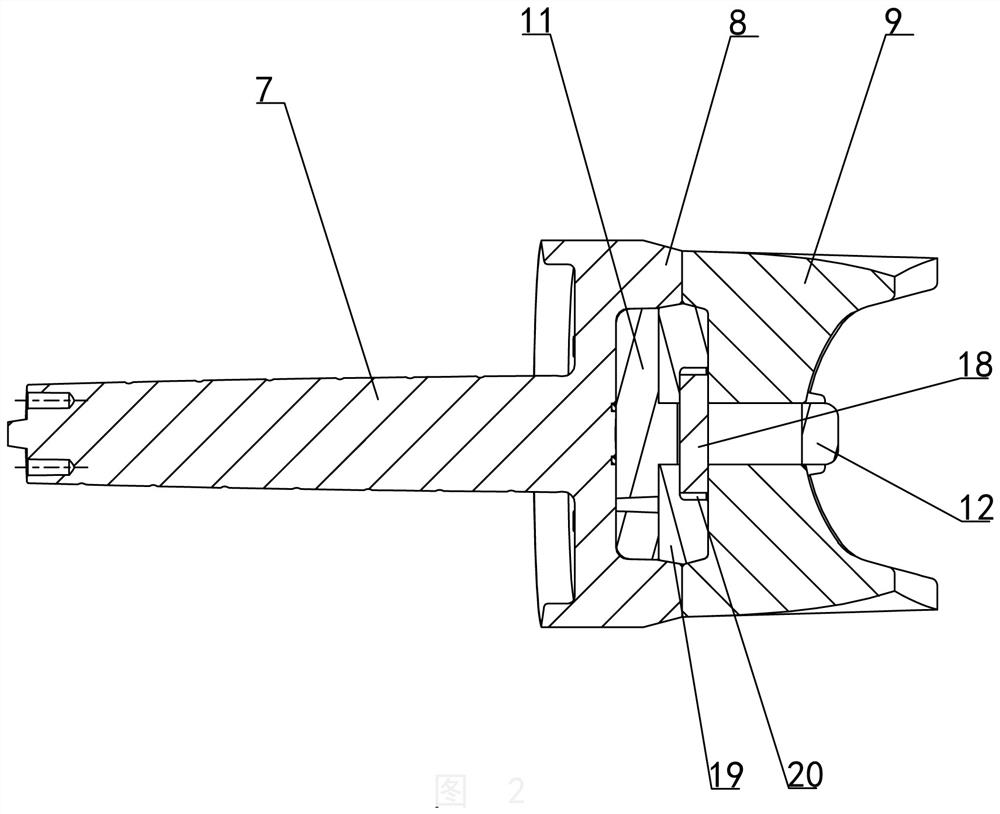

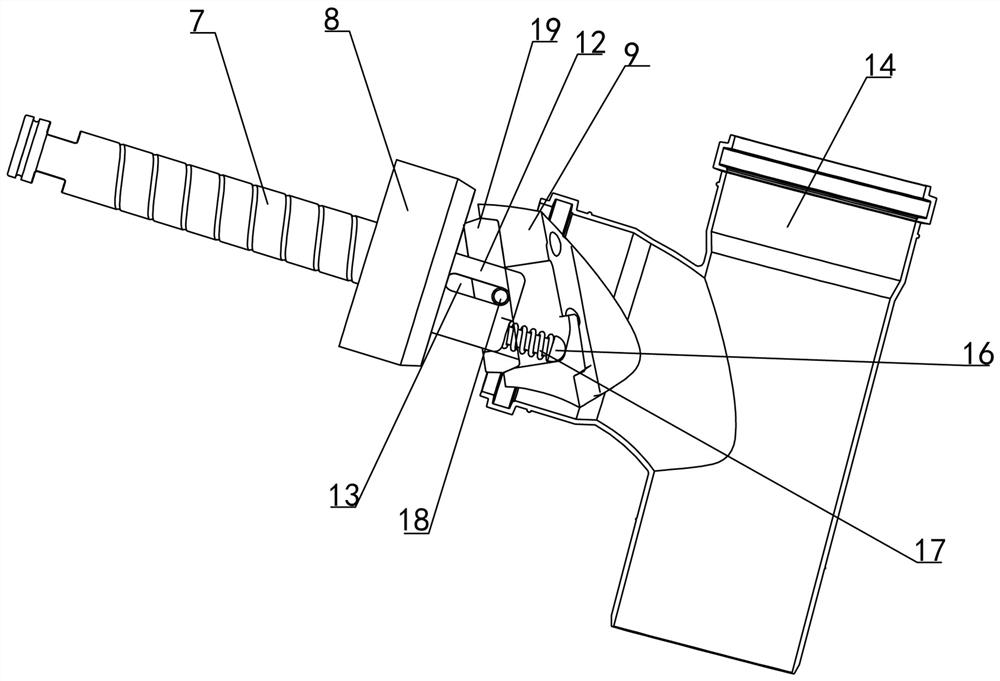

Core pulling mechanism for injection mold

Owner:NINGBO FANGZHENG TOOL

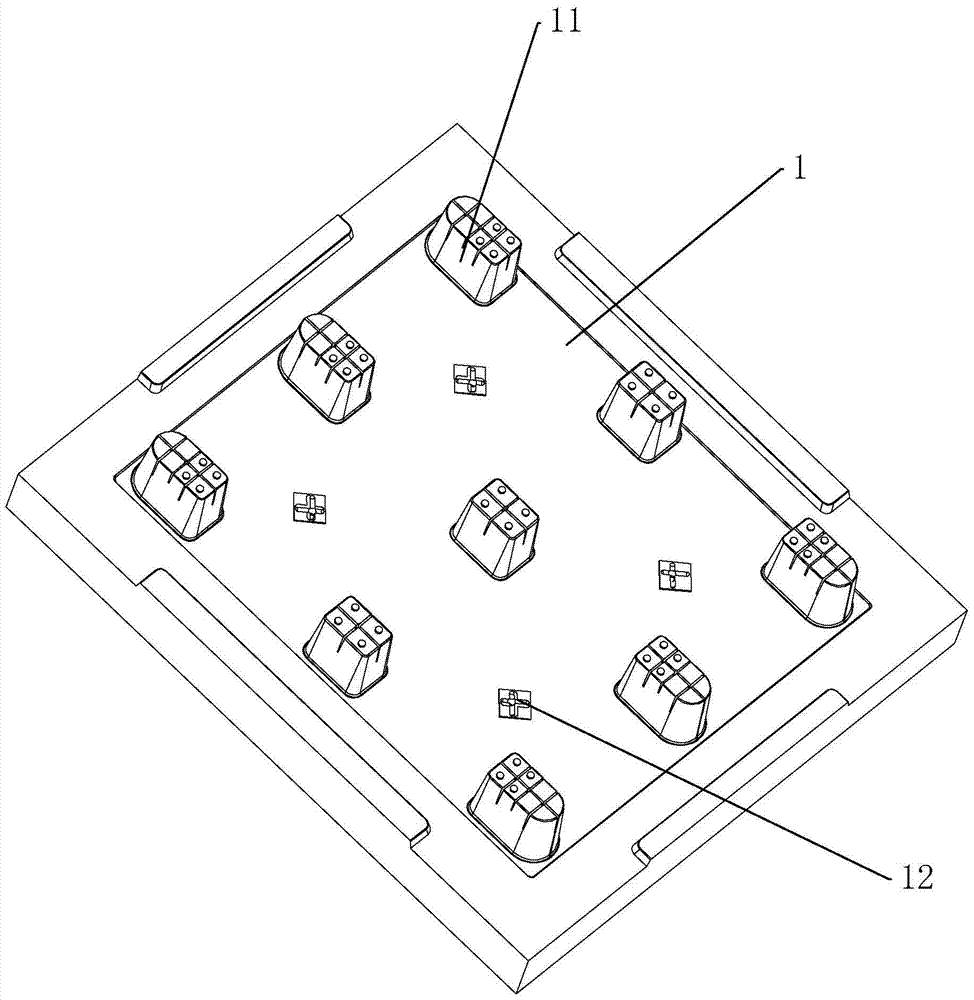

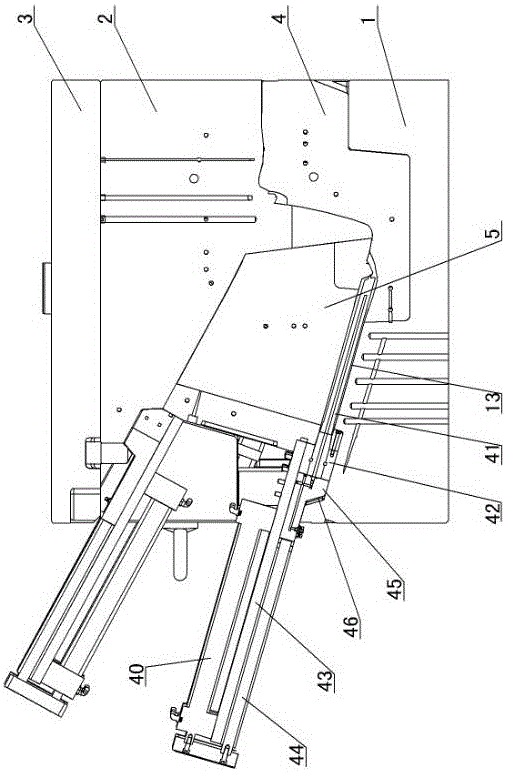

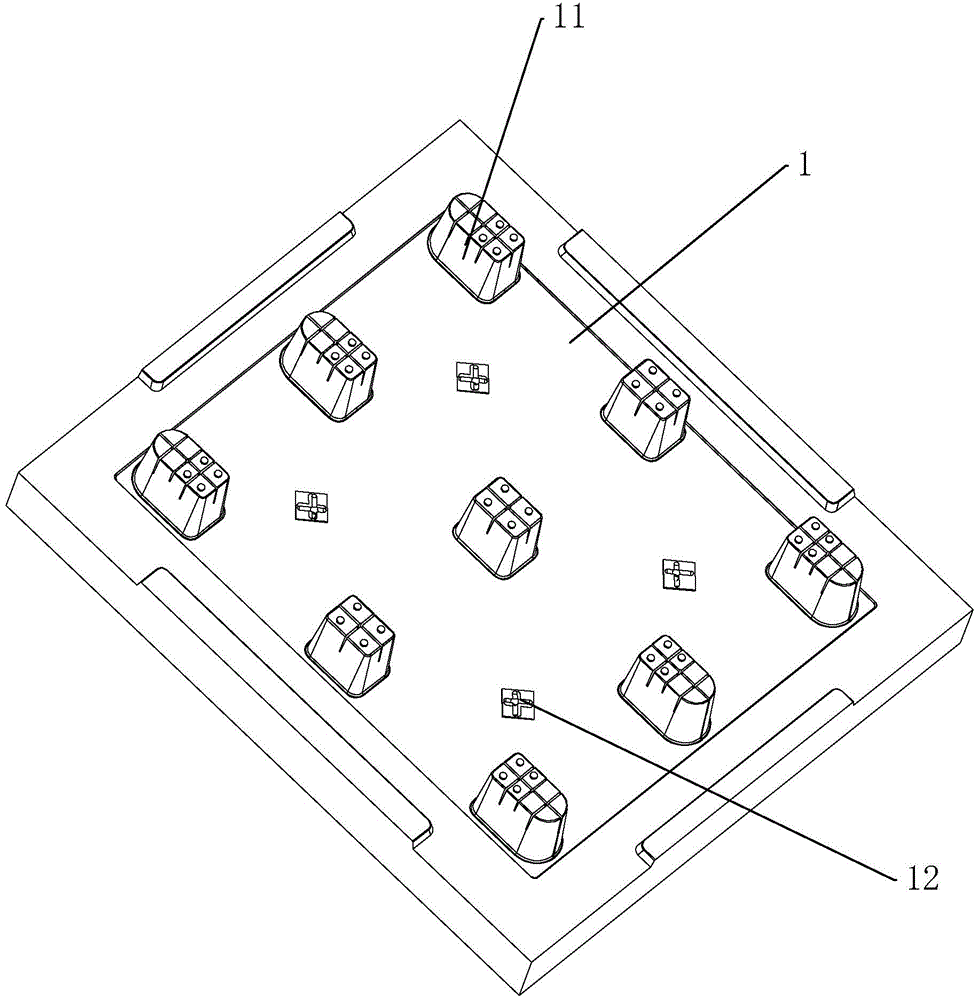

Tray mold for easy injection molding of feet

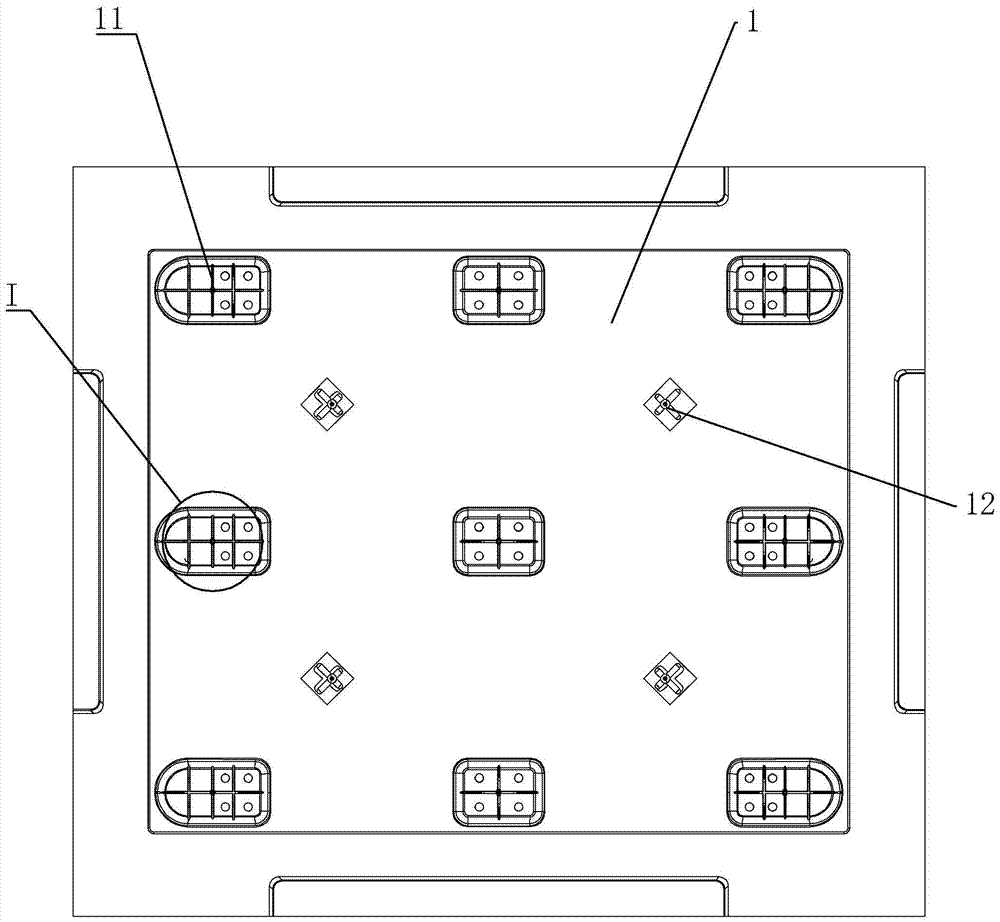

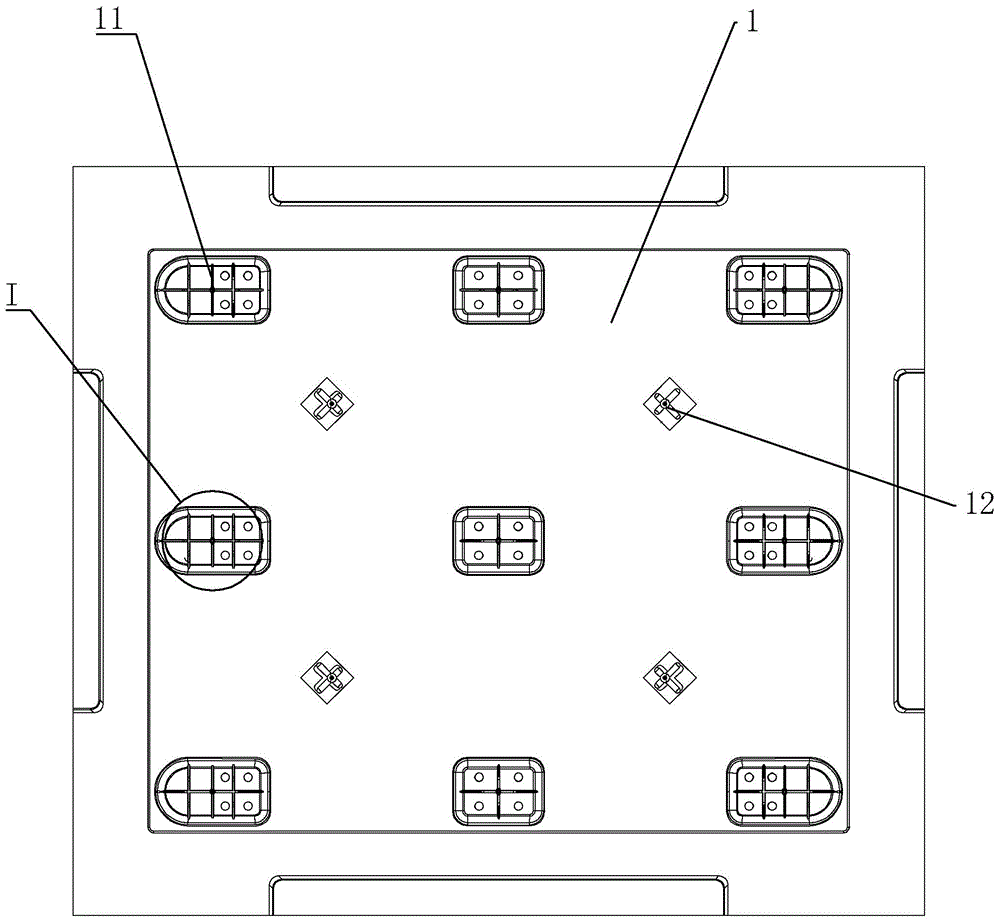

ActiveCN104924529BGuarantee the quality of injection moldingGuaranteed structural strengthInjection molding machineMaterials science

The invention discloses a tray mold facilitating injection molding of bottom feet. According to the technical scheme, the tray mold is characterized in that the tray mold comprises a fixed mold body and a movable mold body; the fixed mold body is provided with a plurality of protrusions for injection molding of the bottom feet; first sprues for injection molding are arranged on the protrusions; second sprues are arranged on the plate face of the fixed mold body; the second sprues and the first sprues are located on the same face of the fixed mold body; a feeding frame for being communicated with the first sprues and the second sprues is arranged on the other face of the fixed mold body; an injection molding opening connected with a nozzle of an injection molding machine is arranged on the feeding frame. One sprue is additionally arranged on each protrusion of the fixed mold body, it is ensured that injection molding of the tray bottom feet can reach the standard, and meanwhile injection molding efficiency is improved.

