Intelligent numerical control plastic beehive injection molding device

A technology for plastics and beehives, applied in fire-retardant coatings, epoxy resin coatings, household components, etc., can solve problems such as plastics sticking to the inner wall of the device, molten plastics are easy to agglomerate, and the quality of injection molding is reduced, so as to achieve surface stability. Good, long service life, ensure the effect of injection molding quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

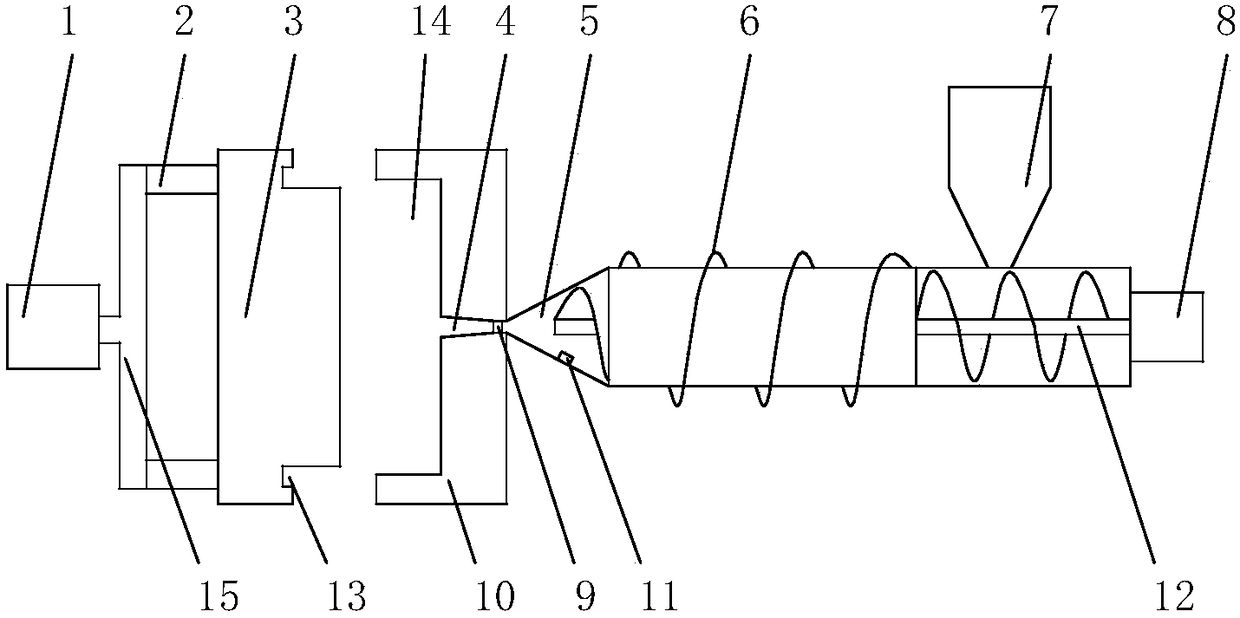

[0033] Embodiment 1, an intelligent digital control plastic beehive injection molding device, comprising a first mold plate 3, a second mold plate 10, a feeding pipe 5 and a feed barrel 7, and the outside of the first mold plate 3 is provided with a number of uniform and symmetrical Distributed fixed push rods 2, and the inside of the first mold plate 3 is provided with a first mold groove 13, and the inside of the second mold plate 10 is provided with a second mold groove 14 that matches the first mold groove 13. The middle part of the second mold groove 14 is provided with an injection groove 4, and the outer side of the injection groove 4 is connected with the feed pipe 5, and the screw feed rod 12 is arranged inside the feed pipe 5, and the upper end of the feed pipe 5 is provided with a feed barrel 7.

[0034] The fixed push rod 2 is a hydraulic rod, and the hydraulic rods are electrically connected to the electrohydraulic regulator 1 through a connecting pipe 15 .

[00...

Embodiment 2

[0038] Embodiment 2, an intelligent digital control plastic beehive injection molding device, comprising a first mold plate 3, a second mold plate 10, a feeding pipe 5 and a feed barrel 7, and the outside of the first mold plate 3 is provided with a number of uniform and symmetrical Distributed fixed push rods 2, and the inside of the first mold plate 3 is provided with a first mold groove 13, and the inside of the second mold plate 10 is provided with a second mold groove 14 that matches the first mold groove 13. The middle part of the second mold groove 14 is provided with an injection groove 4, and the outer side of the injection groove 4 is connected with the feed pipe 5, and the screw feed rod 12 is arranged inside the feed pipe 5, and the upper end of the feed pipe 5 is provided with a feed barrel 7.

[0039] The fixed push rod 2 is a hydraulic rod, and the hydraulic rods are electrically connected to the electrohydraulic regulator 1 through a connecting pipe 15 .

[00...

Embodiment 3

[0049] Embodiment 3, the contents of embodiment 3 and embodiment 2 are basically the same, the similarities will not be repeated, the difference is: 25kg of epoxy resin, 15kg of polybenzimidazole, 6kg of high temperature resistant inorganic non-metallic compound, high temperature resistant filler 20kg, curing agent 1kg, solvent 10kg, silane coupling agent 1kg.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com