Patents

Literature

45results about How to "Reduce free length" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

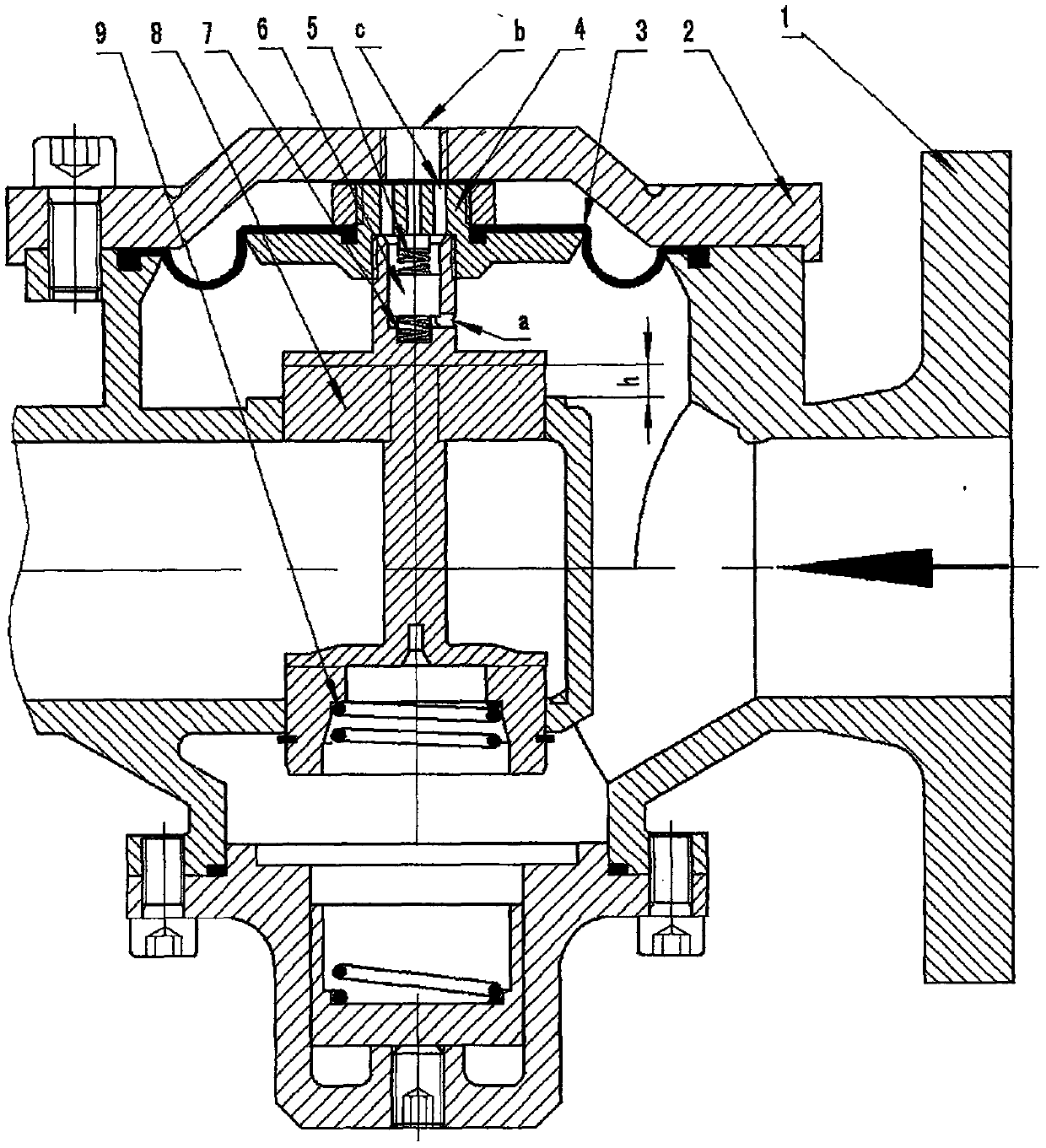

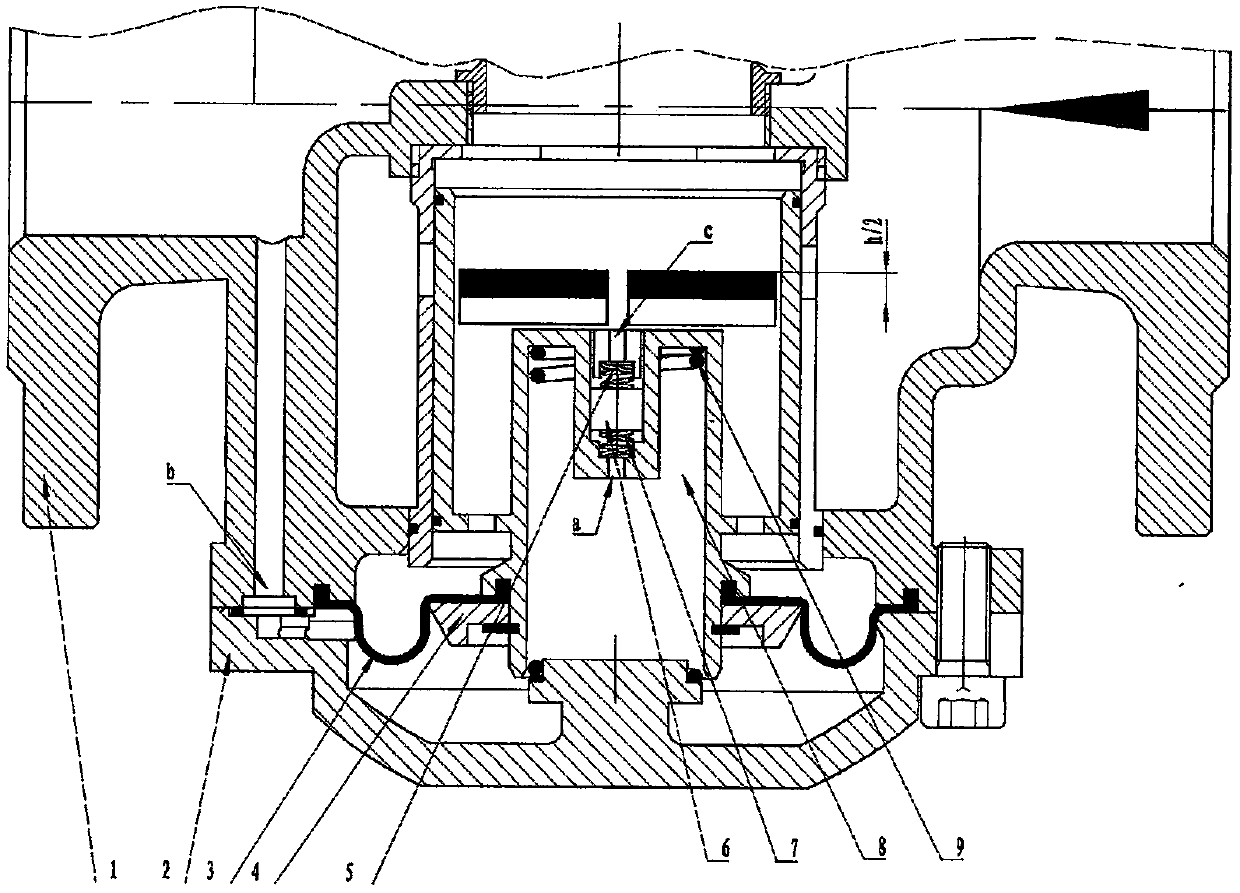

Expansion valve control method, and expansion valve

InactiveCN101135387AImprove responsivenessLow mass flowOperating means/releasing devices for valvesCompression machinesPressure riseEngineering

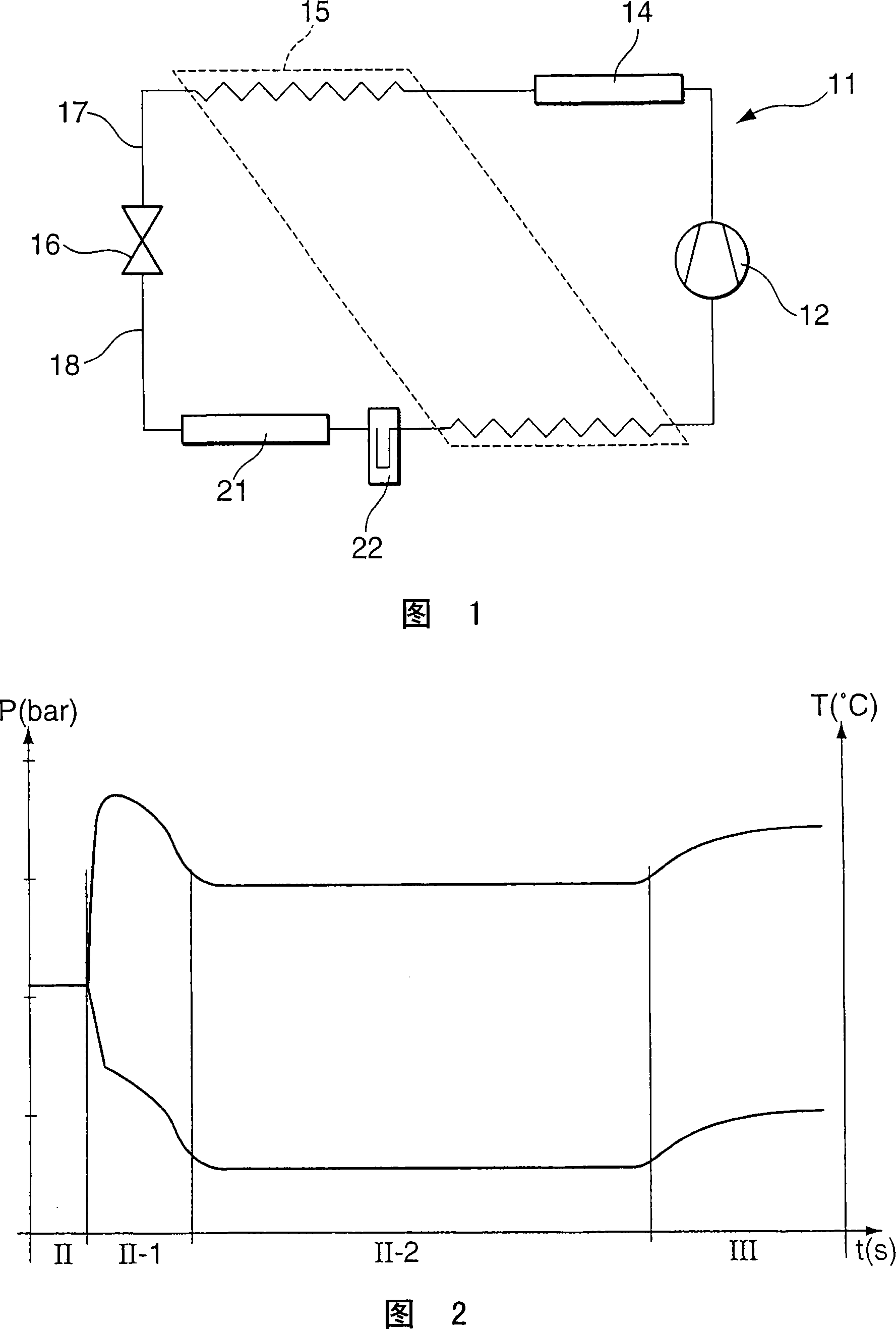

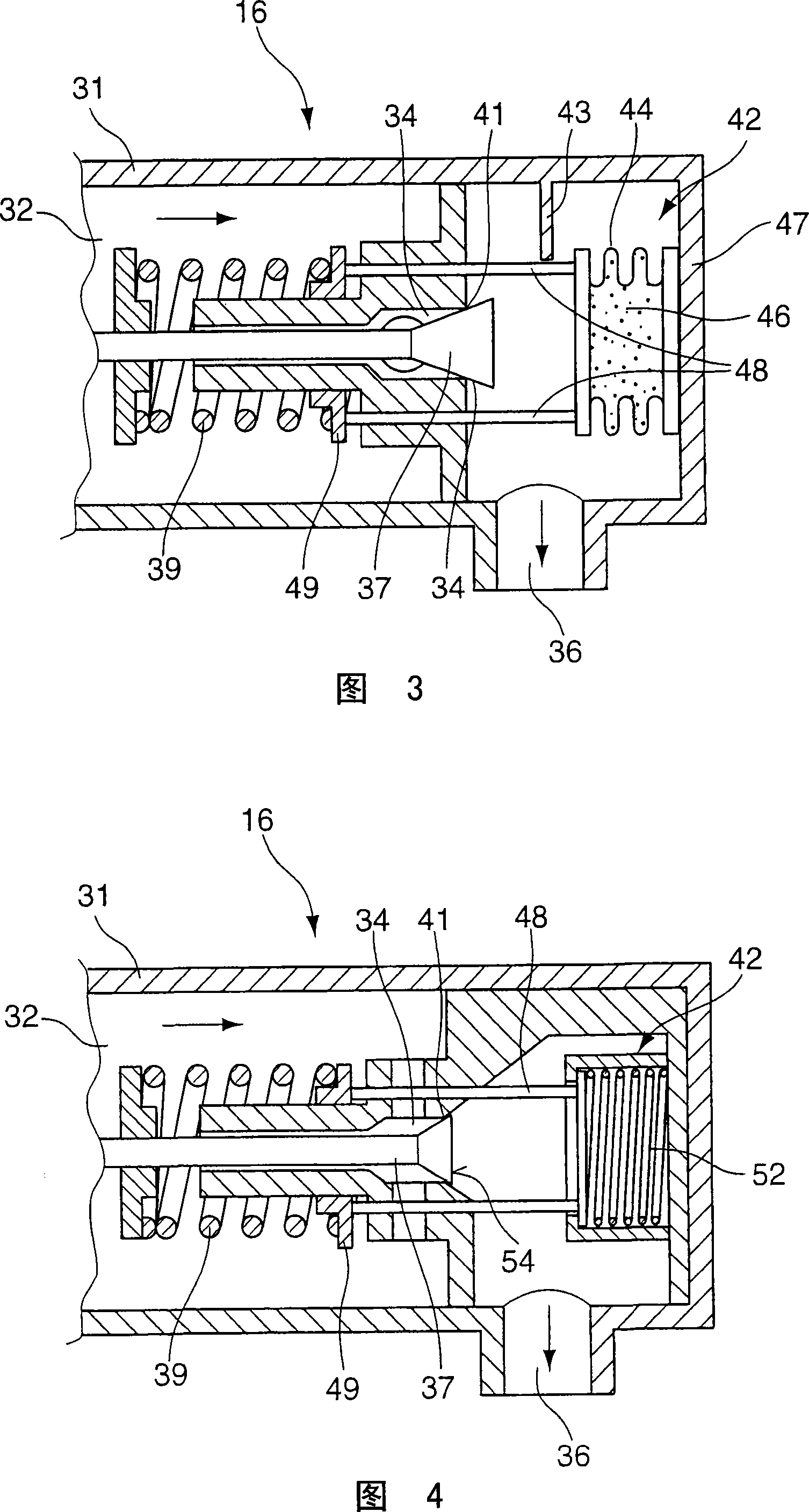

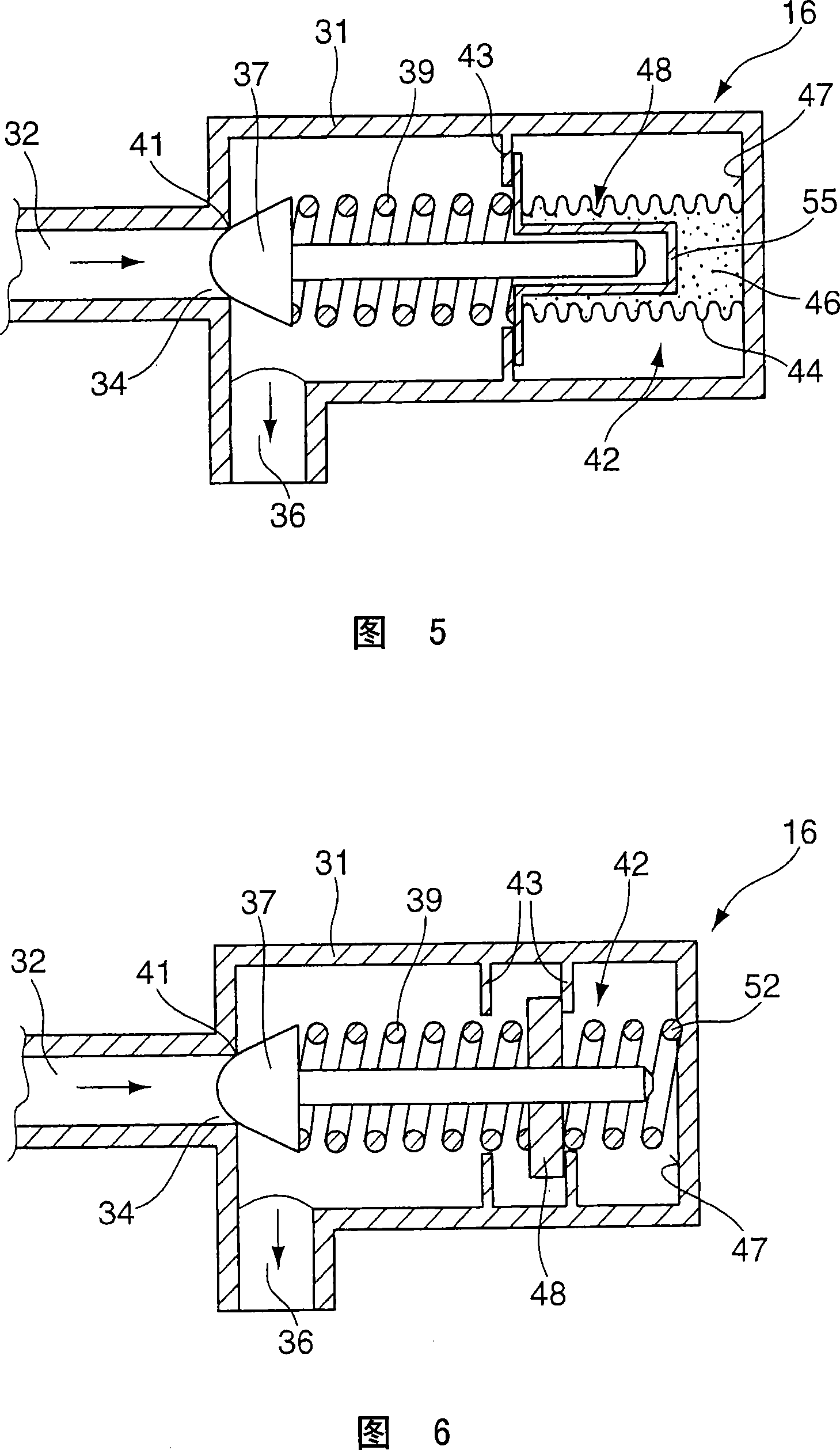

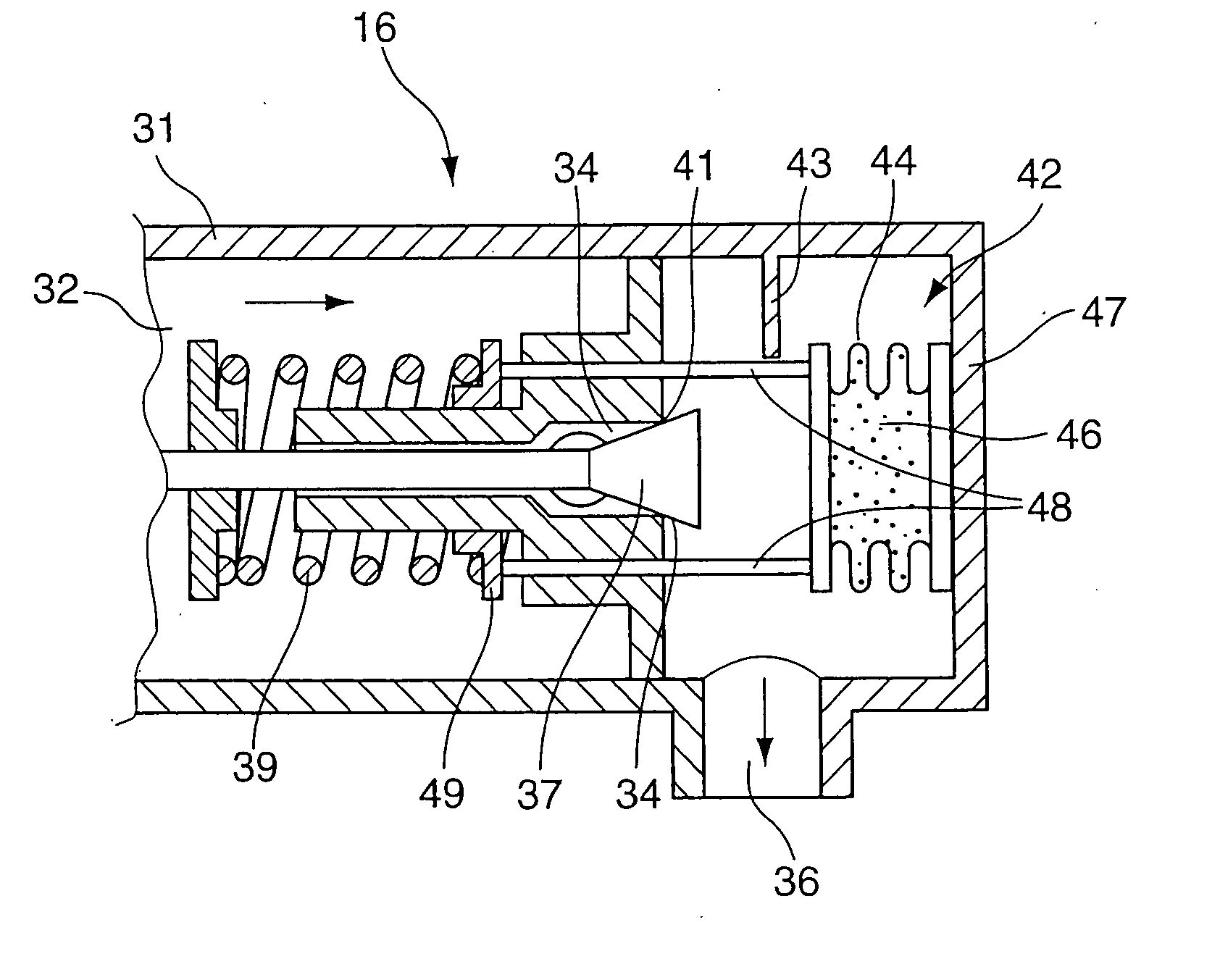

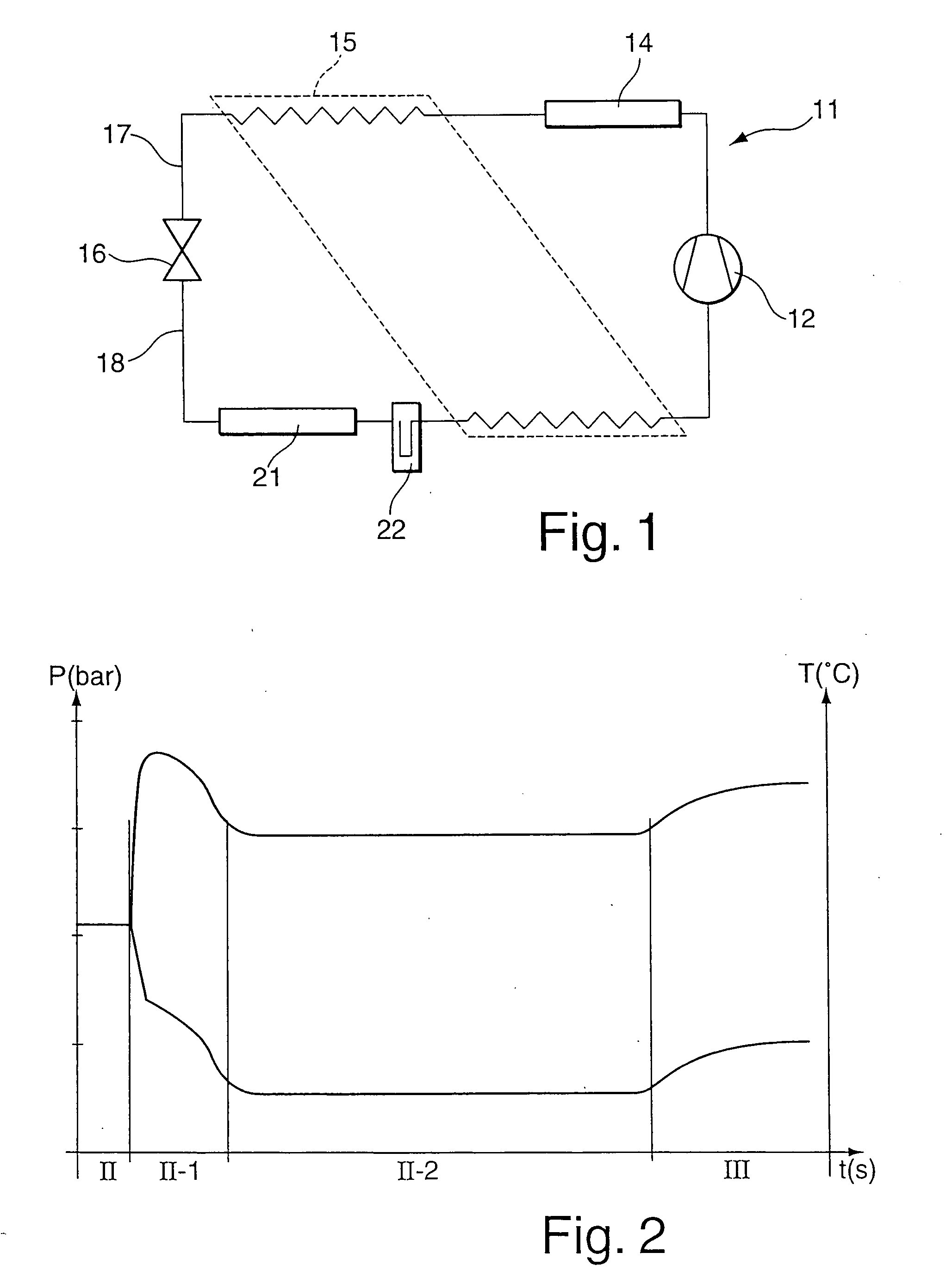

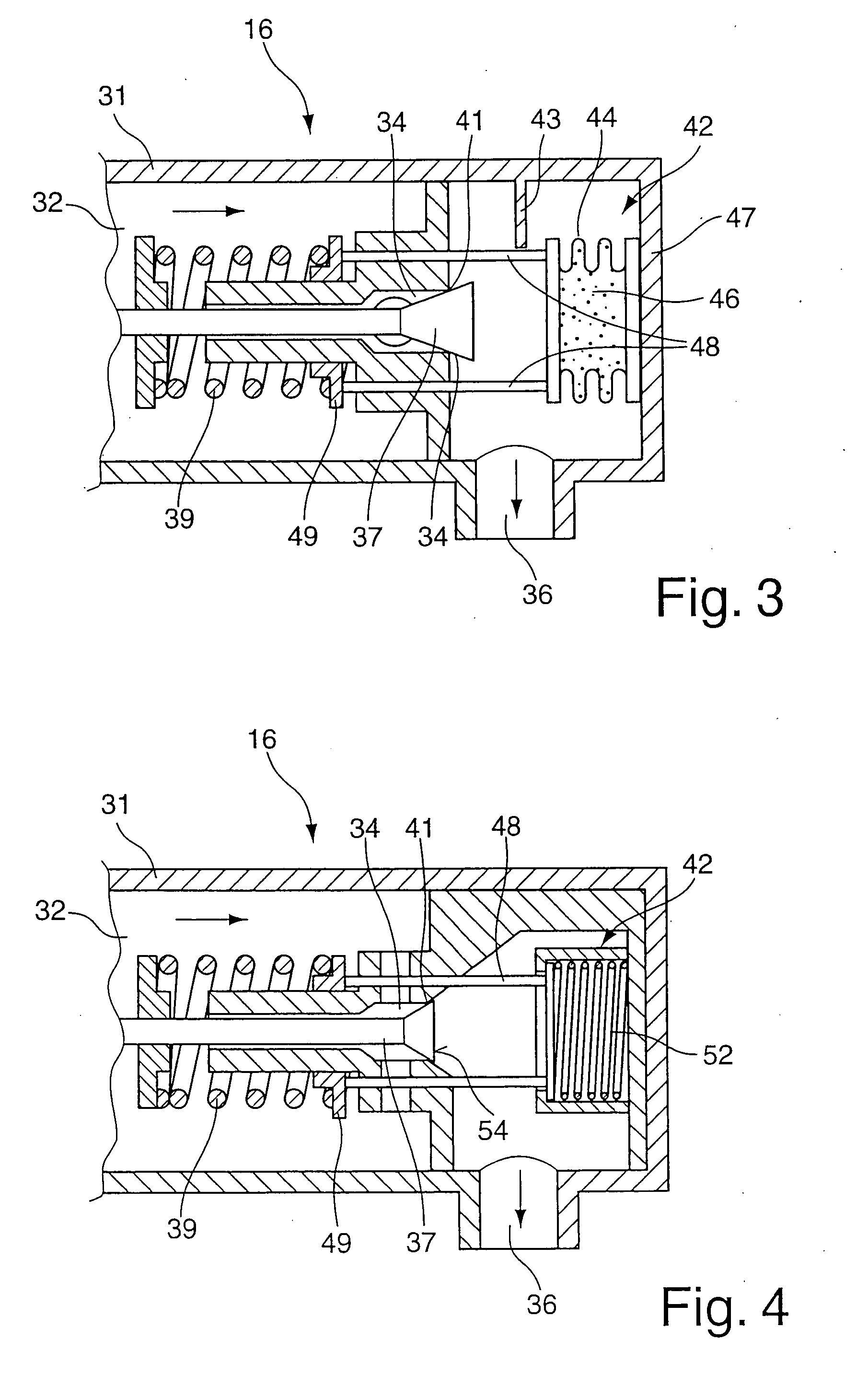

The invention relates to a method for controlling an expansion valve, in particular for vehicle air-conditioning systems operated with CO2 as the refrigerant, with a valve housing which has a feed opening and a removal opening, with a valve-closing member which closes a valve seat of a passage opening arranged between the feed and removal openings, and with a resetting device which acts in the closing direction of the valve-closing member, an adjusting element, which is assigned to the valve-closing member, on the low-pressure side being activated via a predetermined threshold value as the low pressure rises or as the temperature on the low-pressure side rises and actuates at least one actuating element by means of which a closing force of the resetting device acting on the valve-closing member is reduced such that a passage opening is enlarged or a passage of a bypass valve arranged on the low-pressure side, which passage is arranged parallel to the passage opening, is opened.

