Tray mold for easy injection molding of feet

A foot and tray technology is applied in the field of tray molds that are convenient for injection molding of feet. The effect of improving the yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

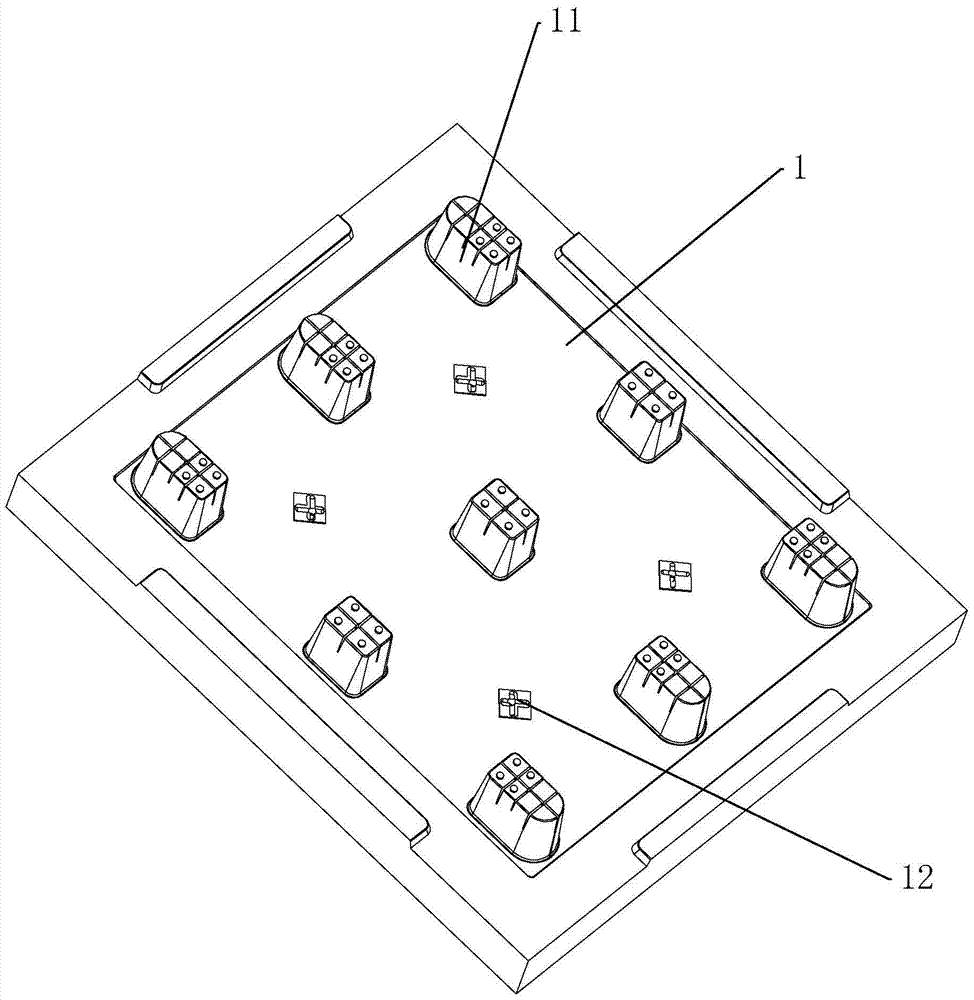

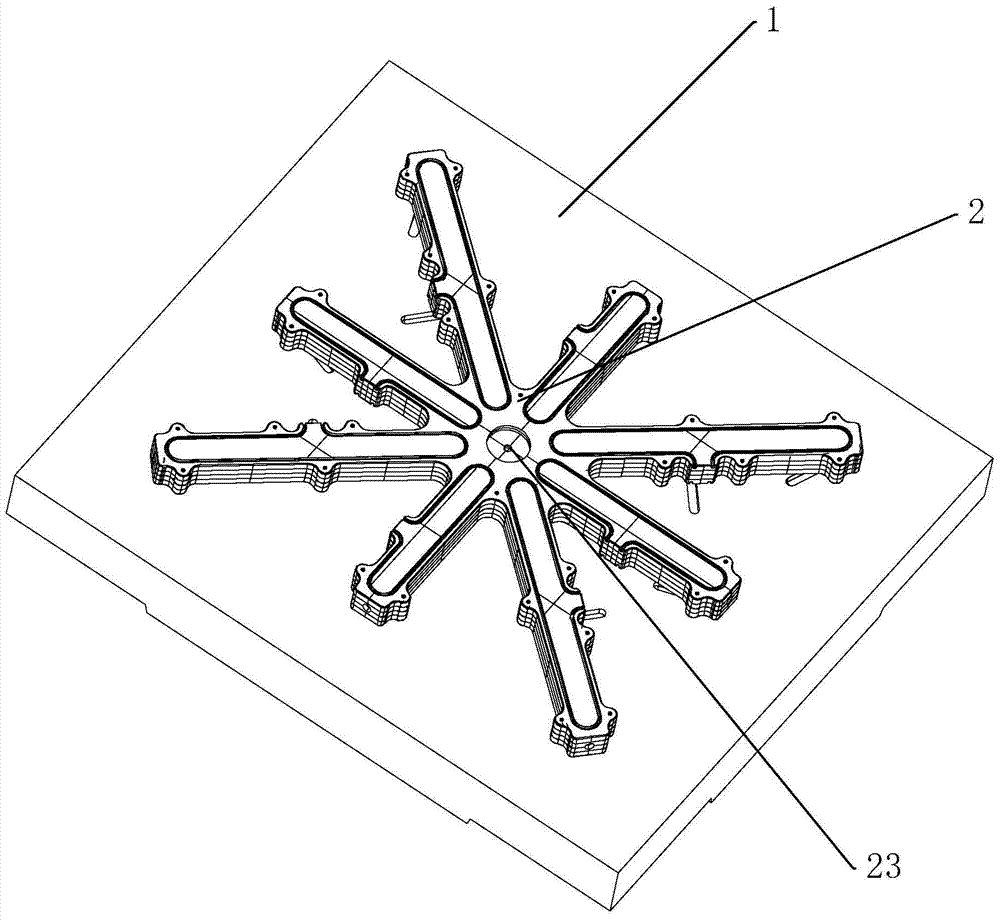

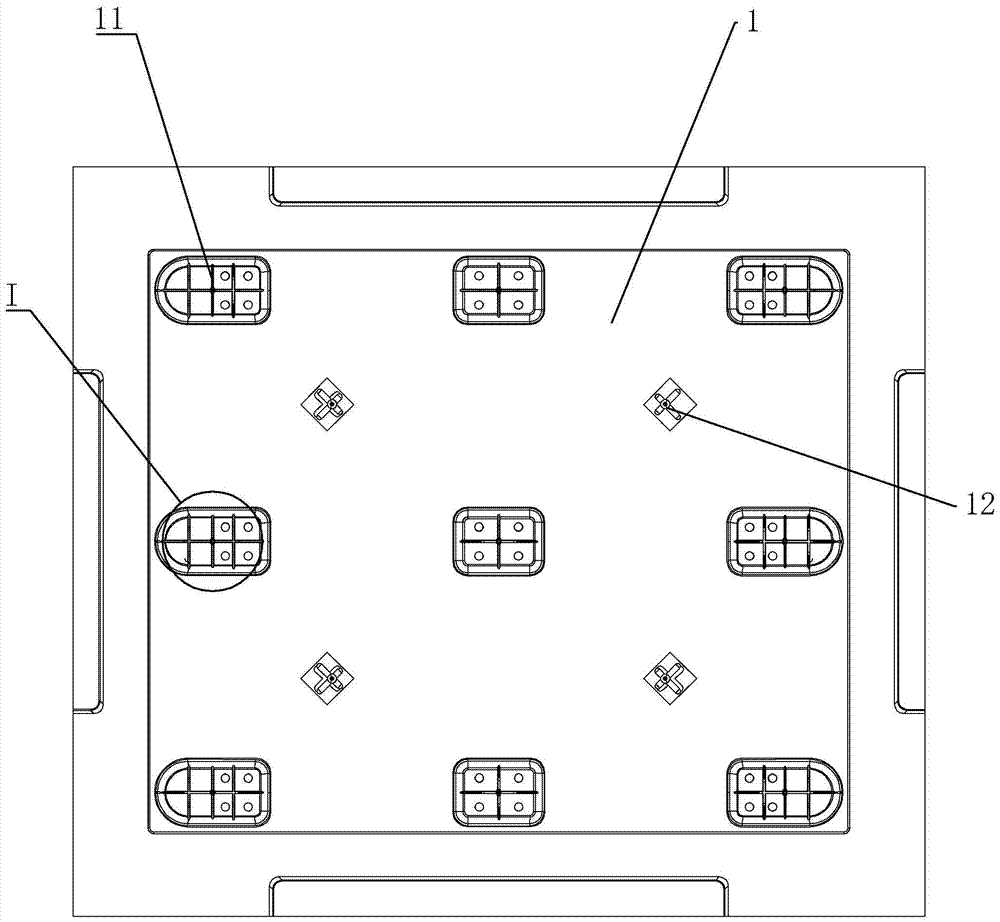

[0016] refer to Figure 1 to Figure 5 Further description will be given to the embodiment of the tray mold for convenient injection molding feet of the present invention.

[0017] A pallet mold for convenient injection molding feet, comprising a fixed mold 1 and a movable mold, the fixed mold 1 is a rectangular formwork, the fixed mold 1 is provided with several protrusions 11 for injection molding feet, and the movable mold is above A concave portion corresponding to the protruding portion 11 is provided, and the protruding portion 11 and the concave portion jointly constitute a processing mold cavity of the foot.

[0018] Such as figure 1 or 3, the protruding portion 11 is provided with a first gate 111 for injection molding, and the plate surface of the fixed mold 1 is provided with a second gate 12, and the second gate 12 is connected to the The first gate 111 is located on the same surface of the fixed mold 1 . Such as figure 2 or 4, the other side of the fixed mold ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com