Owner:ZHEJIANG XINDING PLASTIC +1

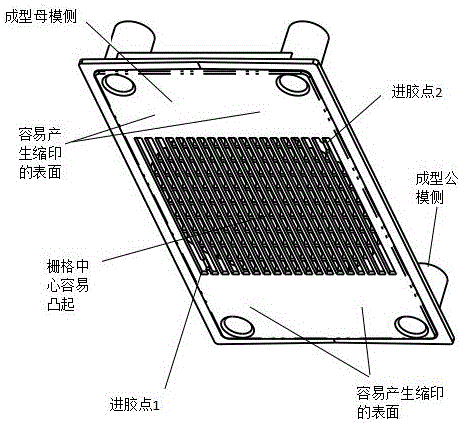

Injection molding method of battery shell grid baffle

ActiveCN105690697AInjection molding is done efficientlyGuarantee the quality of injection moldingCooling temperatureInjection molding process

The invention discloses an injection molding method of a battery shell grid baffle. The method comprises following steps of molding cooling temperature control, wherein the cooling temperature of a male mold is set to 80 DEG C, and the temperature of a female mold is set to 95 DEG C; and injection molding process control, wherein a product injection molding process comprises a four-segment injection molding filling state and a two-segment pressure maintaining stage. According to the injection molding method of the battery shell grid baffle, injection molding of the battery shell grid baffle can be efficiently completed, and the injection molding quality of the battery shell grid baffle can be ensured.

Owner:SUZHOU LICHUANG PRECISION MOLD TECH CO LTD

Anti-collision device for slide block

Owner:TAIDEXING PRECISE ELECTRON KUSN

Chair foot upwarp rod type core loosing and mold locking mechanism of plastic chair mold

ActiveCN106003603AInhibit swellingGuarantee the quality of injection moldingLocking mechanismEngineering

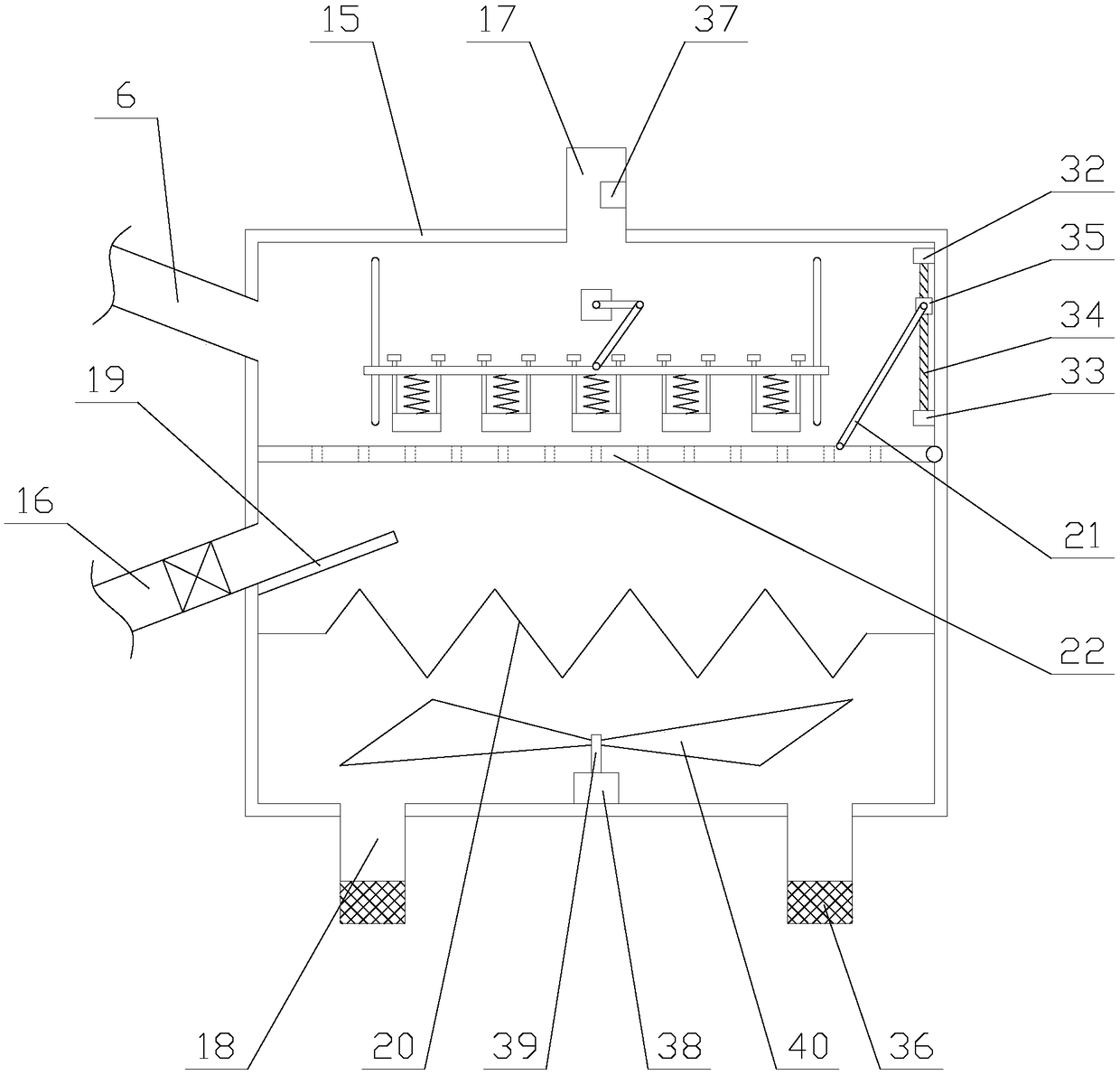

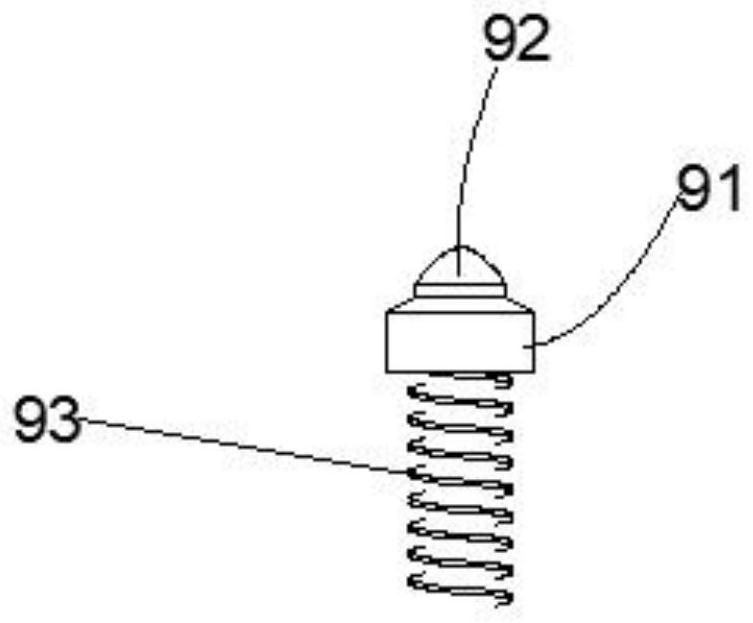

The invention relates to a chair foot upwarp rod type core loosing and mold locking mechanism of a plastic chair mold. The mechanism comprises a moving mold plate and a fixed mold plate, wherein a sprue plate is mounted on the fixed mold plate, chair seat and chair back insert blocks are mounted in the moving mold plate, chair seat and chair foot insert blocks are arranged on the moving mold plate and the chair seat and chair back insert blocks, a backrest insert block is mounted in the fixed mold plate, an upper mold locking lug is arranged on an upper core loosing slide block, one end of a mold locking rod is matched with the mold locking lug, an ejector pin is mounted on the external wall of the moving mold plate and jacks the downside of the other end of the mold locking rod, a compression spring is arranged in the sprue plate, a pressure lever penetrates through the compression spring and is inserted into the other end of the mold locking rod, and the compression spring presses the upside of the other end of the mold locking rod; a lower mold locking lug is arranged on a lower core loosing slide block, a lower mold locking groove is formed in the moving mold plate, the lower mold locking lug is matched with the lower mold locking groove, and a mold opening cylinder is mounted on side walls of the chair seat and chair foot insert blocks and is connected with the fixed mold plate. The simultaneous core loosing and demolding of upper and lower core loosing rods are achieved by combining secondary mold opening and upwarp rod type demolding, so that the product quality is good, and the production efficiency is high.

Owner:TAIZHOU HUANGYAN HANWEI PLASTIC MOLD

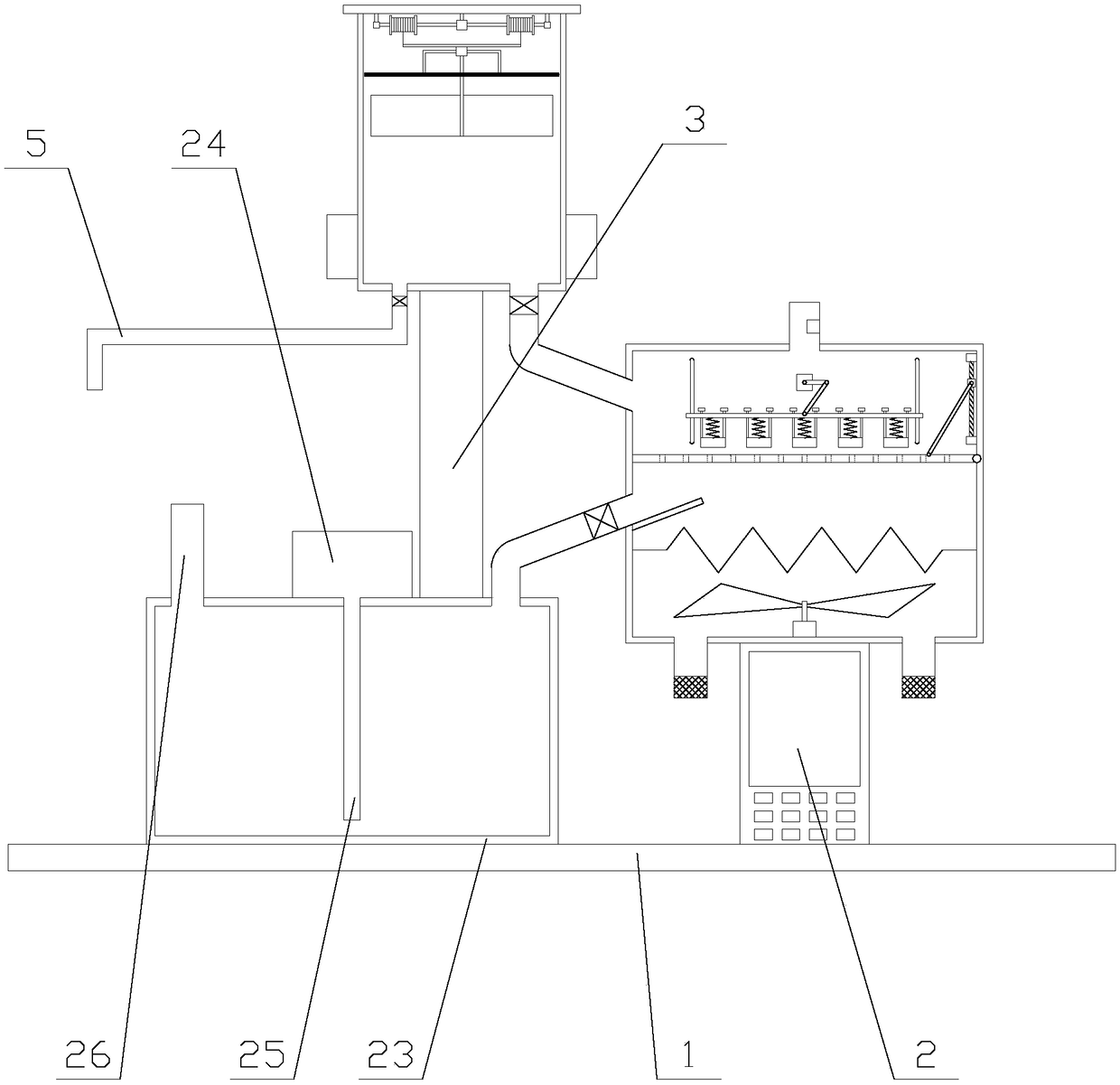

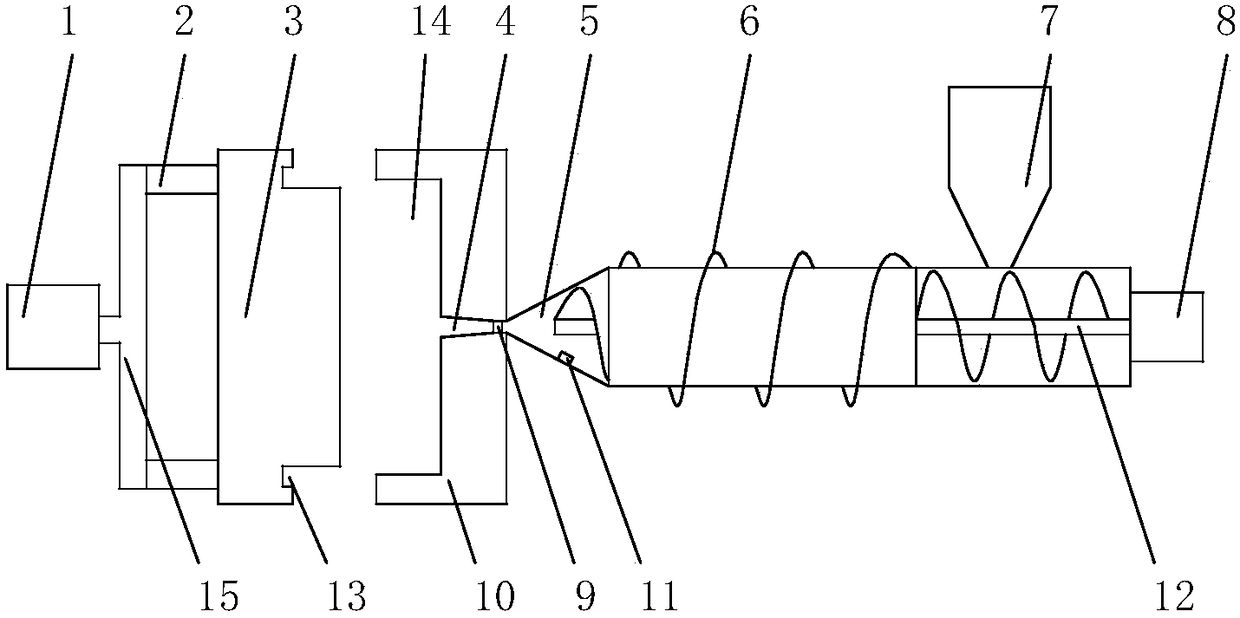

Injection molding system with excellent machining quality

The invention relates to an injection molding system with the excellent machining quality. The injection molding system comprises a base, a controller, a supporting column, an injection molding mechanism, a drying mechanism and a cleaning mechanism; the cleaning mechanism comprises a cleaning box, a drainage pipe, a discharge pipe, a cover plate and two ultrasonic transmitters, and a lifting assembly, a lifting plate, a first motor, a first driving shaft, a first mesh plate, two brackets and two stirring plates are arranged in the cleaning box; and the drying mechanism comprises a drying box,a delivery pipe, an air outlet pipe and two air inlet pipes, and a vibrating assembly, a supporting assembly, a guiding plate, an electric heating wire and an air guiding assembly are arranged in thedrying box. According to the injection molding system with the excellent machining quality, oil stains and dust on the surfaces of plastic particles are removed through the cleaning mechanism, therefore, the plastic particles are clean, and the injection molding quality is guaranteed; and in addition, water on the surfaces of the particles is removed through the drying mechanism, therefore, the clean and dry plastic particles enter a crucible, excellent plastic product production is facilitated, and the equipment practicability is improved.

