Web member structure of concrete-filled steel tube truss type main arch and bridge

A technology of steel tube concrete and web bars, which is applied to bridges, arch bridges, bridge materials, etc., can solve the problems affecting the local stability of the pressure web bars, so as to avoid local instability, improve compressive stiffness and shear stiffness, reduce Effect of Free Length and Slenderness Ratio

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

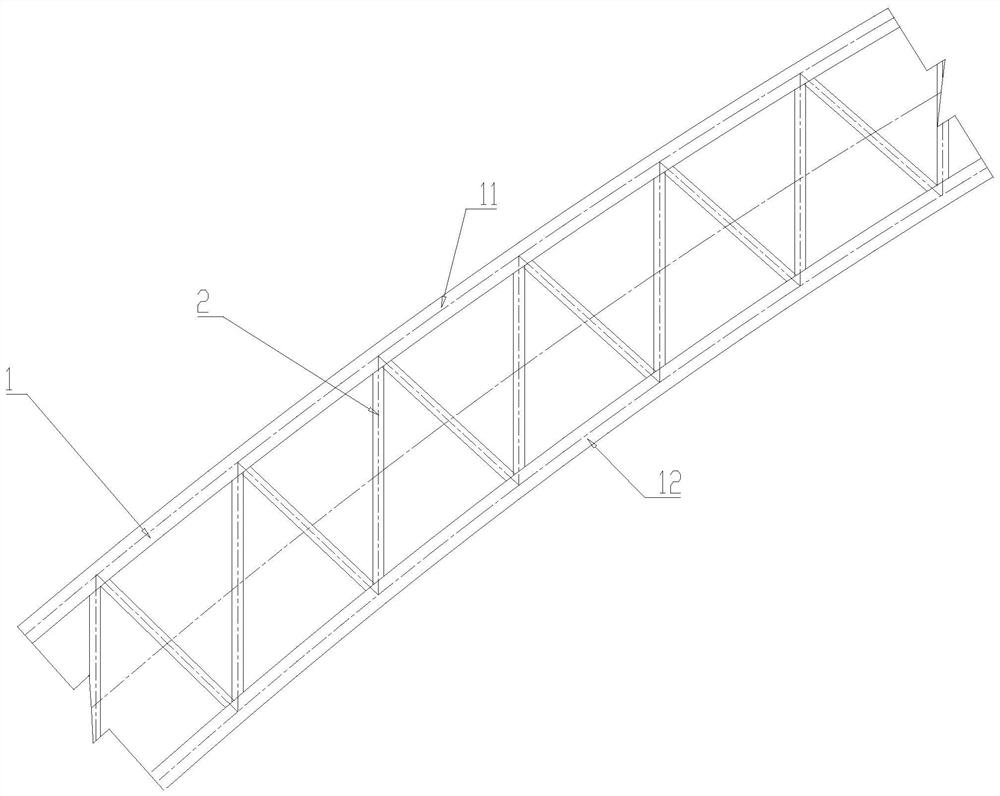

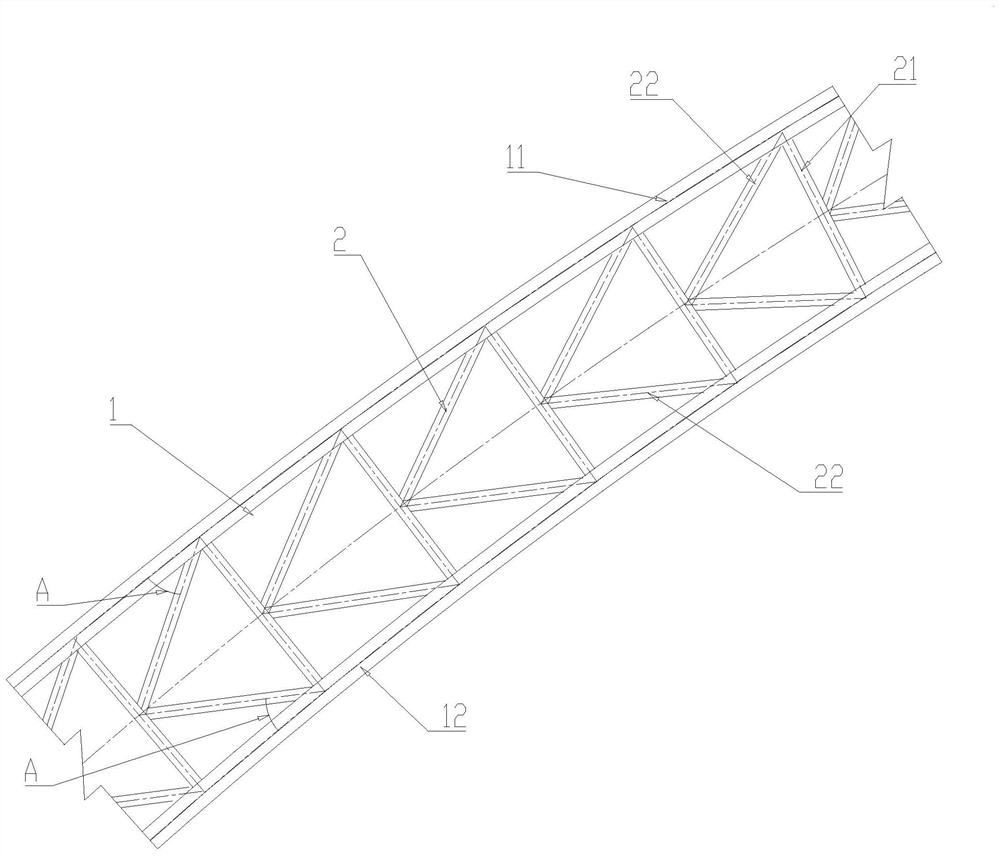

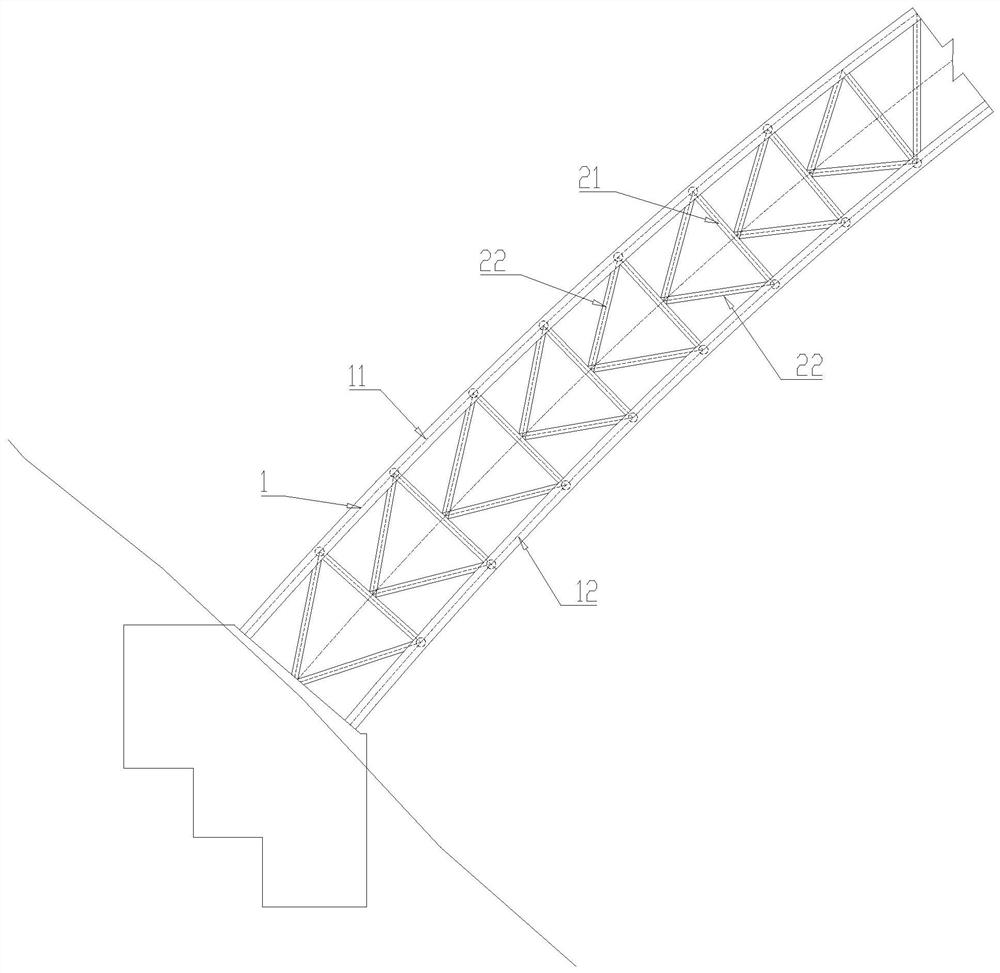

[0031] Such as Figure 1-Figure 3 As shown, this embodiment provides a web member structure of a concrete-filled steel tube truss-type main arch, including a web member assembly 2;

[0032] The number of web member assemblies 2 is several groups, several groups of web member assemblies 2 are arranged in the same direction, and adjacent web member assemblies 2 are fixedly connected;

[0033] The web bar assembly 2 includes a transverse web bar 21 and two diagonal web bars 22, and the transverse web bar 21 and the two diagonal web bars 22 are sequentially connected end to end and form a triangular unit;

[0034] The two ends of the transverse web bar 21 are respectively used to be perpendicular to the upper chord 11 and the lower chord 12 of the main arch 1, and one end of one diagonal web bar 22 is used to connect with the upper chord 11 of the main arch 1 on the corresponding side. The other end of the diagonal web rod 22 is connected to the midpoint of the transverse web rod...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com