Injection mold

A technology of injection molds and mold cores, applied in the field of injection molds, can solve the problems of reducing production efficiency, difficulty of injection molding processing, and scrapping injection molded parts, so as to achieve the effect of ensuring the yield of finished products and improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention is described below in conjunction with accompanying drawing.

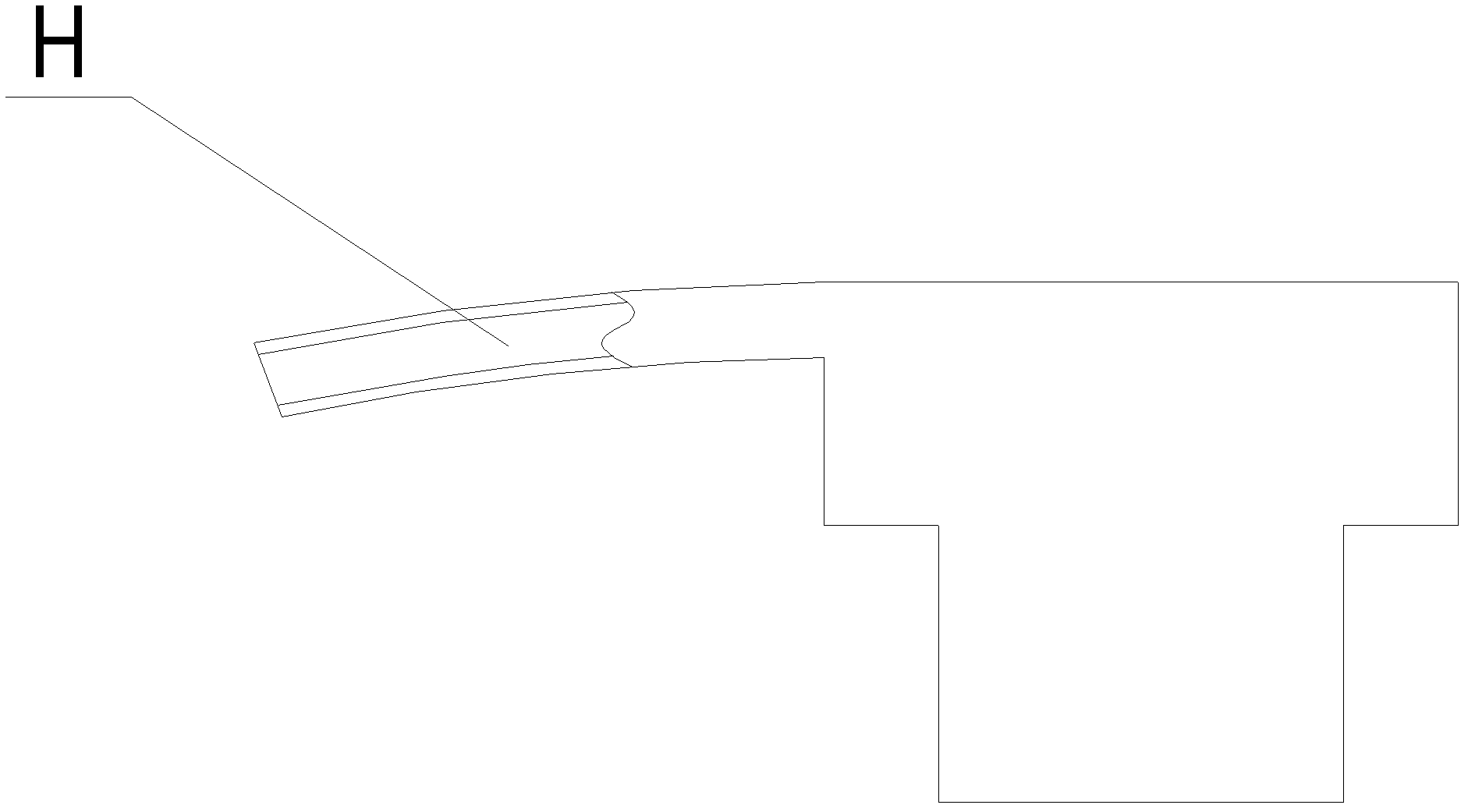