Owner:晋江万智进出口贸易有限公司

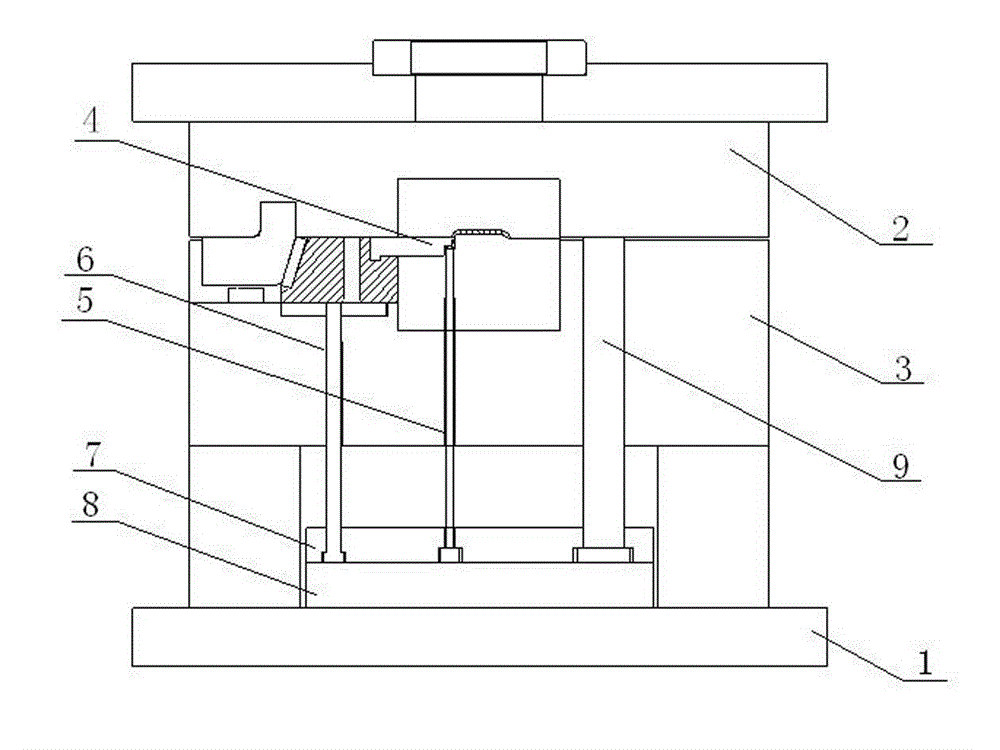

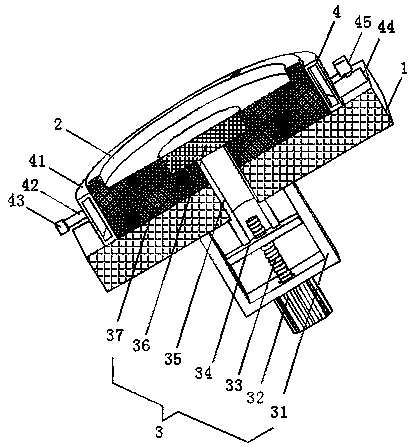

Two-color die for automobile instrument boards

InactiveCN104943070AStable fluid temperatureGuarantee the quality of injection moldingPlastic injection moldingEngineering

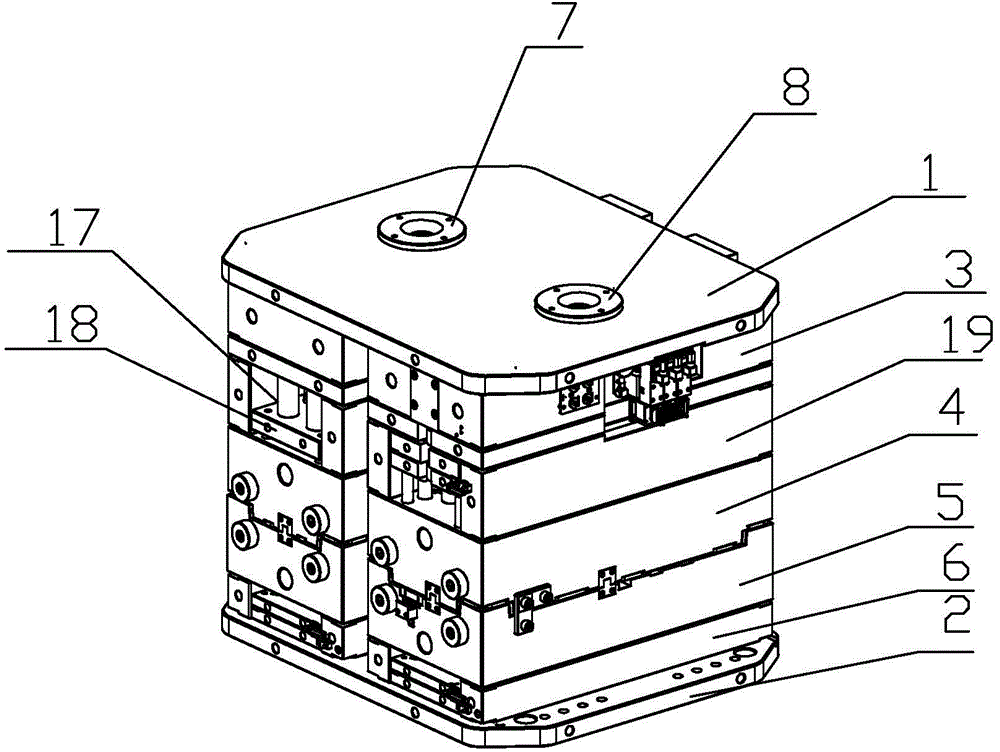

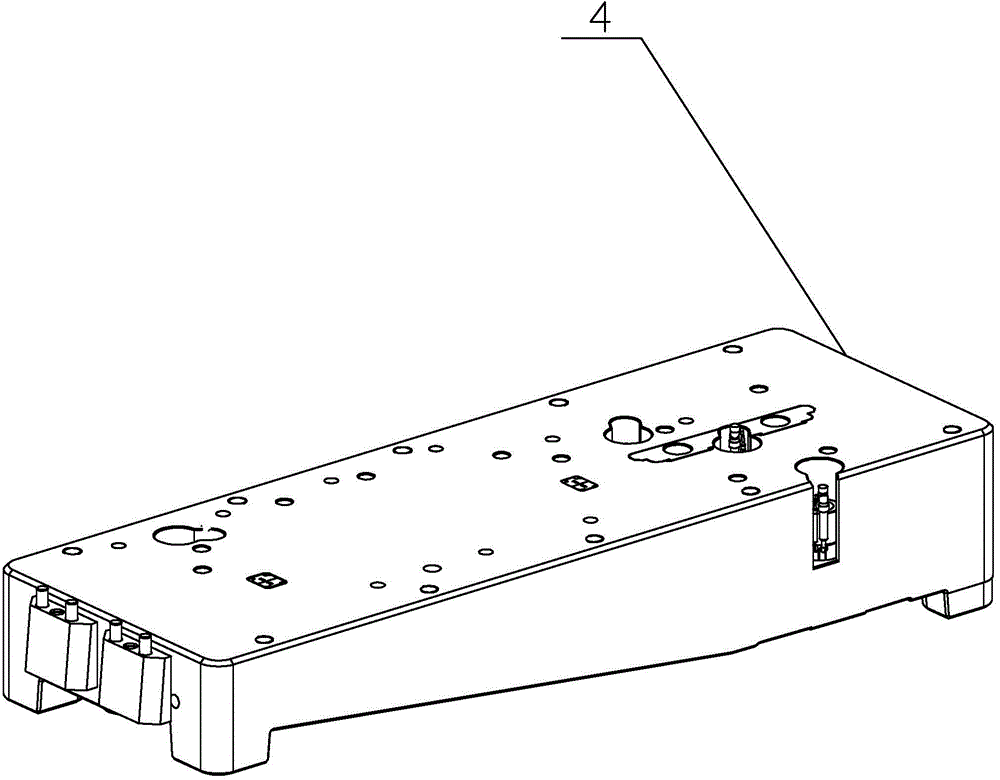

The invention discloses a two-color die for automobile instrument boards. The two-color die comprises a fixed die plate (1), a movable die rotation disc (2), a product (9), a first die and a second die, the fixed die plate (1) is provided with a soft plastic injection molding port (7) and a hard plastic injection molding port (8), the soft plastic injection molding port (7) is arranged on the first die, the hard plastic injection molding port (8) is arranged on the second die, one end of the first die is fixed on the fixed die plate (1), the other end of the first die is fixed on the movable die rotation disc (2), one end of the second die is fixed on the fixed die plate (1), the other end of the second die is fixed on the movable die rotation disc (2), and the first die and the second die respectively comprises a fixed die fixing plate (3), a fixed die (4), a movable die (5) and a movable die fixing plate (6). The two-color die for automobile instrument boards has the advantages of no generation of wastes, low cost, and guaranteeing of the injection molding quality through controlling the temperature of plastics in a runner.