Owner:OTTO EGELHOF GMBH & CO KG

Method for controlling an expansion valve and expansion valve, in particular for vehicle air-conditioning systems operated with CO2 as the refrigerant

InactiveUS20070295016A1Rapid responseRapid of spaceMechanical apparatusCompression machinesPressure riseEngineering

The invention relates to a method for controlling an expansion valve, in particular for vehicle air-conditioning systems operated with CO2 as the refrigerant, with a valve housing which has a feed opening and a removal opening, with a valve-closing member which closes a valve seat of a passage opening arranged between the feed and removal openings, and with a resetting device which acts in the closing direction of the valve-closing member, an adjusting element, which is assigned to the valve-closing member, on the low-pressure side being activated via a predetermined threshold value as the low pressure rises or as the temperature on the low-pressure side rises and actuates at least one actuating element by means of which a closing force of the resetting device acting on the valve-closing member is reduced such that a passage opening is enlarged or a passage of a bypass valve arranged on the low-pressure side, which passage is arranged parallel to the passage opening, is opened.

Owner:OTTO EGELHOF

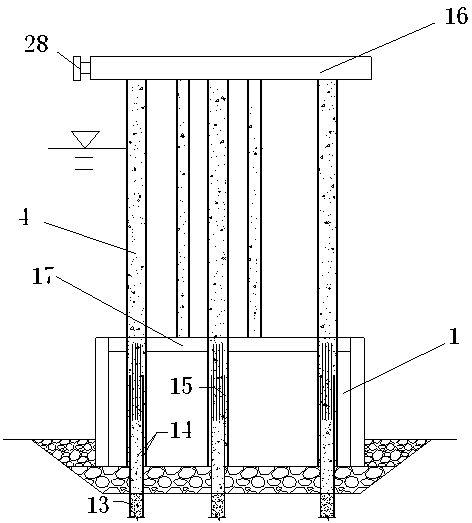

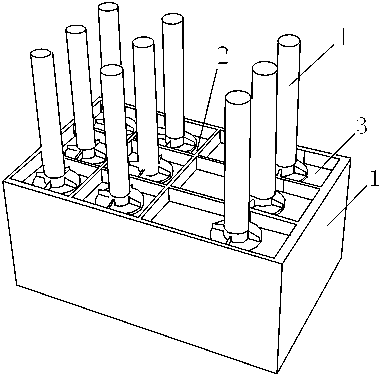

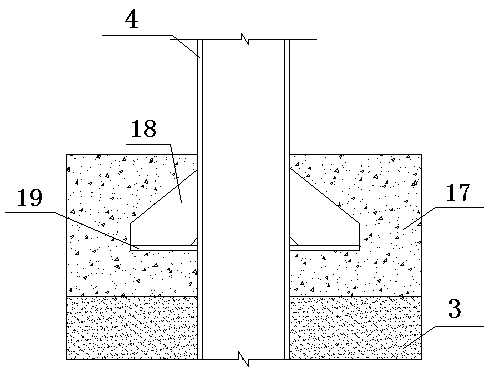

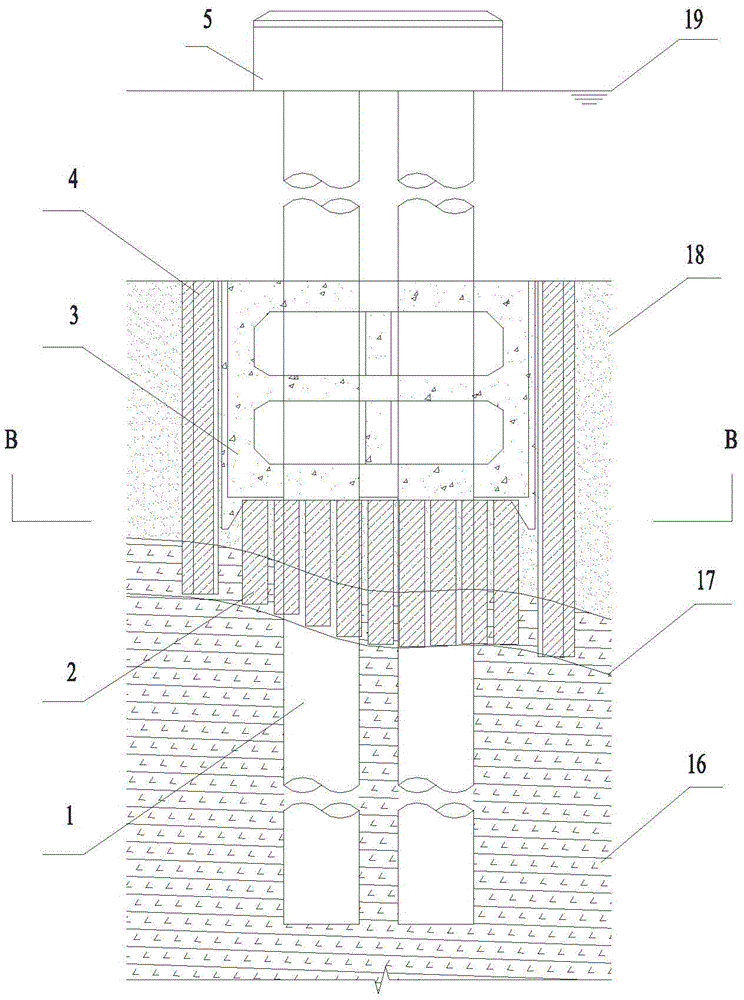

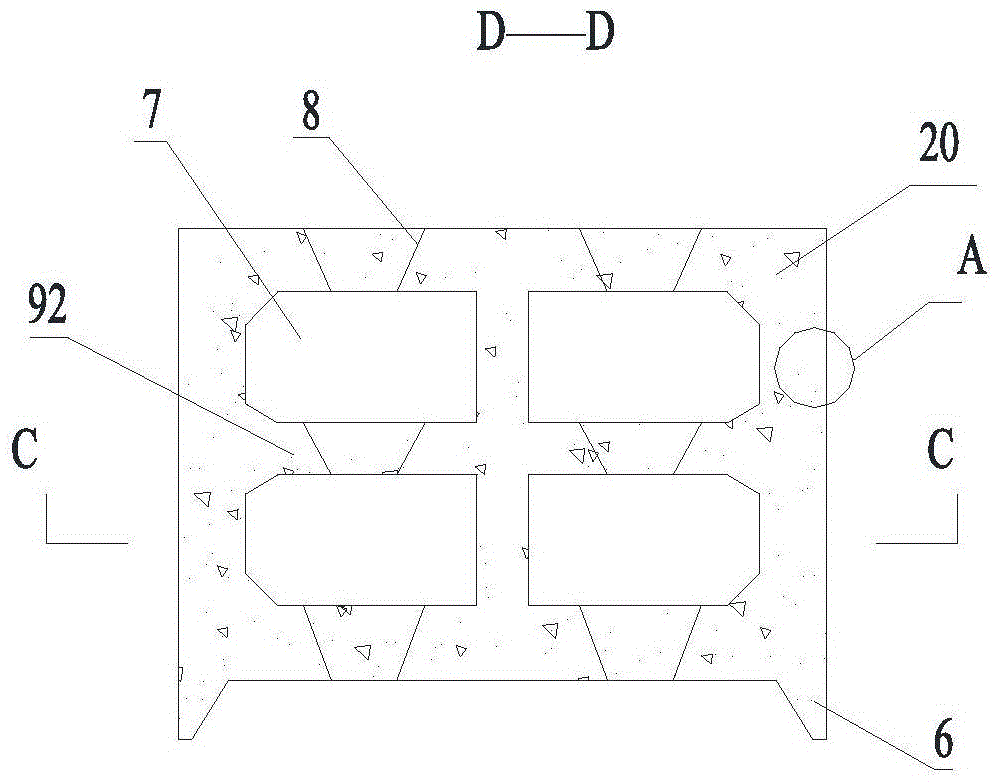

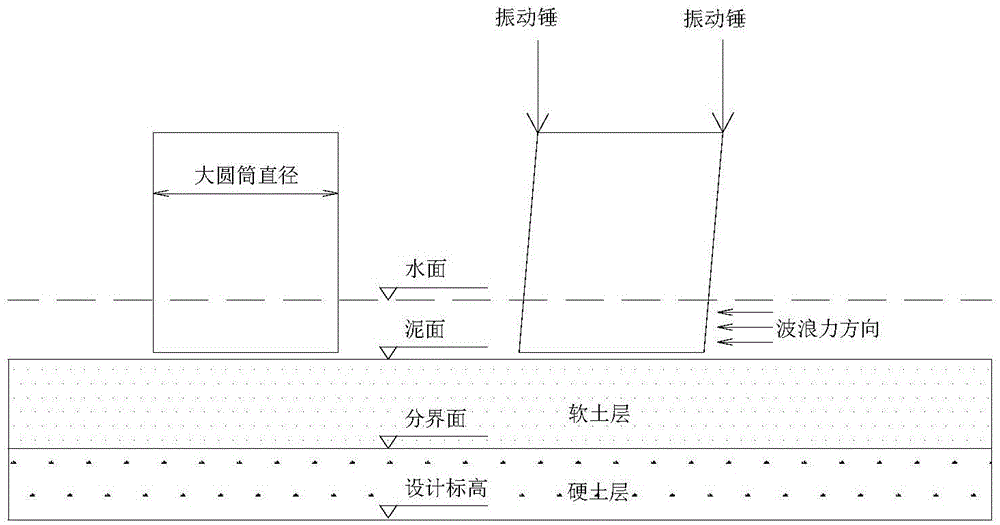

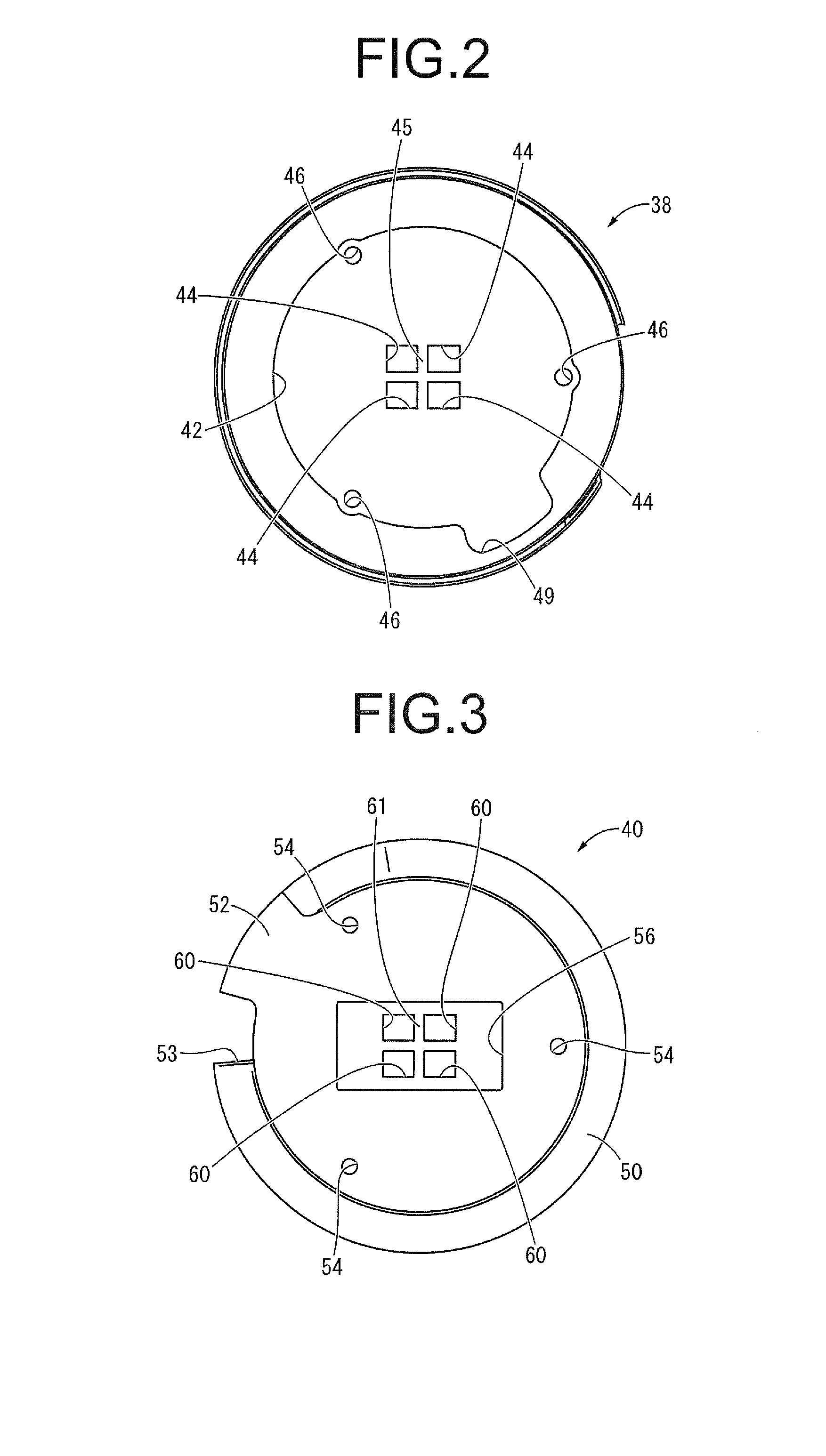

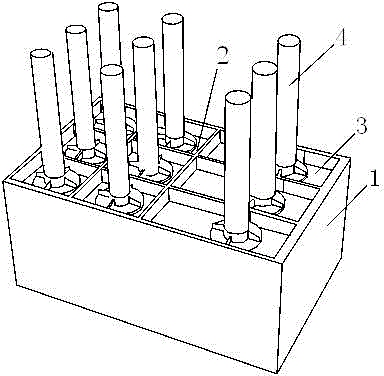

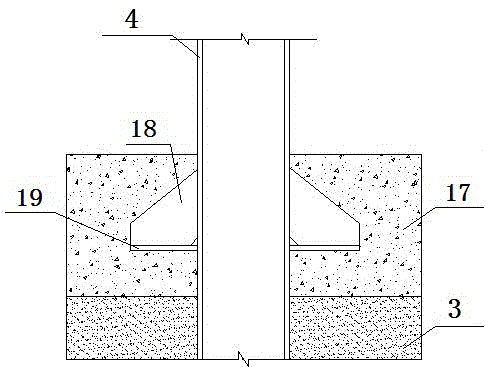

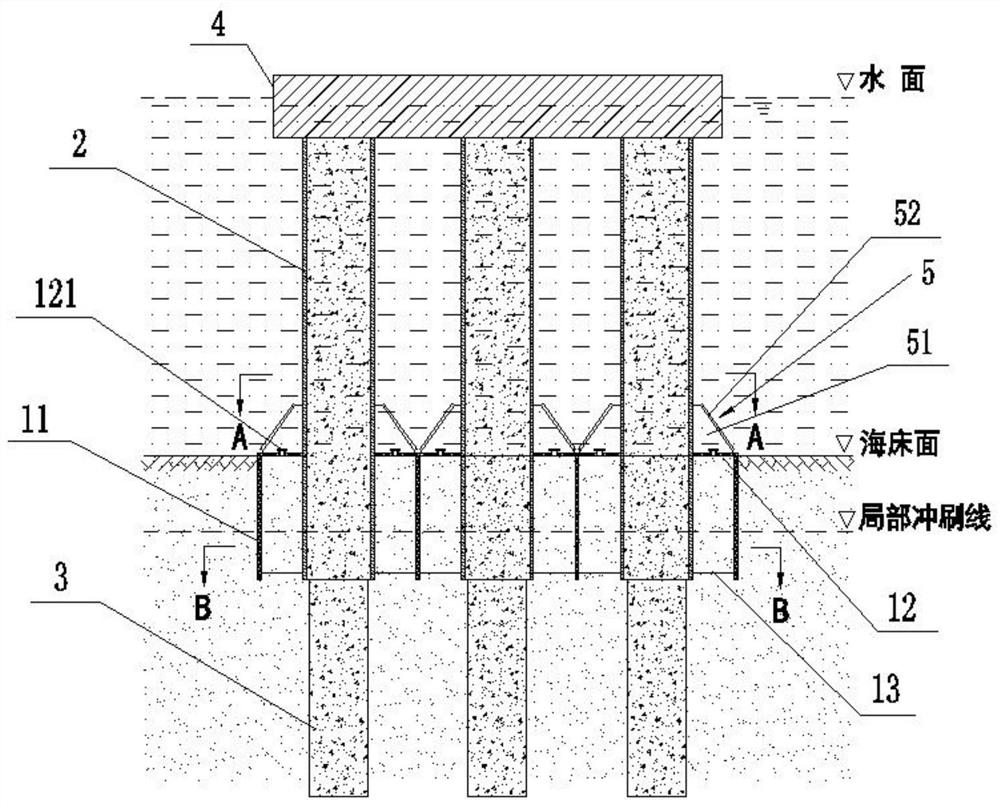

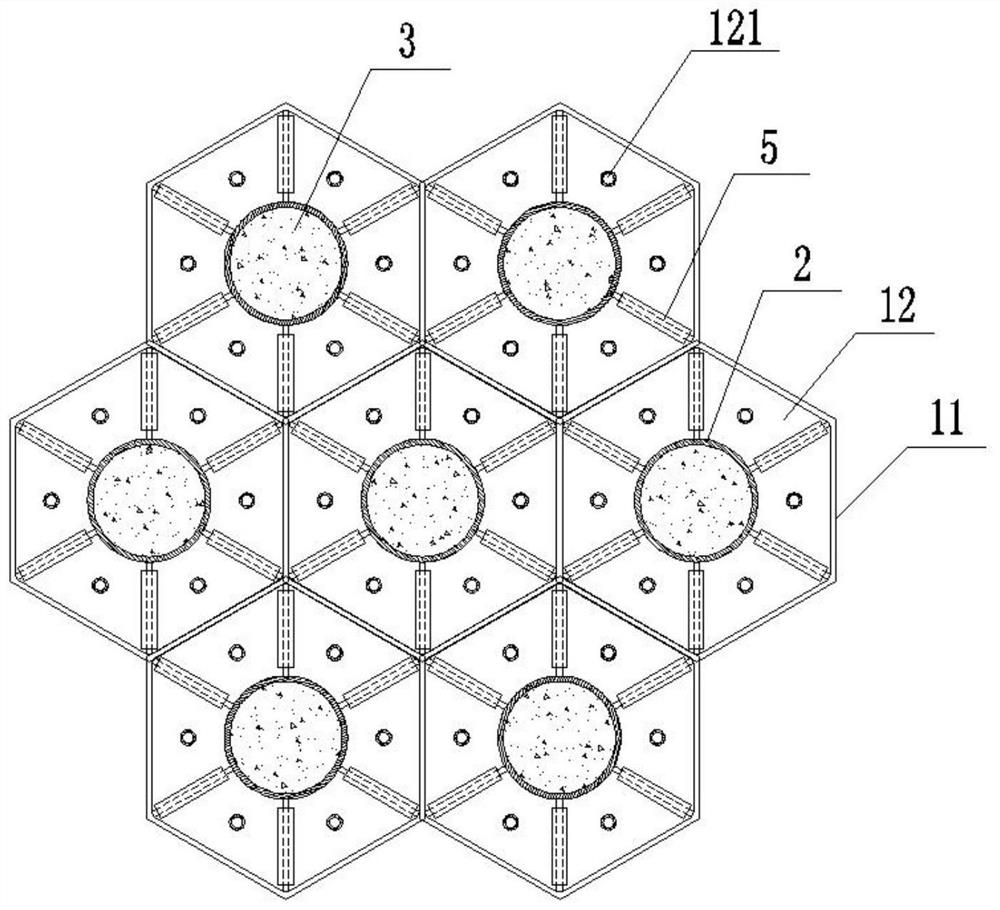

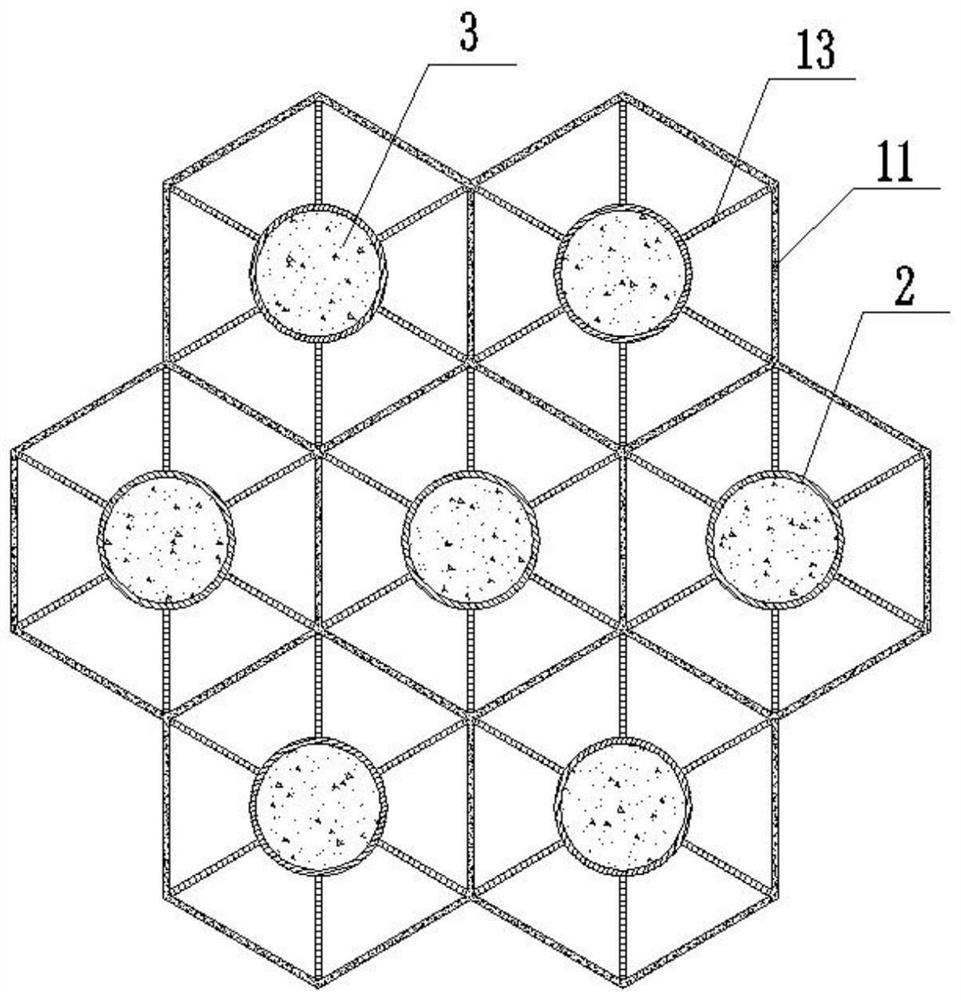

Deepwater open type wharf with combined foundation and method for constructing deepwater open type wharf

The invention discloses a deepwater open type wharf with a combined foundation. A foundation support system of the deepwater open type wharf comprises a caisson gravity structure system and a pile foundation structure system which are fixedly assembled and connected with each other, a caisson is fixed onto a submarine foundation bed in an implantation manner, the pile foundation structure system is of a concrete-filled steel pipe pile bundle structure comprising through long piles and non-through piles, steel pipe piles arranged along the insides of steel casings are driven into a rock-soil bearing stratum to form the through long piles, and the bottoms of the non-through piles are embedded into a top plate of the caisson to be fixedly connected with the top plate of the caisson, so that the wharf with the combined foundation which comprises an open type pile foundation and the gravity caisson is formed. The invention further provides a method for constructing the wharf. The method includes prefabricating the combined foundation on a land; processing the submarine foundation bed; positioning and sinking the combined foundation; manufacturing the through long piles; manufacturing an upper wharf face plate. The deepwater open type wharf and the method have the advantages that merits of the gravity structure and merits of a pile foundation structure are combined with one another, the problem of differential settlement is effectively solved, wharf apron mooring conditions are improved, and the wharf is high in bearing capacity and good in durability.

