High-strength light protective lattice structure material with stable deformation

A lattice structure, high-strength technology, applied in geometric CAD, instruments, calculations, etc., can solve problems such as poor performance, achieve excellent mechanical properties, reduce stress concentration, and improve mechanical properties.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] Below in conjunction with accompanying drawing and embodiment the present invention will be further described;

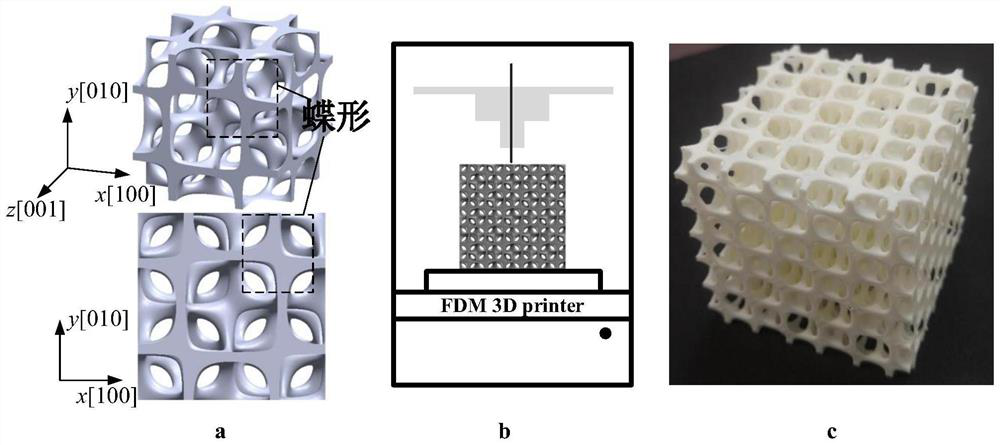

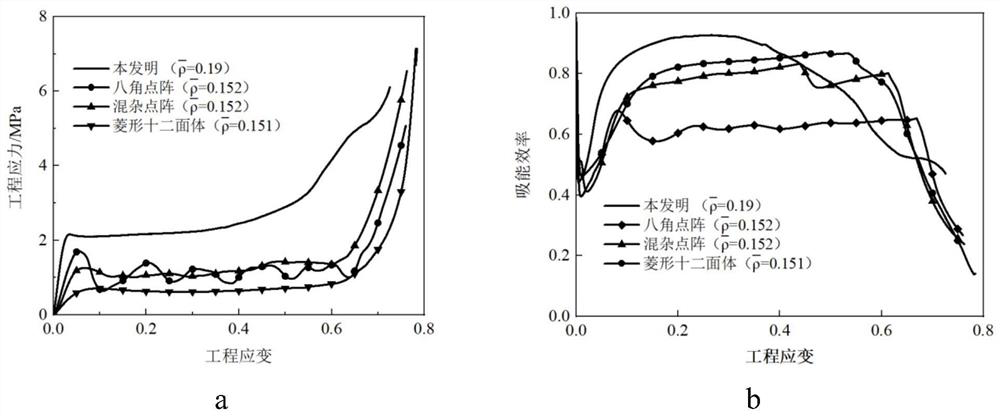

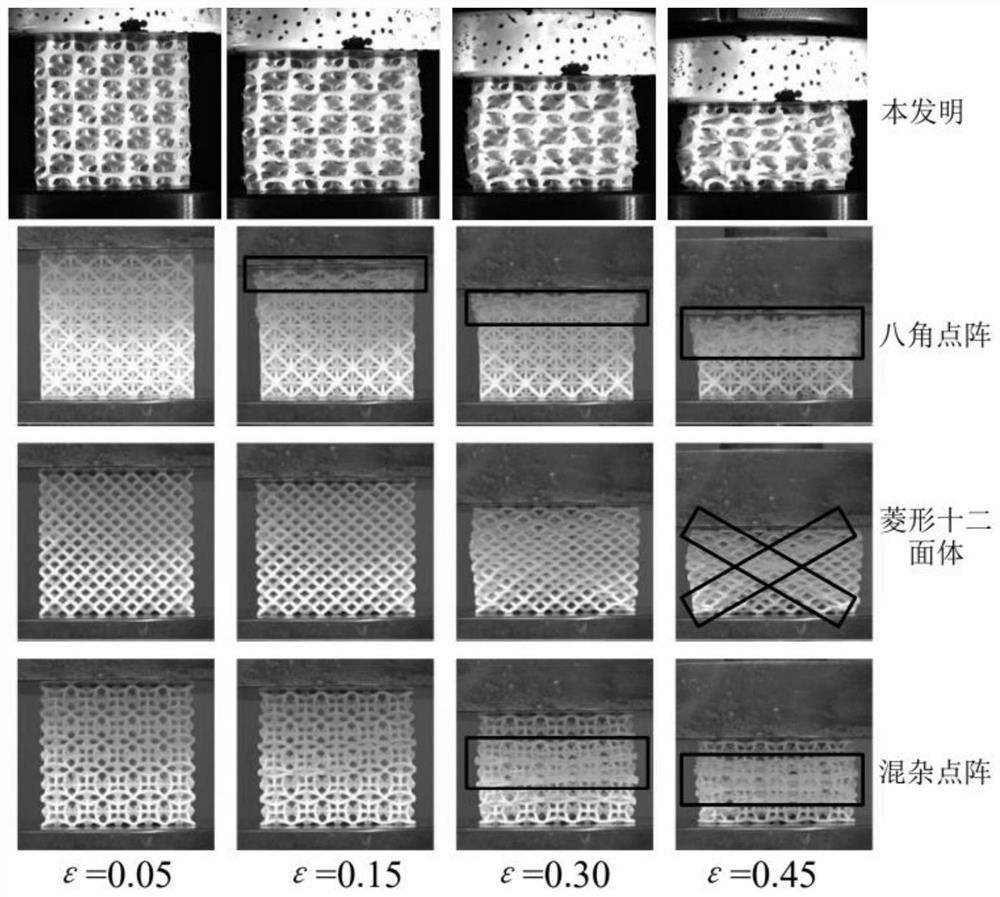

[0032] Commonly used lightweight protective structures usually use porous materials as energy-absorbing main parts, and use the large plastic deformation capacity of porous materials to absorb impact energy, so as to ensure that the impact stress borne by the protected structure is maintained below the allowable stress value, and the protected main structure does not Destruction occurs. Studies have shown that the lattice structure material composed of traditional constant cross-section rods has disadvantages such as low rigidity / strength, low energy absorption capacity, and unstable deformation, and the discontinuity of the connection between the rods and the periodic symmetry of the cell structure It is easy to cause serious local damage to the material, which greatly reduces the service capability of the lattice structure material. The lattice structure m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com