Owner:宁海县现代模具有限公司

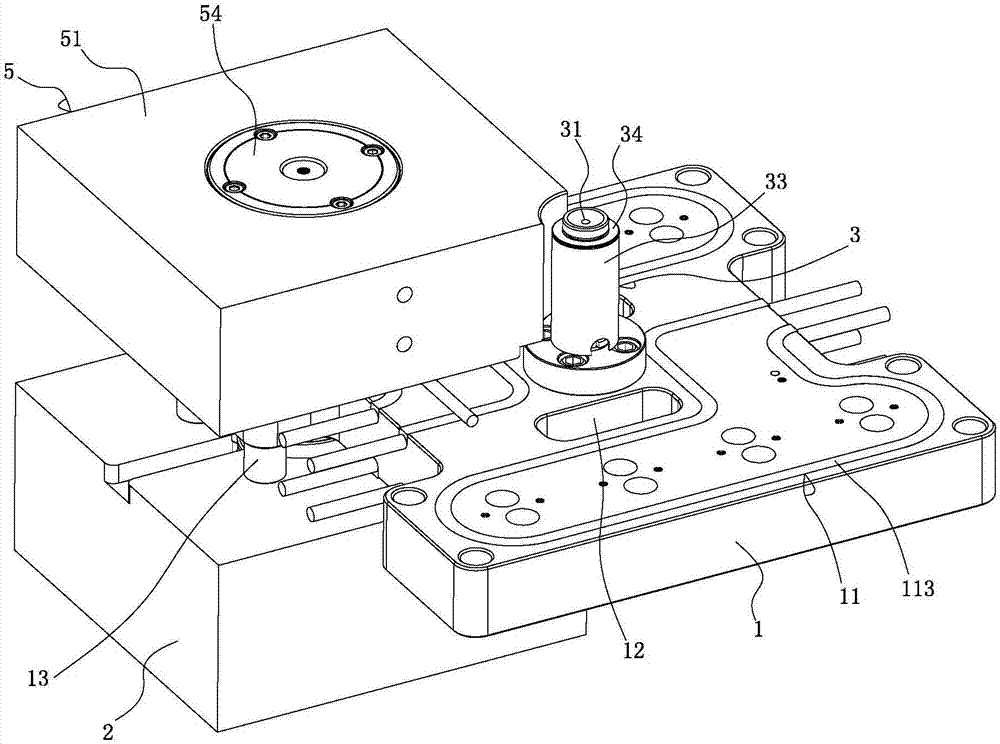

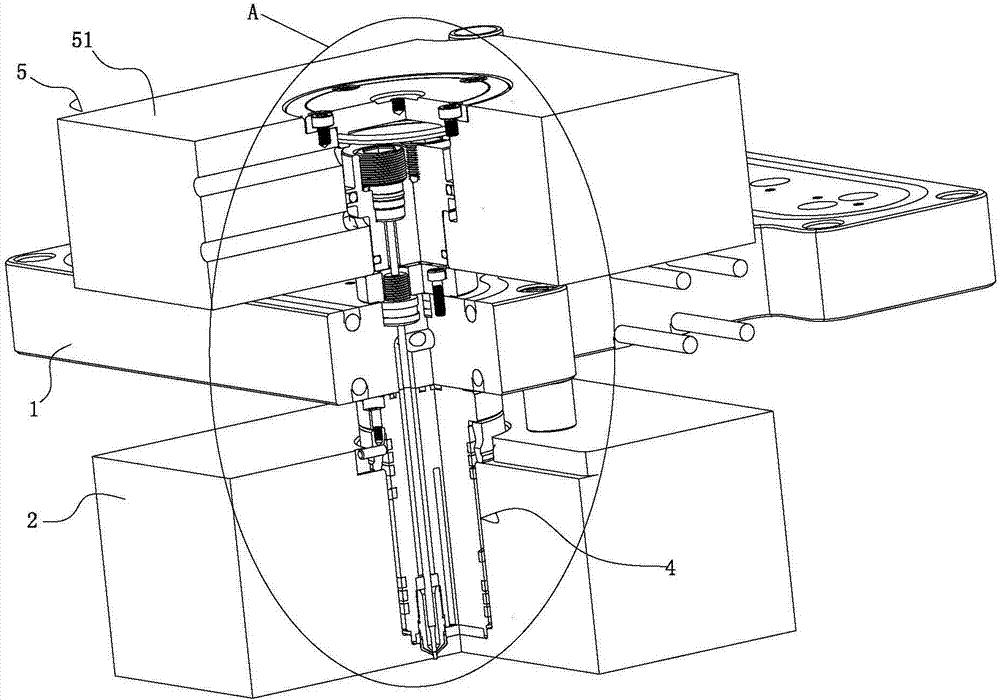

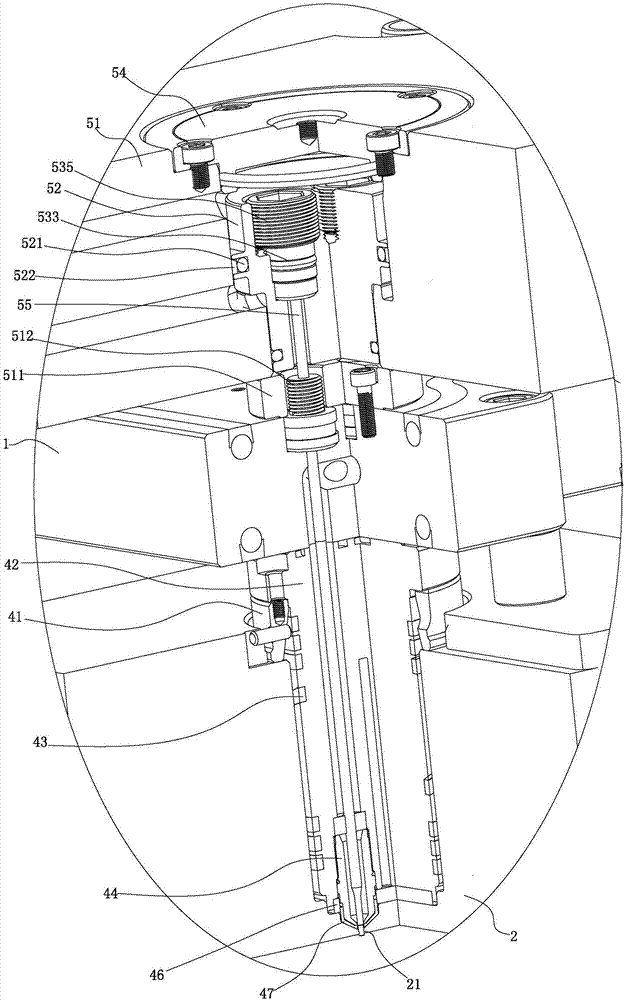

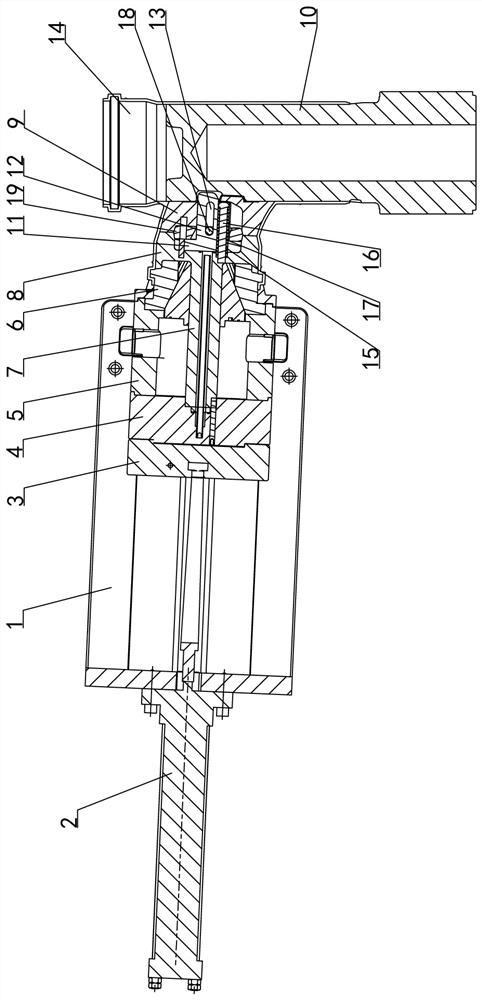

Double-valve-needle type hot runner system

The invention discloses a double-valve-needle type hot runner system comprising a spreader plate, a plate A installed at the lower end of the spreader plate, a main injection nozzle module, a hot sprue device and an air cylinder module, wherein the spreader plate is provided with a heating wire assembly. The main injection nozzle module comprises a main injection nozzle, a first heating coil, a main injection nozzle sleeve and a press sheet. The hot sprue device comprises a hot sprue installed in the plate A through a locating ring in a matched manner, a second heating coil, a first nozzle core, a second nozzle core, a heat insulation plate, a first heat insulation cap and a second heat insulation cap, wherein the heat insulation plate, the first heat insulation cap and the second heat insulation cap are installed at the lower ends of the first nozzle core and the second nozzle core. The first heat insulation cap and the second heat insulation cap are exposed in a first pouring gate and a second pouring gate which are located at the lower end of the plate A correspondingly. The air cylinder module comprises a face plate, a piston, a cylinder cover, a first valve needle and a secondvalve needle. A valve sleeve press block, a first valve sleeve and a second valve sleeve are installed between the face plate and the spreader plate. The lower end of the first valve needle sequentially penetrates through the first valve sleeve, the hot sprue, the first nozzle core and the first heat insulation cap so as to control the liquid discharge amount of the first pouring gate. The lowerend of the second valve needle sequentially penetrates through the second valve sleeve, the hot sprue, the second nozzle core and the second heat insulation cap so as to control the liquid discharge amount of the second pouring gate.

Owner:东莞市瀚茂模塑科技有限公司

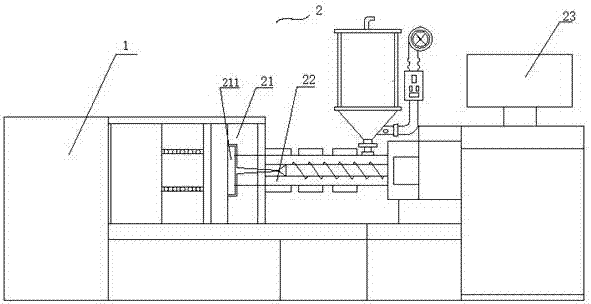

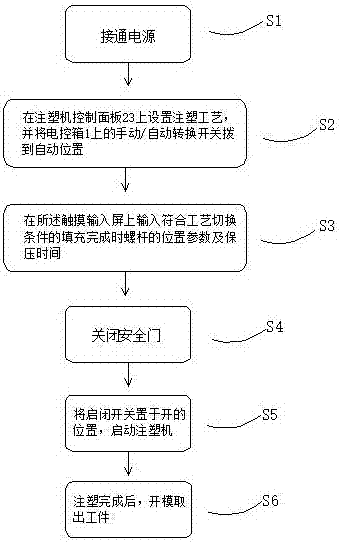

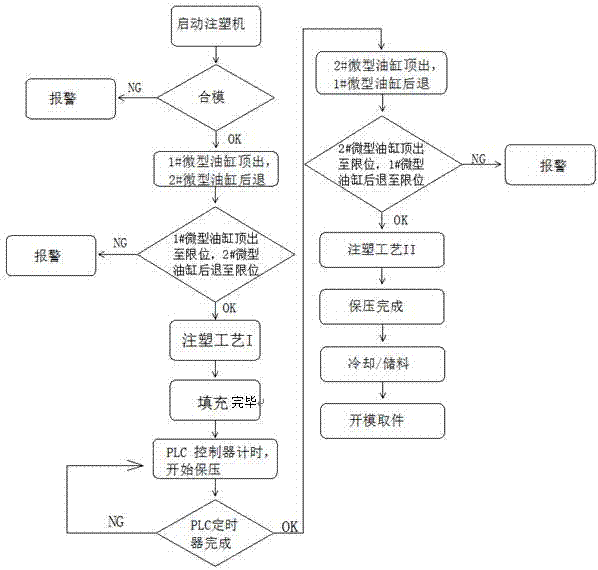

Device and method for achieving one-time molding through multiple injection molding technologies

InactiveCN107283715ASolve the problem of complex process modificationReduce flashMultiple injectionHot runner

The invention relates to the technical field of injection molding technologies, and discloses a device and method for achieving one-time molding through multiple injection molding technologies. The device comprises an electric control box and an injection molding machine controlled by a PLC; the injection molding machine is used for completing at least one injection molding technology and comprises a mold closing system, the mold closing system comprises a mold and a hot runner, filling control structures corresponding to the injection molding technologies one to one are arranged in the mold, each filling control structure comprises a micro oil cylinder, a micro oil cylinder limiting sensor and an electromagnetic valve, the micro oil cylinder limiting sensors are connected with the input end of the PLC, the micro oil cylinders and the electromagnetic valves are connected with the output end of the PLC, and the electric control box is provided with injection molding technology switches corresponding to the injection molding technologies one to one. According to the device and method, the problems that the defects such as flash and burrs of a product are serious due to the fact that different injection molding parts are machined through a same injection molding technology, and the operation of changing the injection molding technology for ensuring the product quality is complex are solved.

Owner:XIAMEN TUBETECH INC

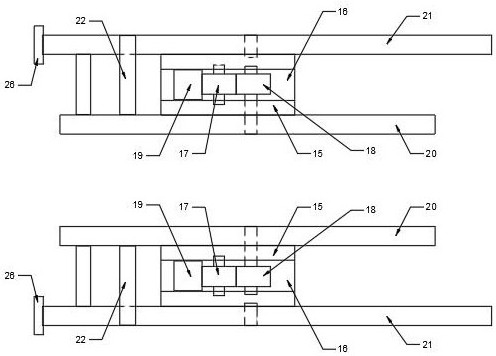

Mold-closing positioning structure of slide block

The invention provides a mold-closing positioning structure of a slide block. Through the mold-closing positioning structure, the slide block is pushed to a preset position and is positioned so that a slide insert does not contact with other front parts, wear is avoided, a precision of an inner cavity of a mold is guaranteed and product injection molding quality is guaranteed. The mold-closing positioning structure comprises a front mold, a rear mold, an A plate, a B plate, the slide insert, a slide block and a wear block. A cavity is formed among the front mold, the rear mold and the slide insert. The tail part of the slide insert is fixedly connected to the slide block. The slide block is supported by the wear block. The wear block is fastened to the B plate. The mold-closing positioning structure is characterized in that the B plate is provided with a screw thread positioning hole; the upper part of the screw thread positioning hole passes through the corresponding position of the wear block; a positioning bolt is in a threaded connection relationship with the interior of the screw thread positioning hole from bottom to top; space is formed between the upper end of the positioning bolt and the upper end surface of the screw thread positioning hole; and a support pillar with a central slotted hole is arranged in the space.

Owner:WUXI CITY NEW DISTRICT WEICHUANGLI MOLD FACTORY

Model injection molding device for manufacturing electronic components

PendingCN113580510AAvoid affecting injection molding qualityGuaranteed to be normalProcess engineeringElectronic component

The invention relates to the technical field of model injection molding, in particular to a model injection molding device for manufacturing electronic components. The model injection molding device for manufacturing the electronic components comprises a heating box and an injection molding head arranged at the bottom of the heating box, and a piston plate is slidably connected to the interior of the heating box and is driven by a first driving mechanism. According to the model injection molding device, compared with the prior art, the model injection molding device for manufacturing the electronic component has the beneficial effects that when injection molding is completed, raw materials remaining in the injection molding head can enter the heating box together, so that the situation that the raw materials in the injection molding head block the injection molding head or the raw materials enter an injection molding product after being condensed is avoided, meanwhile, the injection molding head can be sealed, external dust and other impurities are prevented from entering, meanwhile, the molten raw materials remaining in the injection molding head are completely pushed into the heating box, the injection molding quality is guaranteed, automatic detection and automatic quantitative adding can be conducted on the raw materials in the heating box, injection molding is more convenient, and the injection molding effect is guaranteed.

Owner:阳喜发

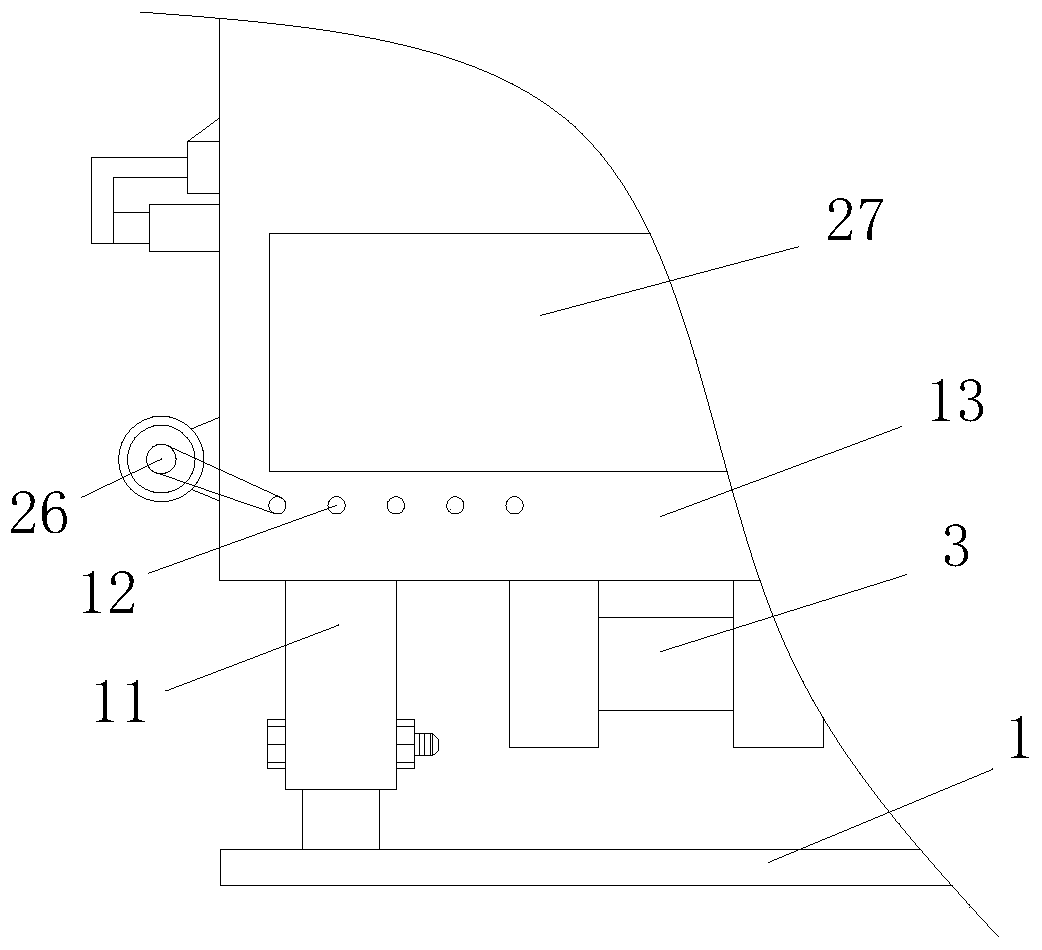

Advanced ceramic part injection mold and injection molding method

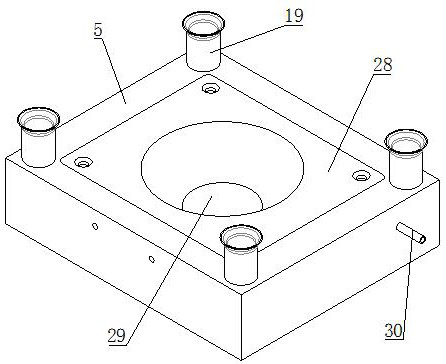

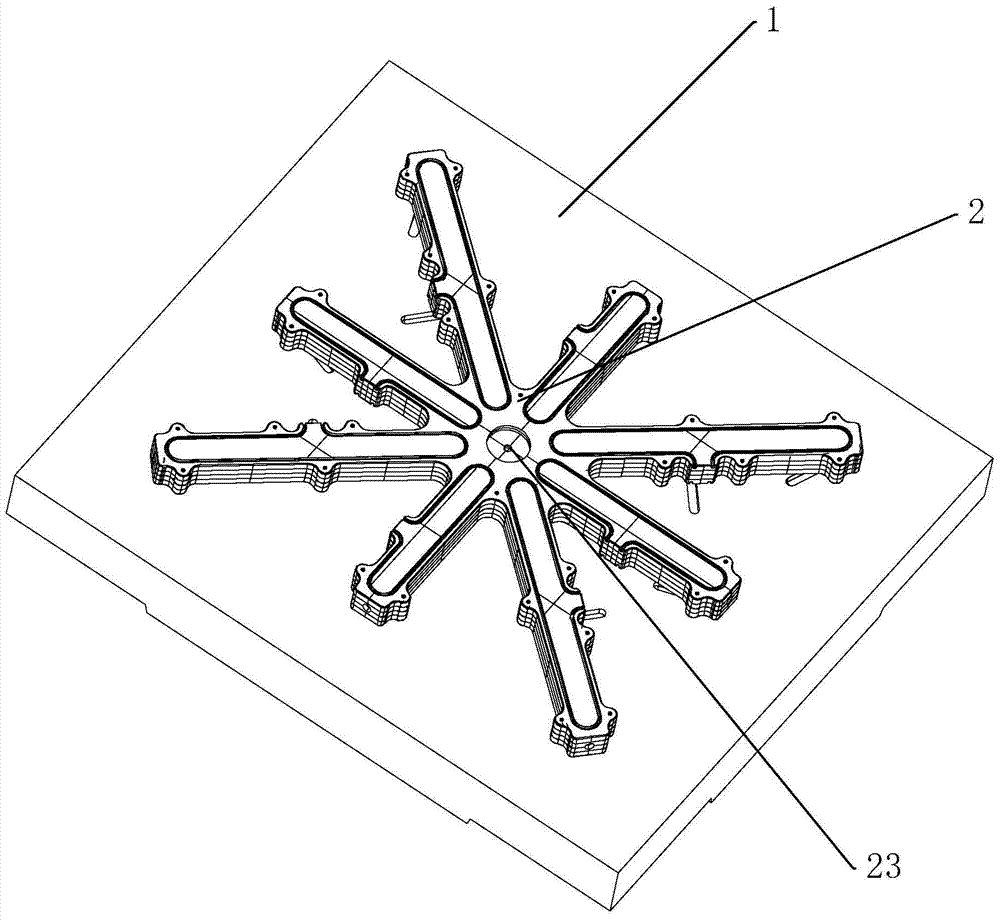

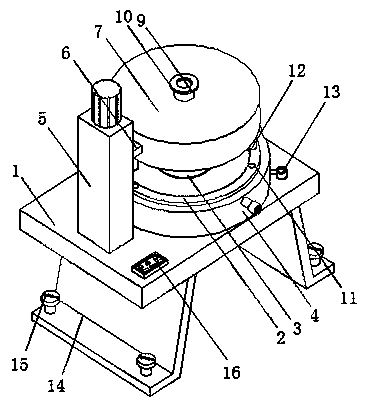

ActiveCN109648684ASimple structureUniform and efficient injectionDischarging arrangementInjection molding machineMaterials science

The invention discloses an advanced ceramic part injection mold and injection molding method. The advanced ceramic part injection mold comprises a base plate. A lower mold plate is arranged at the right side of the upper end of the base plate. An ejection device is arranged inside the lower mold plate. The outer surface of the lower mold plate is provided with a cooling device. A closed separatingdevice is arranged at the left side of the upper end of the base plate. A connecting plate is arranged at the side, close to the center of the lower mold plate, of a support block in the closed separating device. Under the effect of locating pillars and locating holes, an upper mold plate and the lower mold plate are closed through the closed separating device; mixed and compounded slurry is located and guided through a locating annular piece. According to the advanced ceramic part injection mold and injection molding method, the injection mold is simple in structure and convenient to operate; the slurry is injected uniformly and efficiently; the mold can achieve rapid cooling and molding, and materials are convenient and fast to pick; the injection molding method is reasonable and efficient; the injection molding quality of parts is guaranteed; the work load of personnel is lowered; and the injection and molding efficiency is improved.