Owner:SHANGHAI UNIV

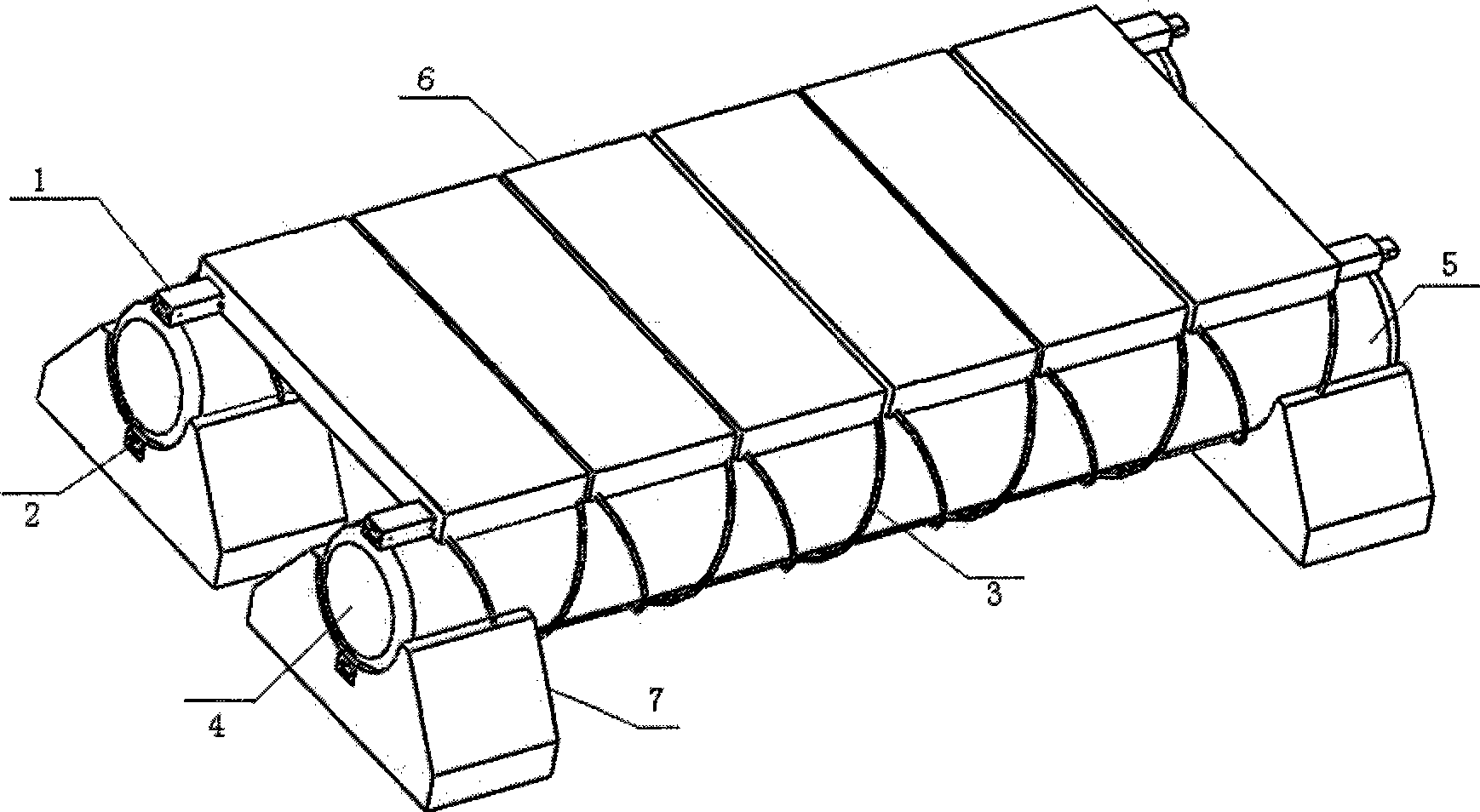

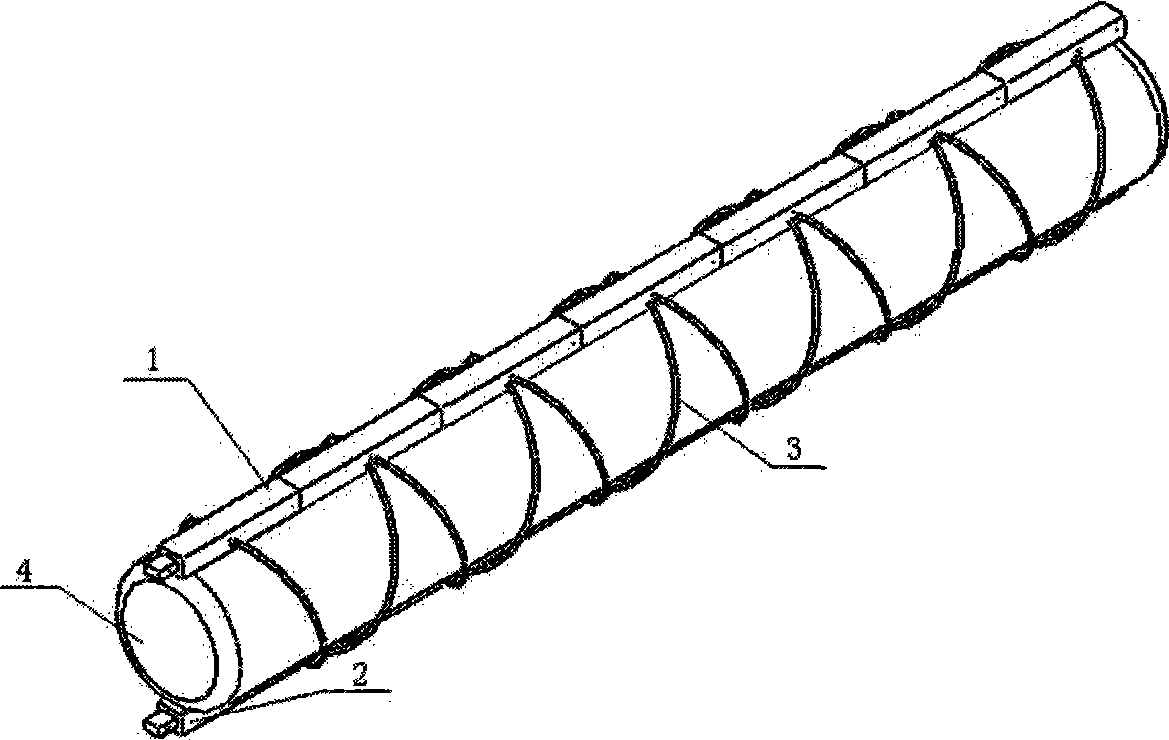

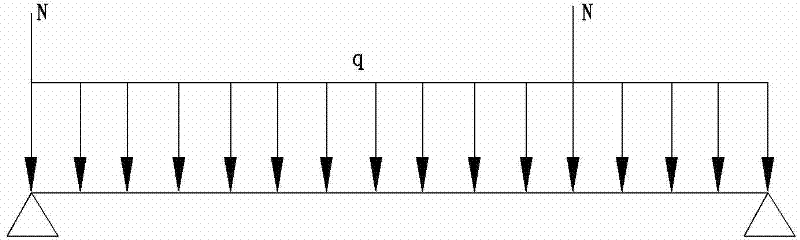

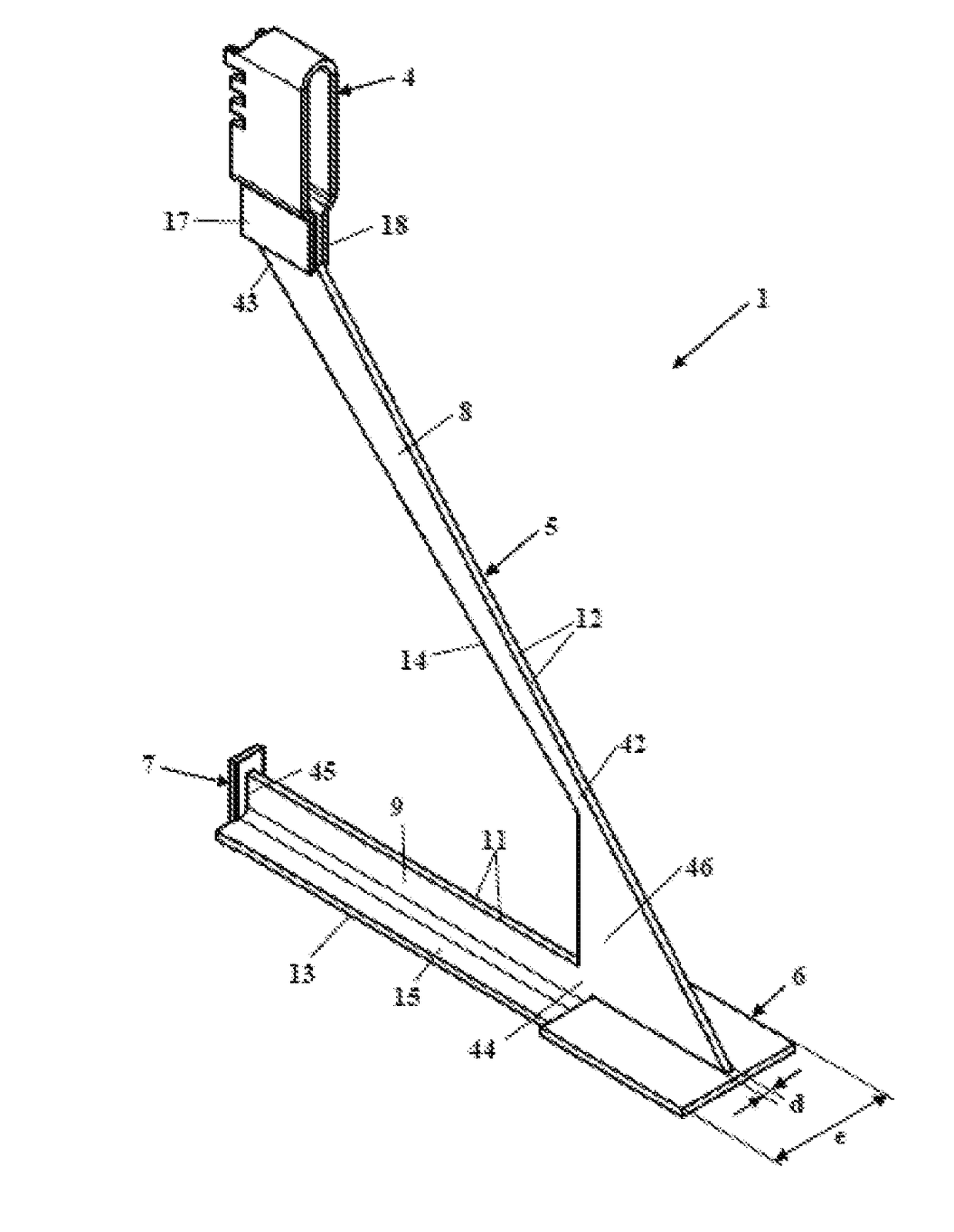

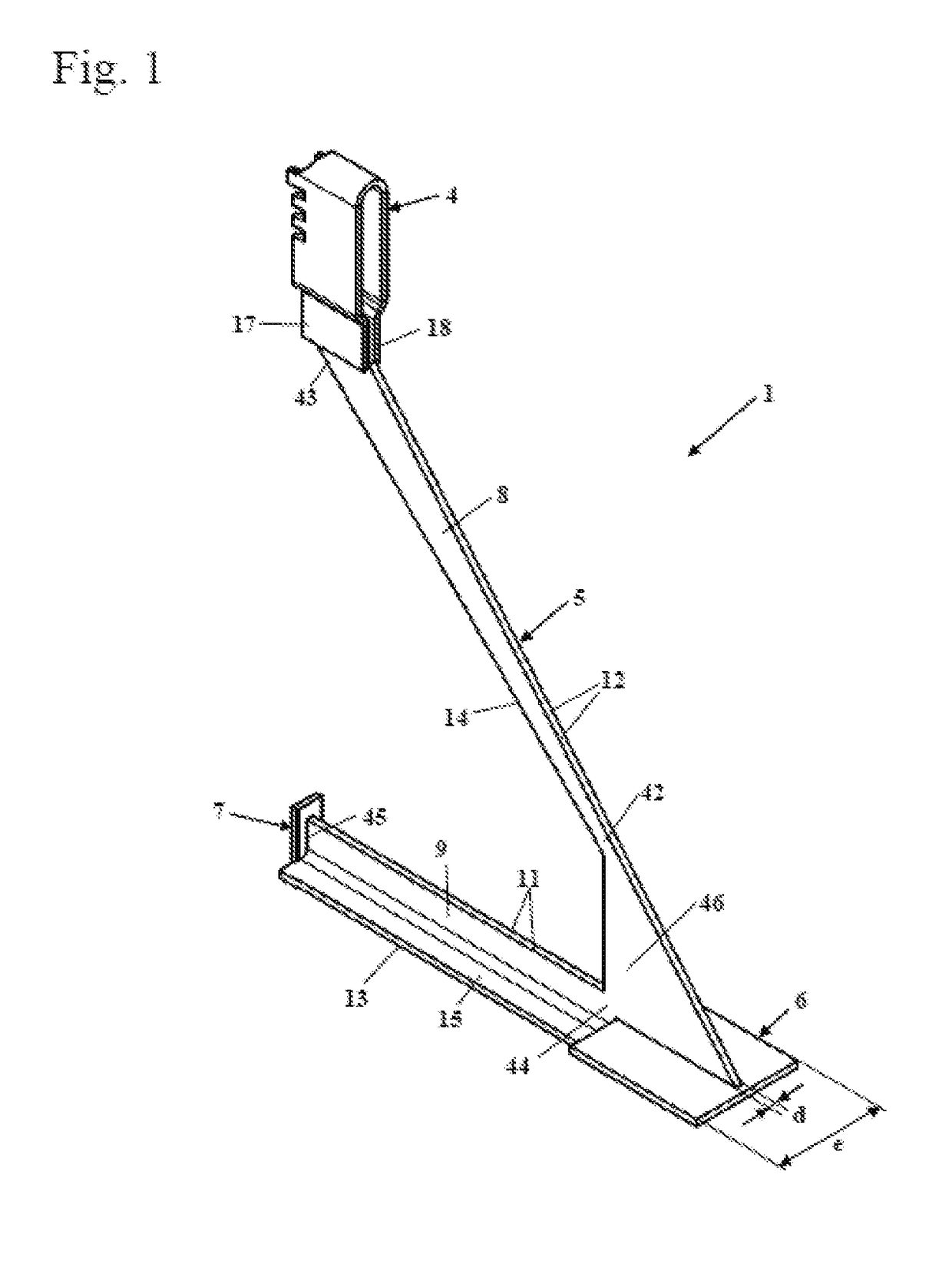

Expansion type cable-rod-film combined emergency bridge

The invention relates to a unfolding type cable-rod-film combined emergency bridge, which consists of a plurality of bridge units; each bridge unit consists of a cable-rod-film composite beam, a bridge faceplate and supports; the cable-rod-film composite beam is mounted in the groove of the supports; and the bridge faceplate is mounted on the cable-rod-film composite beam; the cable-rod-film composite beam consists of a top boom, a bottom boom, a low pressure inflated air bag and a stay cable; the top and the bottom boom are disposed on the upper and lower side of the beam; the low pressure inflated air bag is disposed in the middle of the beam; the stay cables are disposed on both sides of the beam; the bag is disposed on the bottom boom; the top boom is disposed on the bag; cross section of the top and the bottom boom and the low pressure inflated air bag is superposed with the vertical symmetrical axis; the cables are winded individually along both sides of the rod and passed through the node ring disposed on the rod side, and fixed by tightening the cables on both sides to connect the cable, the rod and the low pressure inflated air bag into one integral body. The novel emergency bridge achieves the advantages of extremely light weight, convenience for storing and carrying and rapid installation, and has high practical value and broad application prospect.

