Injection mold with convenient discharging function

A convenient technology for injection molds, applied in the field of injection molds for convenient discharge, can solve the problems of inconvenient discharge and inconvenient use, and achieve the effects of reducing raw material waste, avoiding hollowing, and ensuring injection molding quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

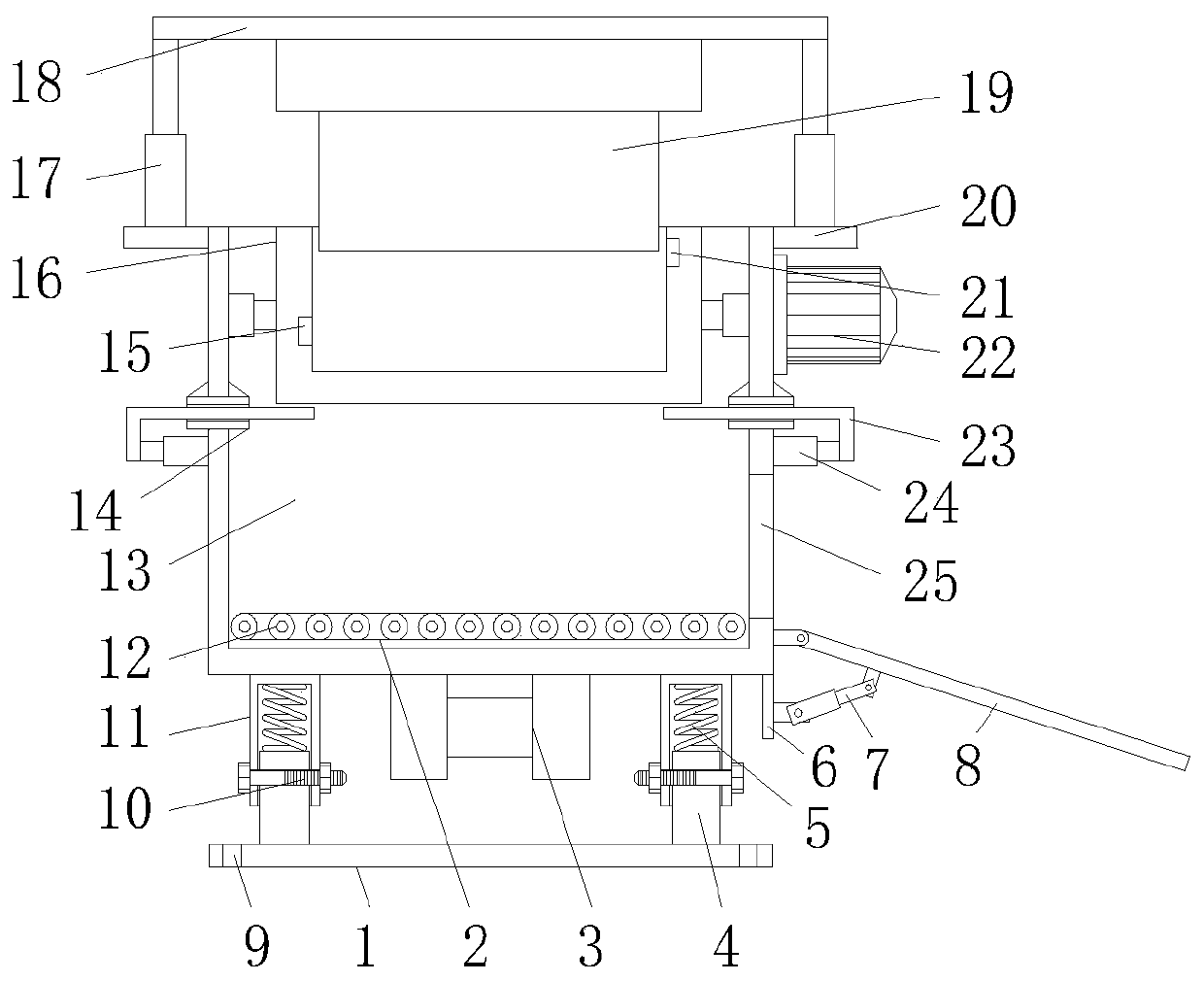

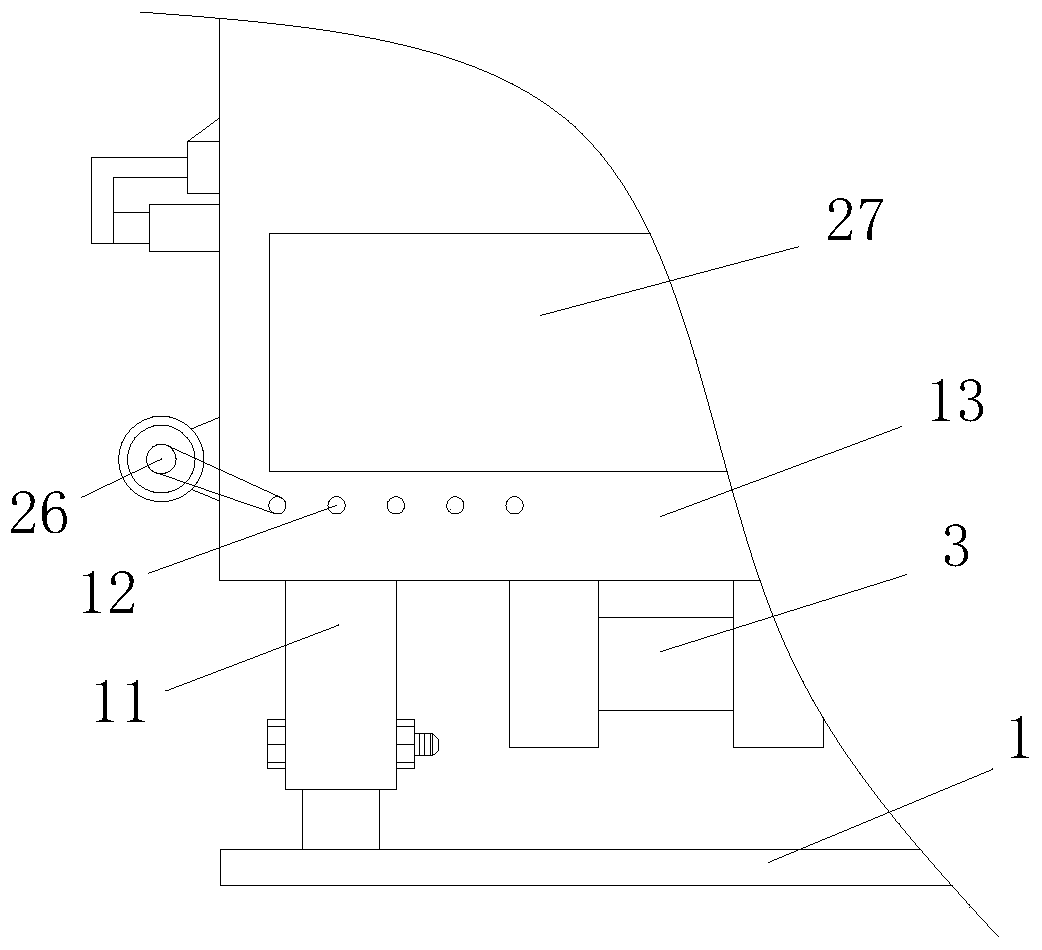

[0016] The following will clearly and completely describe the technical solutions in the embodiments of the present invention with reference to the drawings in the embodiments of the present invention.

[0017] see Figure 1-2 , a kind of injection molding mold that is convenient to discharge, comprises a first support plate 1, and the surrounding of the inner surface of the first support plate 1 is provided with mounting holes 9, and the lower end of the front surface of the connecting seat 13 is provided with an observation window 27, and the observation window 27 Including an acrylic plate, the top of the first support plate 1 is movably connected with a spring 5 through the support leg 4, and the top of the spring 5 is fixedly connected with a sleeve 11 whose inner surface is movably connected with the support leg 4 through a fastening screw 10. The top of the cylinder 11 is fixedly connected with the connecting seat 13 on the bottom of which the vibrating motor 3 is fixed...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com