Owner:湖南犀鸟陶瓷有限公司

Tray mold facilitating injection molding of bottom feet

ActiveCN104924529AGuarantee the quality of injection moldingGuaranteed structural strengthInjection molding machineMaterials science

The invention discloses a tray mold facilitating injection molding of bottom feet. According to the technical scheme, the tray mold is characterized in that the tray mold comprises a fixed mold body and a movable mold body; the fixed mold body is provided with a plurality of protrusions for injection molding of the bottom feet; first sprues for injection molding are arranged on the protrusions; second sprues are arranged on the plate face of the fixed mold body; the second sprues and the first sprues are located on the same face of the fixed mold body; a feeding frame for being communicated with the first sprues and the second sprues is arranged on the other face of the fixed mold body; an injection molding opening connected with a nozzle of an injection molding machine is arranged on the feeding frame. One sprue is additionally arranged on each protrusion of the fixed mold body, it is ensured that injection molding of the tray bottom feet can reach the standard, and meanwhile injection molding efficiency is improved.

Owner:ZHEJIANG XINDING PLASTIC +1

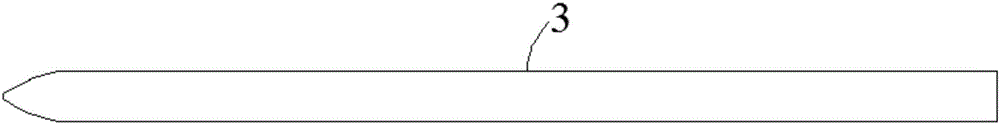

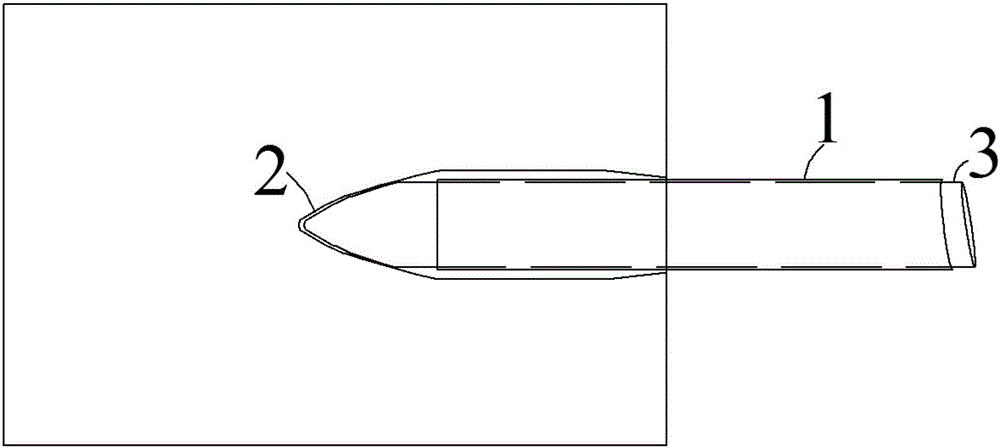

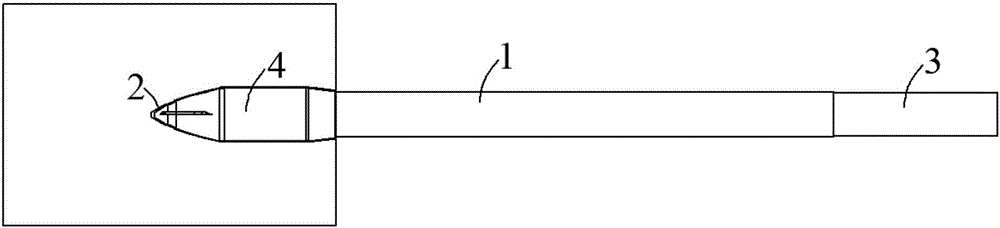

Puncture core rod manufacturing method, puncture core rod and puncture outfit

ActiveCN106335159AAvoid enteringEfficient separationSurgical needlesDomestic articlesInjection molding machineInjection moulding

Owner:FENGH MEDICAL CO LTD

Cross double-channel lens barrel mold structure and forming method thereof

ActiveCN114734582AImprove consistencyImprove injection molding efficiencyGlass productionAdhesive glueStructural engineering

The invention belongs to the technical field of lens cone molds, and particularly relates to a cross-shaped double-flow-channel lens cone mold structure which comprises a base, a lower mold plate is arranged at the top of the base, two fixing plates are fixedly connected to the two sides of the lower mold plate correspondingly, sliding rods are inserted into the fixing plates in a sliding and penetrating mode, and the sliding rods are fixedly connected with the base. The part, located at the bottom of the fixing plate, of the sliding rod is sleeved with a first spring, and a containing groove is formed in the bottom of the lower die plate. In the injection molding process, after injection molding glue enters the glue inlet pipe, due to the fact that the distances from the main injection molding pipe to the branch pipes are the same, the time and pressure of the injection molding glue entering all the first annular pipes are the same, and therefore the consistency of products can be conveniently improved; and then the injection molding glue entering the first annular pipe simultaneously enters the second annular pipe through the two symmetrical connecting pipes located on the outer side of the second annular pipe, so that compared with a traditional injection mold arranged in a straight line, the injection molding efficiency is improved.

Owner:HUBEI HUAXIN PHOTOELECTRIC CO LTD

Synchronous mold-opening mechanism

The invention belongs to the technical field of an injection mould produced by an automobile component, and provides a synchronous mold-opening mechanism. The synchronous mold-opening mechanism comprises a master mold, a male mold, mold feet, an ejector plate member and a lower fixed plate, the male mold and the master mold have a hook member, an upper end of the hook member is fixed at the mastermold, the hook member integrally passes through the master mold and is connected with the ejector plate member in a cooperation mode, and a mechanical-type synchronous mold-opening apparatus used fordriving synchronous mold-opening of the master mold and the ejector plate member is arranged at a cooperation position of the hook member and the ejector plate member. The synchronous mold-opening mechanism can realizes synchronous mold-opening of the master mold and the ejector plate member through a driving lever and a sliding block, by employing a mechanical type, the whole mold-opening mechanism has the advantages that the structure is simple, the synchronism is good, the integral manufacture cost is low, and the injection moulding quality of the final product can be guaranteed.

Owner:JIAXING XINYUAN PRECISION MOLD TECH

Injection molding mold with efficient heat dissipation function for television face frame production

The invention discloses an injection molding mold with an efficient heat dissipation function for television surface frame production, which comprises an upper mold base and a lower mold base for realizing mold closing and mold opening states, an injection molding cavity is defined by mold closing between the upper mold base and the lower mold base, the upper mold base and the lower mold base are respectively provided with an opening-shaped ring cavity, the ring cavity is arranged along the contour of the injection molding cavity in a wrapping manner, and the opening-shaped ring cavity is communicated with the injection molding cavity. A ring channel cavity formed in the upper die base is sealed through an upper sealing cover, a ring channel cavity formed in the lower die base is sealed through a lower sealing cover, transverse channels are arranged on the left side and the right side of the ring channel cavity in a communicating mode respectively, a vertical channel is arranged on the transverse channel on each side in a communicating mode, and a first opening and closing mechanism for sealing or opening is arranged at the tail of each vertical channel. The first opening and closing mechanism enables the annular channel cavities formed in the upper die base and the lower die base to be communicated up and down or closed. By the adoption of the technical scheme, temperature rise or temperature reduction between the upper mold base and the lower mold base is uniform, and non-uniform injection molding heating or cooling in the mold closing state is avoided.

Owner:SHENZHEN SEIKEN TECH CO LTD

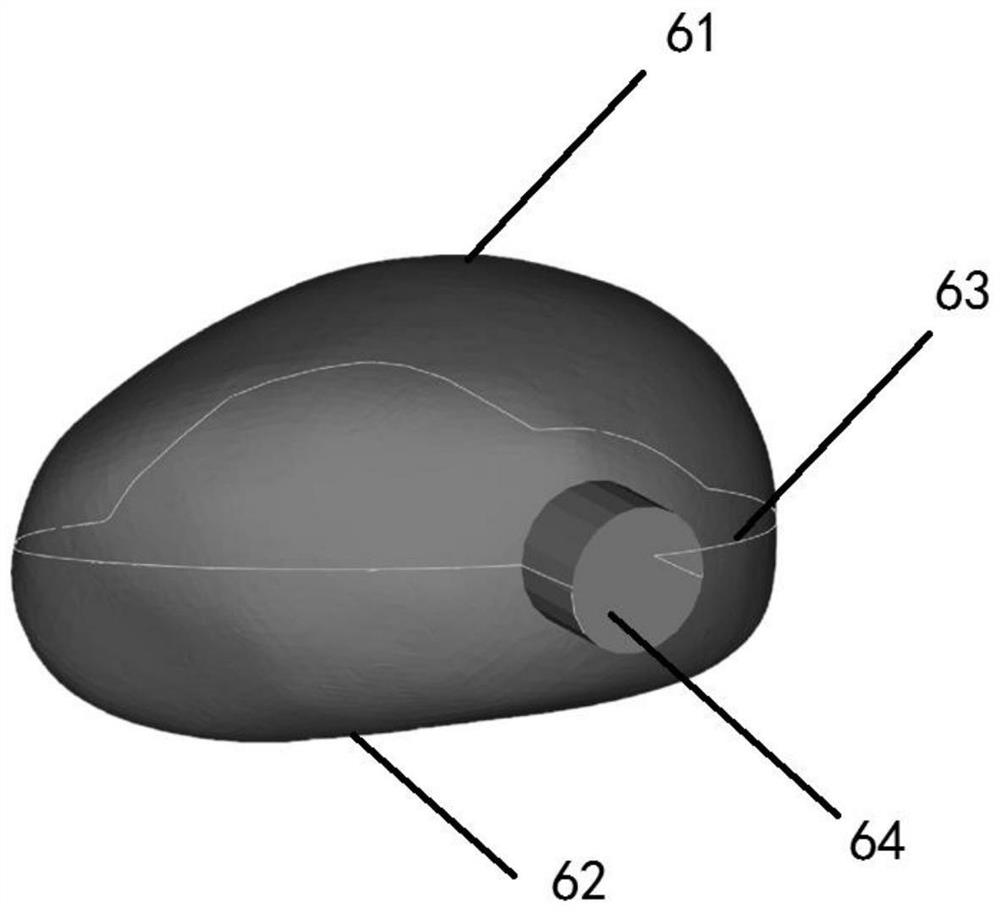

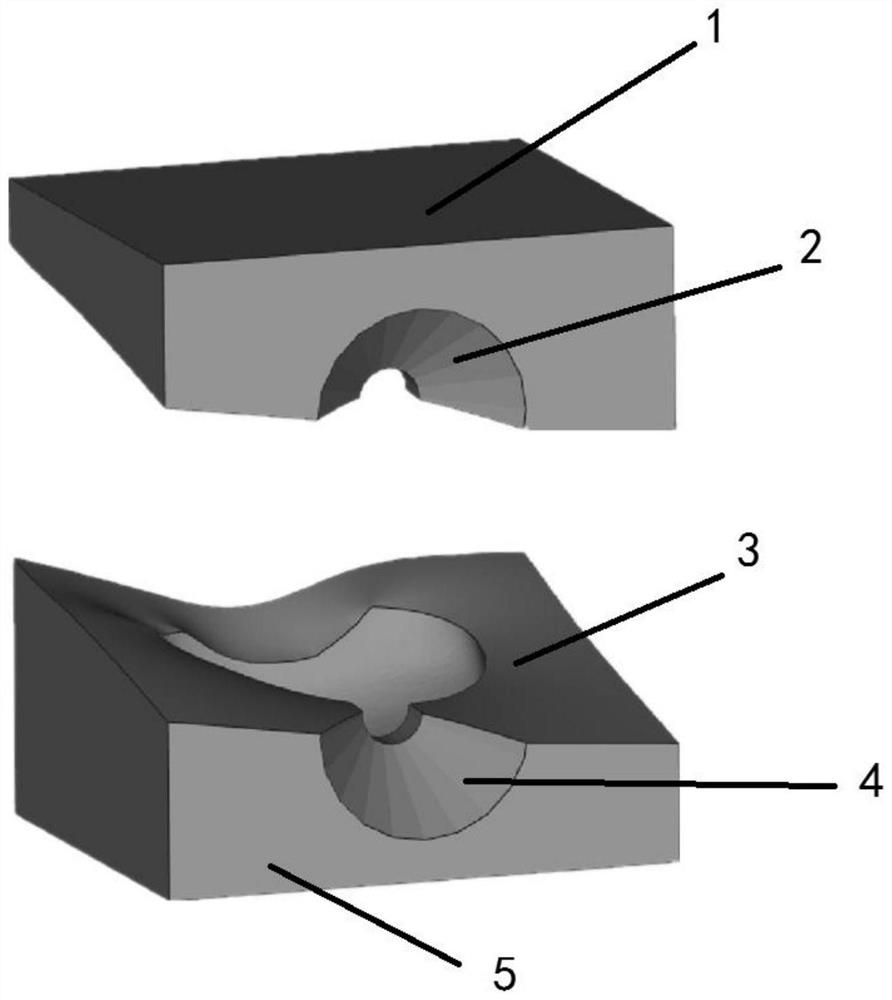

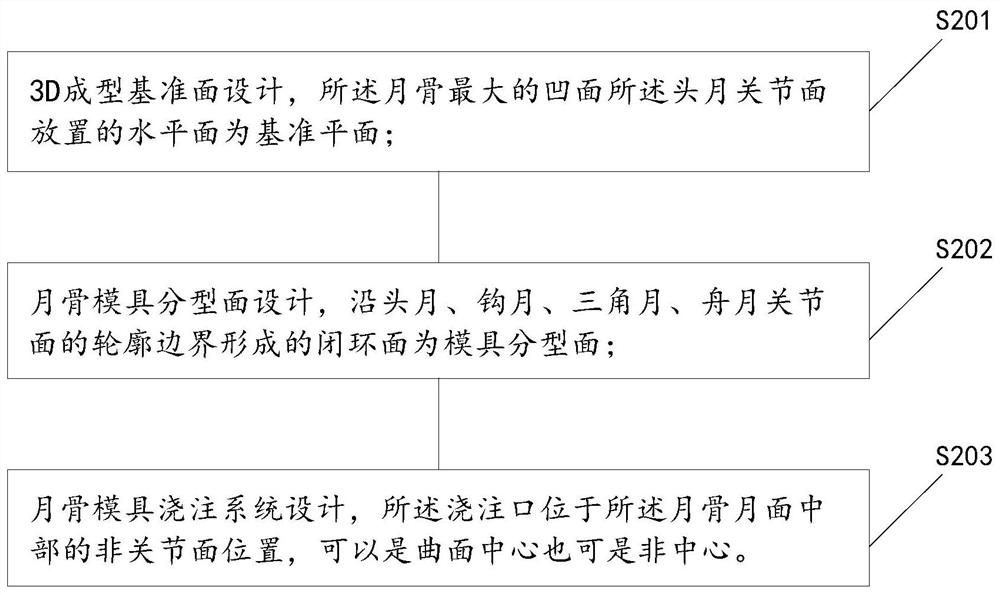

Novel lunate prosthesis, and design and preparation method thereof

PendingCN113069247AGuarantee the quality of injection moldingEasy to take outWrist jointsAnkle jointsProsthesisInjection moulding

The invention discloses a novel lunate prosthesis, and a design and preparation method thereof. With overall consideration of the process constraint of a 3D printing molding technology and an injection molding technology, and through a mold design method based on a lunate geometry, the lunate can have contralateral lunate (lunate concave surface) and radiolunate joint (lunate convex surface), and targeted 3D forming reference surface selection and mold parting surface design can be performed on a lunate mold prepared through 3D forming. The mold includes an upper layer mold and a lower layer mold; an upper pouring port is manufactured in the upper layer mold; and a lower pouring port is manufactured in the lower layer mold, and the lower layer mold has a parting surface. Therefore, the injection molding quality of the lunate prosthesis can be guaranteed, and the lunate prosthesis can be conveniently taken out.