Owner:BEIHANG UNIV

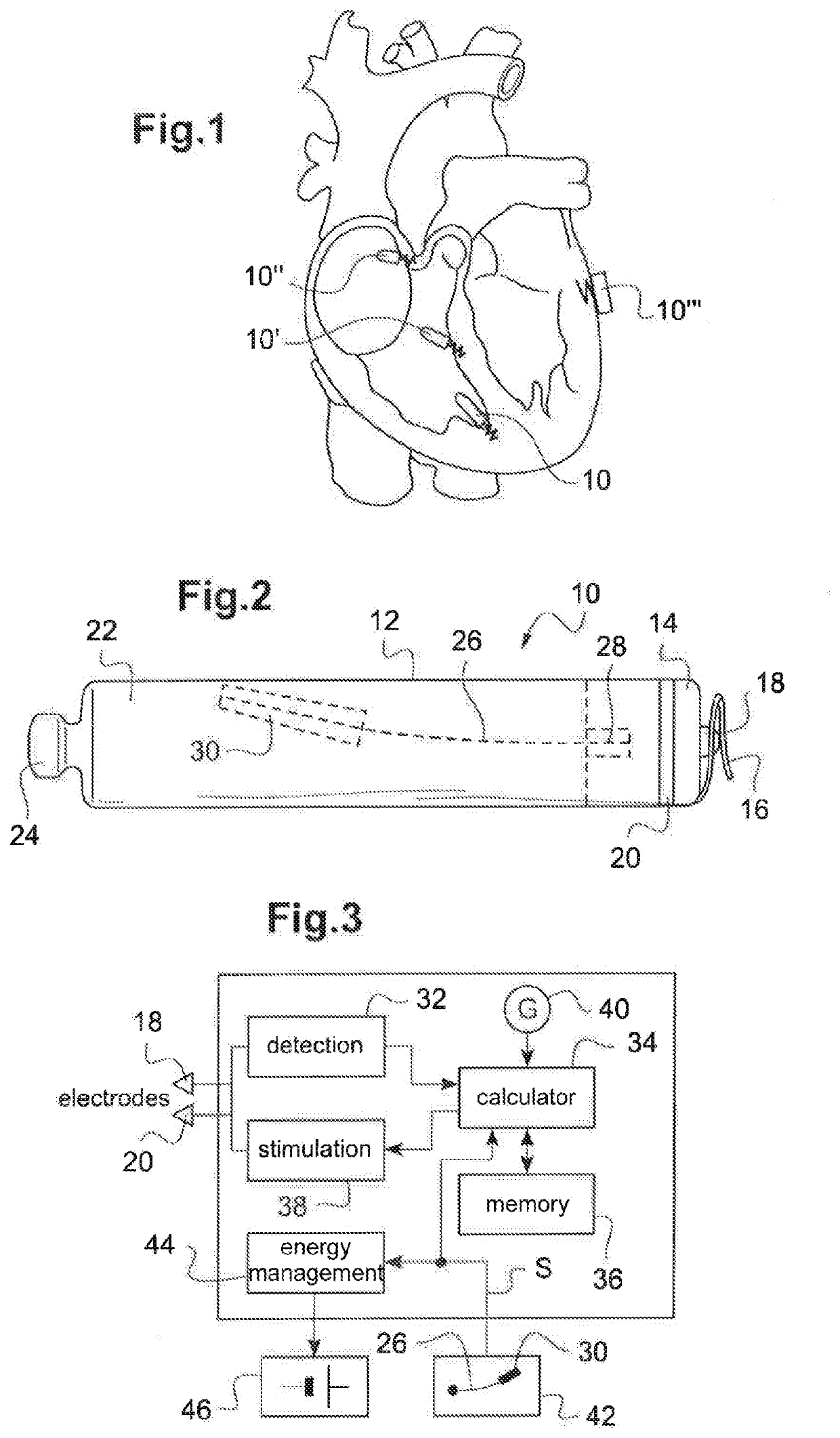

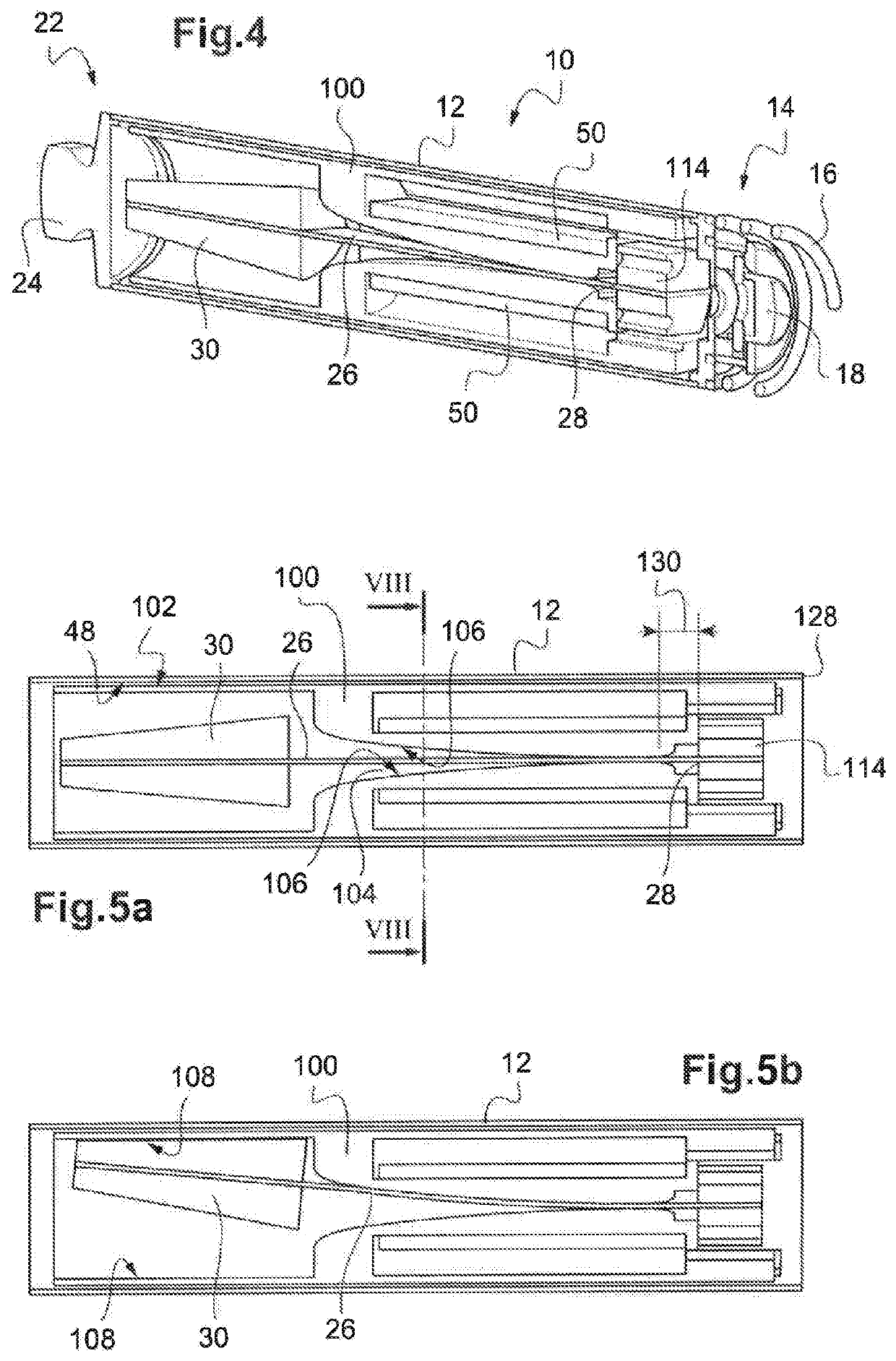

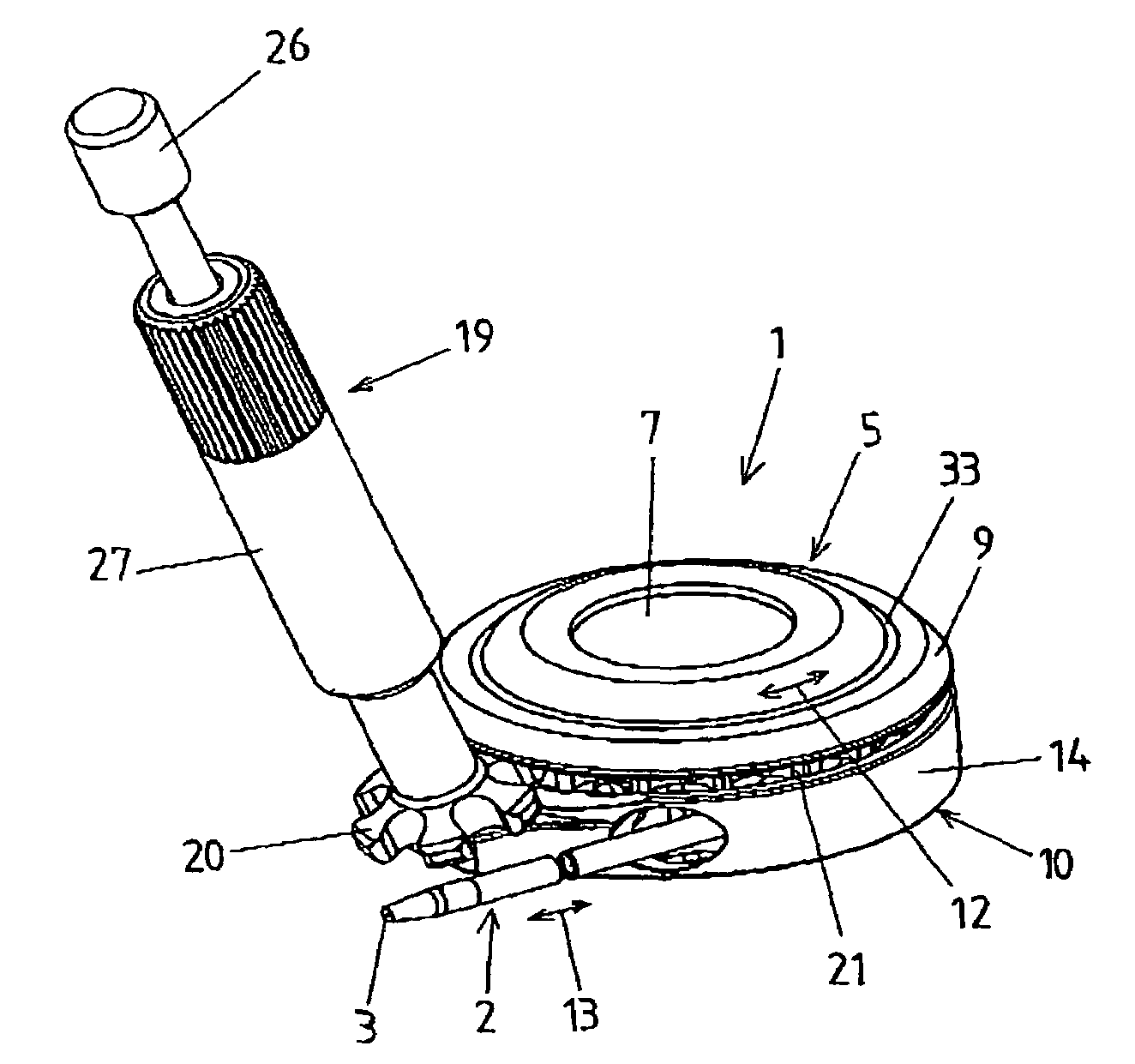

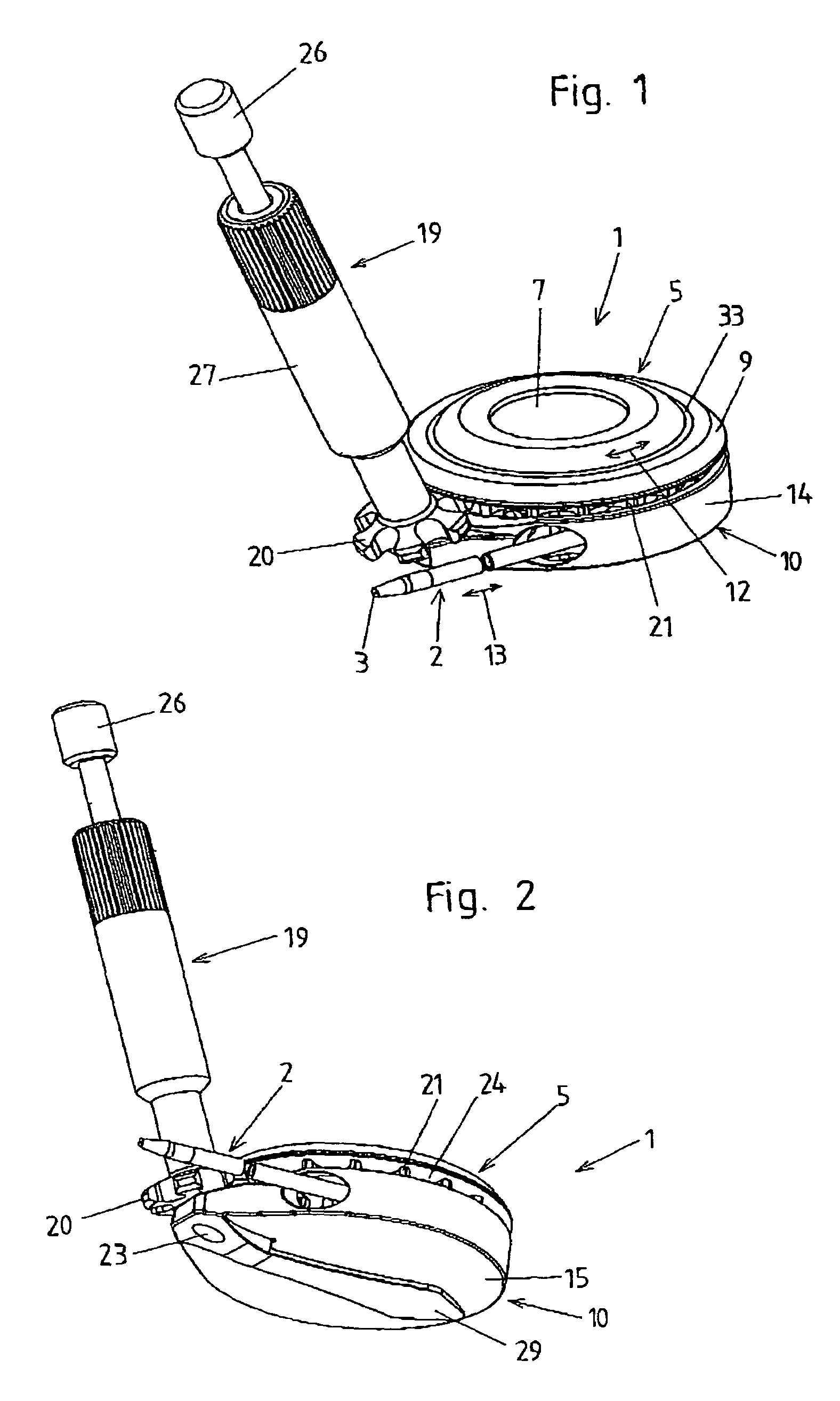

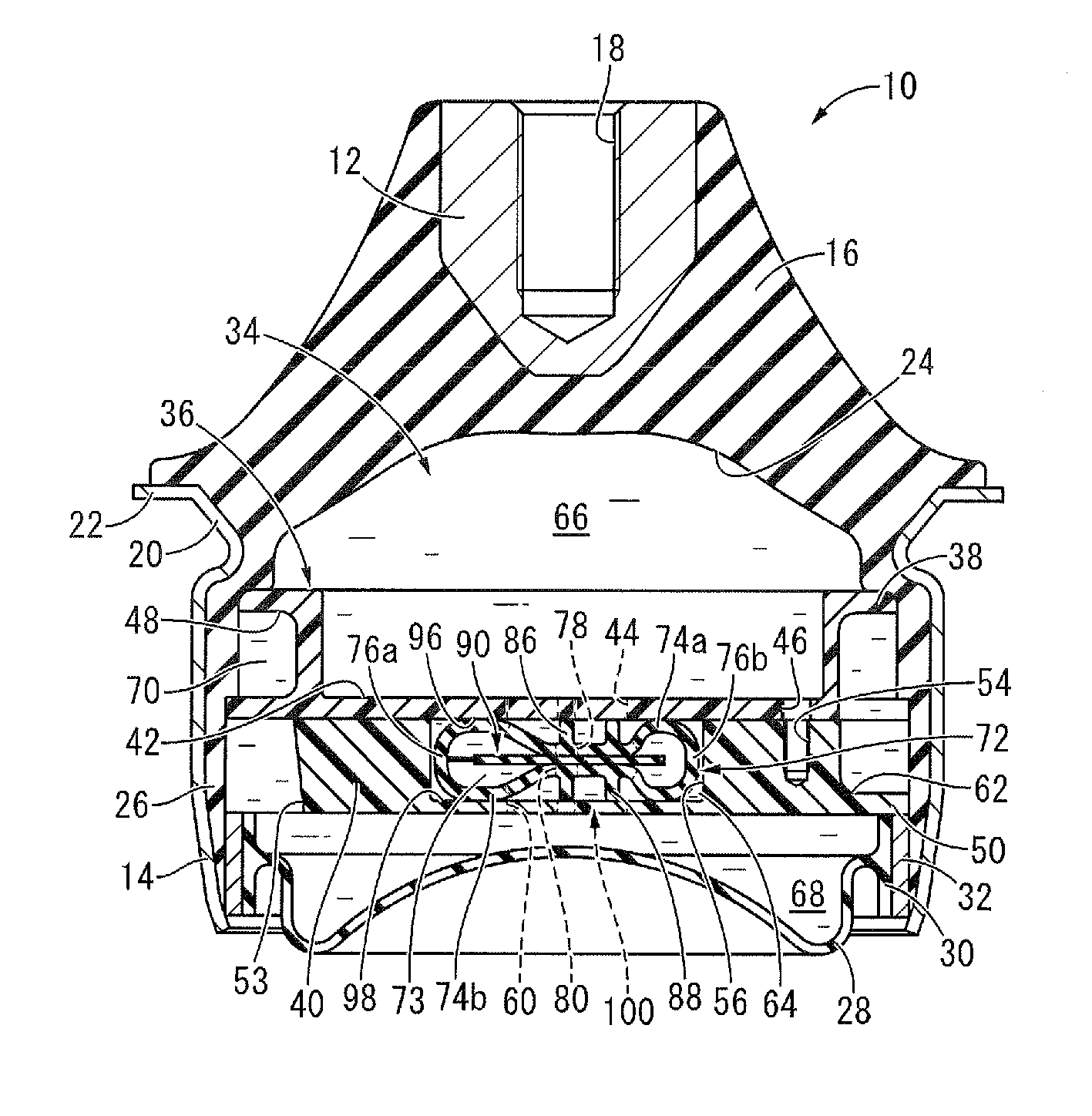

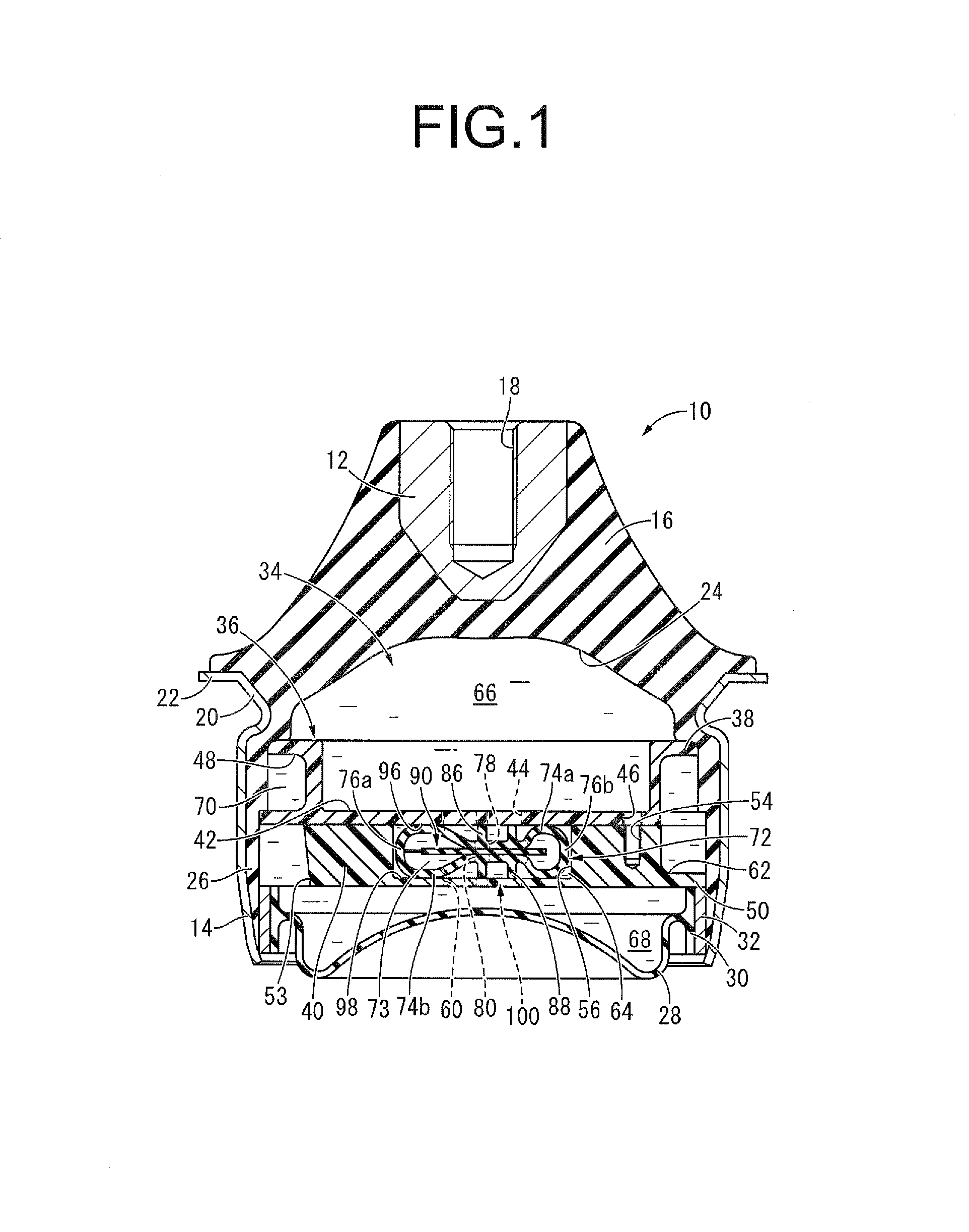

Autonomous cardiac implant of the leadless capsule type, including a piezoelectric beam energy harvester

ActiveUS20190381325A1Reduce free lengthElectrotherapyPiezoelectric/electrostriction/magnetostriction machinesInertial massEnergy harvester

The device includes an energy harvesting module with a pendular unit formed of an elastically deformable piezoelectric beam associated with an inertial mass. A multifunction part includes an axial through-recess with inner bearing surfaces opposite respective outer faces of the beam. These bearing surfaces having an increasing transverse spacing, such as, during an oscillation cycle, the beam comes into contact with one of the bearing surfaces, hence reducing the free length of the beam as the bending of the latter goes along. The multifunction part also allows rationalizing the manufacturing and the assembly of the capsule, with high-level integration of the inner components of the implant.