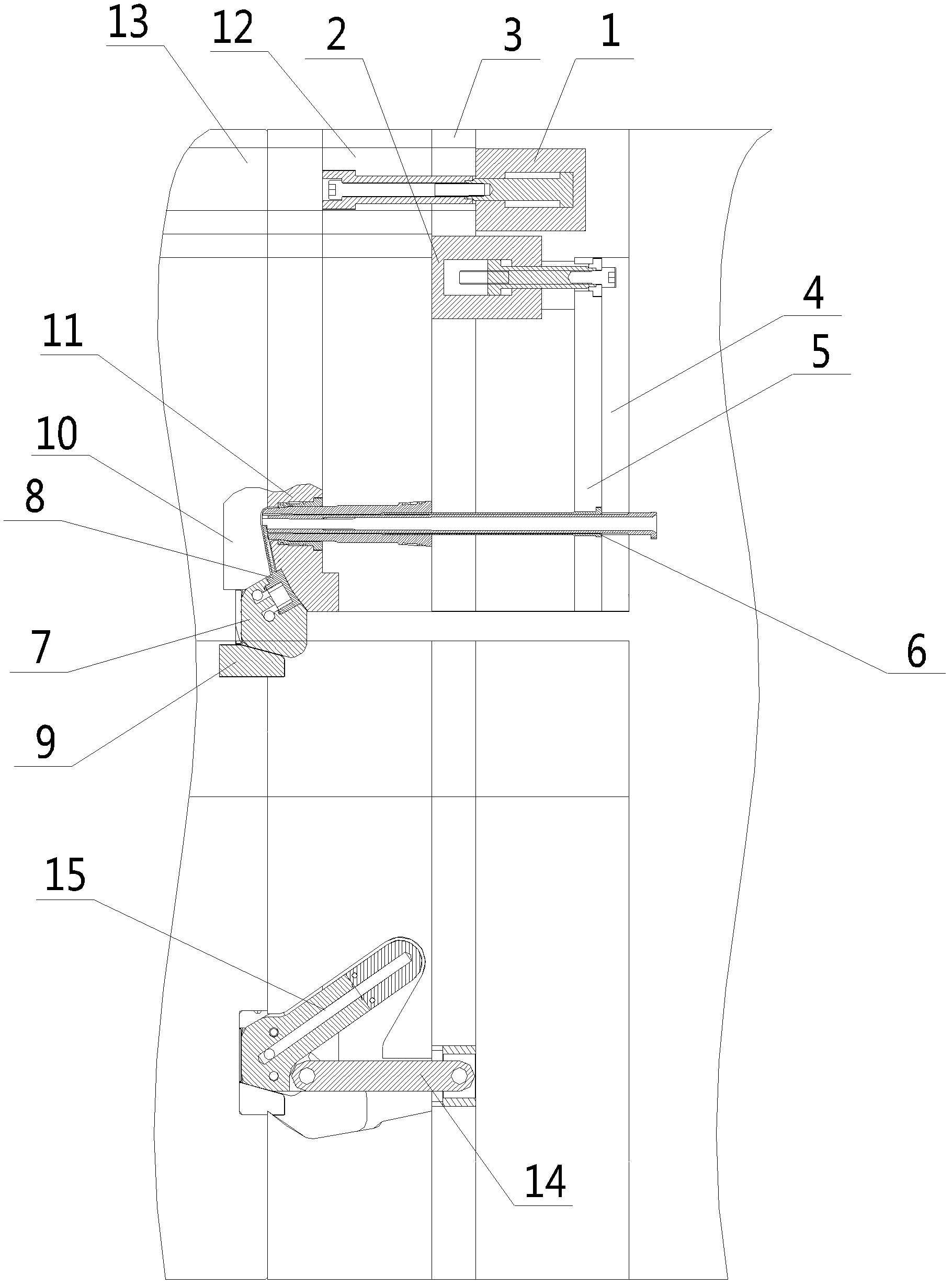

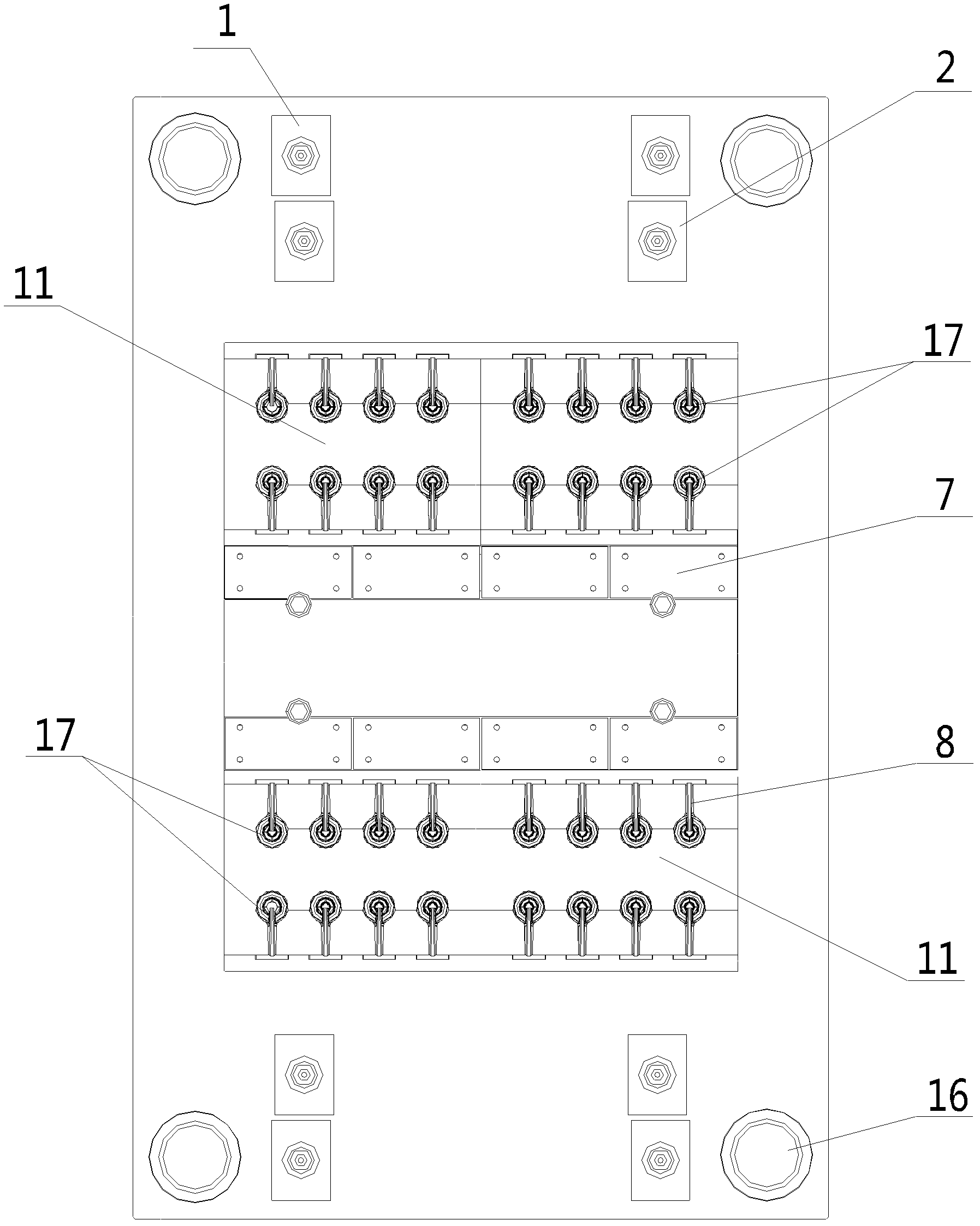

[0019] attached figure 2 , 3 For the injection mold of the present invention placed on the horizontal injection molding machine, it includes a fixed template 13, a movable template 12, a fixed mold kernel 10, a movable mold kernel 11, a cylinder 6, oil cylinder A group 1, oil cylinder B group 2, and a slide block Inlet 8, slide block seat 7, first connecting rod 14, second connecting rod 15, push plate 3, bottom needle plate 4 and face needle plate 5; said fixed template 13 is provided with a fixed mold kernel 10; said There are four fixed die cores 10, which are evenly arranged on the fixed template 13; on the side where the fixed template 13 matches the movable template 12, four movable die cores 11 corresponding to the fixed die cores 10 are provided. ; Form eight cavities (not shown in the figure) between each pair of fixed mold cores 10 and movable mold cores 11, and each cavity...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com