Device and method for achieving one-time molding through multiple injection molding technologies

A process and injection molding machine technology, applied in the field of multiple injection molding process devices, can solve the problems of complicated injection molding process operations, improve production efficiency and machine utilization, ensure injection molding quality, and solve the effect of complex process modification.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

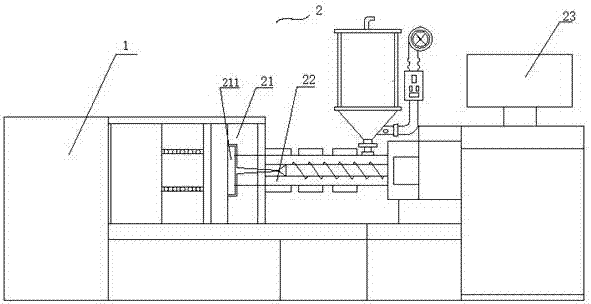

[0036] In order to solve the problems existing in the prior art that different injection molded parts use the same injection molding process to cause serious defects such as product flashes and burrs, and the problem of complicated operation of changing the injection molding process to ensure product quality. The invention provides a multi-injection molding device for one-time molding, refer to figure 1 As shown, the device includes an electric control box 1 and an injection molding machine 2 controlled by a PLC controller, and the injection molding machine 2 is used to complete at least one injection molding process, including a mold clamping system 21, and the mold clamping system 21 includes a mold 211, the mold 211 is provided with a filling control structure corresponding to the injection molding process one by one, the filling control structure includes a miniature oil cylinder, a miniature oil cylinder limit sensor and a solenoid valve, and the miniature oil cylinder lim...

Embodiment 2

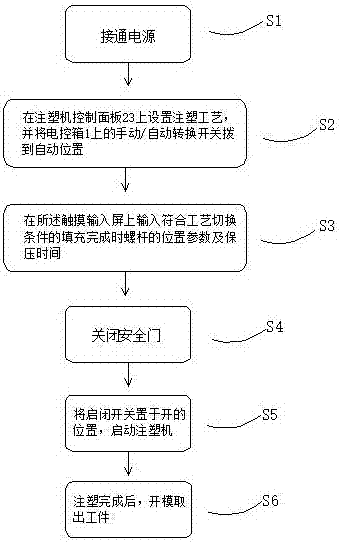

[0045] In order to solve the problems existing in the prior art, the present invention also provides a method of multi-injection molding at one time, specifically, refer to figure 2 As shown, the method includes the following steps:

[0046] S1, turn on the power;

[0047] S2. Set the injection molding process on the control panel 23 of the injection molding machine, and turn the manual / automatic switch on the electric control box 1 to the automatic position;

[0048] S3. On the touch input screen, input the position parameters of the screw and the pressure holding time when the filling is completed and meet the process switching conditions;

[0049] S4, close the safety door;

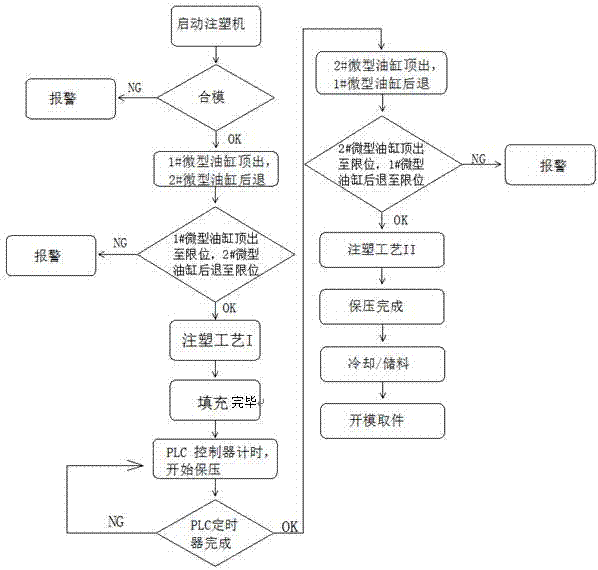

[0050] S5. Put the on-off switch in the open position and start the injection molding machine 2. Specifically, when the injection molding machine 2 is started, the mold clamping starts. If the injection molding machine 2 fails to start, the mold clamping fails, and the injection molding machine 2 wi...

Embodiment 3

[0060] In this embodiment, the injection molding machine completes three injection molding processes. Specifically, the difference from Example 1 is that the injection molding process includes injection molding process I, injection molding process II and injection molding process III. The difference from embodiment 2 is that , on the touch input screen, input the position parameters that the screw needs to reach when the filling of injection molding process I and injection molding process II is completed, so as to determine the switching from injection molding process I to injection molding process II, and switching from injection molding process II to injection molding process II Toggle condition.

[0061] In this embodiment, it also includes 3# miniature oil cylinder, 3# miniature oil cylinder limit sensor and solenoid valve III. The position sensor is used to sense the signal of the 3# miniature oil cylinder to push out to the limit and back to the limit, and transmit the s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com