Owner:CAIRDAC

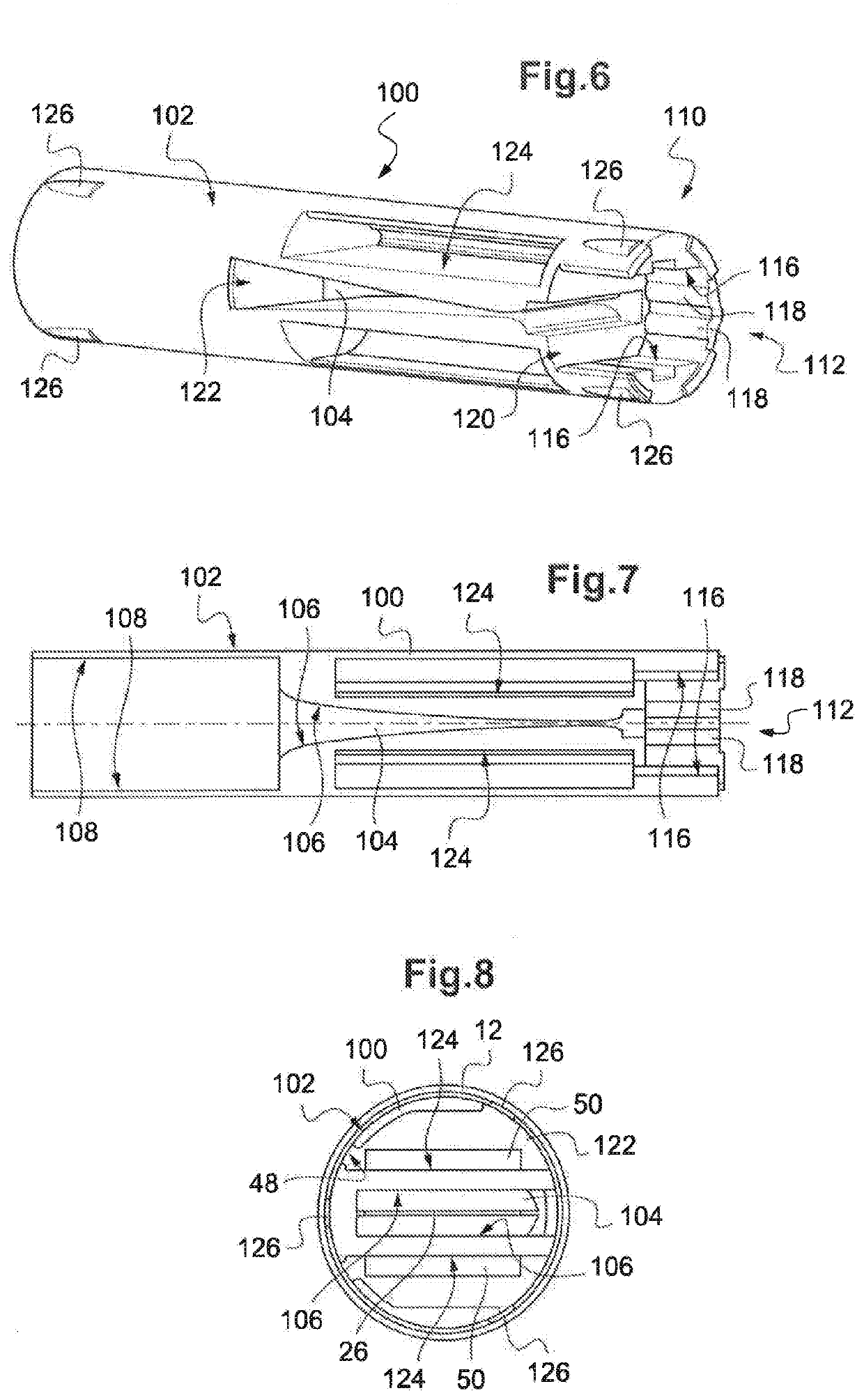

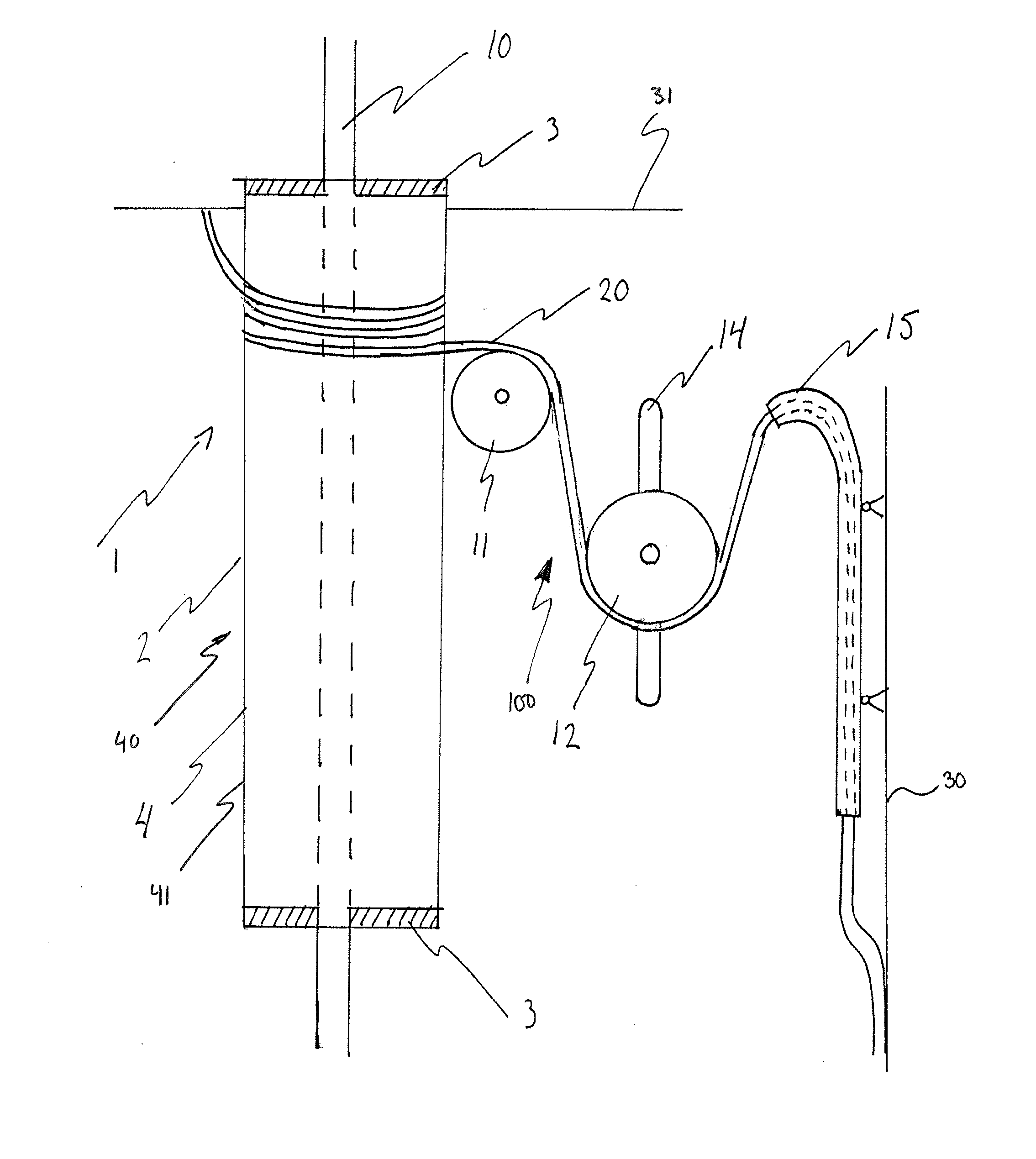

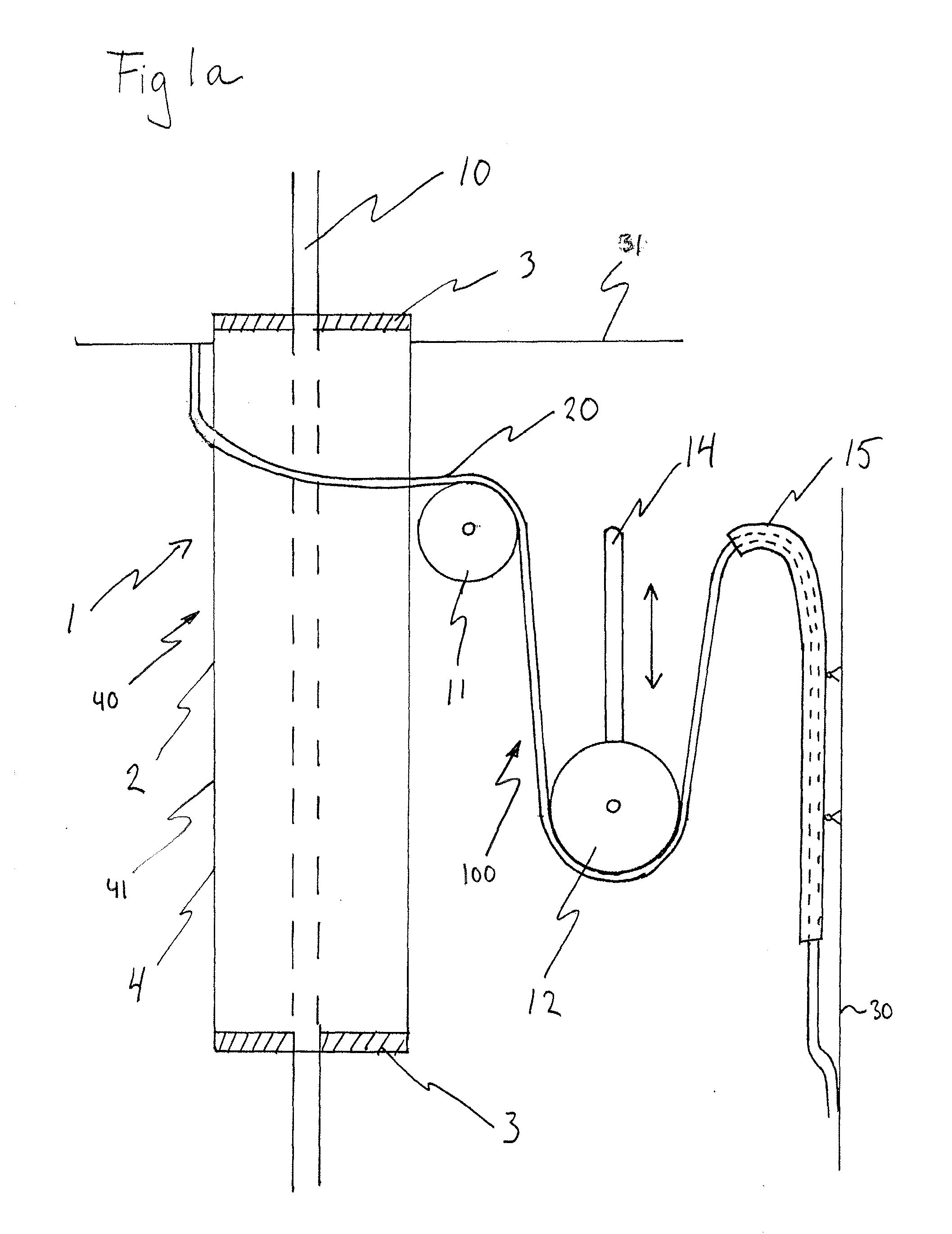

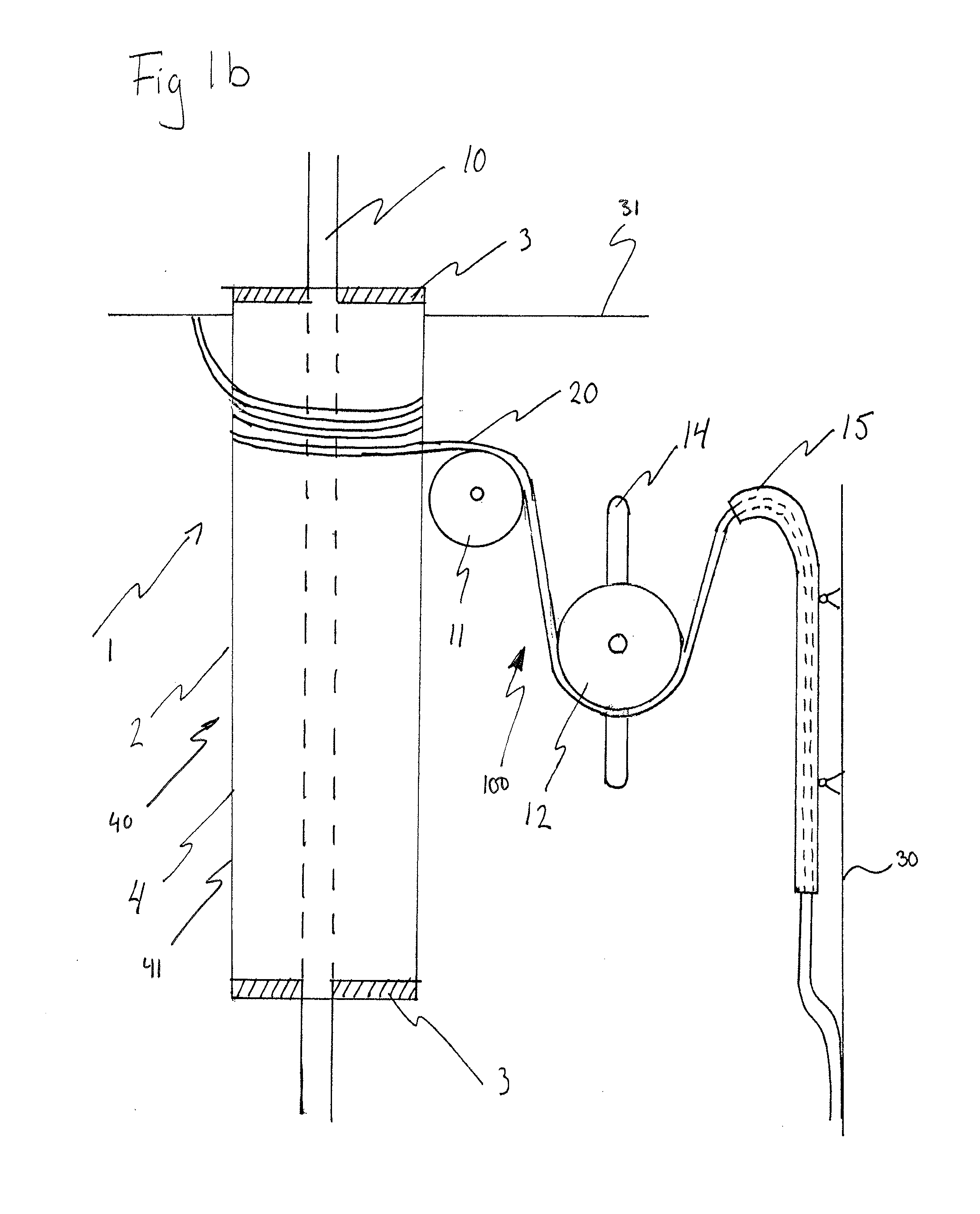

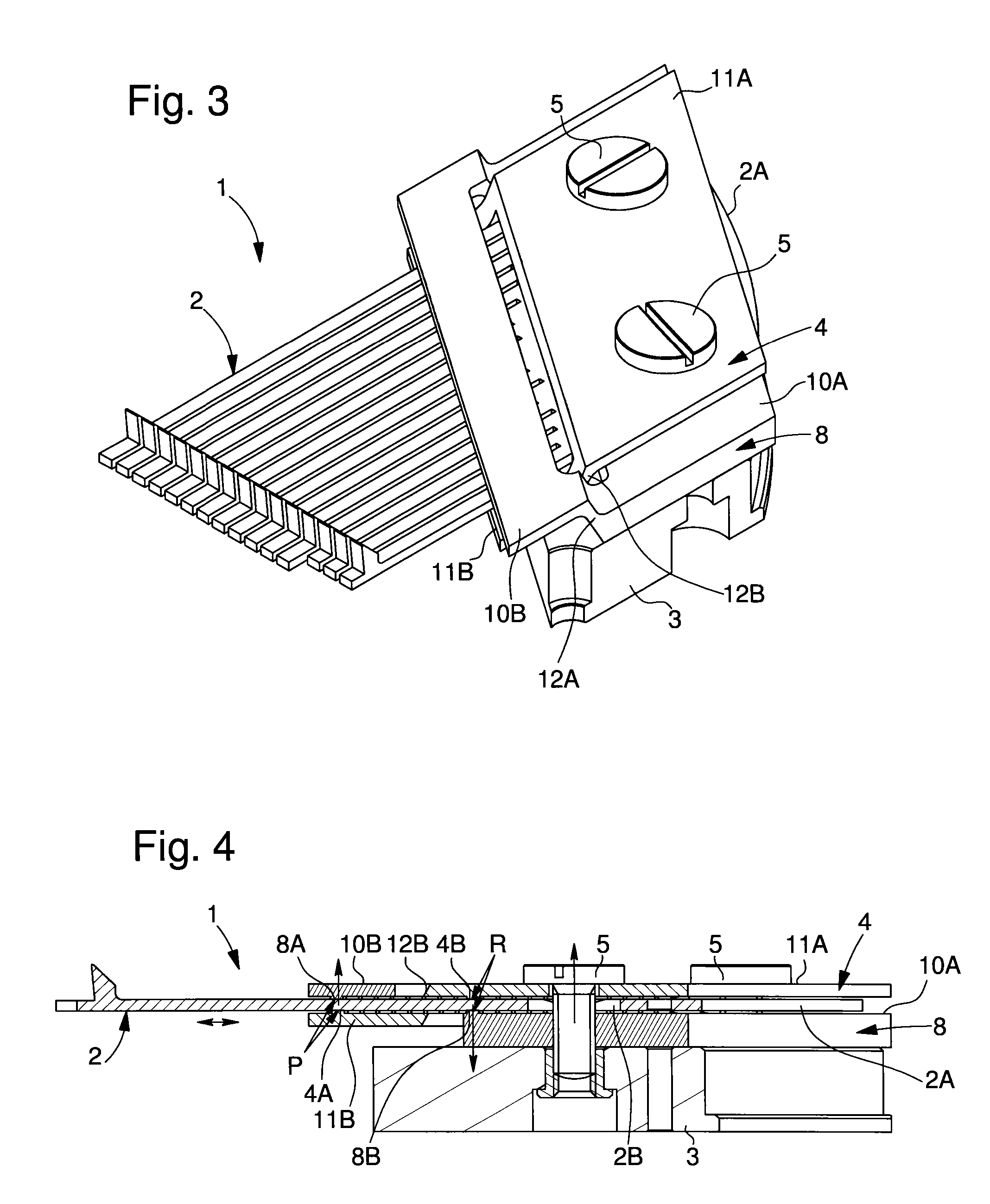

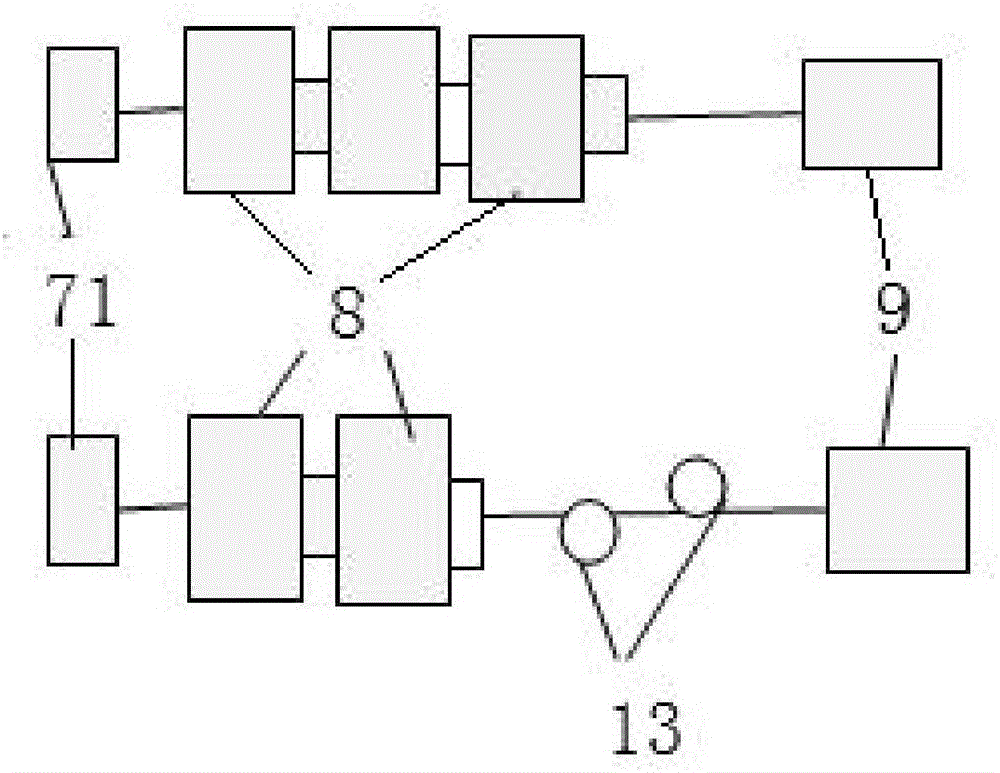

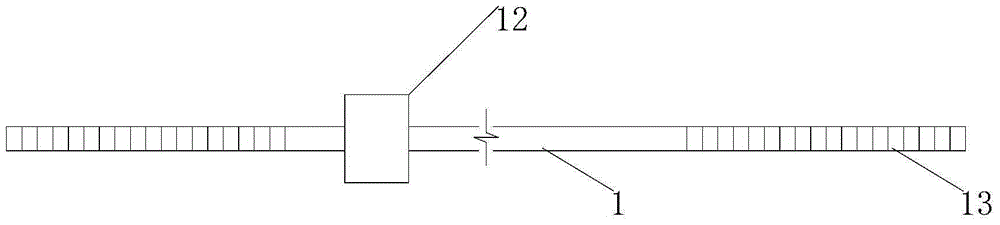

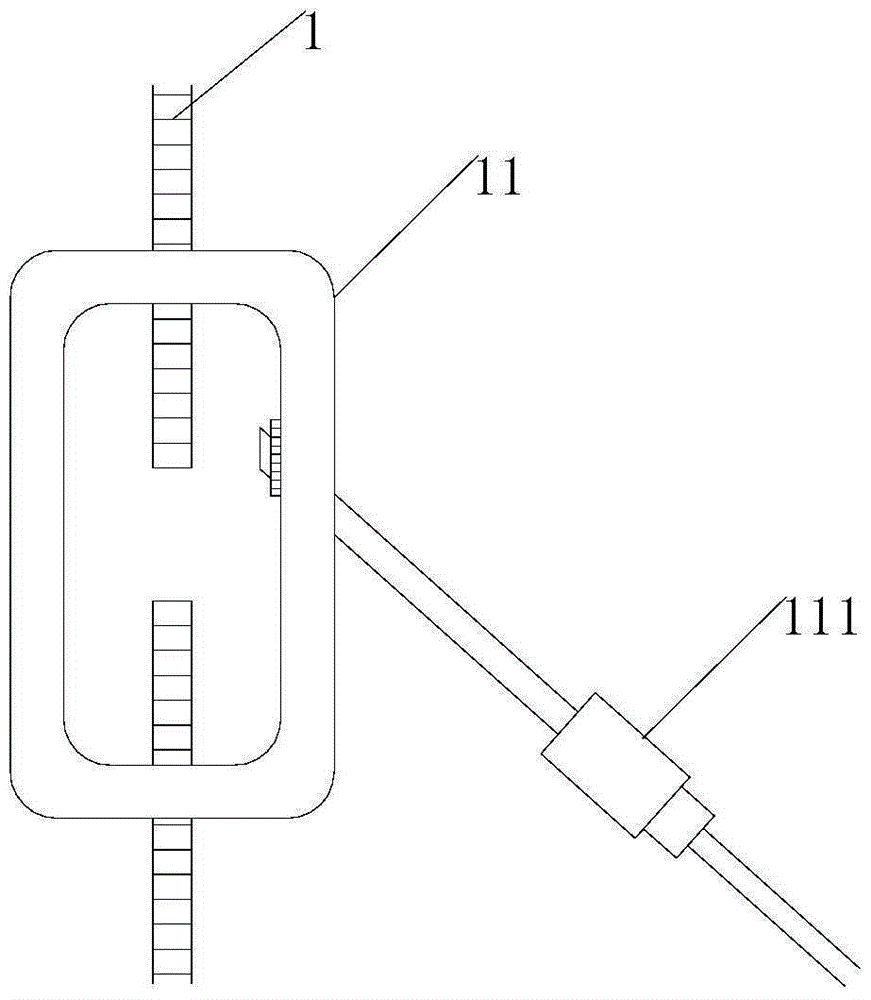

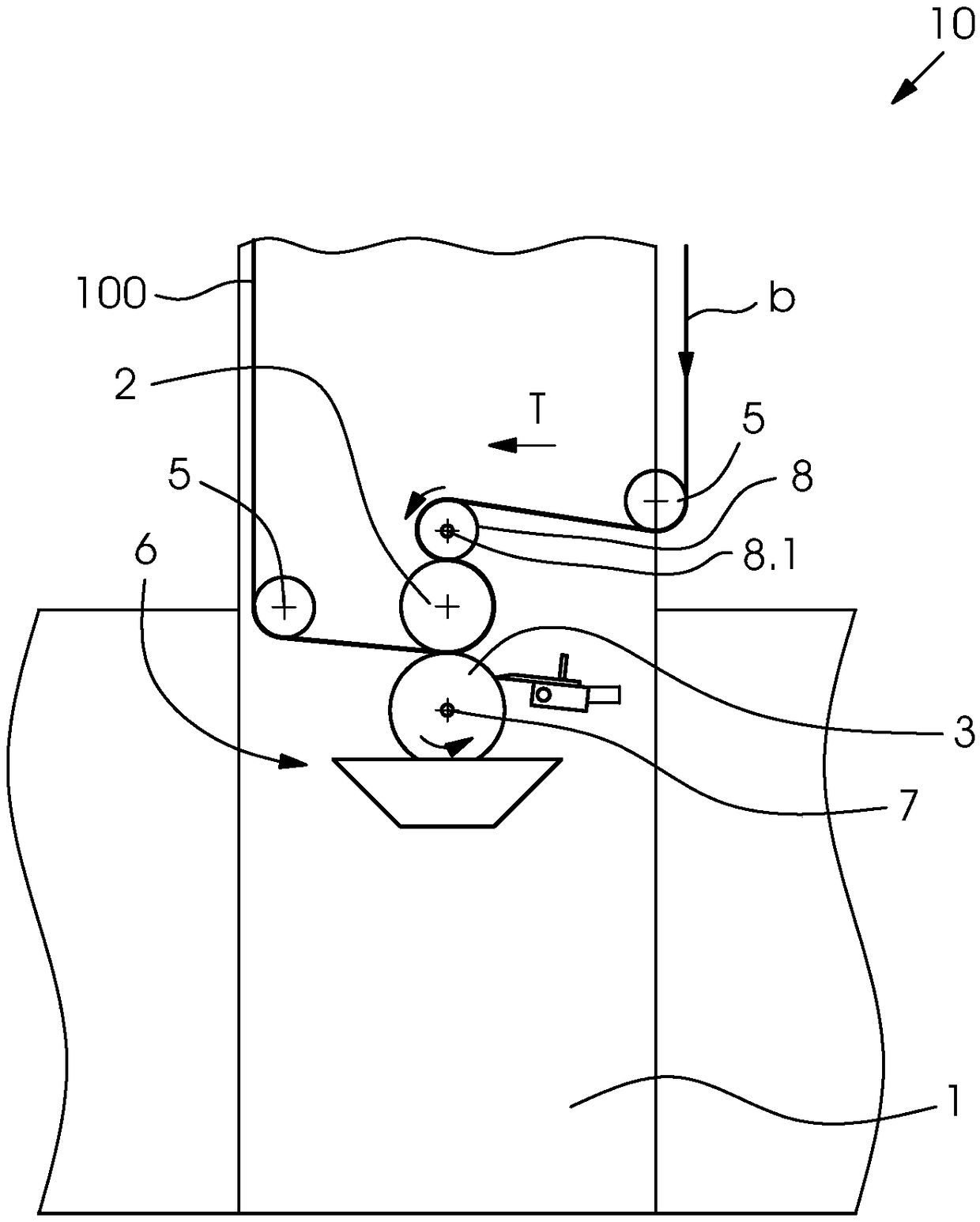

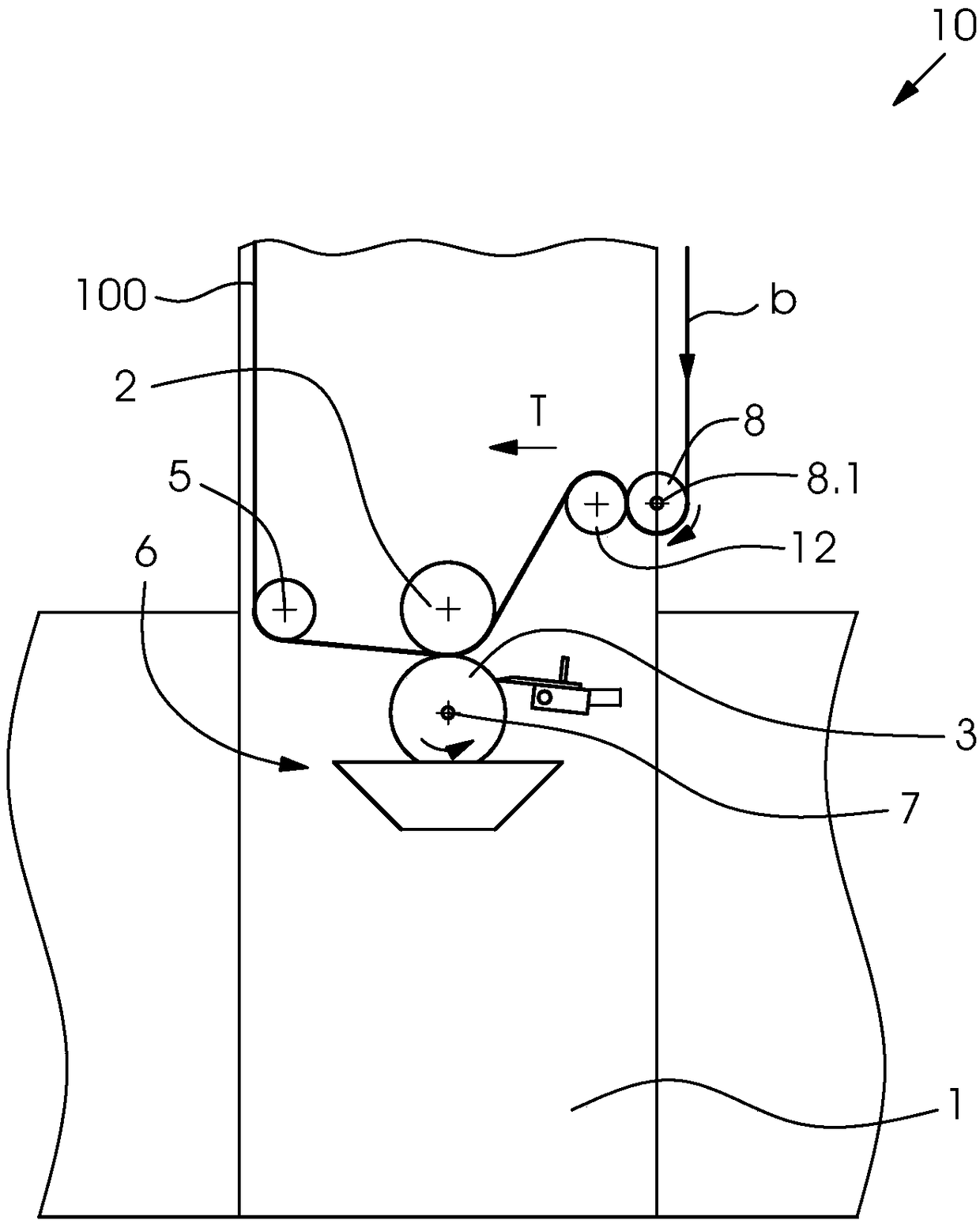

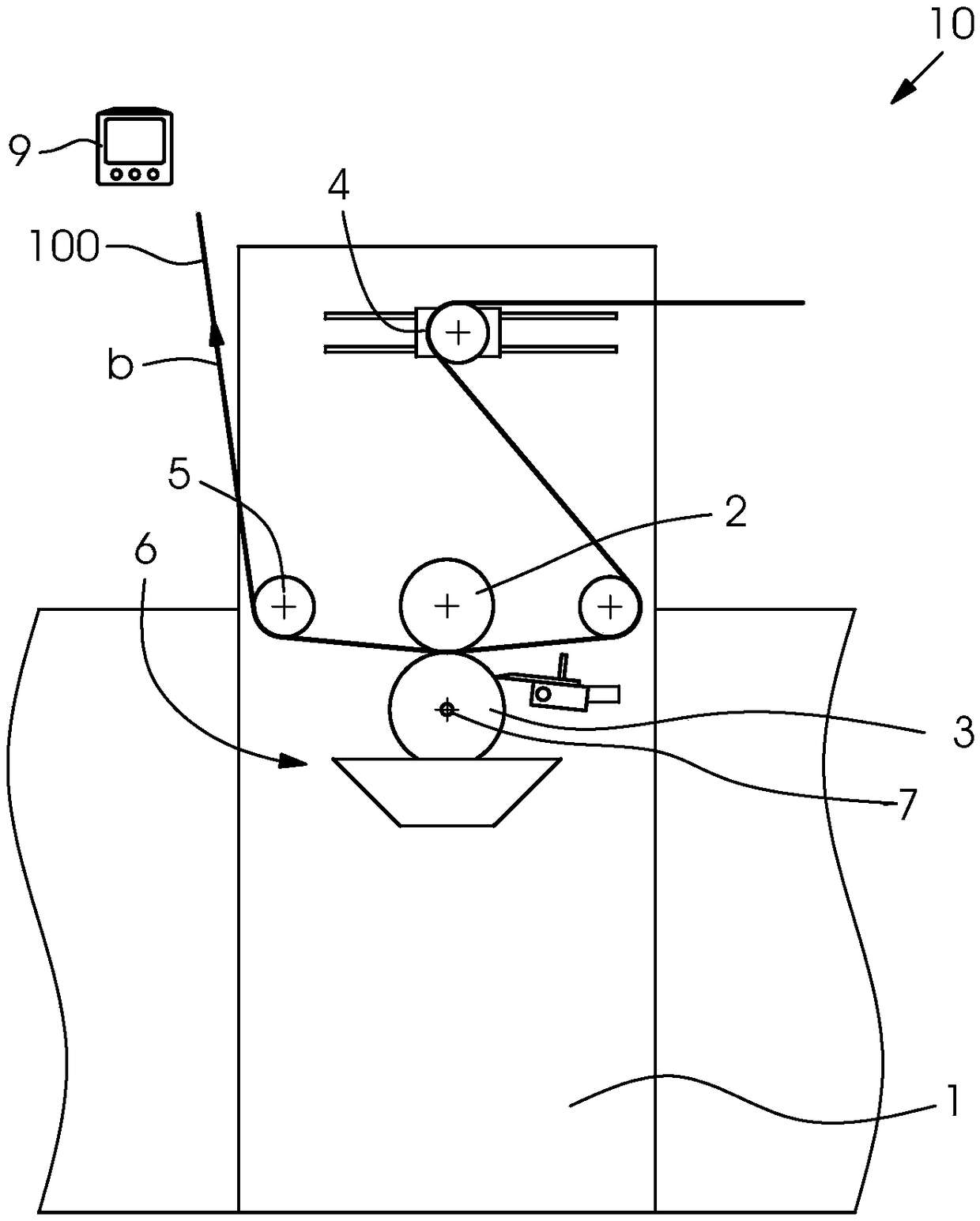

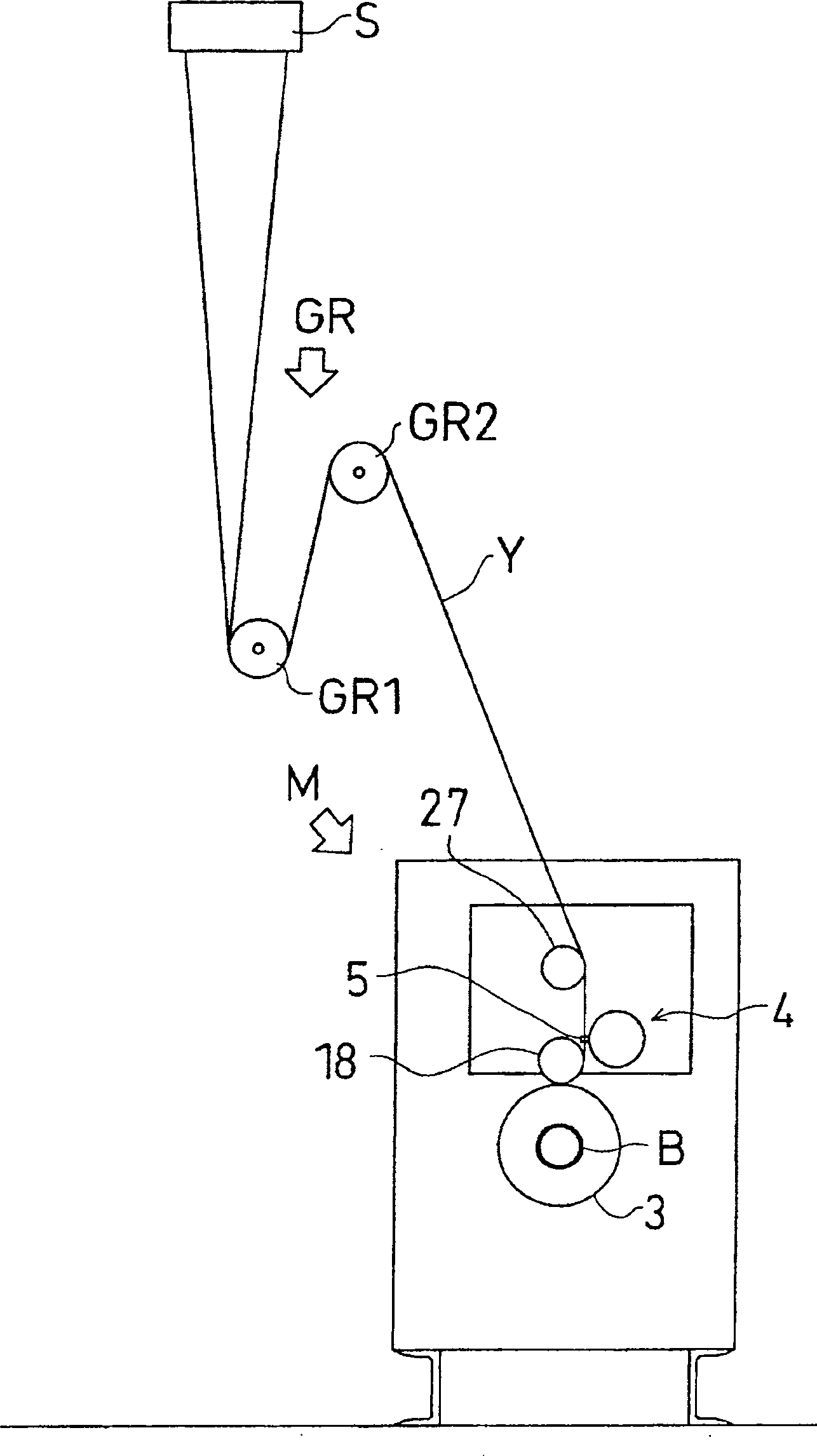

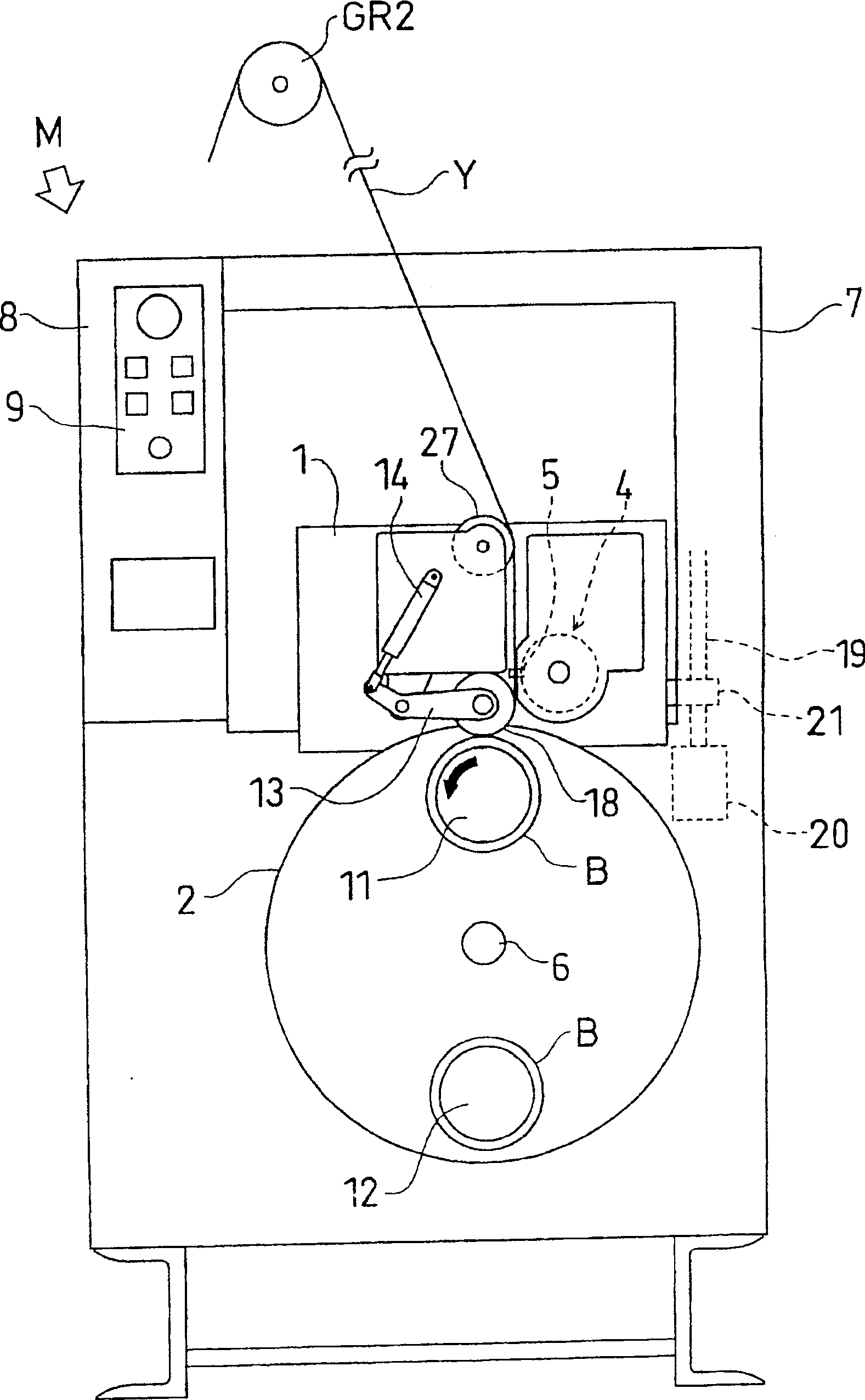

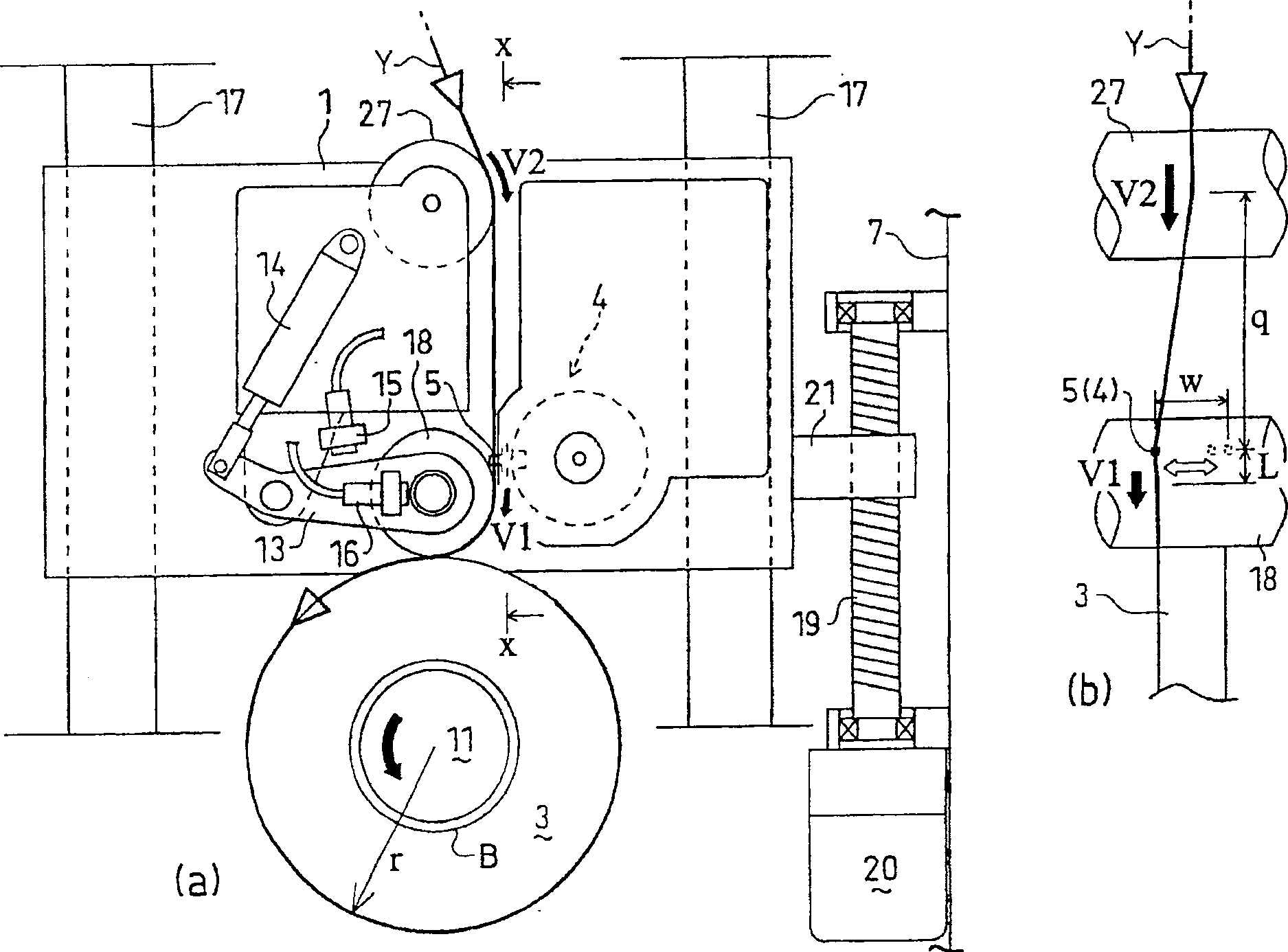

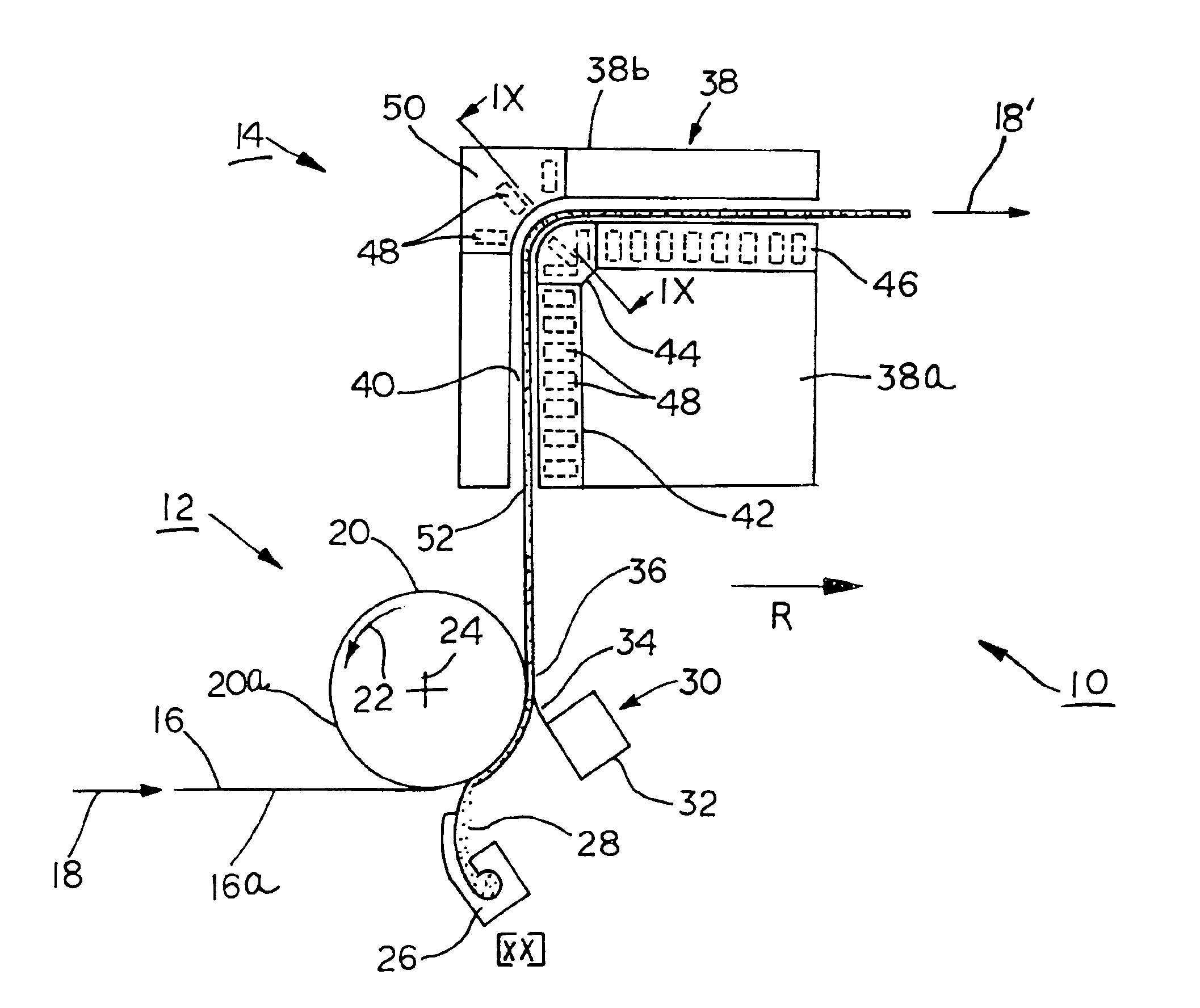

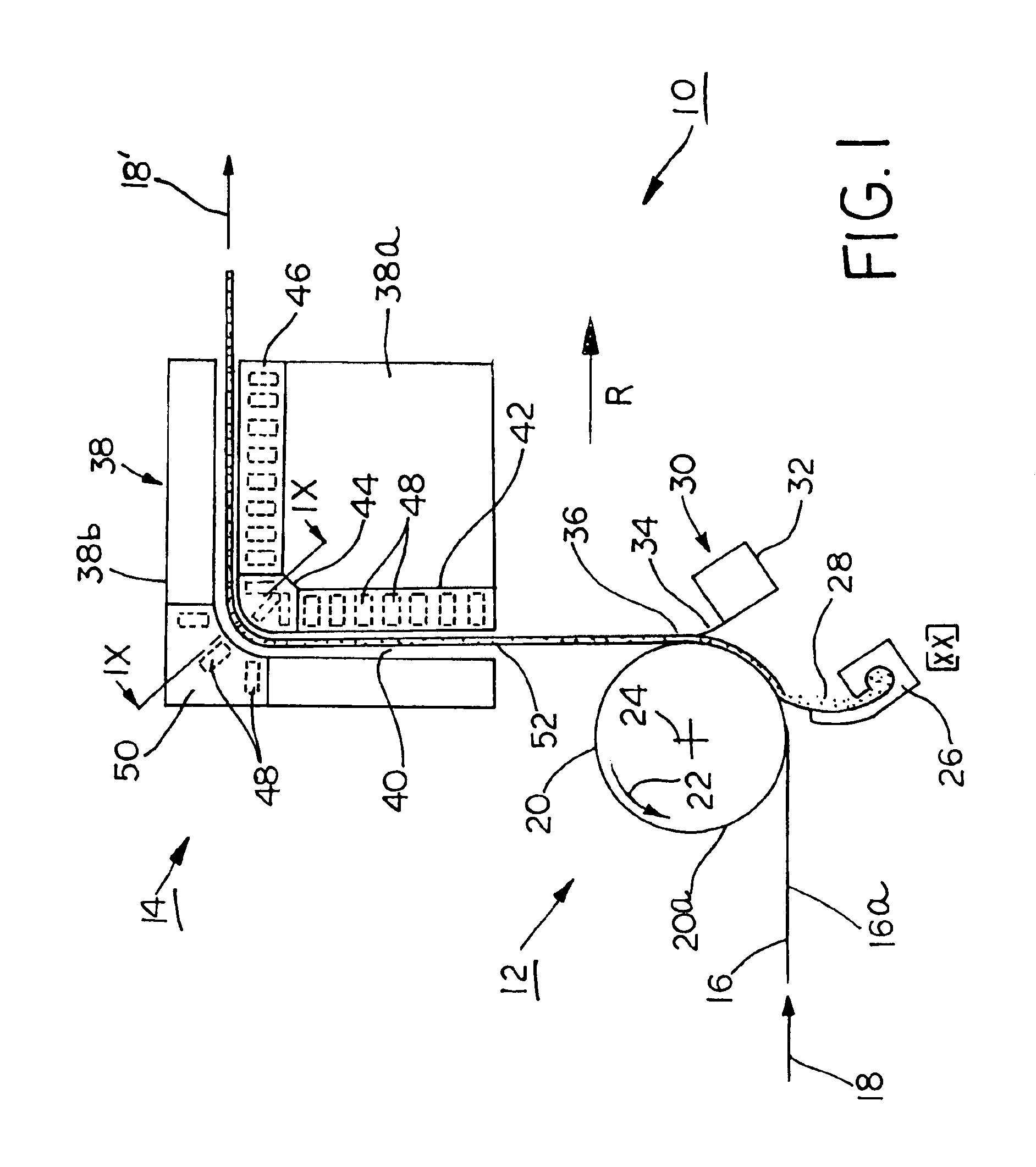

Yarn winding machine and yarn winding method

ActiveCN101804925AReduce the increase and decreaseCompact structureFilament handlingWinding machineYarn

The present invention provides a technique to prevent possible ribbon winding regardless of yarn type while inhibiting possible bulging. The winder 1 includes a contact roller 8 configured to come into contact with a package 4 during formation of the package 4, a traverse device 7 located upstream side of the contact roller 8 in the traveling direction of an elastic yarn 2, a free length varying means 9 for enabling the free length FL of the elastic yarn 2 located between the contact roller 8 and the traverse device 7 to be varied during formation of the package 4, and a control section 80 configured to control the free length varying means 9 in such a manner that the free length FL is increased during winding start of the package 4 and then reduced toward winding end.

Owner:TMT MACHINERY INC

Arrangement for cable guiding and a wind turbine using such arrangement

ActiveUS20110155420A1Reduce riskAvoid entanglementEngine fuctionsInsulated cablesTurbineAutomotive engineering

