Injection moulding method for stylus

A technology of stylus and pen body, which is applied in the direction of coating, etc., can solve the problems of high mold cost, difficult positioning of stylus, unreasonable ratio of input and output, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

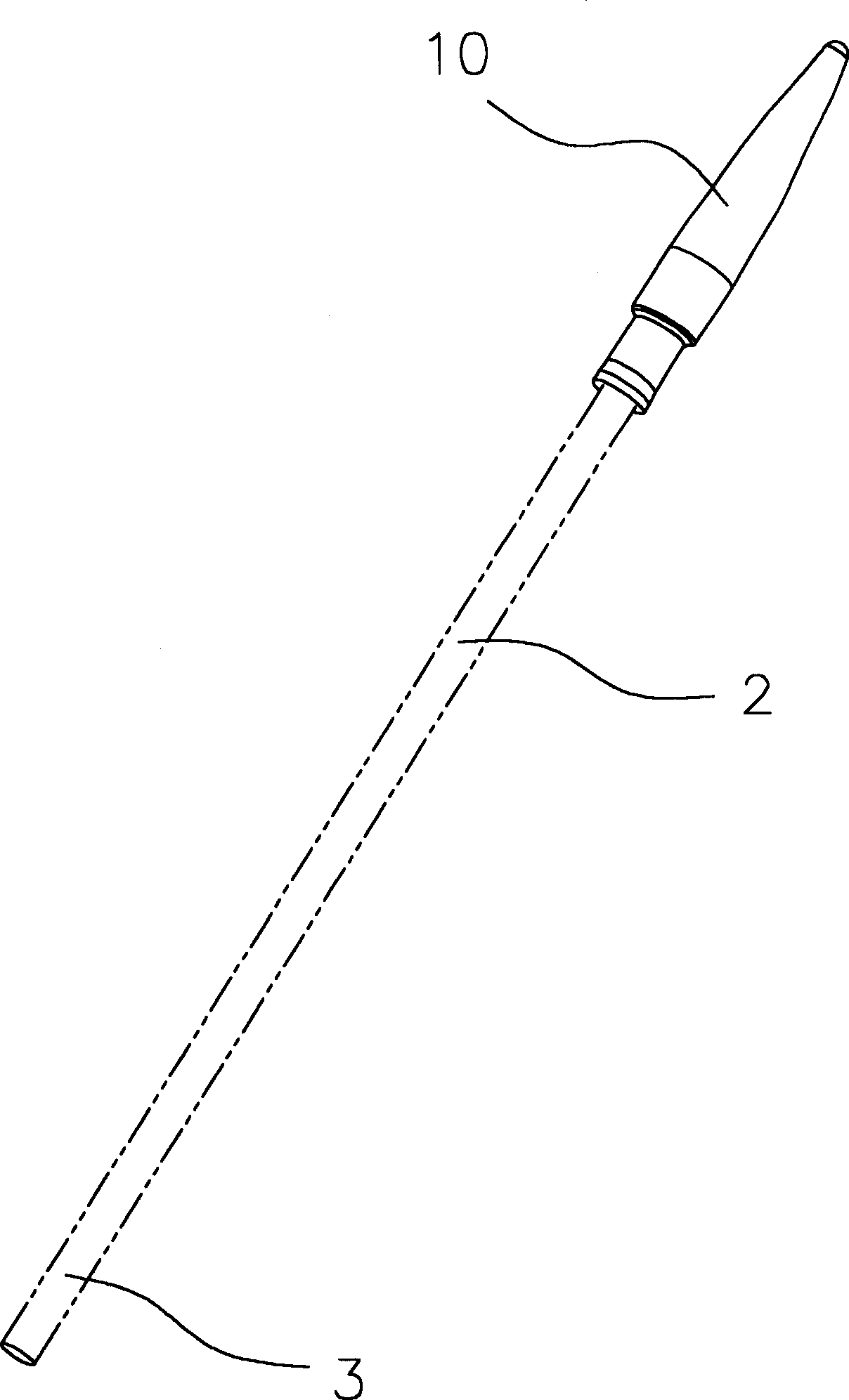

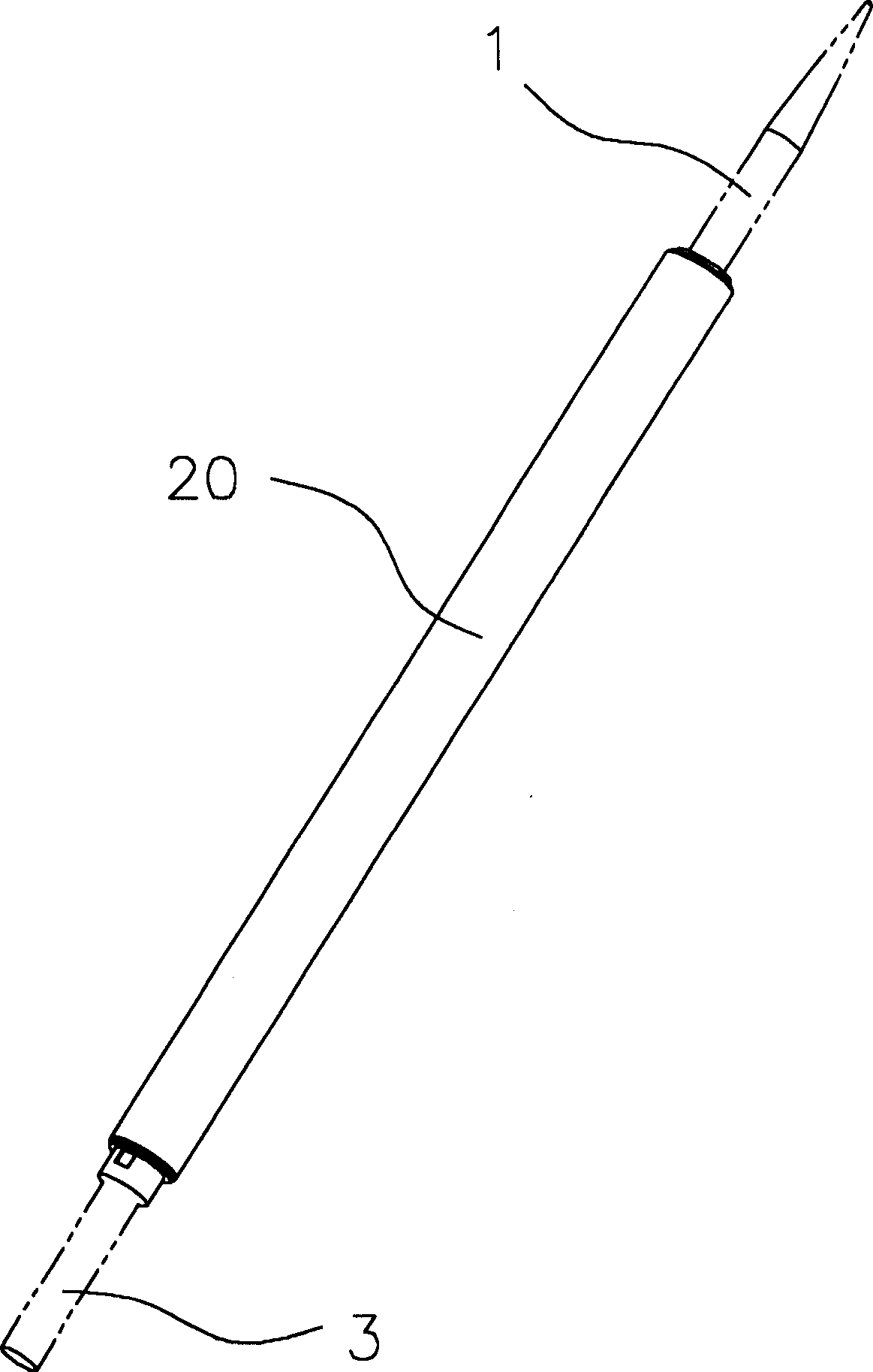

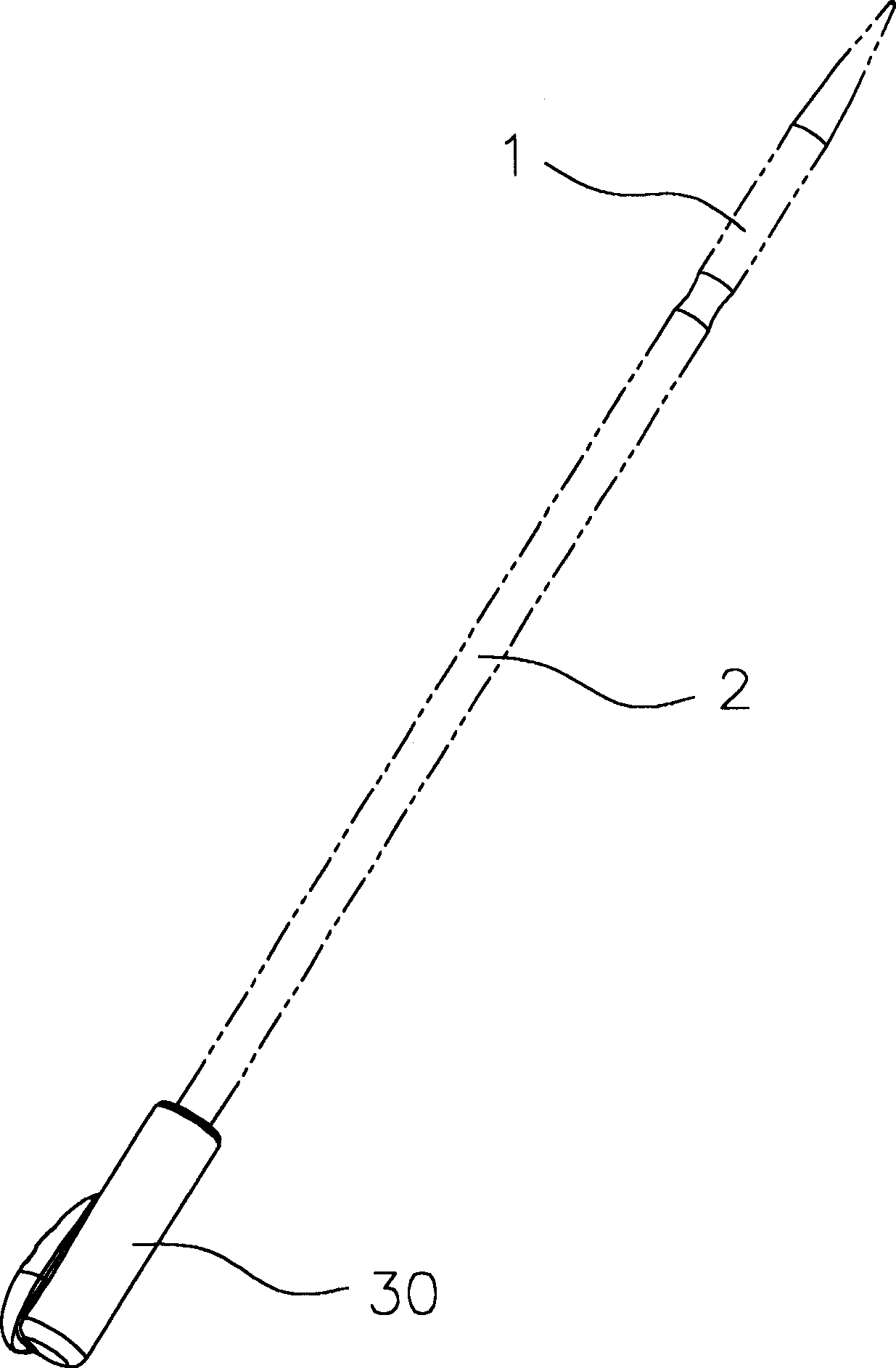

[0020] see Figure 1 to Figure 3 As shown, it is a schematic diagram of the injection sequence of a manufacturing method of a stylus for a handheld computer disclosed by the present invention. During the process of injecting the stylus, the inner pen body is sequentially placed into the corresponding main injection mold. Create the fixing tool described above to clamp and fix the stylus, and shoot out the contact end 10, the middle section 20, and the buckle end 30 of the stylus in sequence, so that the plastic can completely cover the inner pen body to form an insulating outer pen Each part of the injection will cover the remaining filling point of the last time, so that only one filling hole is left when the injection molding is finally completed, and the finished product of the stylus is the finished product after the filling mouth is rested and deburred.

[0021] see Figure 4 , 4A , 4B, and 4C are schematic diagrams of the structure of the main fixing tool for the injec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com