Machining method for conical inclined crown of blade

A processing method and blade technology, applied in the processing field of medium-voltage nuclear power engine blades, can solve the problems of uneven allowance, accelerated tool wear, long processing time, etc., achieve uniform and stable peaks and valleys, reduce tool shank diameter, increase Effect of large cutting diameter

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] All features disclosed in this specification, or all disclosed steps in a method or process, may be combined in any way except mutually exclusive features and / or steps.

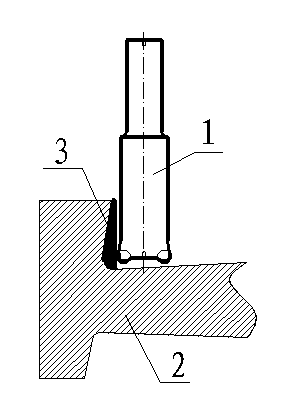

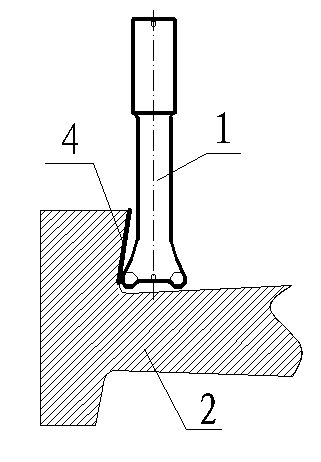

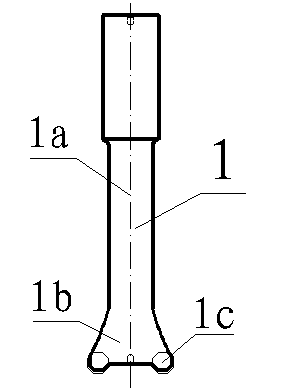

[0018] like figure 2 and image 3 As shown in the figure, the processing method of the conical oblique crown of the blade of the present invention is characterized in that: firstly, the blade is installed on the machine tool; A shank 1a and a truncated cone shaped cutter head 1b, the shank 1a is connected to the small end of the truncated cone shaped cutter head 1b, wherein a number of octagonal blades 1c are evenly distributed on the large end edge of the truncated cone shaped cutter head 1b, so that the The milling cutter uses the helical feed method to process the opening surface of the blade crown twice; in the first processing, the speed of the milling cutter needs to be controlled to be 2200 rpm / min, and the feed speed is 3000-3200 mm / min (preferably 3000 mm). / min, can be 3100mm / min and 3200m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com