Injection mold with service life easy to control

A technology of injection mold and lifespan, which is applied in the field of life control of consumable injection molds to prevent the reduction of precision and ensure the quality of injection molding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] Aiming at the defects and drawbacks of traditional injection molds in terms of precision maintenance, the present invention proposes an innovative improvement scheme. By counting parts in the combination of traditional injection molds, it provides a comprehensive solution for injection molds from core design, preliminary processing, and testing. Provide a series of counting programs for molds, deep processing, retesting molds, precision machining and actual production, etc., to help and provide convenient and standardized technical basis for technicians to grasp the use of molds.

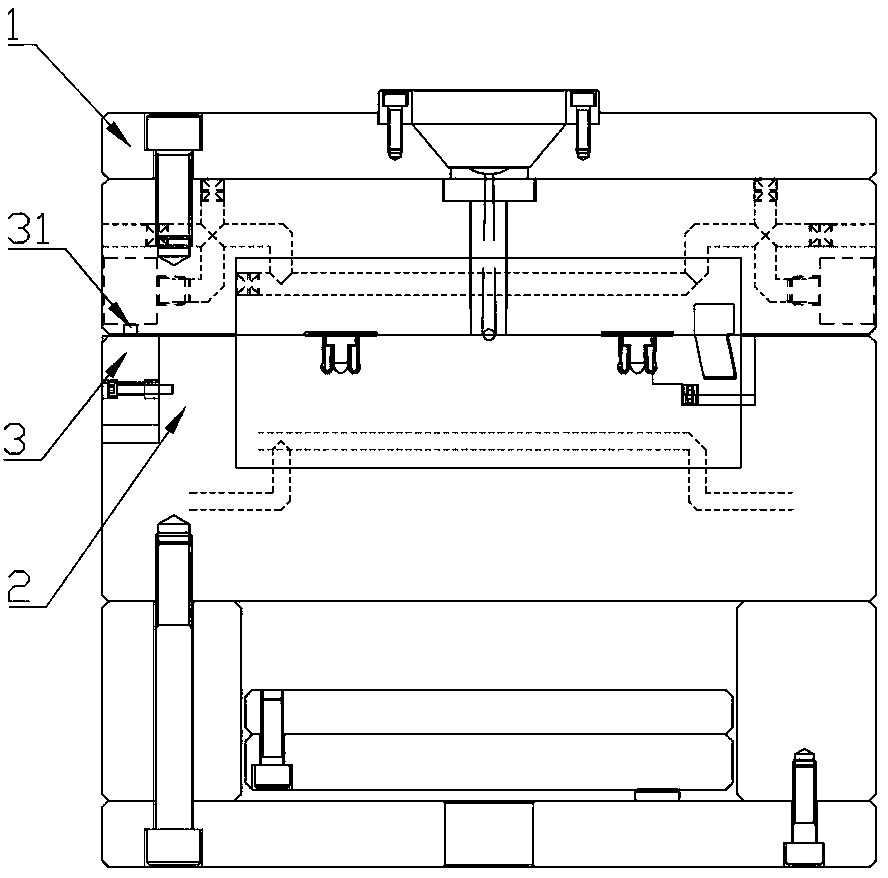

[0013] like figure 1 Shown is a structural schematic diagram of an injection mold with easy-to-control lifetime according to the present invention. It can be seen from the diagram that the injection mold consists of an upper mold base 1 and a lower mold base 2 with controlled opening and closing. As an innovative feature, the injection mold is equipped with a counter for counting the number ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com