The present invention relates to an arrangement (1) for cable guiding, comprising a first guide member (40) adapted to enclose a first cable (10) along at least a part of the length of said first cable. The first guide member (40) has an outside surface adapted to form at least one first guide surface (41) supporting at least one second cable (20) along at least a part of the length of said first cable. The present invention further relates to a wind turbine comprising such an arrangement and to the use of such an arrangement.

Owner:VESTAS WIND SYST AS

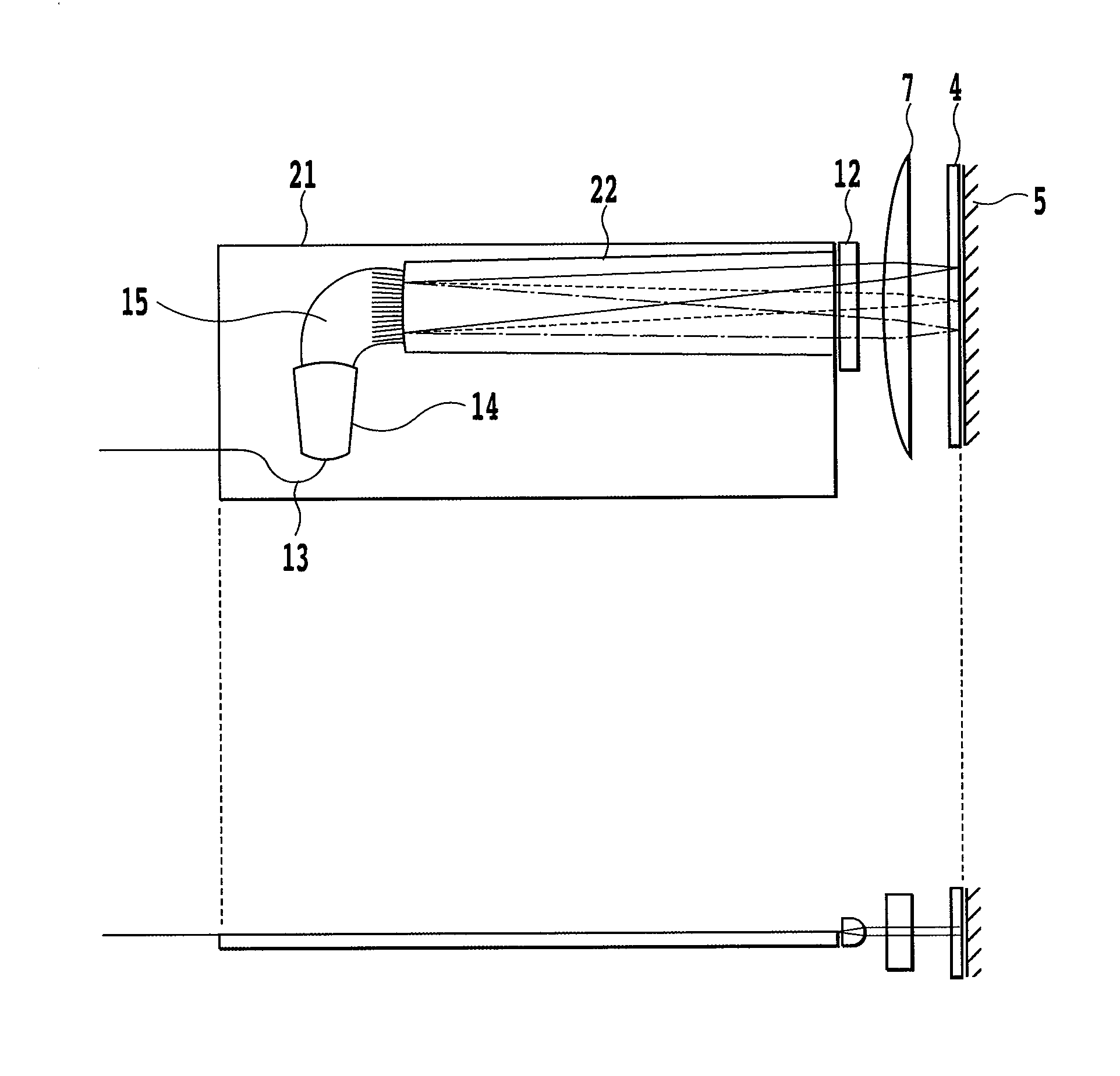

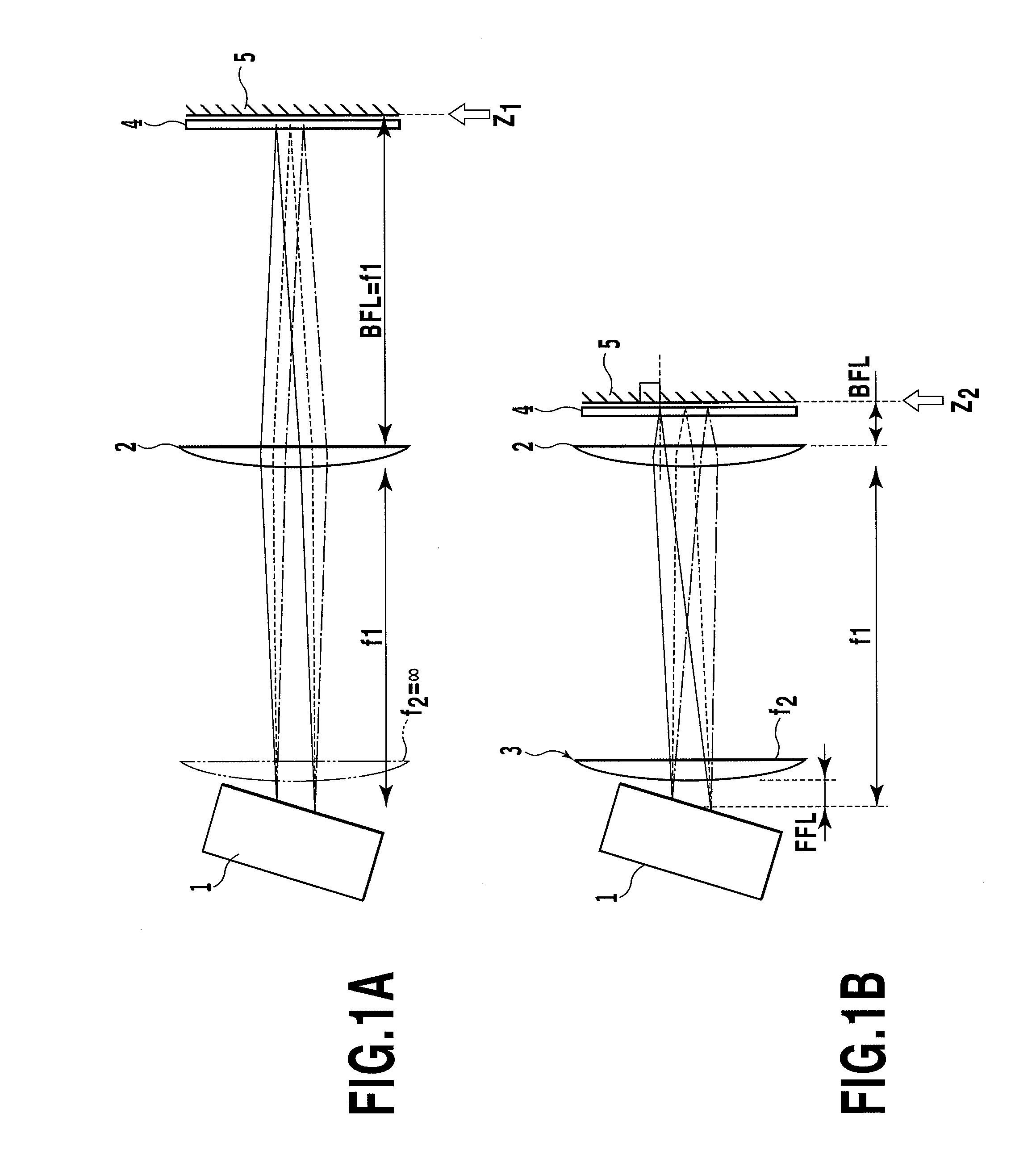

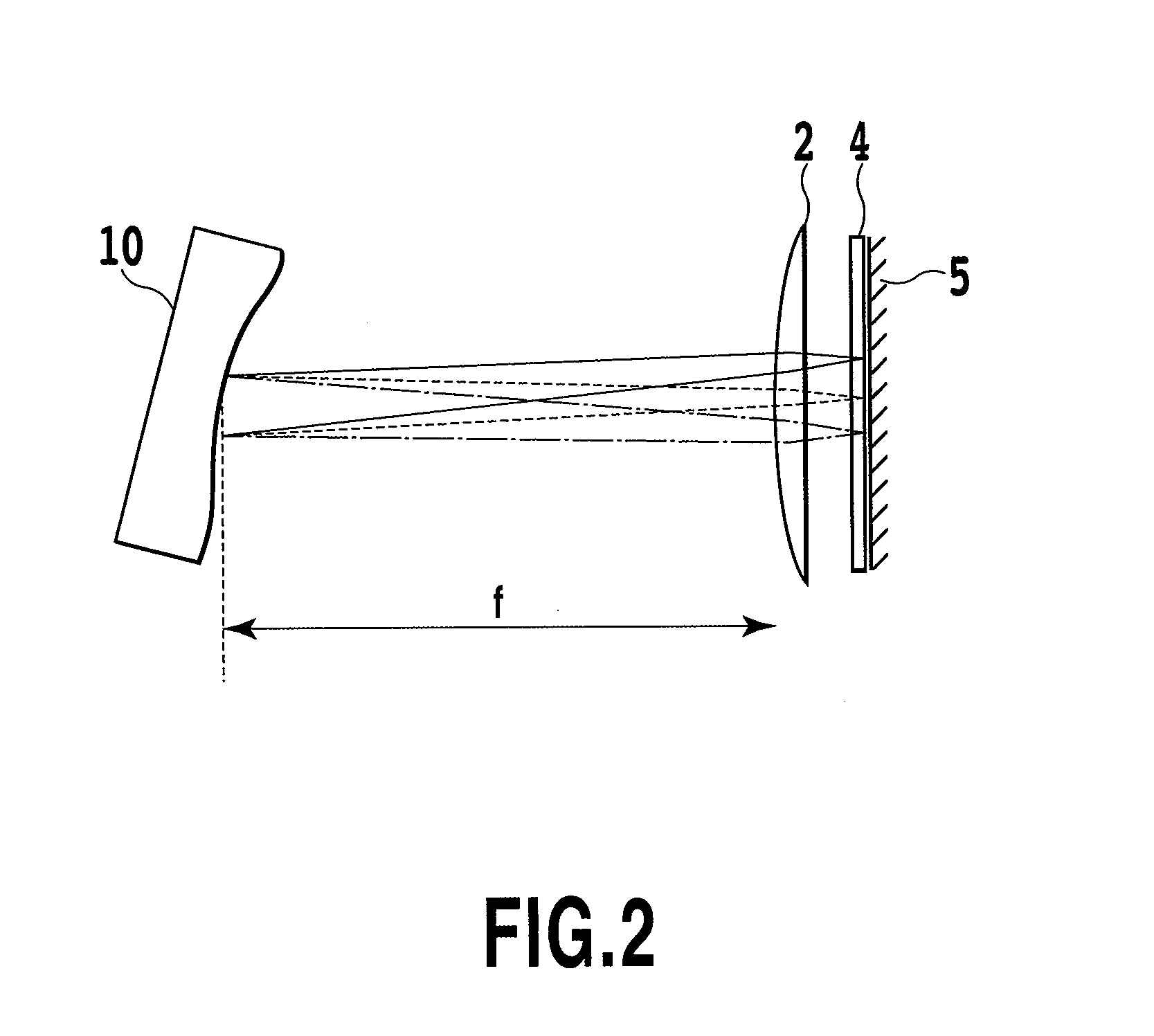

Optical signal processing device

ActiveUS20110228374A1Easily adjustShortens free space optical systemCoupling light guidesNon-linear opticsIntermediate pointPhysics

In a conventional optical signal processing device, a confocal optical system is configured in which a focusing lens is positioned at a substantially-intermediate point of a free space optical path. Thus, the free space optical system had a long length. It has been difficult to reduce the size of the entire device. The optical signal processing device of the present invention uses a lens layout configuration different from the confocal optical system to thereby significantly reduce the length of the system. The optical signal processing device consists of the first focusing lens positioned in the close vicinity of a signal processing device, and the second focusing lens positioned in the vicinity of a dispersing element. A distance between the dispersing element and the signal processing device is approximately a focal length of the first focusing lens. Compared with the conventional technique, the length of the optical path can be halved.

Owner:NIPPON TELEGRAPH & TELEPHONE CORP

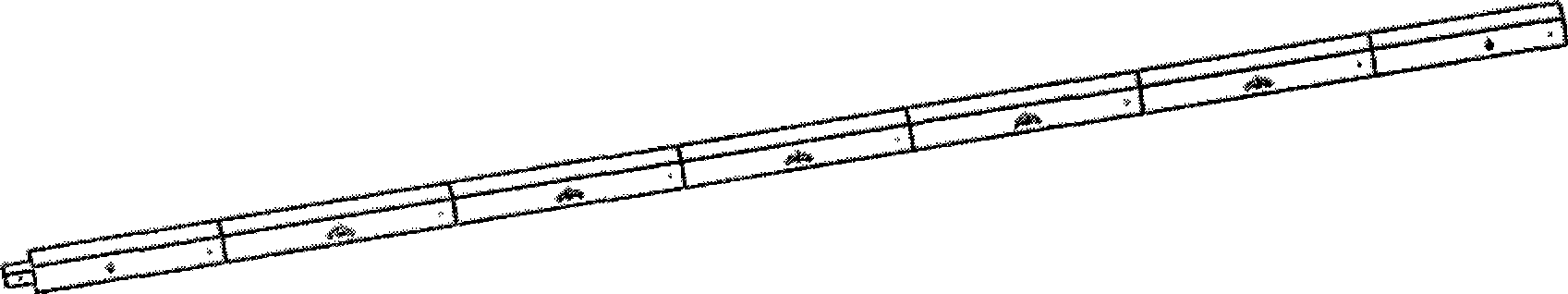

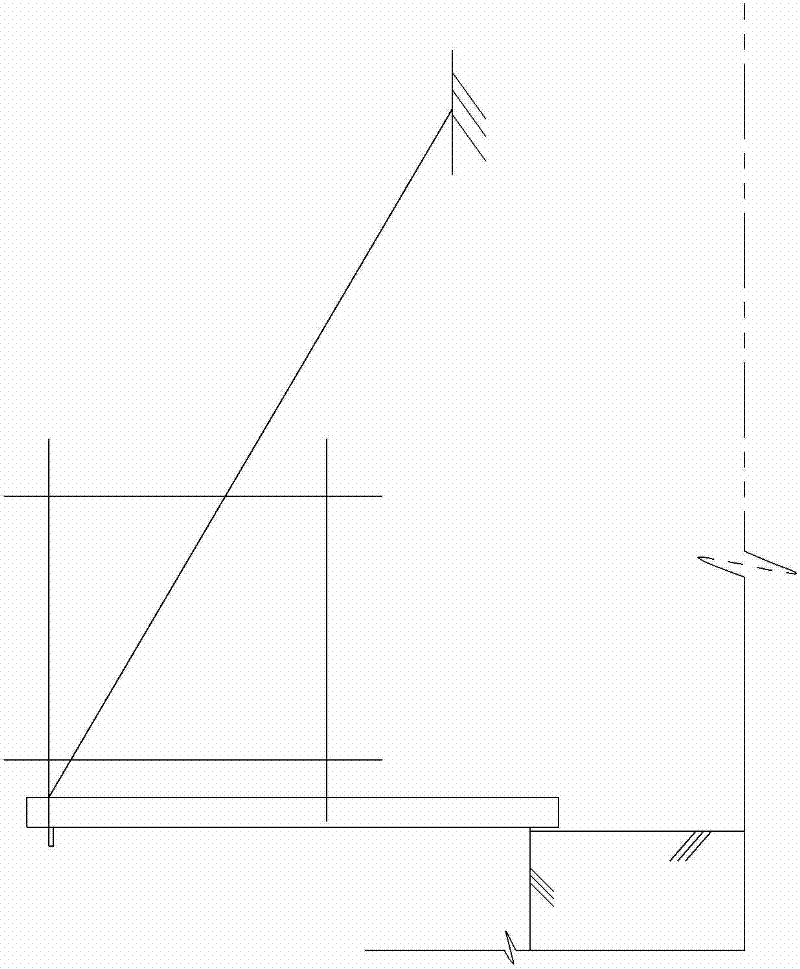

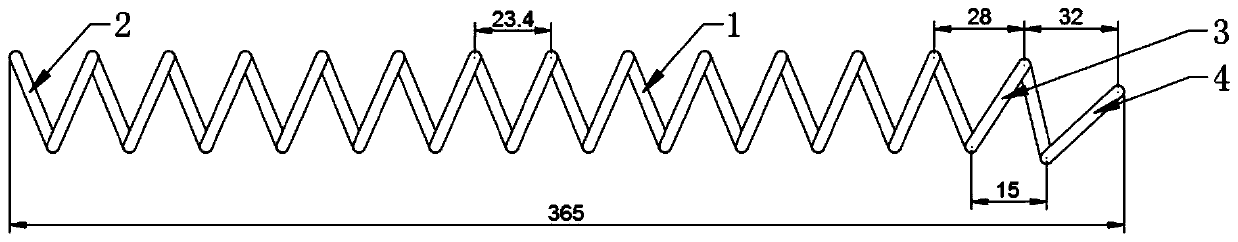

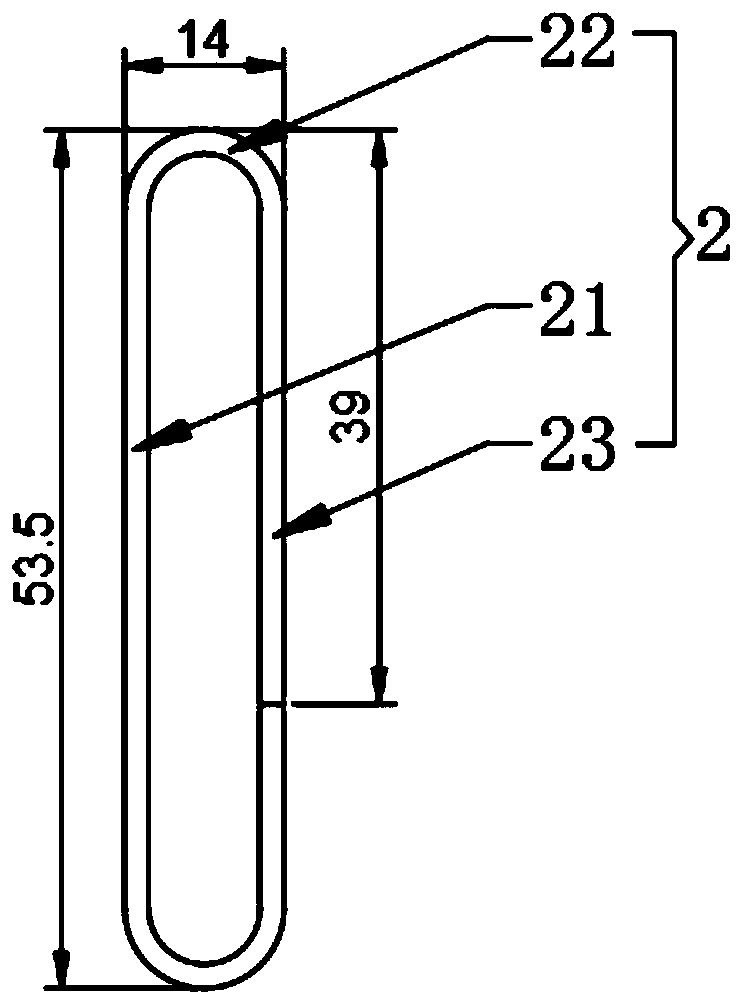

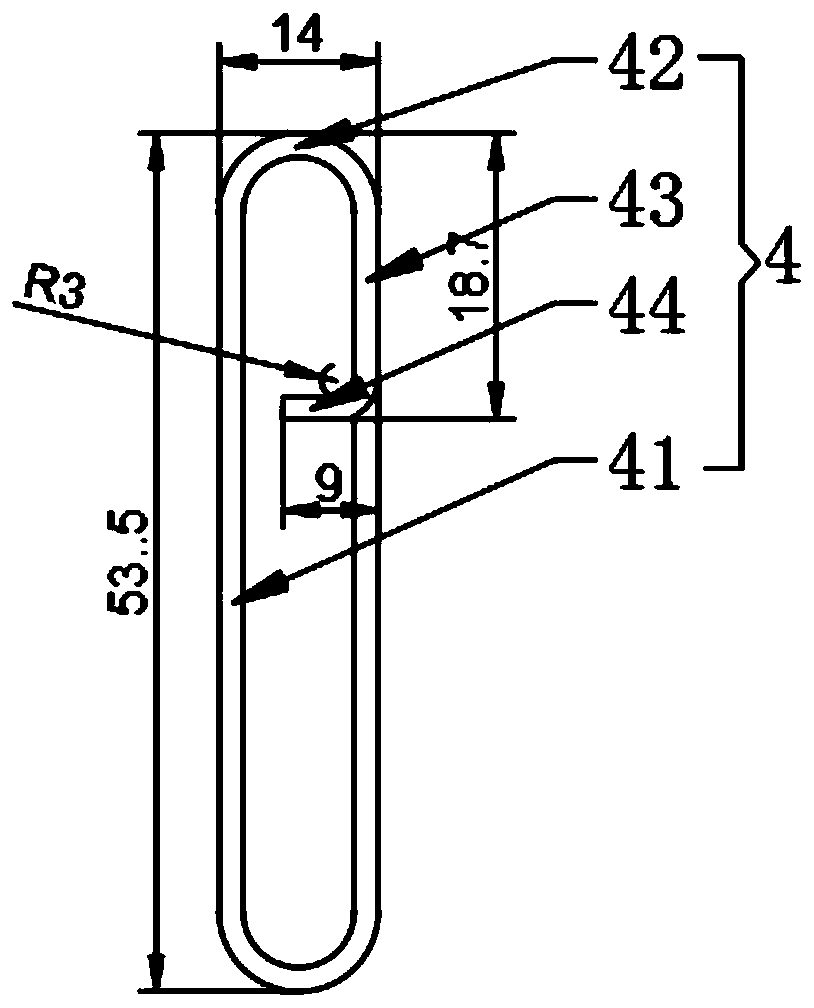

The bearing structure of the frame body at the male corner of the segmented scaffolding

