Paper tube crushing machine

A crusher and paper tube technology, applied in grain processing, etc., can solve the problems of frequent replacement, long feeding interval, short knife replacement cycle, etc., and achieve the effects of simple manufacturing process, reduced manufacturing cost, and extended service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

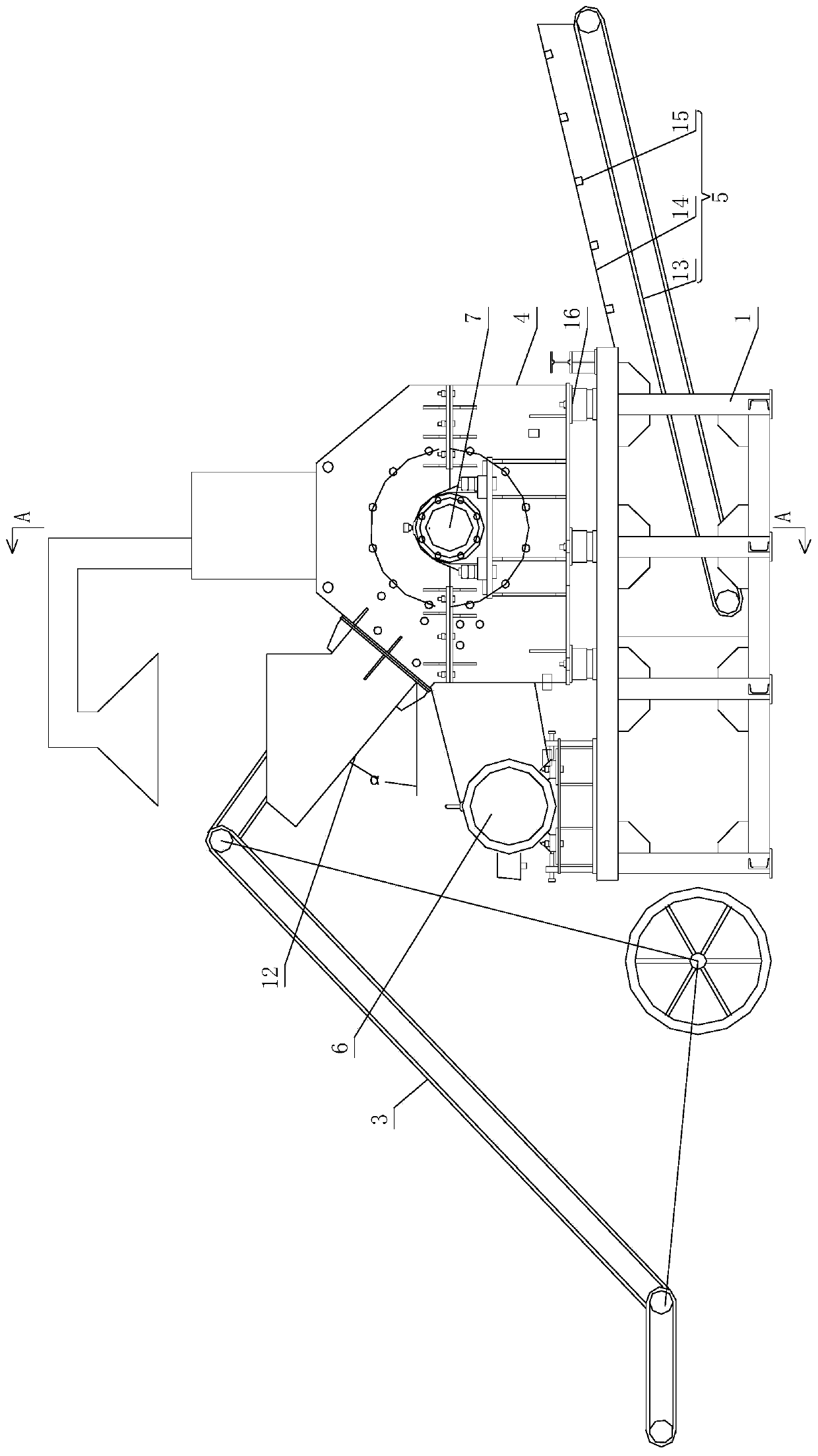

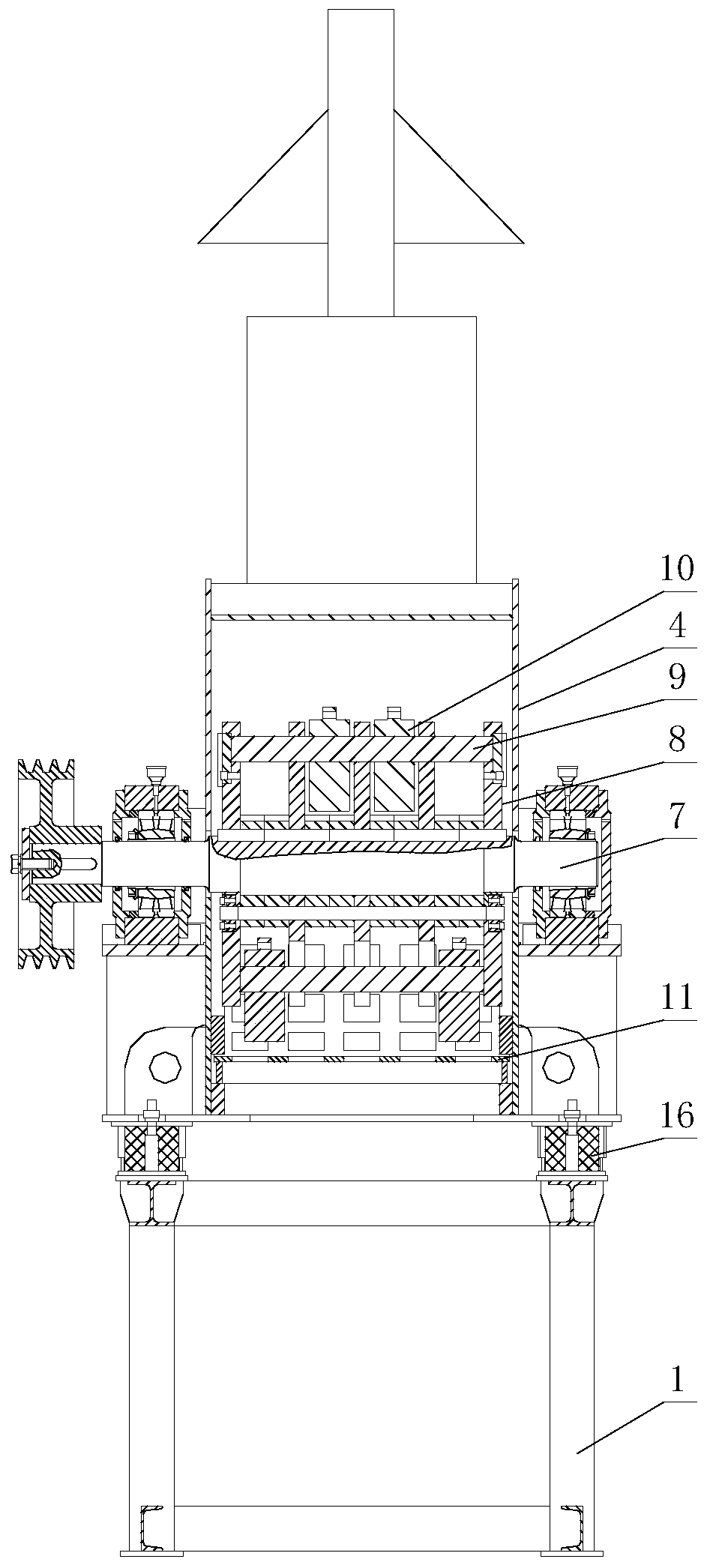

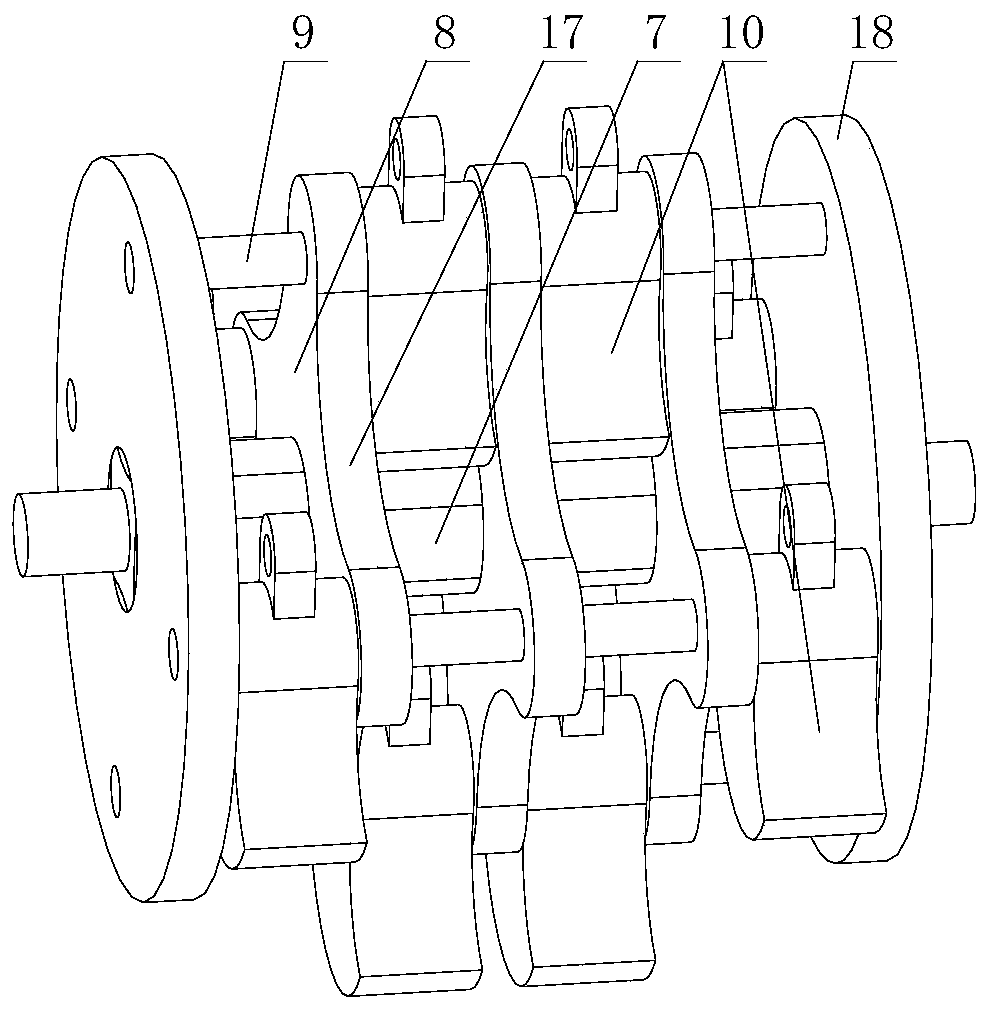

[0018] The present invention relates to a paper tube crusher, comprising a frame 1, a feeding unit 3 sequentially arranged on the frame 1 along the conveying direction of the paper tube 2, a crushing box 4 and a discharge system 5, and crushing tools are arranged in the crushing box 4, The frame 1 is provided with the driving motor 6 of the crushing tool. The key is that the crushing tool includes a power shaft 7 arranged on the crushing box 4 by means of a mounting plate 18, a limiting plate 8 arranged at intervals on the power shaft 7, A set of pin shaft 9 and breaking hammer 10 arranged outside the power shaft 7 and penetrating through the limiting plate 8, the breaking hammer 10 is connected with the pin shaft 9 and respectively arranged between the mounting plate 18 and the limiting plate 8, adjacent to each other. Between the bit plates 8 , the breaking hammer 10 has a degree of freedom of rotation on the pin shaft 9 , and the bottom of the breaking box 4 is provided with...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com