Automatic electrowelding electrode feeder

An automatic electric welding and power device technology, applied in auxiliary devices, arc welding equipment, welding equipment, etc., can solve the problems of difficult welders, inaccurate and inconvenient dimensions of precision welding, and achieve uniform feed speed and improved welding quality effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] Below in conjunction with embodiment the present invention is further described:

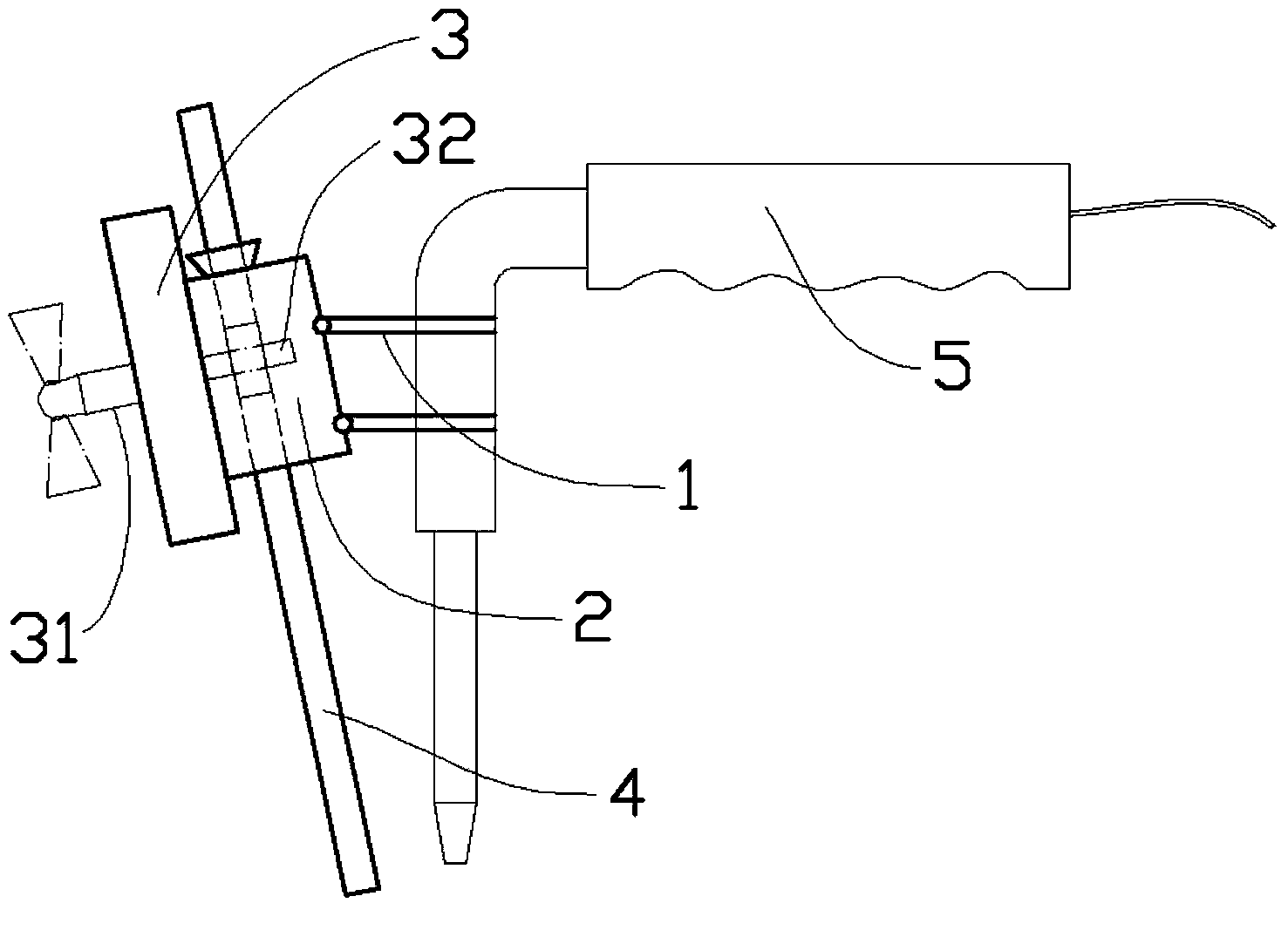

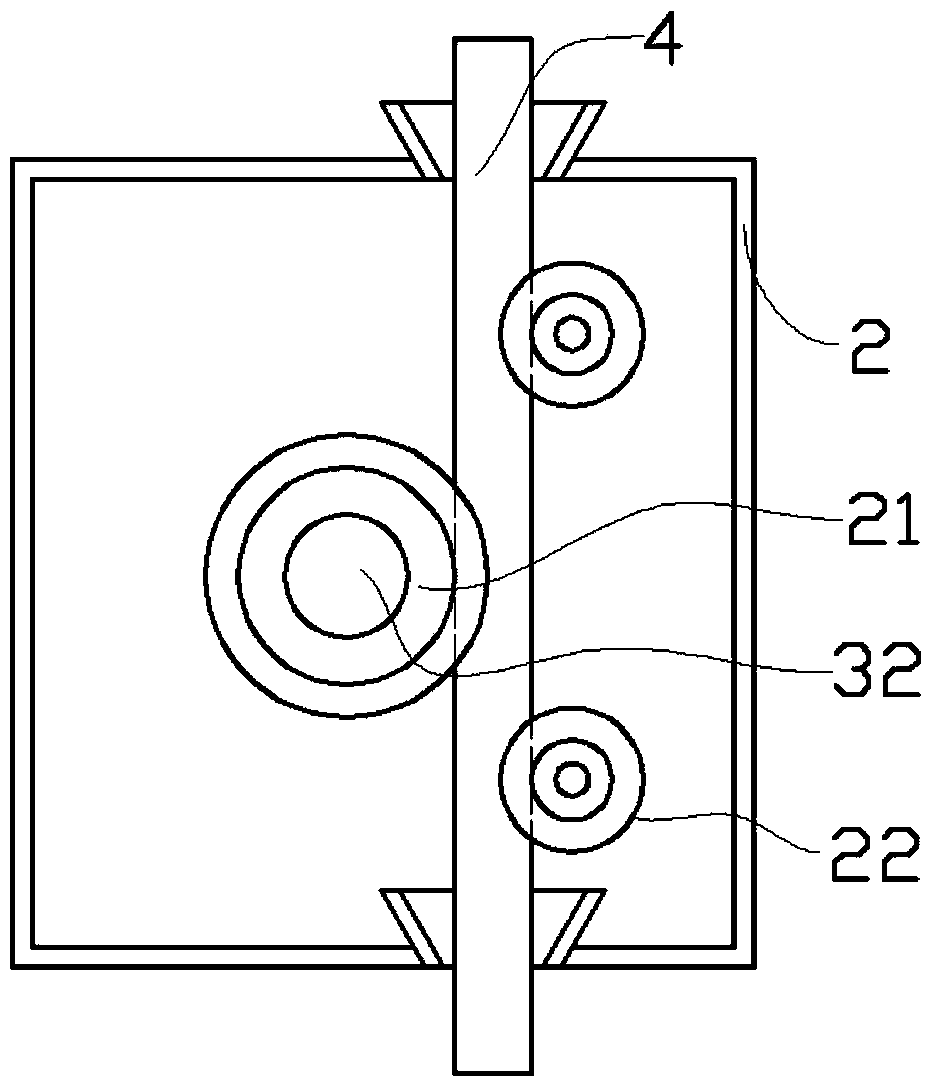

[0012] Such as figure 1 As shown in the embodiment, the automatic electric welding strip device includes a connecting frame 1, a feed box 2, and a power unit 3, and the device is assembled on a welding torch 5 that uses a welding wire 4 for welding. 3 Assembled on the end of the welding torch 5 through the connecting frame 1, the welding wire 4 used for welding passes through the feed box 2, the feed box 2 is designed with a transmission structure, and the welding wire is driven by the power device 3 4 advancing; the advancing direction of the welding wire 4 and the heat flow direction sprayed by the welding torch 5 meet at one point.

[0013] The automatic electric welding rod continuation device can be used in shielded arc welding, brazing, gas welding and other welding torches 5 that use hot-melt welding wire 4 welding methods. The end of the welding wire 4 to be welded passes through...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com