Owner:重庆熙科医疗科技有限公司

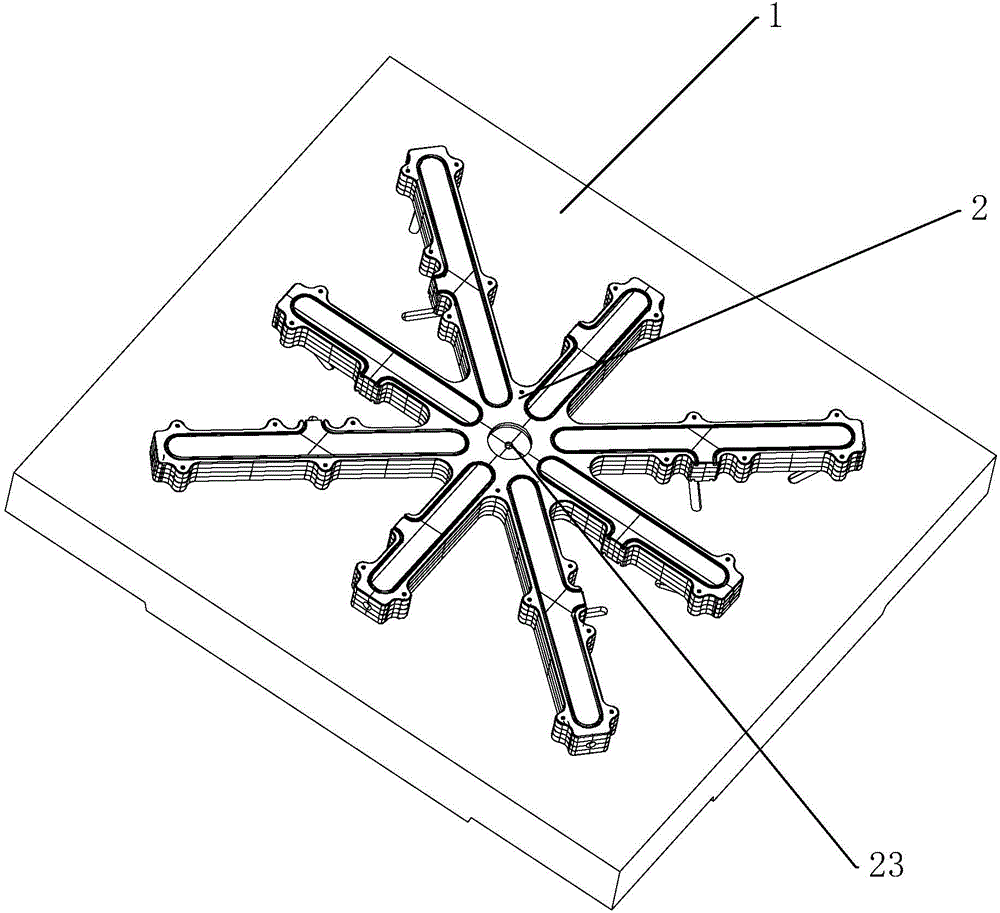

Single-cylinder multi-point hot runner system

The invention discloses a single-cylinder multi-point hot runner system, which is characterized in that a cavity is formed in a cylinder body, and an annular piston is arranged in the cavity; the annular piston is in sliding fit with the inner wall of an accommodating cavity and divides the accommodating cavity into an upper annular air cavity and a lower annular air cavity which are sealed respectively; an end cover is arranged at the opening of the cavity and is in sealed connection with the inner wall of the cavity; hot runners which are communicated with one another are arranged in a flowdividing plate, and the flow dividing plate is arranged below the cylinder body; a feeding nozzle is connected with the flow dividing plate, and an internal runner of the feeding nozzle is communicated with an inlet of each hot runner; a plurality of needle valves are arranged, each needle valve comprises a valve body and a valve needle; the upper end of the valve body is connected with the flow dividing plate, an internal runner of the valve body is communicated with the hot runner, and the valve bodies are uniformly arranged around the central axis of the annular piston; the upper end of thevalve needle is connected with the annular piston, and the lower end is inserted into the valve body; the lower end of the needle valve is connected with a pouring gate of the mold, and the valve needle is used for controlling opening and closing of the needle valve. According to the invention, the opening and closing of the needle valves can be synchronously controlled, so that the dynamic balance performance of an injection molding product is enabled to be higher.

Owner:FRENK HOT RUNNER TECH CO LTD

Horseshoe-shaped core pulling mechanism of downstream pipe fitting mold

ActiveCN112622195AExtended service lifeIncrease productivityDomestic articlesPipe fittingEngineering

The invention discloses a horseshoe-shaped core pulling mechanism of a downstream pipe fitting mold. The horseshoe-shaped core pulling mechanism comprises a core pulling support; a core pulling oil cylinder, a core pulling sliding block, a connecting block and a hollow sliding base are arranged on the core pulling support; the connecting block is connected with a connecting rod, the connecting rod is provided with a connecting base, the connecting base is connected with a horseshoe core, and the horseshoe core is matched with a straight pulling core; a downstream pipe fitting formed through injection molding is arranged outside the horseshoe core and the straight pulling core, a swing base is arranged on the connecting base, a swing protruding block is arranged on the swing base, a limiting groove and a spring hole are formed in the swing protruding block, a spring pin is arranged in the spring hole, one end of the spring pin abuts against the connecting base, the spring pin is sleeved with a spring, and a limiting pin is arranged in the limiting groove; the swing protruding block is sleeved with a positioning plate, the horseshoe core is connected to the positioning plate, and the swing protruding block stretches into the horseshoe core; and the other end of the spring pin abuts against the inner wall of the horseshoe core, a positioning groove is formed in the positioning plate, the limiting pin is matched with the positioning groove, and the horseshoe core is pressed on the limiting pin.

Owner:TAIZHOU HUANGYAN WEIDA PLASTIC MACHINERY

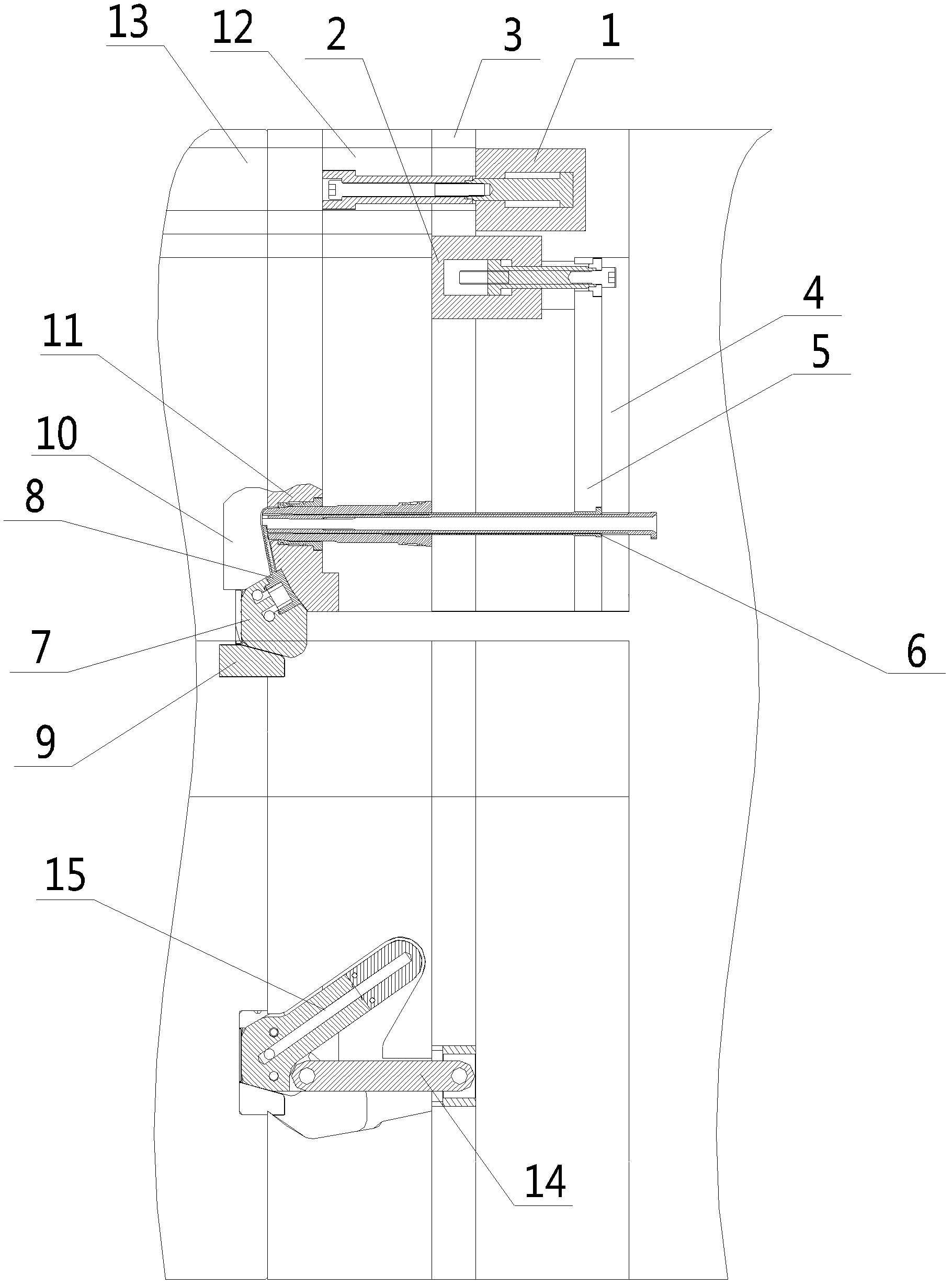

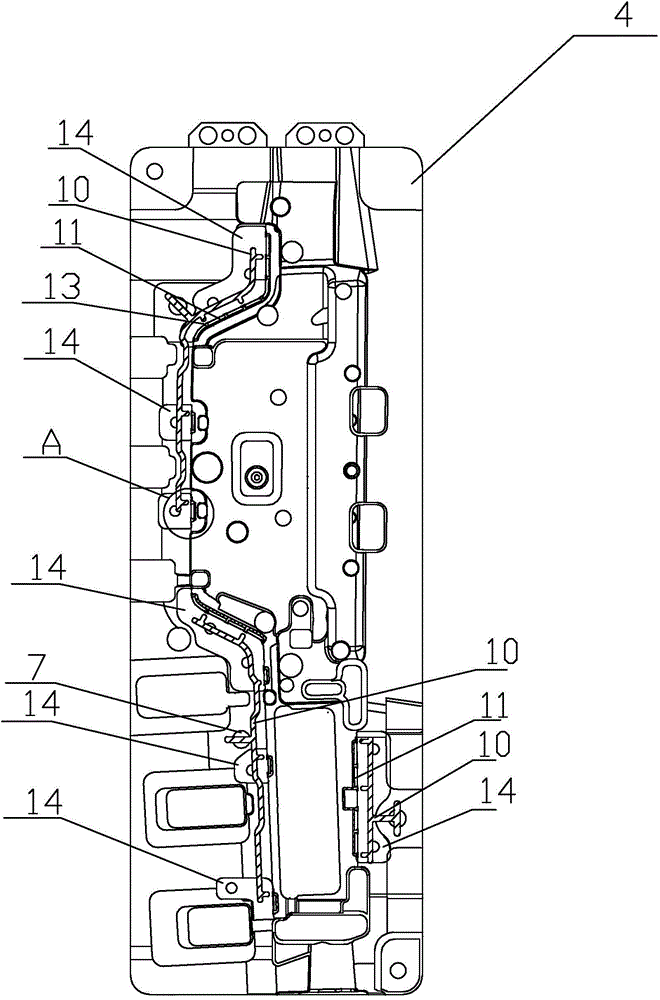

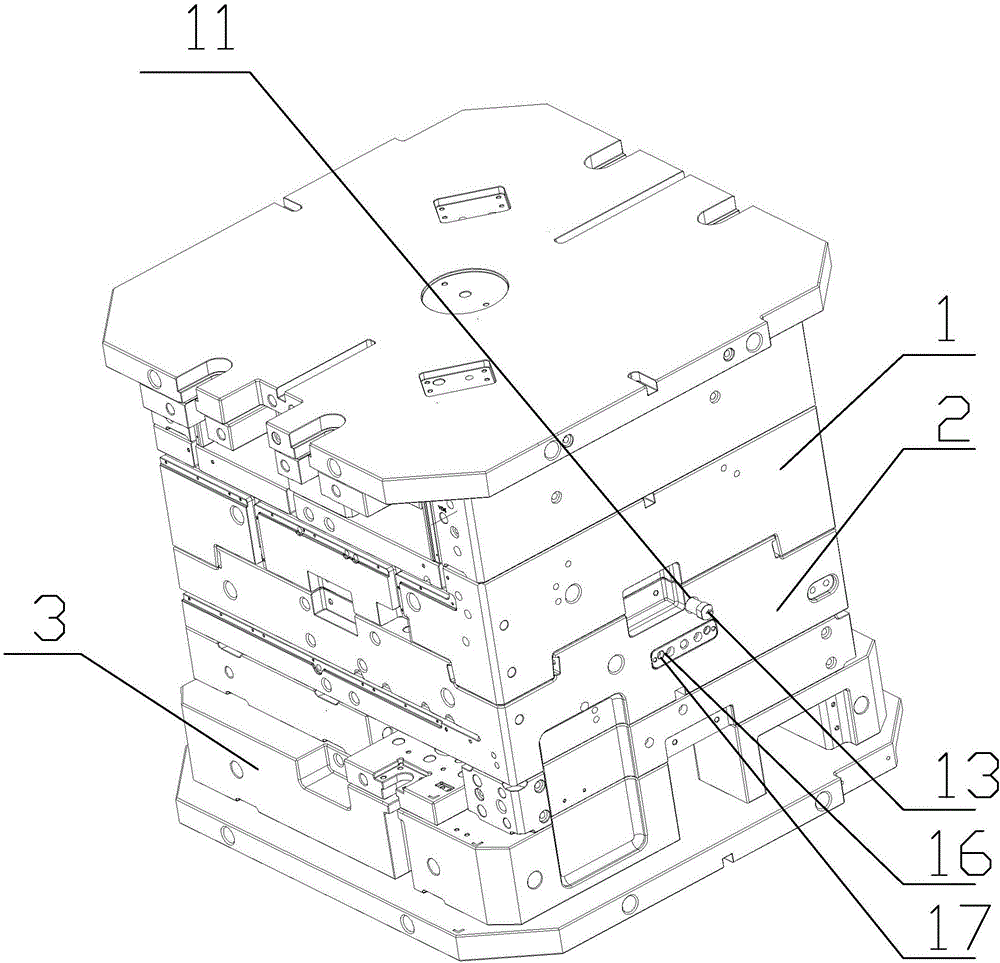

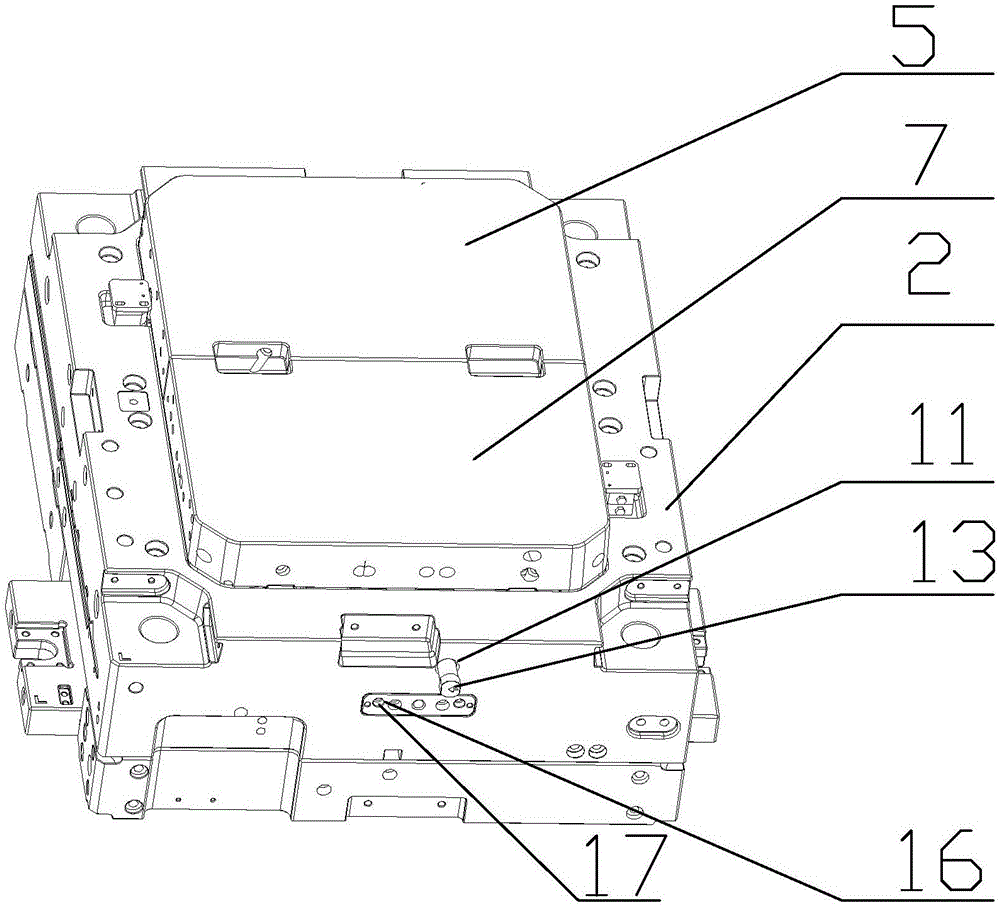

Injection mold for side frame of car boot

ActiveCN106273267AMeet assembly requirementsEasy to assembleDomestic articlesUltimate tensile strengthMechanical engineering

The invention discloses an injection mold for a side frame of a car boot. The injection mold comprises a moving template (1), a fixing template (2), a support block (3) and at least two products (4); the fixing template (2) is fixed at the upper part of the support block (3), and the moving template (1) is located at the upper part of the fixing template (2). The injection mold is characterized in that the moving template (1) and the fixing template (2) are internally provided with a flexible glue template group for performing the injection molding on the side frames of the products (4) and a hard glue template group for performing the injection molding on the part in the side frames of the products (4); the flexible glue template group comprises a first upper die core (5) arranged at the lower surface of the moving template (1) and a first lower die core (6) arranged at the upper surface of the fixing template (2). According to the invention, the injection mold for the side frame of the car boot can exchange mold inserts mutually, so that the processing efficiency is high, labor intensity is low and the production efficiency of the injection molding is high; moreover, the injection mold can meet the assembling requirement of automobile fittings.

