Dry powder machining process using fire extinguisher dry powder reuse machining system

A processing system and fire extinguisher technology, applied in drying, fire rescue, drying of solid materials, etc., can solve the problems of dust and soil pollution, achieve the effect of high degree of automation, increase service life, and avoid filter element blockage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

[0022] The subject of protection of the present invention and embodiment are as follows:

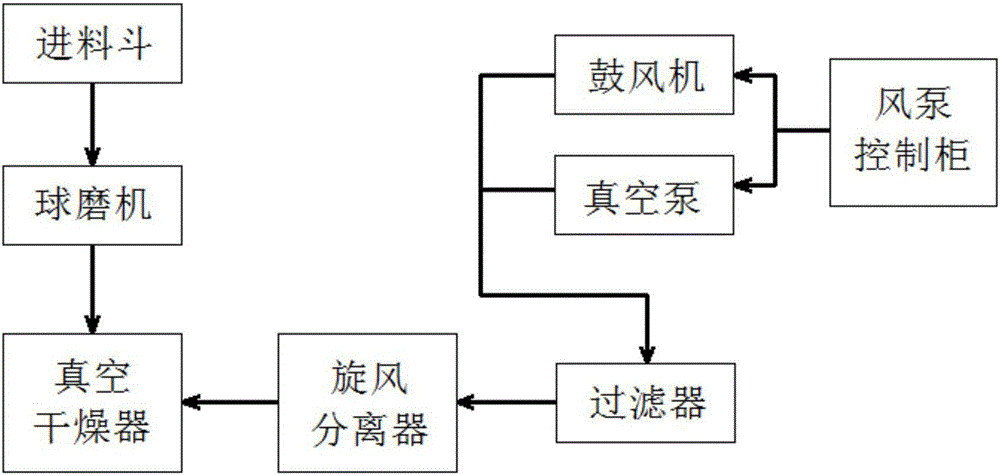

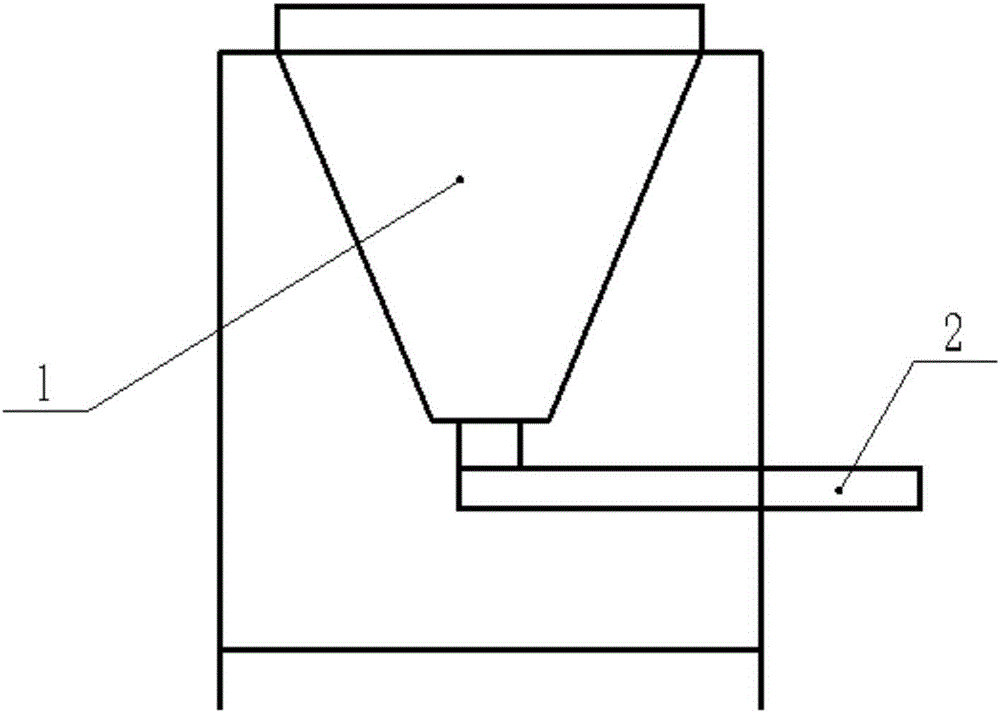

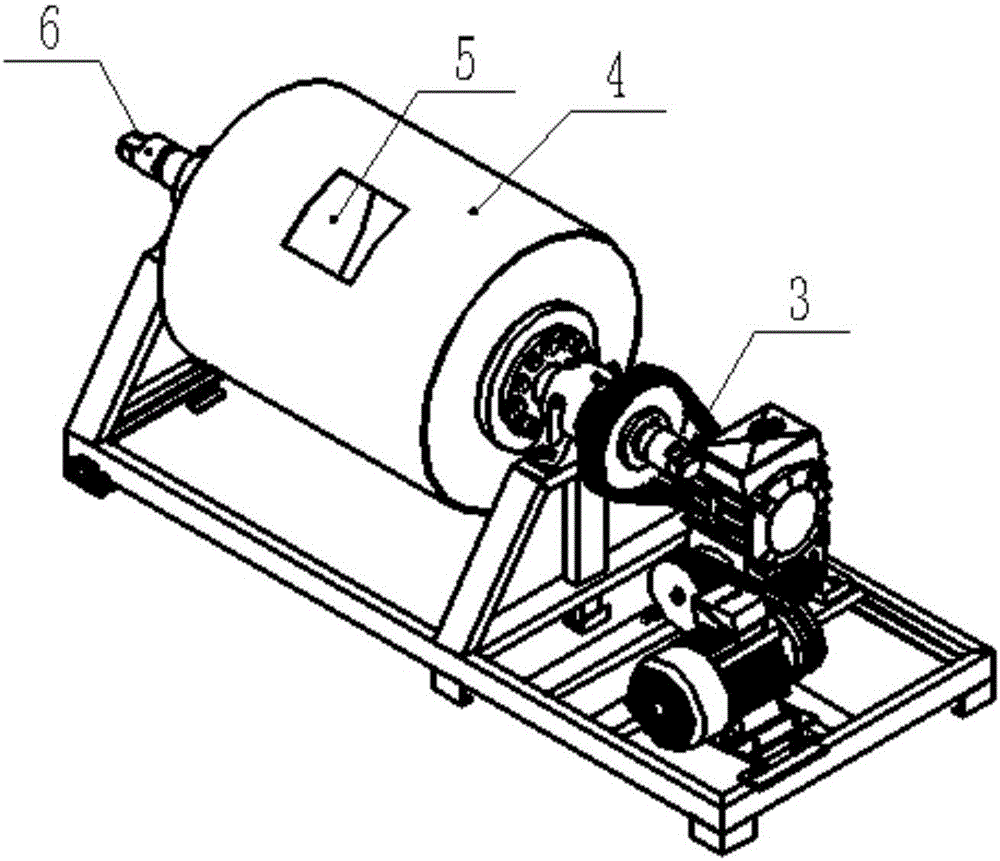

[0023] The dry powder processing technology provided by the present invention utilizes the dry powder recycling processing system of the fire extinguisher, and the connection relationship of the processing system is as follows: figure 1 As shown, including feed hopper 1, ball mill, vacuum system, vacuum dryer, such as figure 2 , 3 As shown, the bottom end of the feed hopper 1 is provided with a discharge pipe 2, and the ball mill includes a feed joint 3, a vacuum joint 6, and a cylinder 4, and the discharge pipe 2 is connected to the feed joint 3 of the ball ink machine. connected with each other, the dry powder raw material enters the ball mill barrel 4 through the feed joint 3, and is pulverized and refined by grinding in the barrel 4.

[0024] like Figure 5 As shown, the vacuum system includes a cyclone separator 20, a filter 23, a blower 25, a vacuum pump 24, and an air pump con...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com