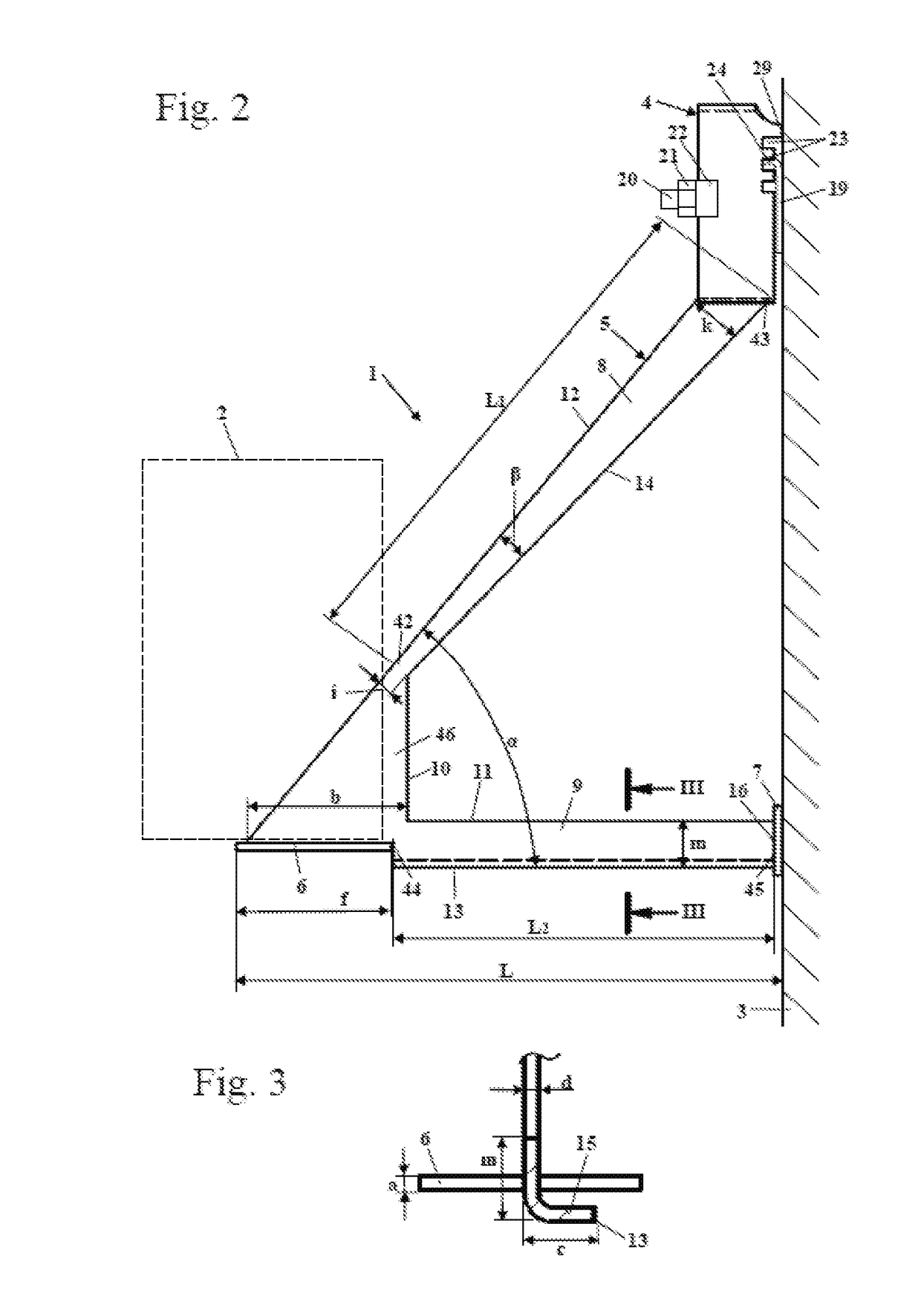

InactiveCN102296798AReduce free lengthReduce the absolute value of the bending momentScaffold accessoriesBuilding support scaffoldsBeam angleEngineering

The invention discloses a frame body load-bearing structure at the male corner part of a scaffold erected in sections with a simply supported structure, which overcomes the defects of stress concentration and uneven appearance of the existing cantilever beam structure, is economical and reasonable, and can ensure The construction is safe, and the appearance of the scaffolding is beautiful and uniform. The frame load-bearing structure includes 3 steel beams and 6 cable-stayed wire ropes. The 3 shaped steel beams include: main beam (1), left sub-beam (2), right sub-beam (3); 6 cable-stayed steel wire ropes (4) are respectively arranged at the outer ends of the 3 shaped steel beams, that is, each shaped steel The beam is equipped with two cable-stayed steel wire ropes, one of which is used as a stress rope and the other as a safety protection rope. The main girder is arranged along the bisector of the sun angle, and the left sub-beam and the right sub-beam are respectively arranged on both sides of the main girder, and the included angle with the main girder is 45 degrees, and the intersection of the three is welded into a whole. The length of the left and right sub-beams of the shaped steel beams is the same, and the direction is horizontal. The length of the shaped steel beams other than the corners of the external corners is the same as that of the sub-beams, as long as they are arranged in parallel according to the calculated longitudinal distance of the scaffolding poles. , easy to operate and beautiful in appearance.

Owner:CHINA CONSTR FIFTH ENG DIV CORP LTD

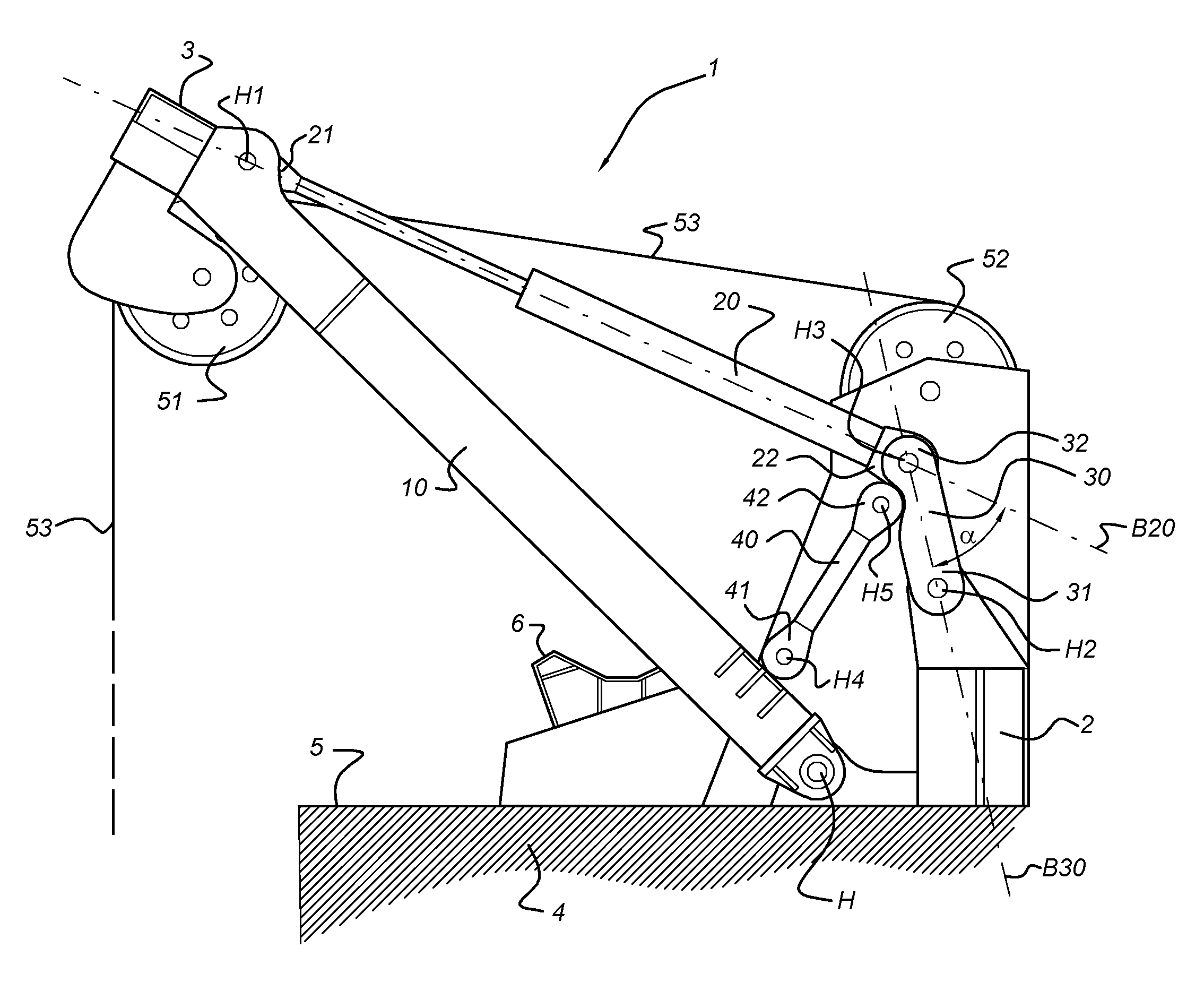

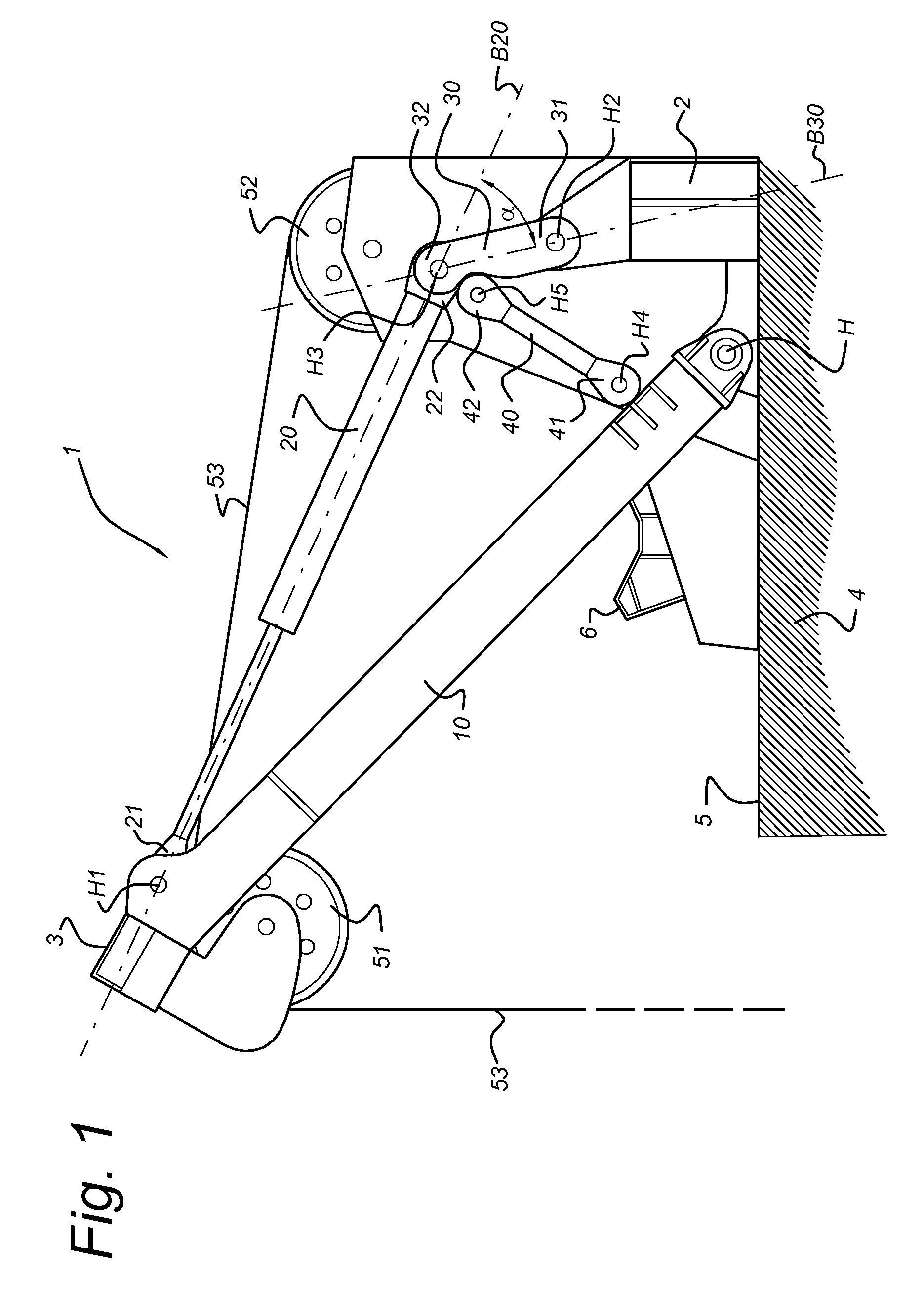

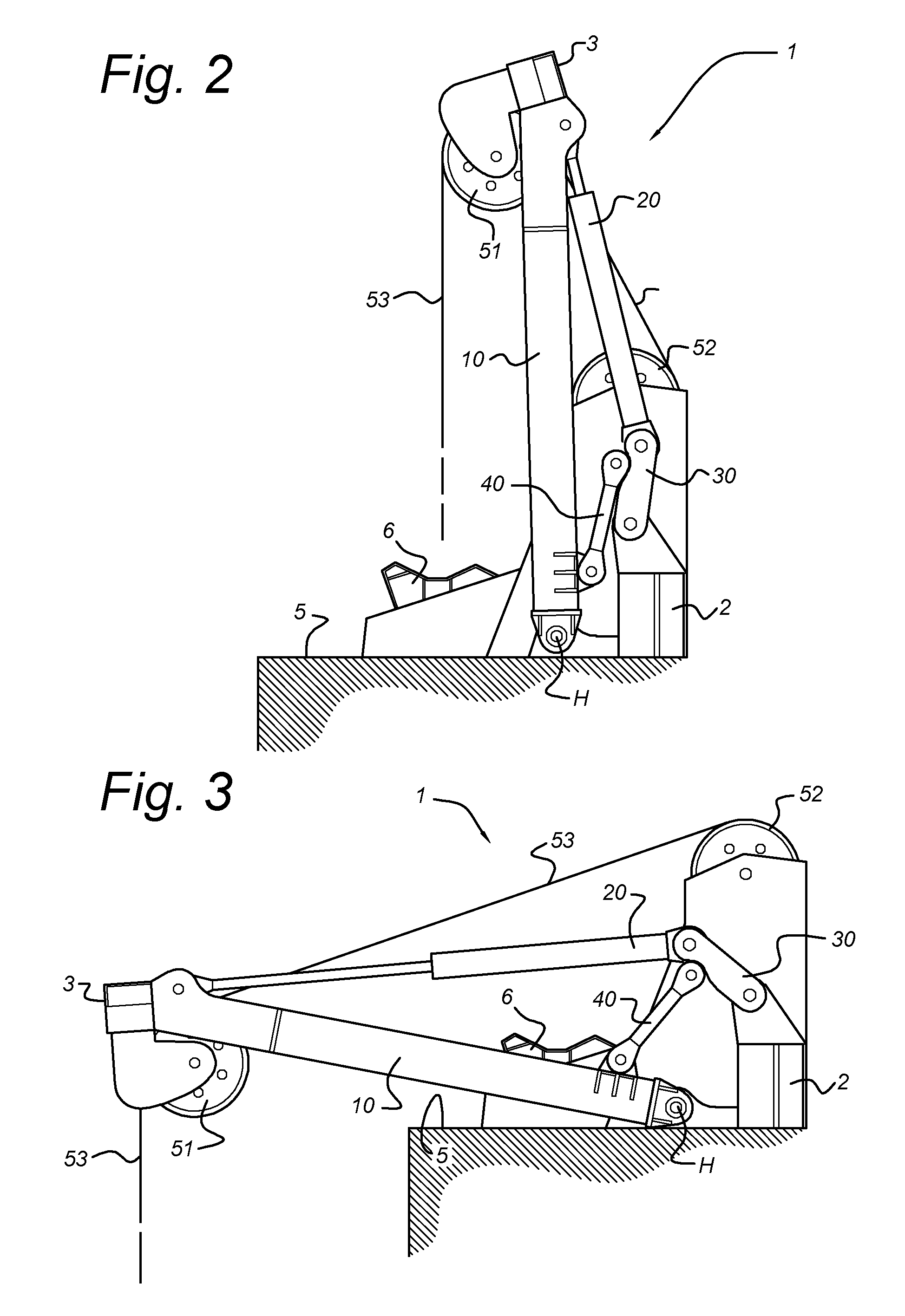

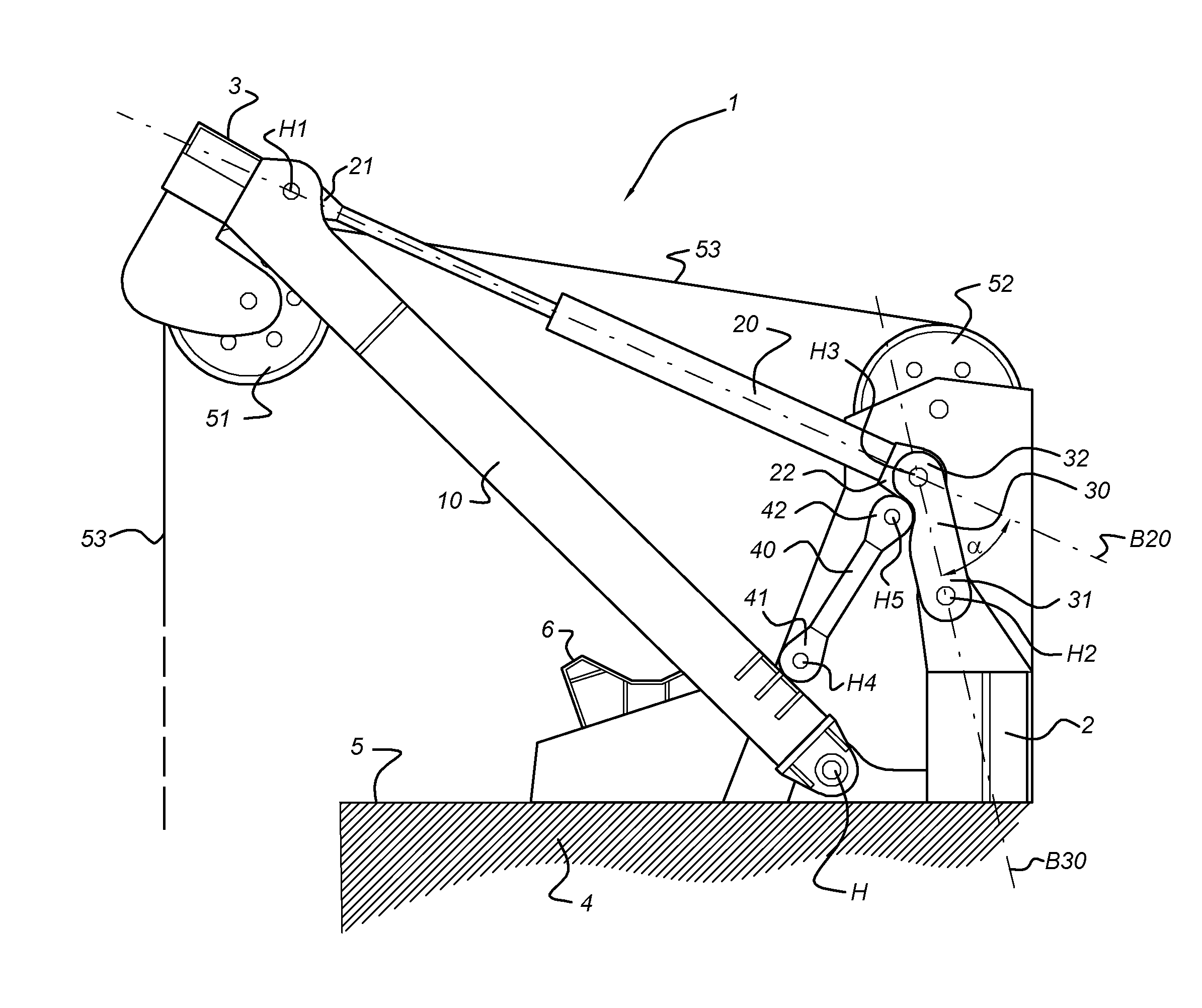

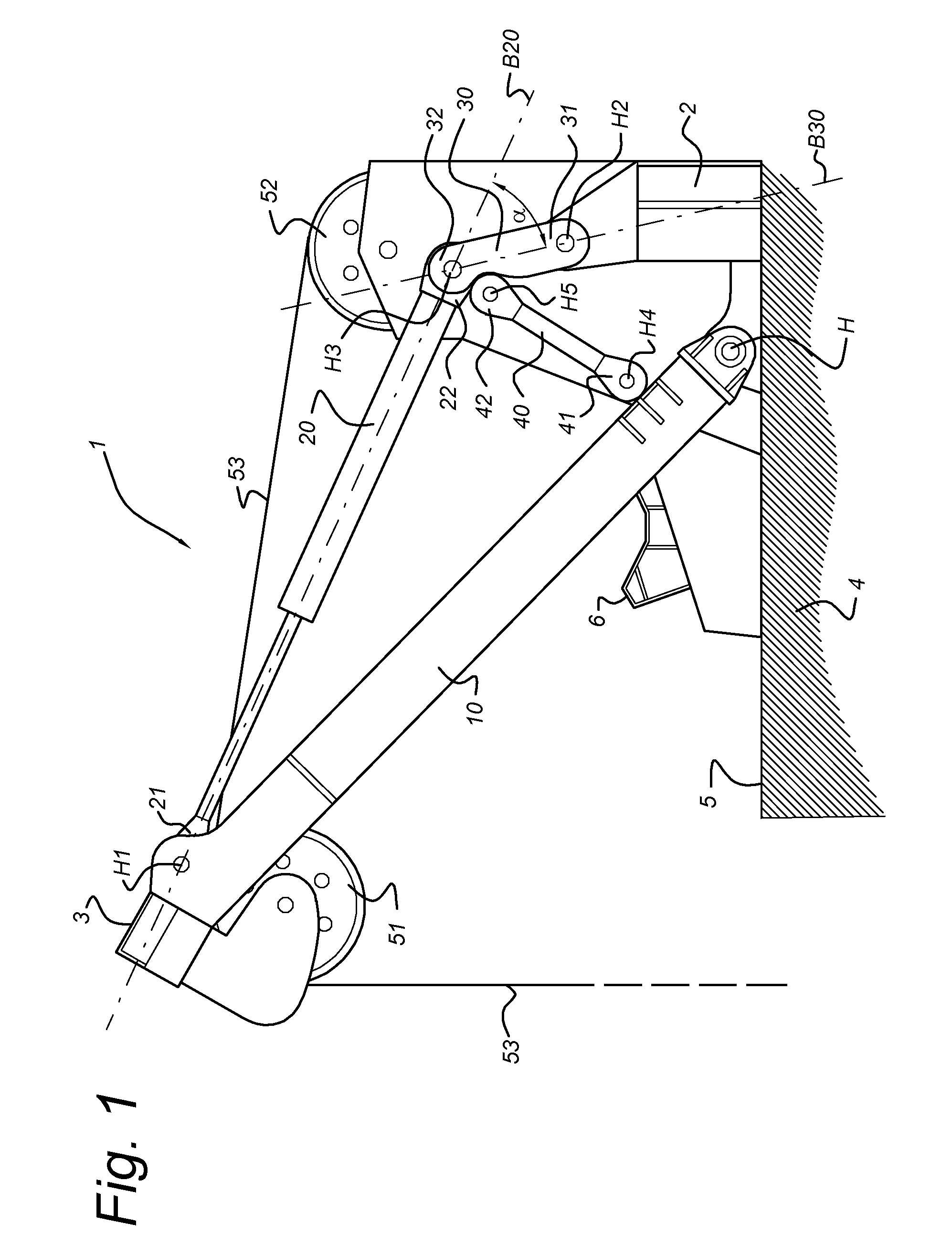

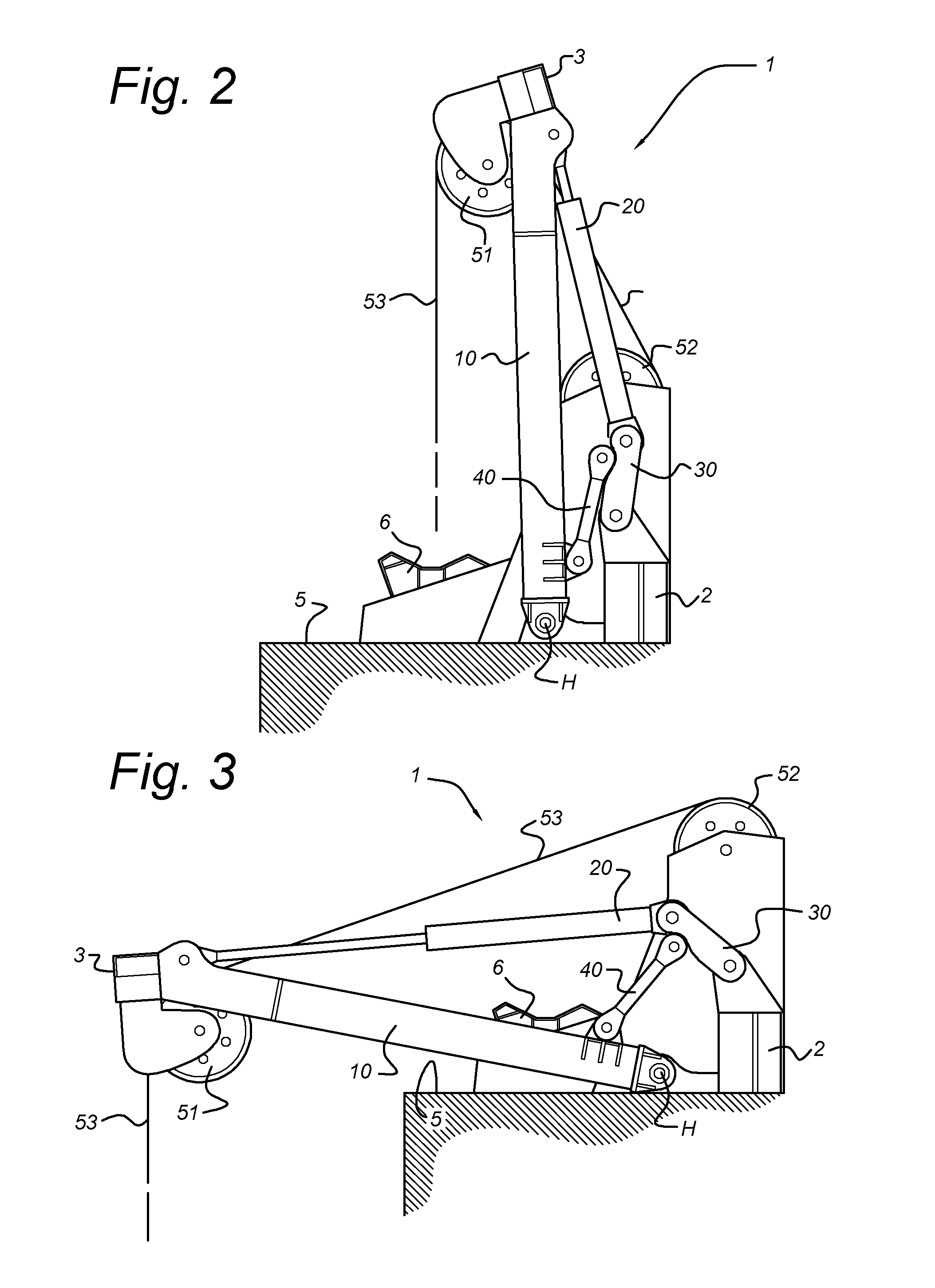

Vessel comprising a crane

ActiveUS9290241B2Increased freedom of movementLow positionCargo handling apparatusMechanical machines/dredgersEngineering

A vessel (4) includes a crane (1) connected to a deck (5) of the vessel. The crane (1) includesa frame (10) which is rotatable about a horizontal hinge axis (H),a rotation mechanism (20) connected to the frame (10) at a position away from the horizontal hinge axis (H), arranged to rotate the frame (10) about the horizontal hinge axis (H) from an upper position to a lower position and vice versa, anda swivel member (30), which is with a first end (31) rotatable connected to the deck (5) and which is with a second end (32) rotatable connected to the rotation mechanism (20). The swivel member (30) is rotatable between an inward position associated with the upper position of the frame (10) to an outward position associated with the lower position of the frame (10).

