A vacuum aluminum plating machine

A technology of vacuum aluminum plating and aluminum film coating, which is applied in the field of machinery, can solve the problems of expensive equipment, aluminum film is easy to wrinkle, and affects product quality, etc., and achieves the effects of uniform feeding speed, preventing wrinkling, and good neutrality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The following are specific embodiments of the present invention and in conjunction with the accompanying drawings, the technical solutions of the present invention are further described, but the present invention is not limited to these embodiments.

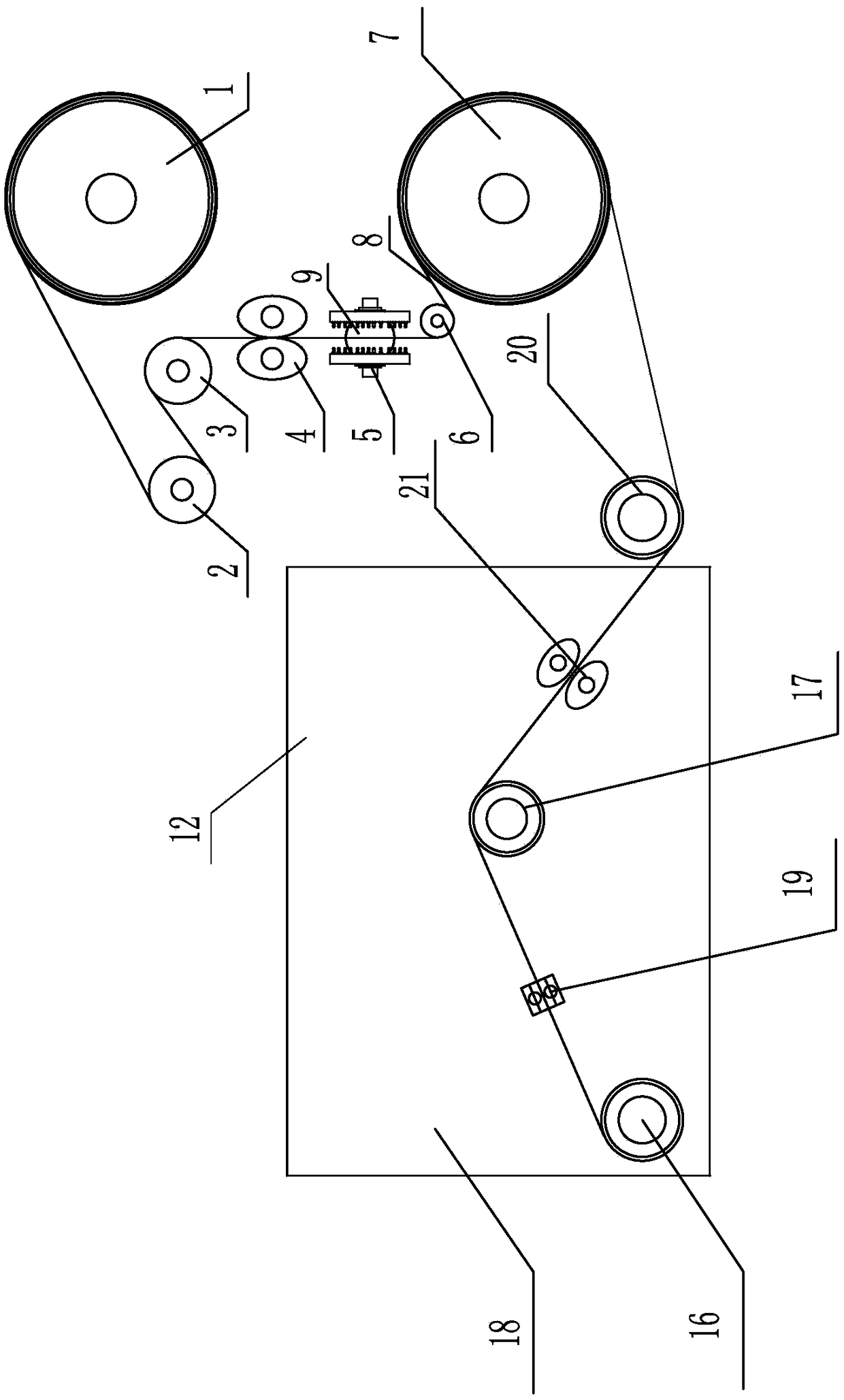

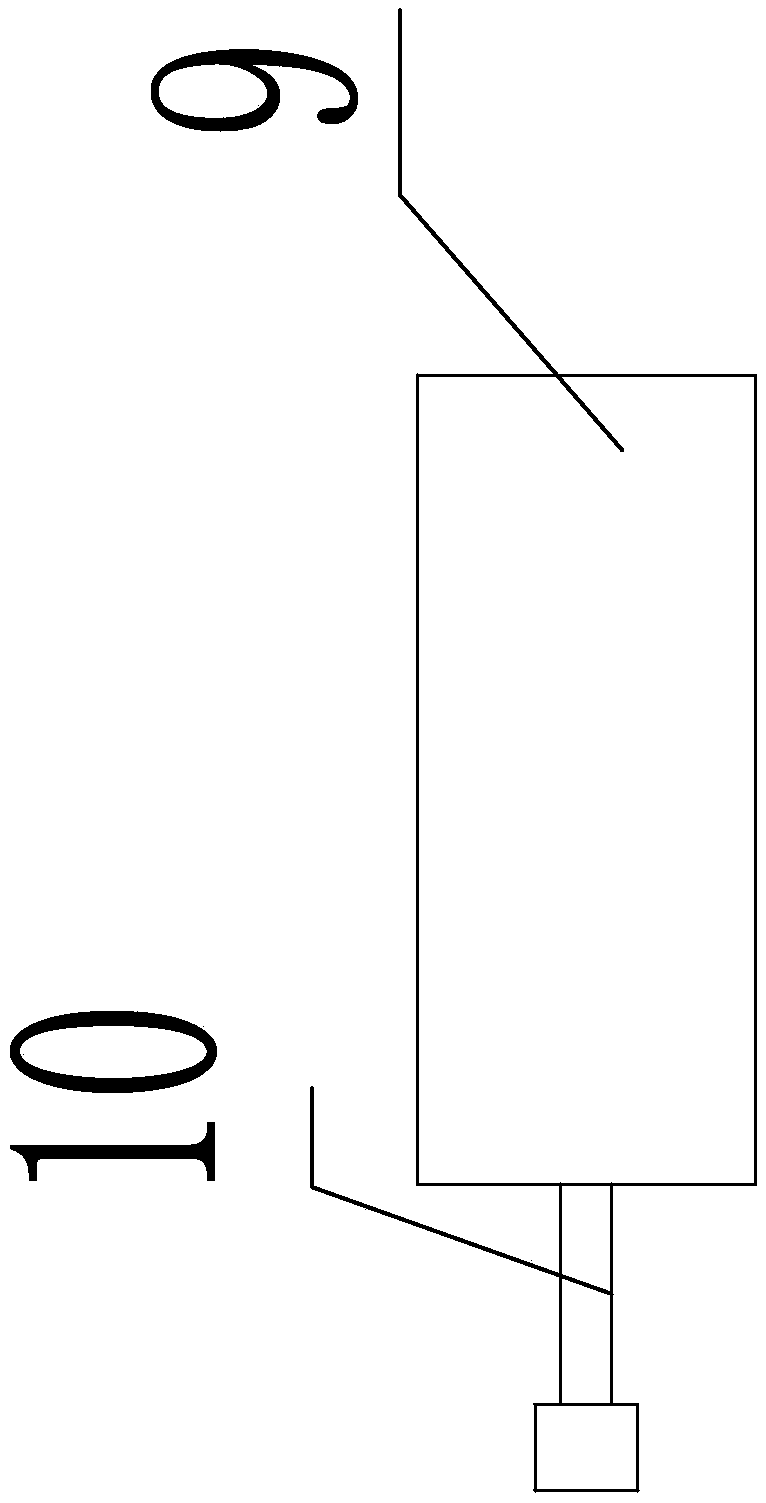

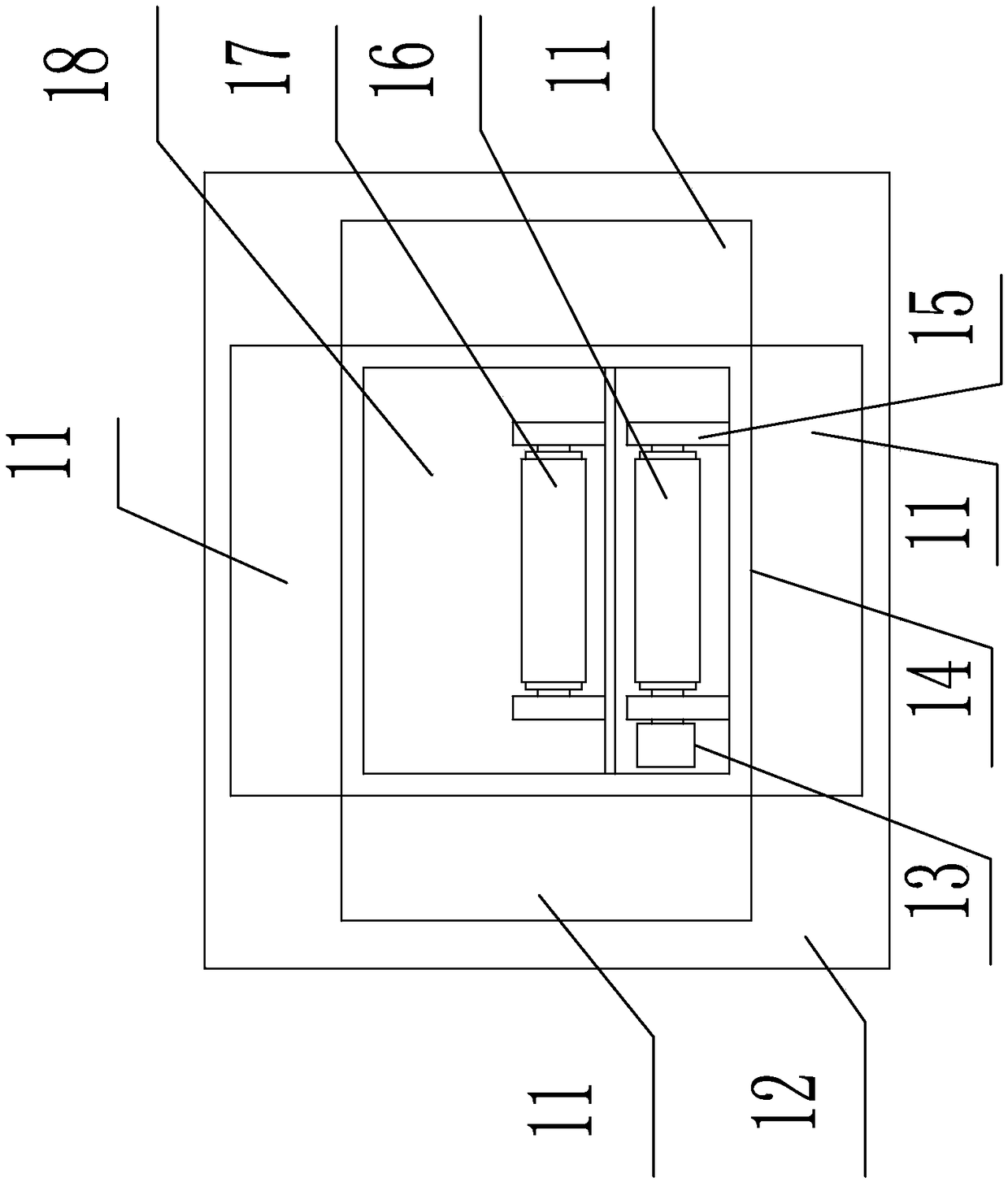

[0024] Such as figure 1 , figure 2 As shown, the vacuum aluminum plating machine includes a centralizing mechanism and a drying mechanism, and the centralizing mechanism includes a first roller 1, a first guide roller 2, a second guide roller 3, a centralizing roller 4, a high-temperature air injection device 5, a tension pulley 6, The second roller 7, the aluminized film 8, the high temperature evaporator 9 and the gas delivery pipe 10; the aluminized film 8 wound on the first roller 1 passes through the first guide roller 2 and the second guide roller 3 in turn, and is located on the second guide roller The aluminized film 8 on the 3 passes through the gap between the two centering rollers 4 and the high-temperature ai...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com