Owner:宁波如强模塑有限公司

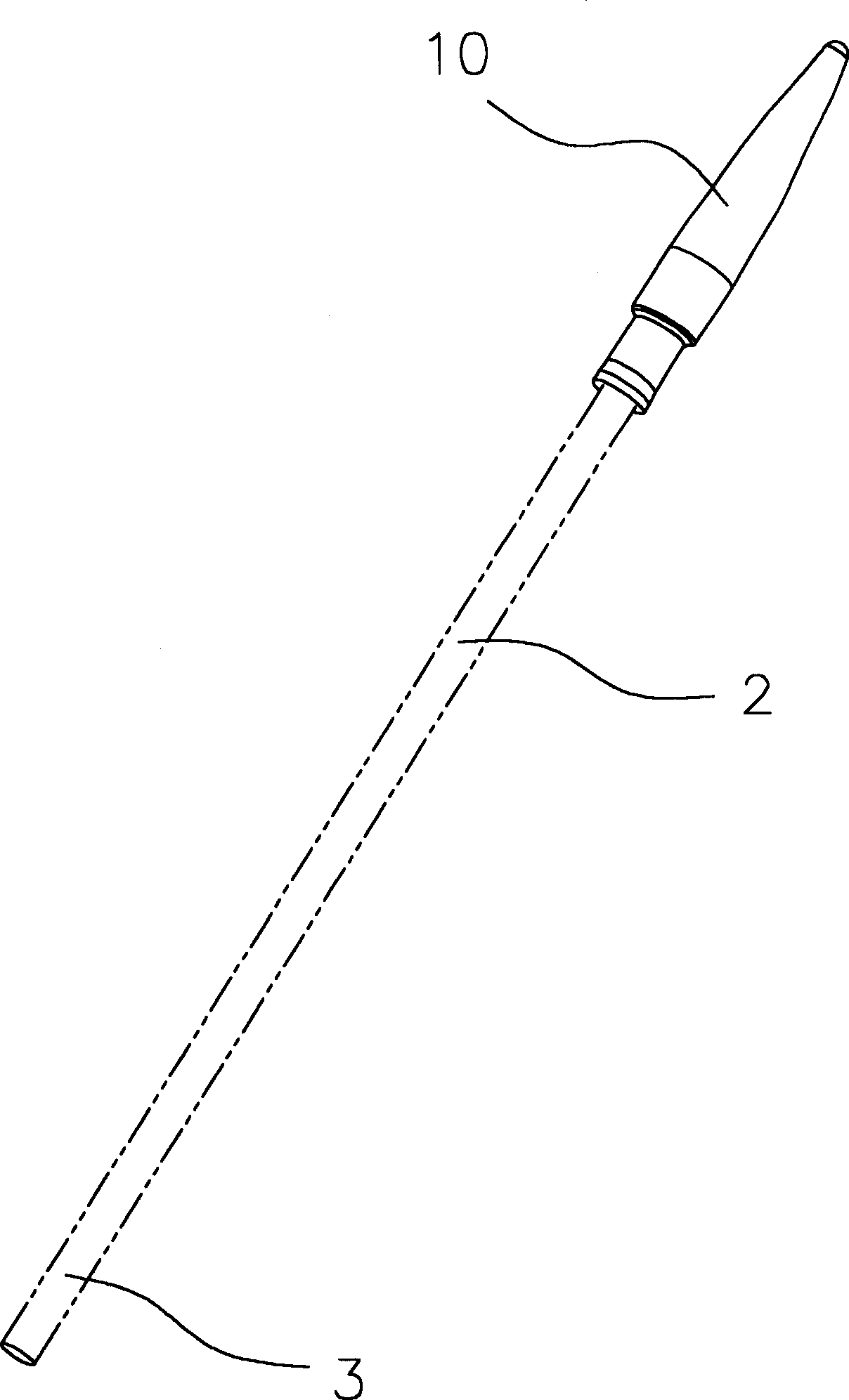

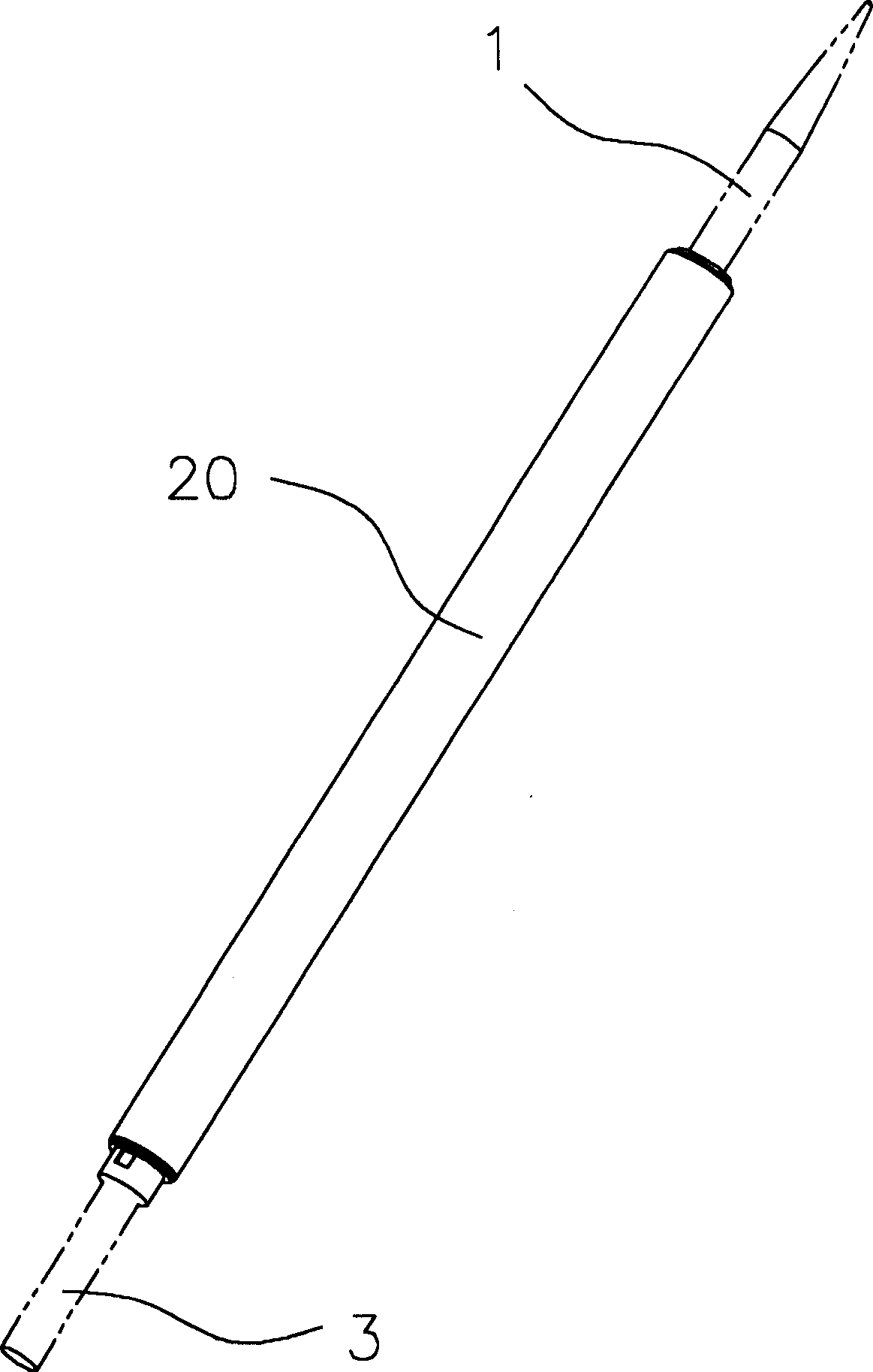

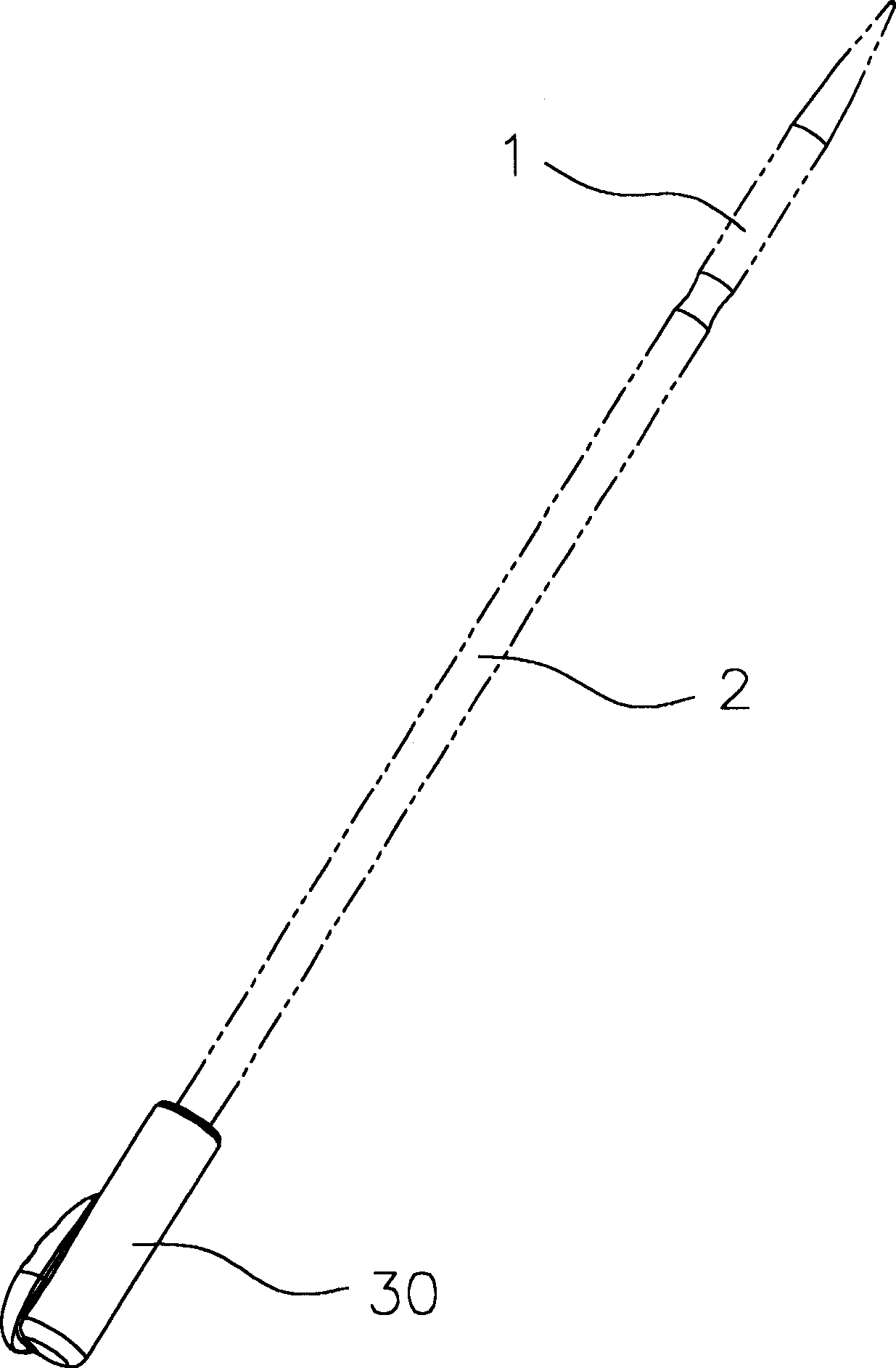

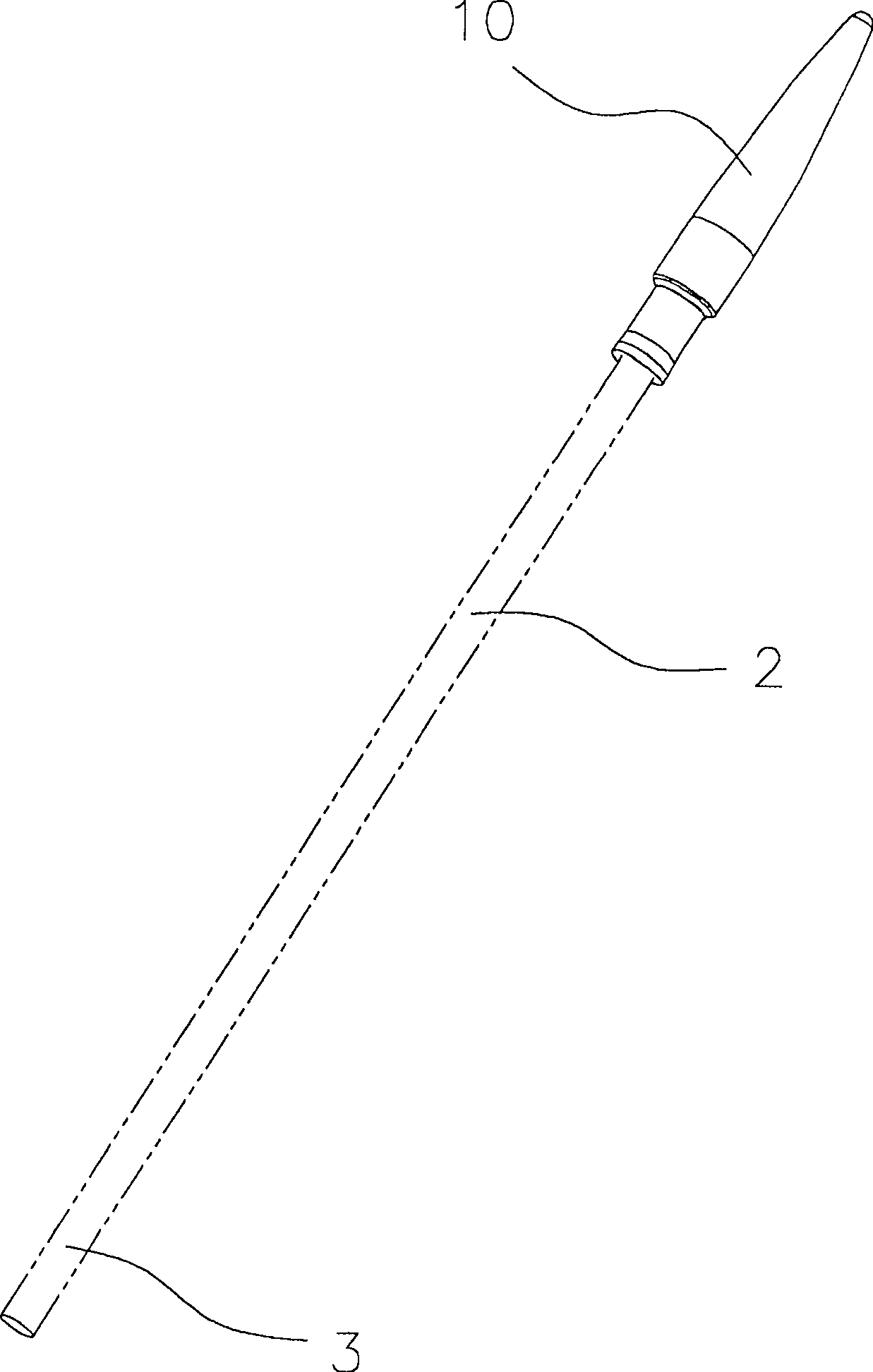

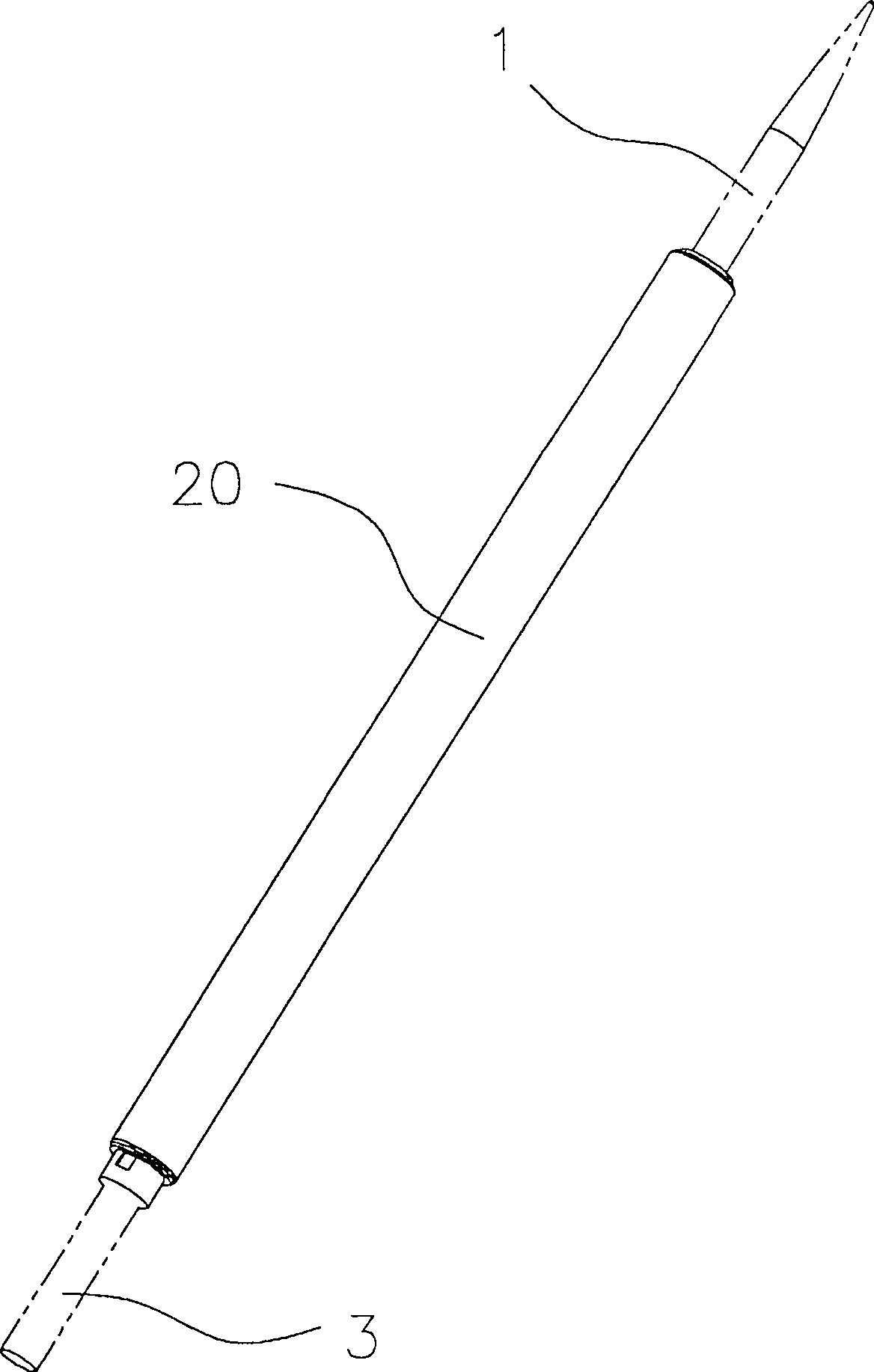

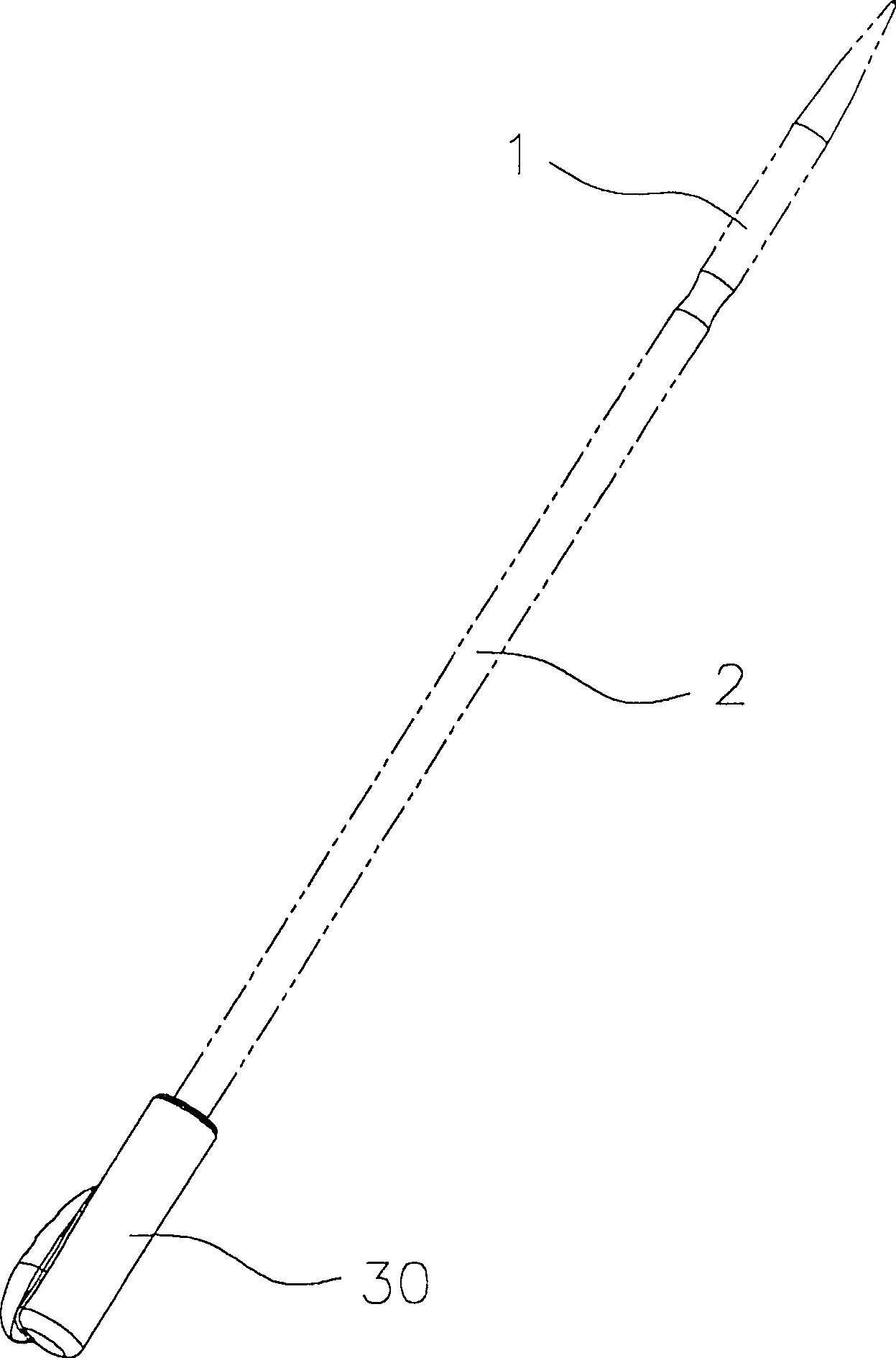

Injection moulding method for stylus

InactiveCN1485194AGuarantee the quality of injection moldingEasy to take outCoatingsEngineeringInjection moulding

The invention discloses an injection moulding method for touch pens, in order to guarantee the moulding quality, the touch pen can be achieved through the injection moulding of three sets of dies, placing the inner pen units in sequence into the main spray dies. the tough pen is injected though the sequence of sequence end, intermediate section and the fastening end, which improves the quality oftouch pen injection. íí

Owner:MITAC COMP (SHUN DE) LTD

Injection mold with service life easy to control

The invention discloses an injection mold with service life easy to control. The injection mold is composed of an upper mold base and a lower mold base which are controlled to open and close. Particularly, the injection mold is provided with a counter used for performing statics of the number of times of mold closing. The counter is provided with a counting chip, a visually visible reading window and an interface connected with a computer reset chip. The injection mold in use has the remarkable advantages that the counter is arranged to achieve the statics of the number of times of mold closing and visually present the statics, the maintenance of the injection mold is facilitated according to the number of times of using the injection mold, precision reduction caused by abrasion of the injection mold is effectively prevented, and injection molding quality of a formed product is guaranteed.

Owner:SUZHOU INDAL PARK XIELI PLASTIC

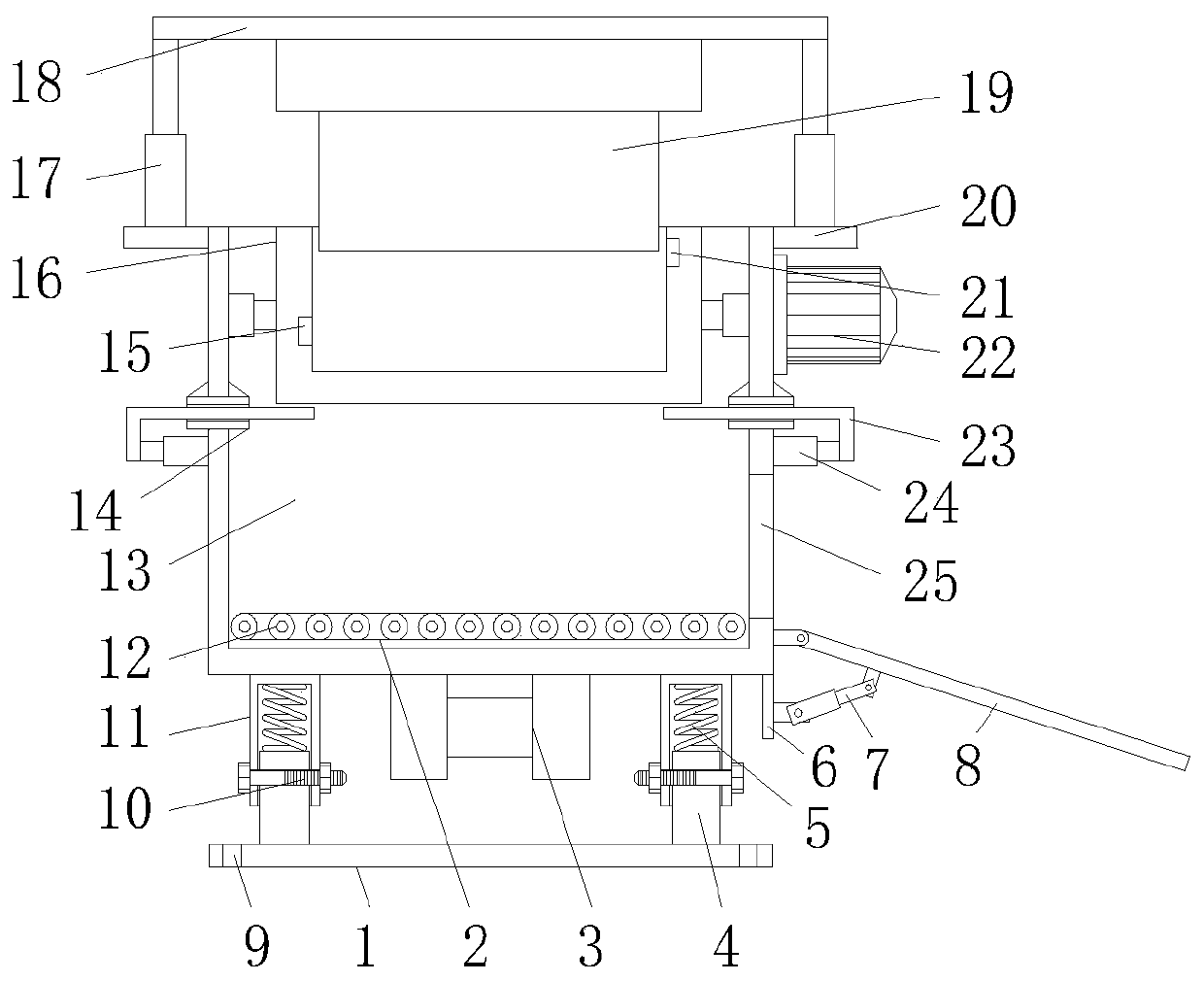

Intelligent numerical control plastic beehive injection molding device

ActiveCN108501334AStable temperatureGuarantee the quality of injection moldingFireproof paintsDomestic articlesNumerical controlInductor

The invention discloses an intelligent numerical control plastic beehive injection molding device which comprises a first die plate, a second die plate, a conveying pipe and a feeding barrel; a plurality of fixed push rods which are uniformly and symmetrically distributed are arranged on the outer side of the first die plate; a first die groove is formed in the inner side of the first die plate; asecond die groove which is matched with the first die groove is formed in the inner side of the second die plate; an injection molding groove is formed in the middle part of the second die groove; the outer side of the injection molding groove is connected with the conveying pipe; the conveying pipe is internally provided with a spiral conveying rod; the upper end of the conveying pipe is provided with the feeding barrel; a feeding pipe is provided with a spiral heating resistance tube; and through control of a temperature inductor, an injection molding material in the feeding pipe always keeps a stable temperature, and the injection molding quality is ensured. The design is simple to operate, strong in comprehensive practicability and liable in popularization and use.

