Grinding and drying technology for catalyst

A drying process and catalyst technology, used in dryer combination, granular material drying, drying and other directions, can solve the problems of water absorption and deterioration, insufficient reaction of large-particle solid catalysts, etc., achieve easy grinding, improve strength, increase jitter amplitude and The effect of frequency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

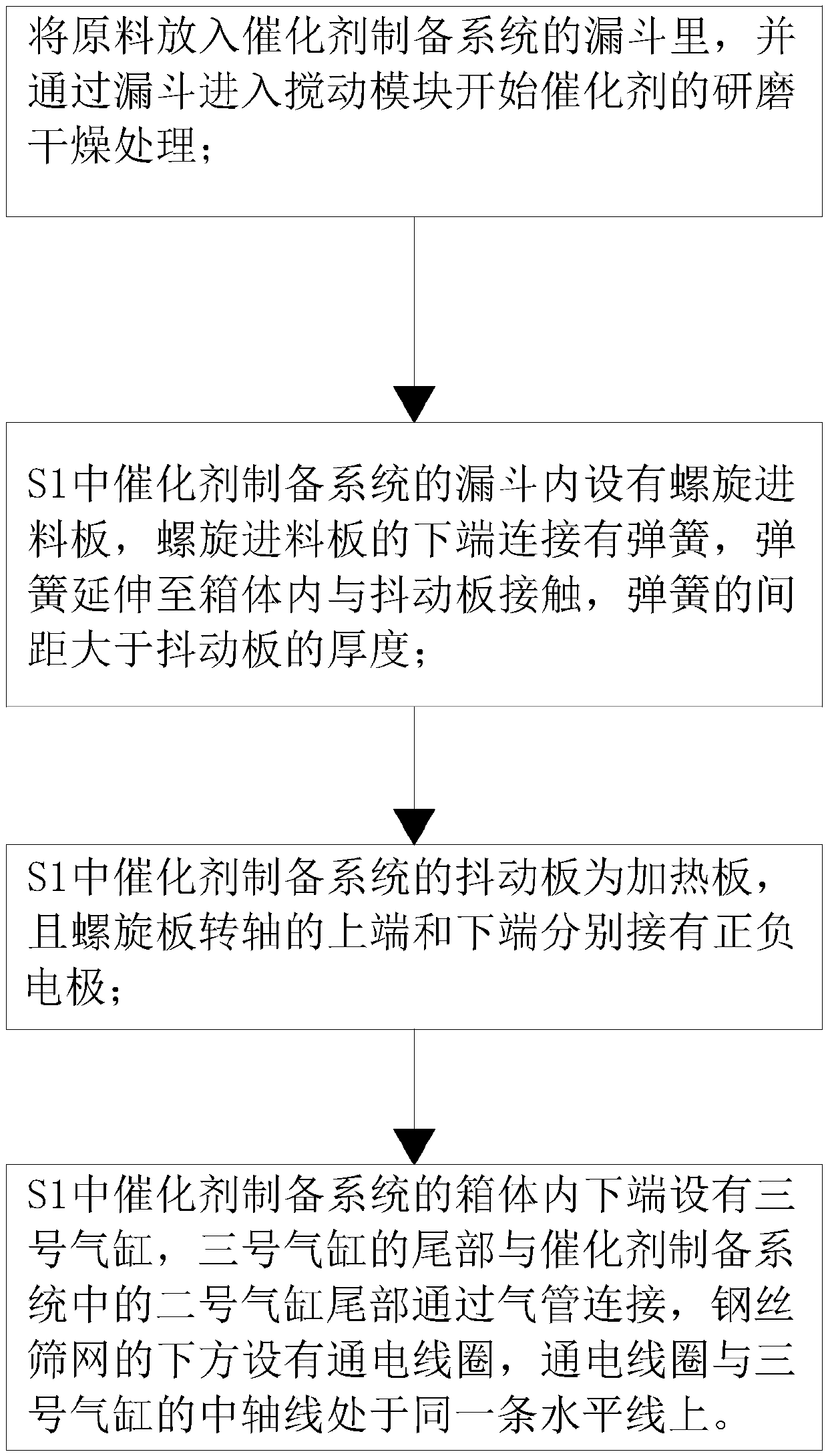

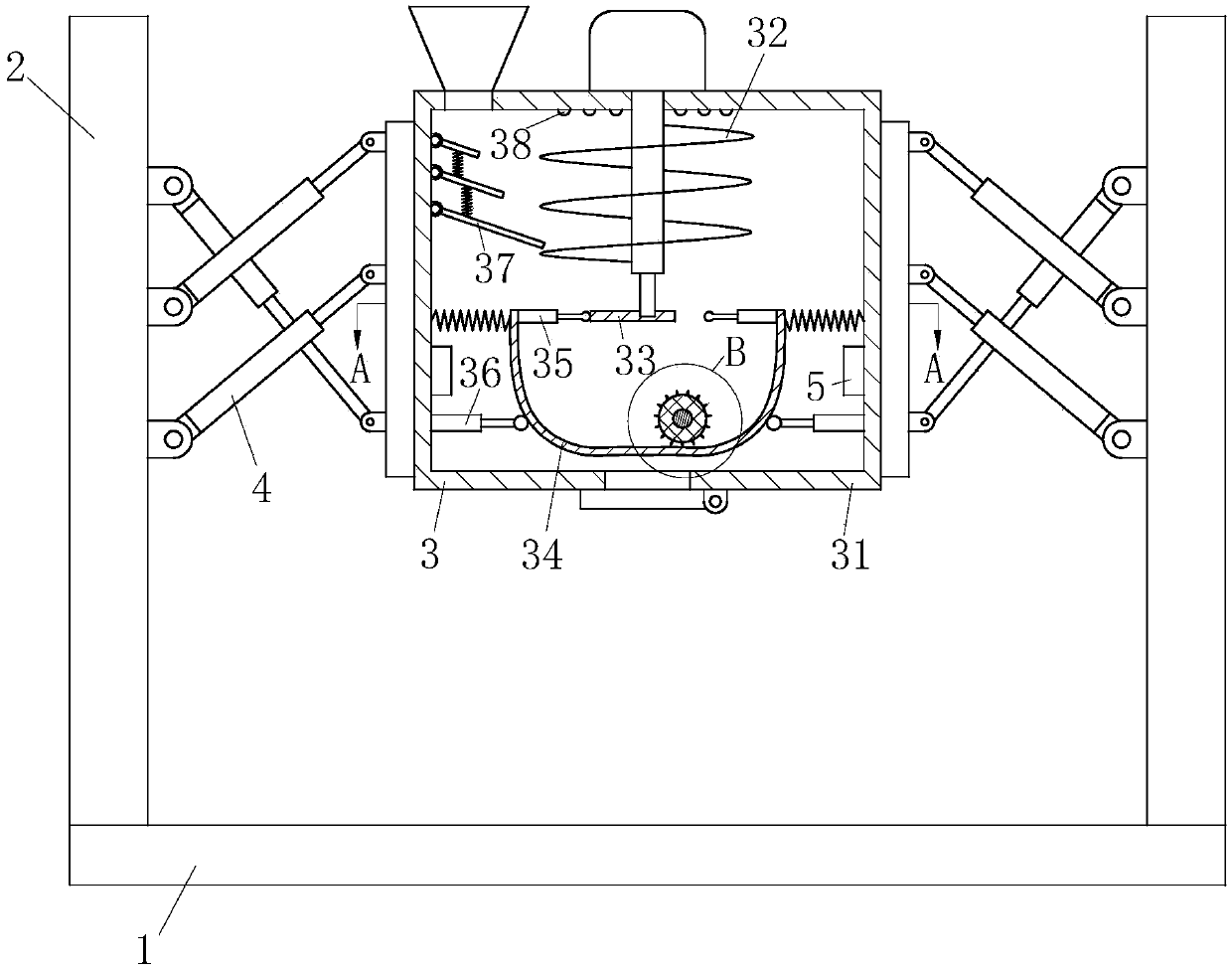

[0028] use Figure 1-Figure 6 The grinding and drying process of a catalyst according to an embodiment of the present invention is described as follows.

[0029] like figure 1 , figure 2 and Figure 5 Shown, the grinding and drying process of a kind of catalyst of the present invention, this process comprises the steps:

[0030] S1: Put the raw materials into the hopper of the catalyst preparation system, and enter the agitation module through the funnel to start the grinding and drying treatment of the catalyst; by using the catalyst preparation system, the agitation effect is improved, and the efficiency of catalyst preparation is improved;

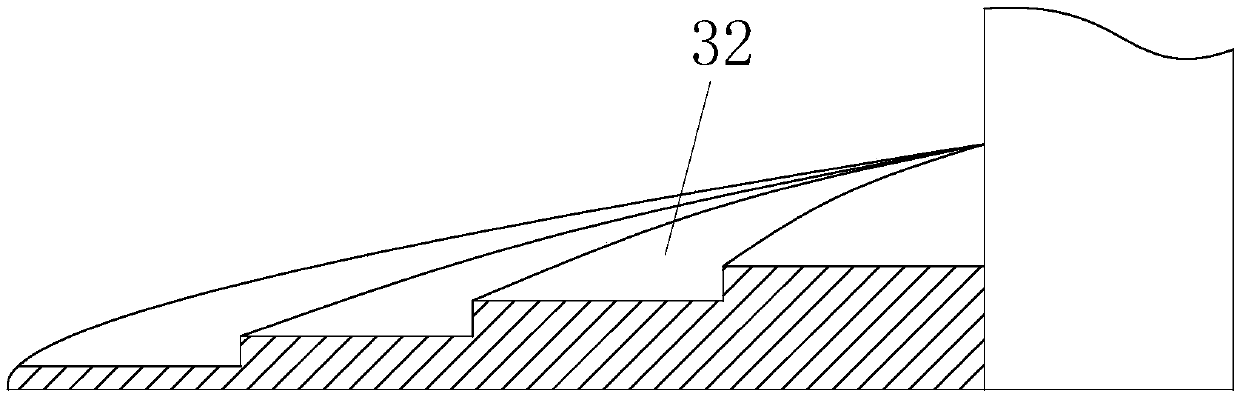

[0031] S2: In S1, the funnel of the catalyst preparation system is provided with a spiral feeding plate, the lower end of the spiral feeding plate is connected with a spring, the spring extends to the box and contacts the shaking plate, and the distance between the springs is greater than the thickness of the shaking plate; by control...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com