Groove pipe cutting all-in-one machine

An all-in-one machine and frame technology, which is applied in the direction of pipe shearing device, shearing device, shearing machine equipment, etc., can solve the problems of increased weight of the spindle turntable, inability to process, and the weight of the spindle turntable, etc., and achieve uniform cutting speed and feed speed , Reduce the chance of tool damage, improve the effect of tool rotation speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be described in detail below in conjunction with the accompanying drawings and embodiments.

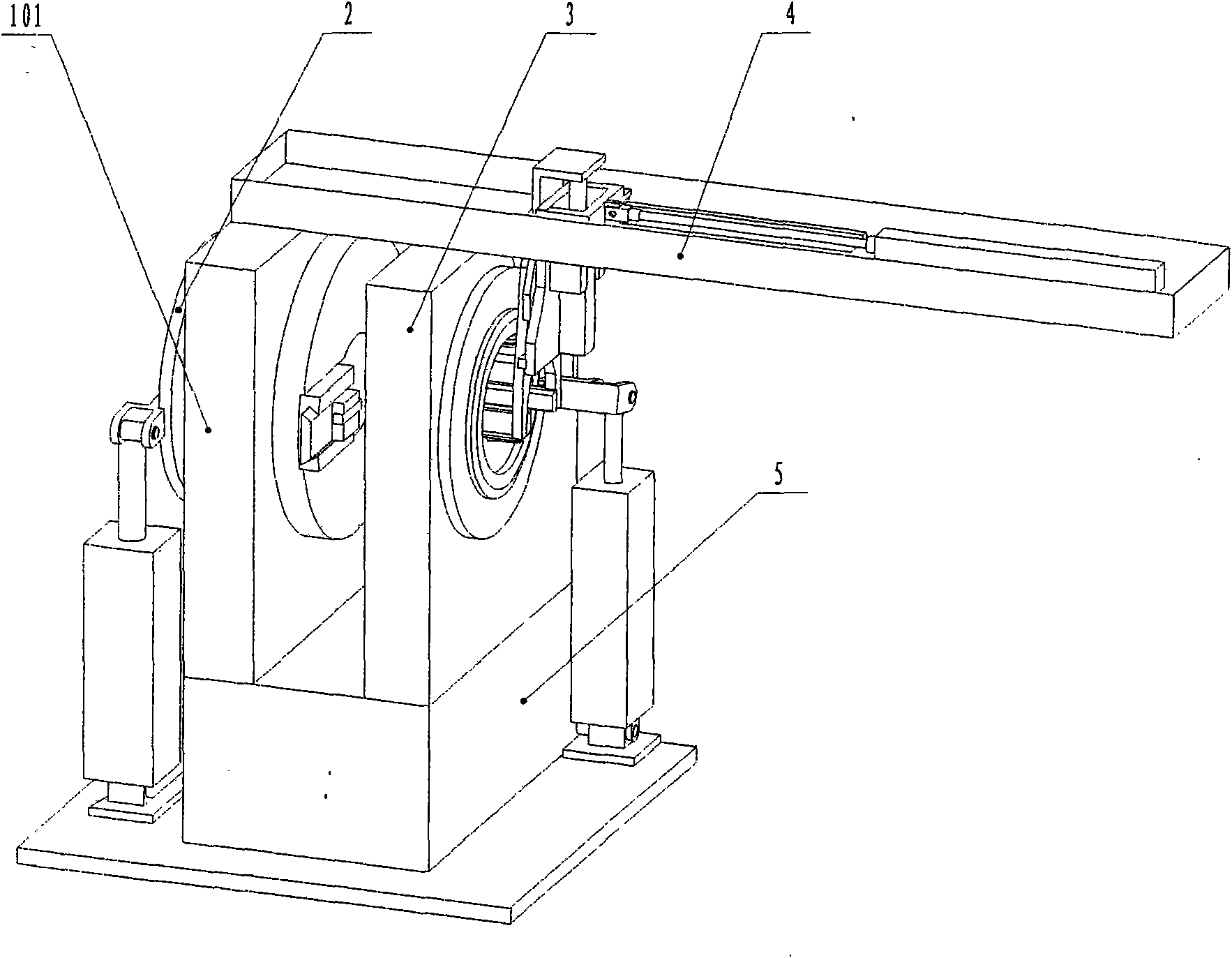

[0021] figure 1 An embodiment of a fully automatic bevel pipe cutting machine is given, which consists of a frame 101, a front clamping mechanism 2, a rear clamping mechanism 3, a discharge mechanism 4, a lifting and centering mechanism 5, and a control system, wherein The control system is the prior art.