Owner:安徽飞镖知识产权服务股份有限公司

Injection mold with convenient discharging function

Owner:杭州蒙图机械设计有限公司

High-strength and impact-resistant automobile stand column mold

The invention discloses a high-strength and impact-resistant automobile stand column mold. The mold comprises a base, stand columns are arranged at the four corners of the base, an upper top plate is horizontally arranged at the tops of the stand columns, a plurality of lifting devices are arranged at the bottom of the upper top plate, an upper mold is arranged at the tail ends of execution shafts of the plurality of lifting devices, and an upper mold cavity is formed in the bottom of the upper mold; an injection molding opening is formed in the top of the upper mold, a fixing frame is arranged at the top of the base, a lower mold is arranged at the top of the fixing frame, a lower mold cavity is formed in the top of the lower mold, a plurality of through holes communicating with the interior of the fixing frame below the lower mold are formed in the bottom of the lower mold cavity, and ejecting columns are arranged in the plurality of through holes; and a fixing plate is horizontally arranged at the bottoms of the ejecting columns, ejecting blocks are arranged at the tops of the plurality of ejecting columns correspondingly, ejecting mechanisms used for driving the fixing plate to ascend and descend are further symmetrically arranged in the fixing frame on the two sides of the fixing plate, and a controller is further arranged on one side of the base. According to the mold, the formed stand columns can be conveniently ejected out, and the efficiency is improved.

Owner:JINGJIANG XINCHENG VEHICLE PARTS

Injection molding method for stylus

InactiveCN100506506CGuarantee the quality of injection moldingEasy to take outCoatingsEngineeringInjection molding machine

The present invention mainly discloses an injection molding method for a touch pen. In order to ensure the injection quality of the touch pen, the touch pen can be injection molded through three sets of molds, and the inner pen body is sequentially placed into the corresponding main injection mold. According to the order of the contact end, middle section, and buckle end, they are injected three times respectively; in view of this injection molding feature, the creator designed the main fixing tool and auxiliary fixing tool for the stylus to improve the stability of the stylus. Injection quality.

Owner:MITAC COMP (SHUN DE) LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com