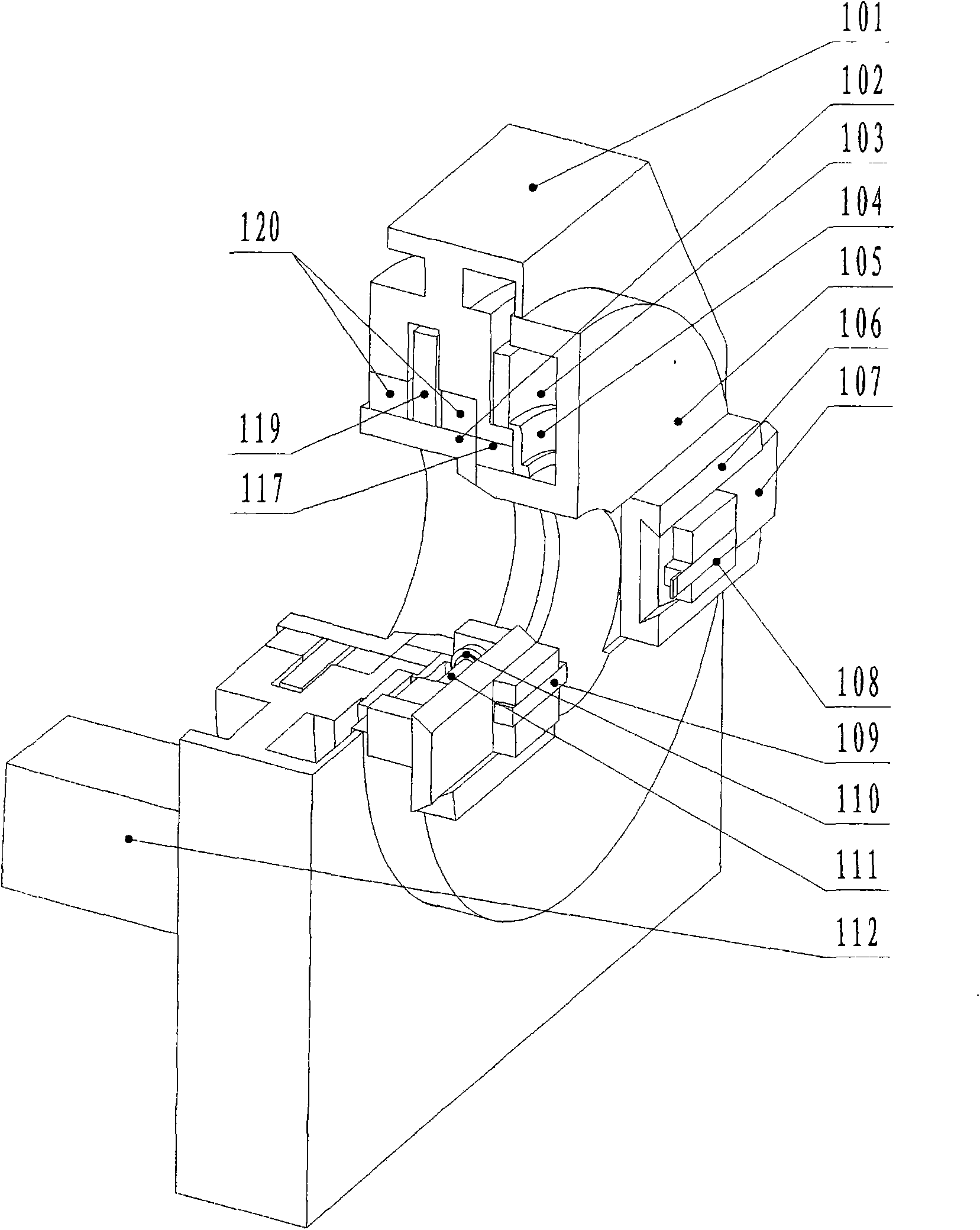

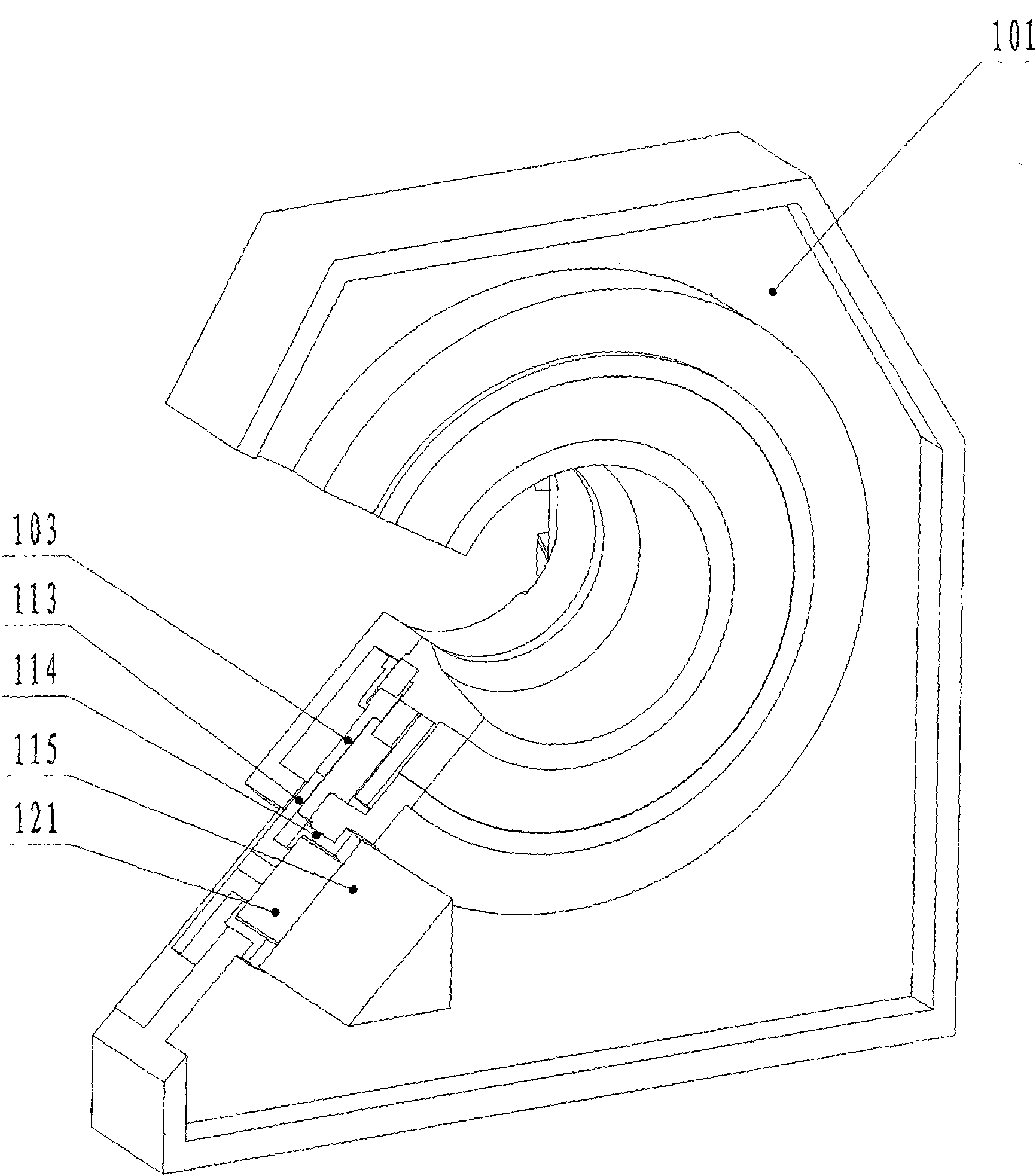

[0022] The present invention is a fully automatic bevel pipe cutting machine, which mainly includes a frame 101, on which a main shaft 102, a tool rotating disc 105, a tool feeding disc 103, a tool moving device and a tool feeding servo motor are arranged. And the cutting mechanism composed of the spindle rotating servo motor, the front and rear of the frame are respectively equipped with clamping mechanisms, the bottom of the frame is equipped with a lifting mechanism composed of a bottom plate, a top plate and a lifting power unit, and a beam is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com