Owner:IHC HOLLAND NV

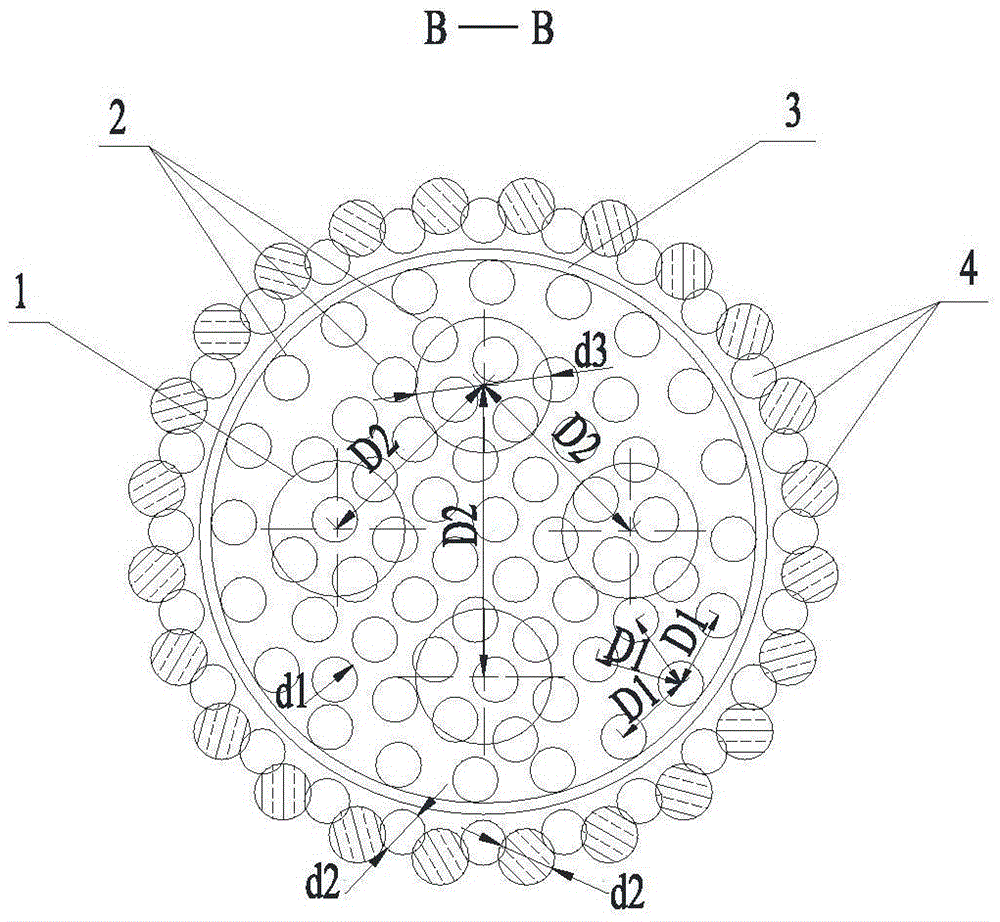

Combined foundation structure suitable for lagoon face island-reef environment and construction method thereof

ActiveCN105544597AEffective reinforcementImprove bearing capacityCaissonsBulkheads/pilesHigh pressureLarge deformation

The invention discloses a combined foundation structure suitable for a lagoon face island-reef environment and a construction method thereof, and relates to the field of geotechnical designs and island-reef development. The combined foundation structure suitable for the lagoon face island-reef environment and the construction method thereof are suitable for coral lagoon geological conditions. The combined foundation structure suitable for the lagoon face island-reef environment comprises high-pressure jet grouting stabilization piles, a prefabricated caisson, lateral restraining high-pressure jet grouting piles, prefabricated bored sinking pipe piles and a prefabricated bearing platform, wherein the prefabricated caisson is located on the high-pressure jet grouting stabilization piles and in a curtain structure formed by the lateral restraining high-pressure jet grouting piles and is in rigid connection with the prefabricated bearing platform into a whole for collaborative bearing through the prefabricated bored sinking pipe piles. The combined foundation structure suitable for the lagoon face island-reef environment and the construction method thereof not only overcome the disadvantageous engineering characteristics of a coral lagoon foundation structure such as high structural performance, low bearing capacity and large deformation, but also bring the bearing capacity of each layer of rock and earth mass of the coral lagoon foundation structure into full play, have the characteristics of large rigidity, high bearing capacity and fast, excellent and economical construction and the like, have the advantage of adapting to construction in island areas, have broad application prospects, and make it possible to build an airport and other overhead reclamation engineering on a coral lagoon foundation.

Owner:CHINA RAILWAY MAJOR BRIDGE ENG GRP CO LTD

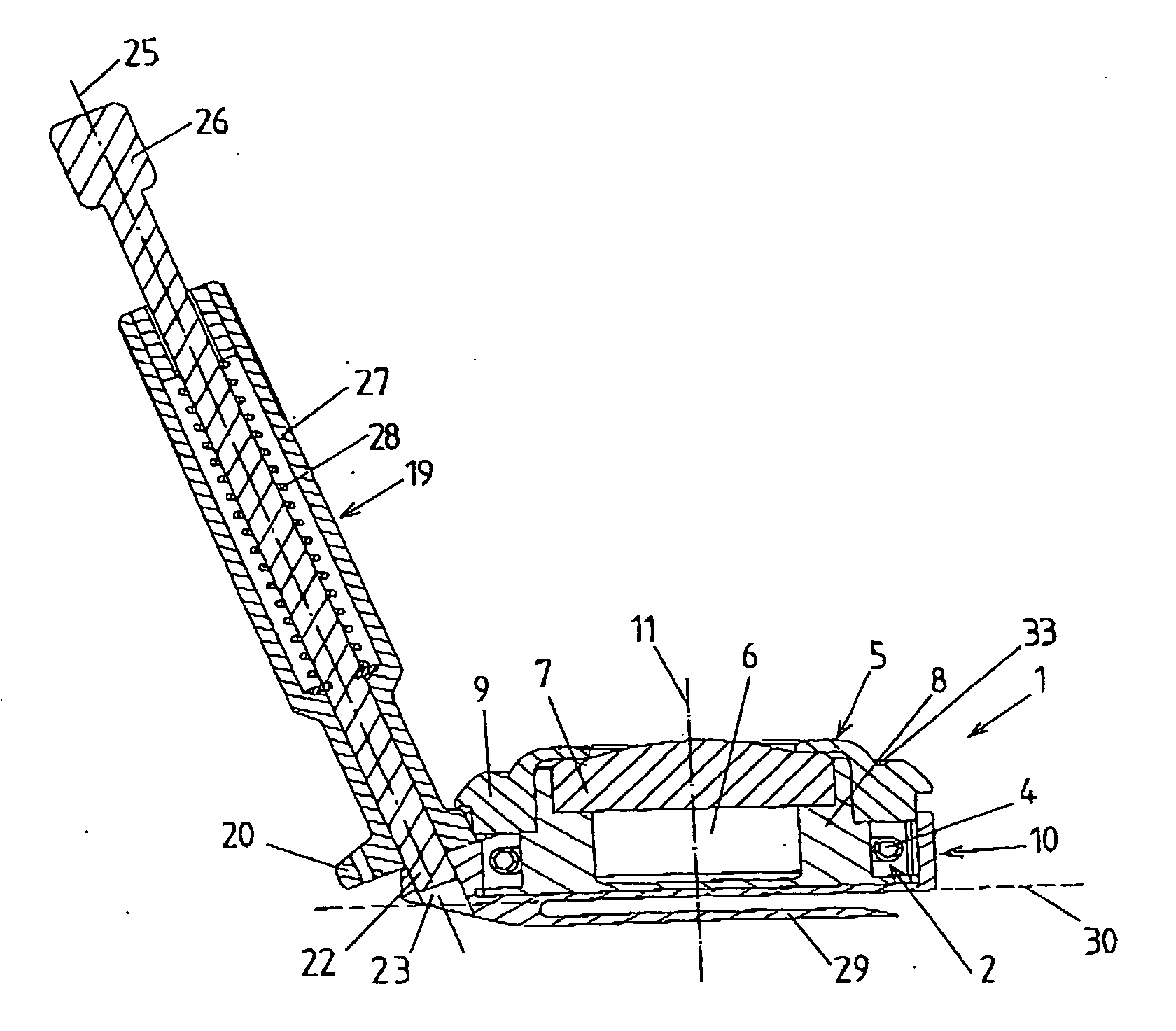

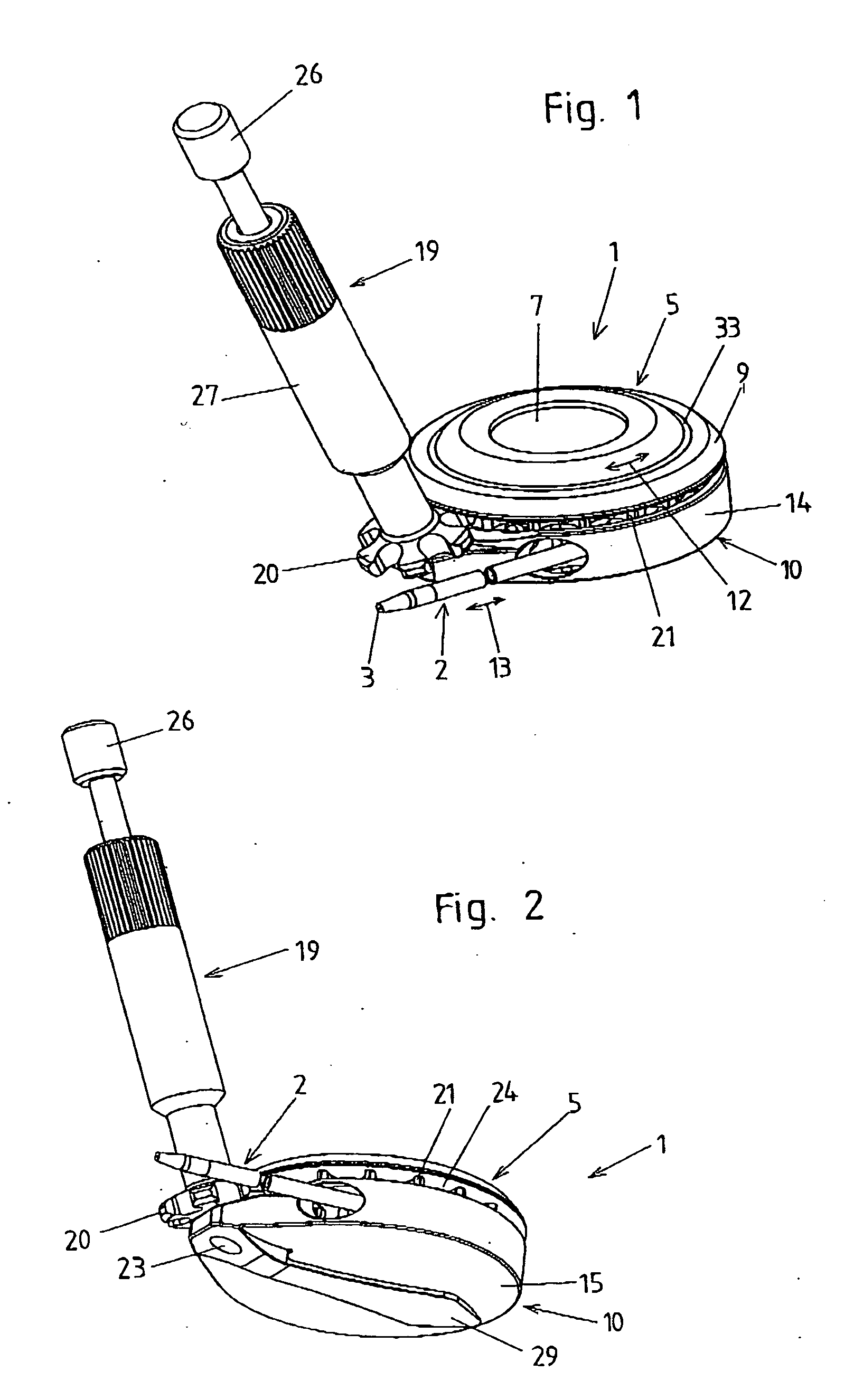

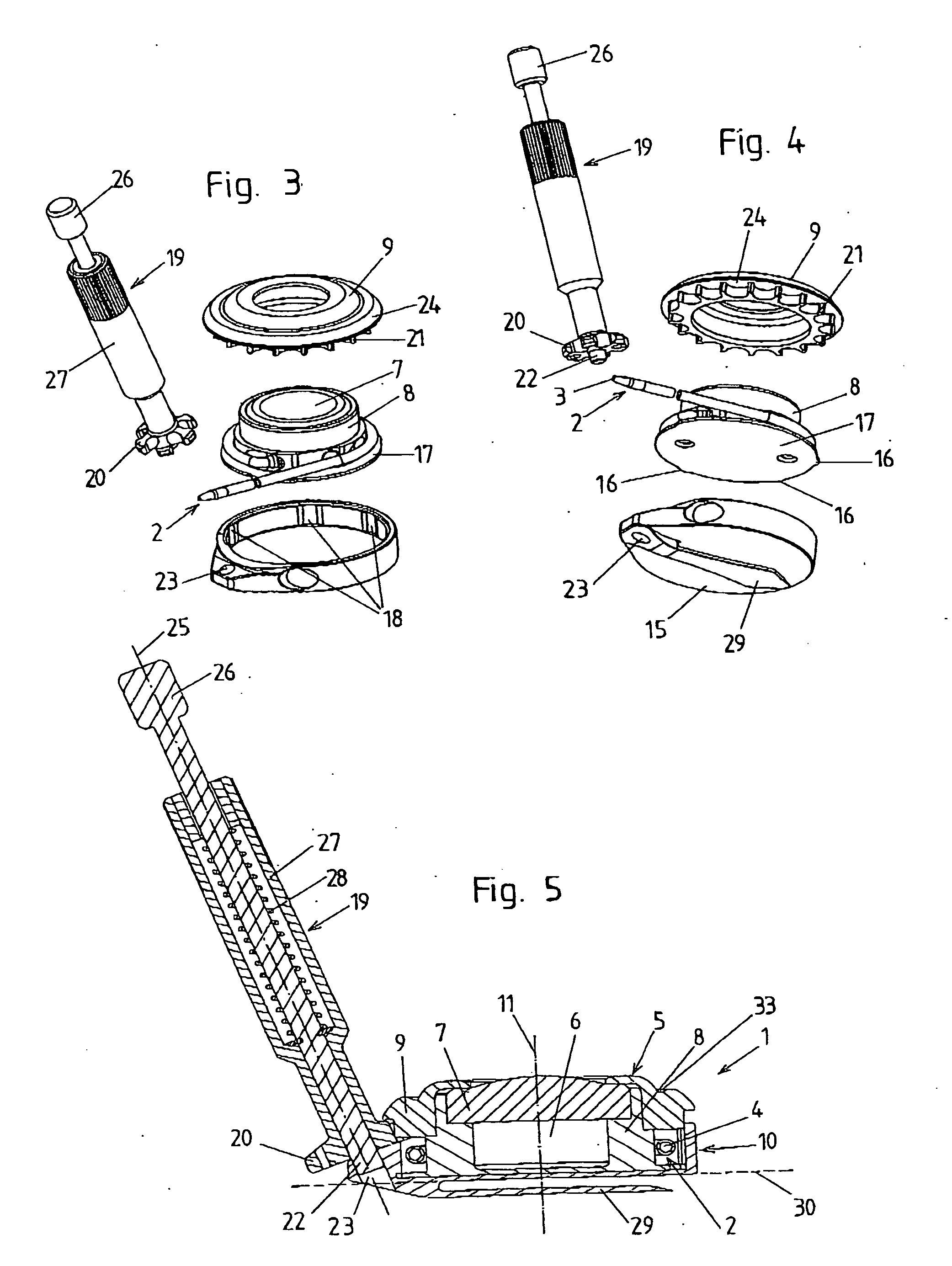

Method for adjusting the vibration frequency range of a sound producing device with vibrating tongues

ActiveUS20140366705A1Easy to adjustEasy to createElectrophonic musical instrumentsAcoustic indicationBiomedical engineering

The invention concerns a method for adjusting the vibration frequency range of a sound producing device with vibrating tongues. The device includes an assembly formed of a comb extended by at least one vibrating tongue, said comb having at least one hole for the securing thereof to a support by means of a support jaw and of a tightening element traversing the support jaw and the hole in the aforecited comb. According to the method, the frequency range is adjusted by reducing the free length of the vibrating tongue or tongues by the localised clamping of said tongues between the support jaw and a local counter-support.

Owner:MONTRES BREGUET

Portkatheter

InactiveUS7678088B2Requirement to contact the port unit itself is decreased or avoidedReduce free lengthMedical devicesCatheterAnimal body

A port catheter for introducing a fluid into a hollow organ of a human or animal body includes a port unit implantable into the human or animal body, which port unit includes an interior chamber, to which the fluid to be introduced into the hollow organ of the human or animal body can be supplied. The port catheter further includes a tube connected to the port unit, which tube includes an inner channel through which fluid can be conducted into the hollow organ. The port catheter further includes a grip piece connected to the port unit and removable from it, for the manipulation of the port unit during the implantation of the port catheter into the human or animal body.

Owner:A M I AGENCY FOR MEDICAL INNOVATIONS GMBH

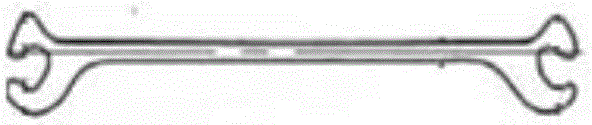

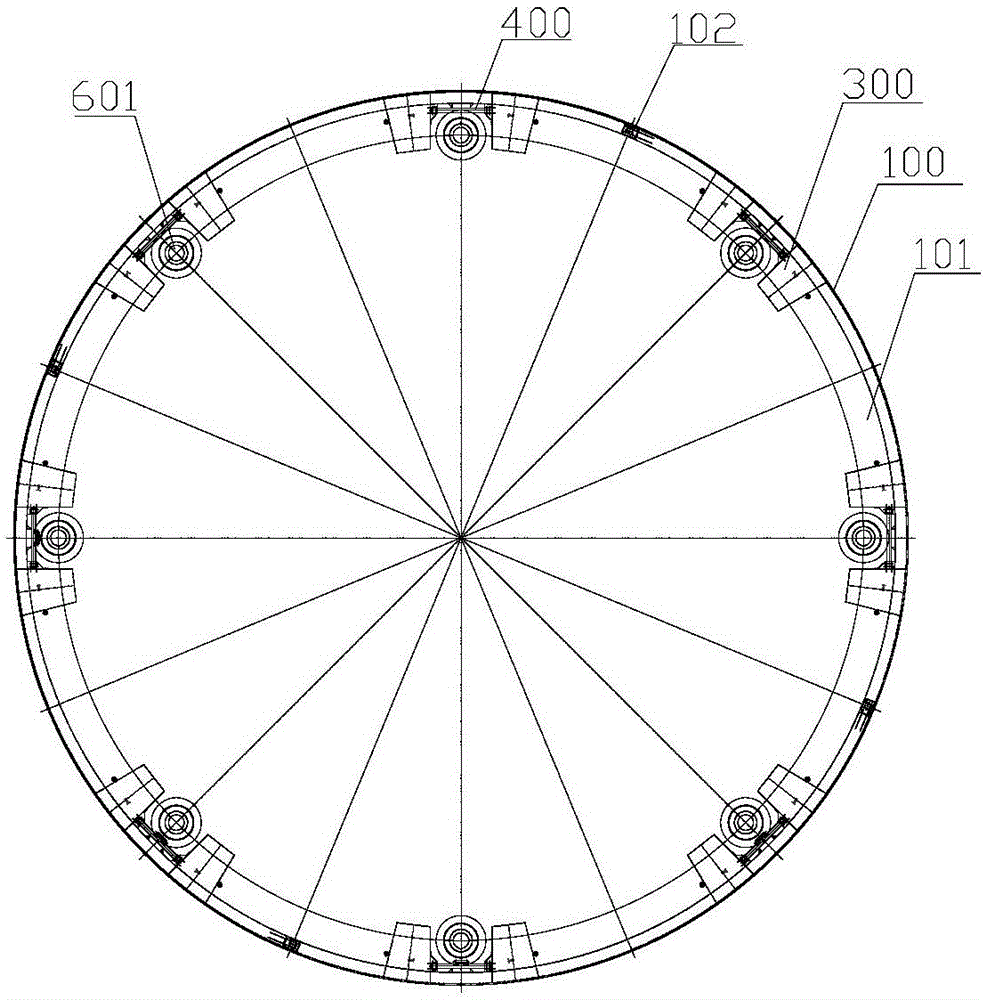

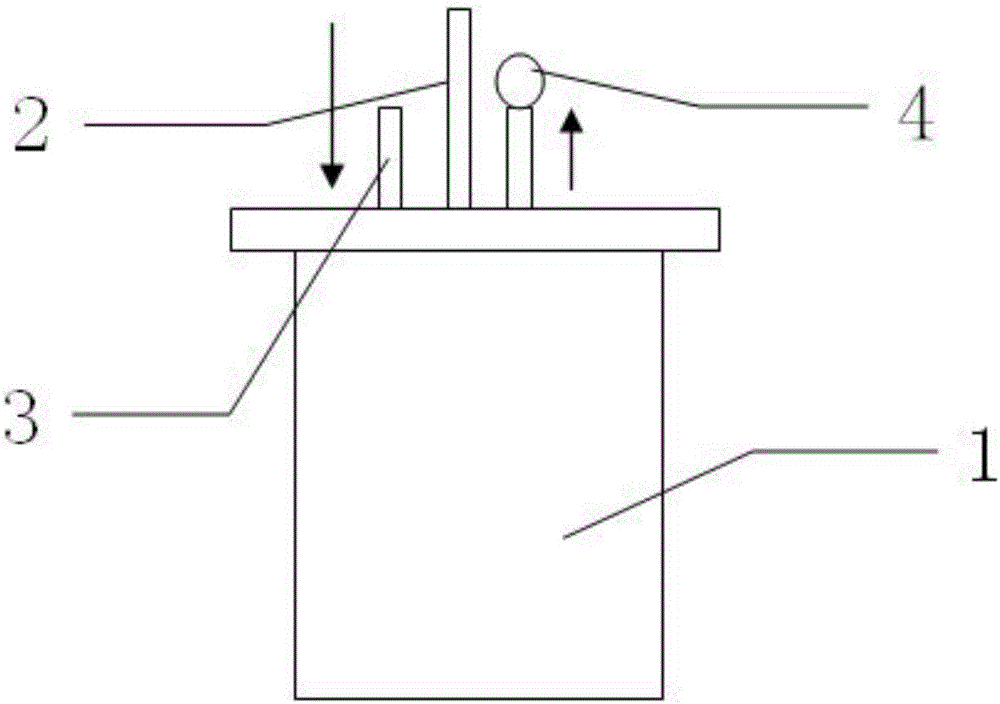

Vibration sinking construction underwater guiding device and construction technology of grid plate pile large cylinder

The invention discloses a vibration sinking construction underwater guiding device and a construction technology of a grid plate pile large cylinder. The underwater guiding device comprises a steel ring beam, a guiding unit, a steel floating box, a limiting device and a lifting device. The outer diameter of the steel ring beam corresponds to the inner diameter of the grid plate pile large cylinder. The guiding unit is arranged on the steel ring beam and is in contact with the inner side of the grid plate pile large cylinder for guiding; the steel floating box is arranged on the steel ring beam, and the position of the steel ring beam in water is controlled through buoyancy; the limiting device is arranged on the steel ring beam and limits horizontal moving and rotating of the steel ring beam after the steel ring beam is positioned underwater; and the lifting device is arranged on the steel ring beam and used for lifting the steel ring beam out of the water face. Through the underwater guiding device, deviation, perpendicularity, deformation and other indexes of a vibration sinking steel plate pile can be greatly improved, the construction efficiency is obviously improved, and the construction quality is greatly improved.

Owner:CCCC THIRD HARBOR ENG +1

Portkatheter

InactiveUS20090259187A1Improve sterilityRequirement to contact the port unit itself is decreased or avoidedInfusion syringesMedical devicesCatheterAnimal body

A port catheter for introducing a fluid into a hollow organ of a human or animal body includes a port unit implantable into the human or animal body, which port unit includes an interior chamber, to which the fluid to be introduced into the hollow organ of the human or animal body can be supplied. The port catheter further includes a tube connected to the port unit, which tube includes an inner channel through which fluid can be conducted into the hollow organ. The port catheter further includes a grip piece connected to the port unit and removable from it, for the manipulation of the port unit during the implantation of the port catheter into the human or animal body.

Owner:A M I AGENCY FOR MEDICAL INNOVATIONS GMBH

Magazine spring and manufacturing method thereof

InactiveCN110762147AEasy to assembleSmooth outer surfaceFurnace typesWire springsManufacturing technologyEngineering

The invention discloses a magazine spring and a manufacturing method thereof in the technical field of magazine springs. A magazine spring body is included. The left end of the magazine spring body isprovided with a bearing spring section. A transition section is arranged at the right end of the magazine spring body. The right end of the transition section is provided with a supporting spring section. The magazine spring body, the bearing spring section, the transition section and the supporting spring section are an integrally-formed left-handed rotation spring and are the same in outer diameter, and the machining precision is higher. Meanwhile, an automatic spring reeling machine and other traditional spring manufacturing technologies can be overcome, and the situation that in the magazine spring shot charging and conveying process, torsion deformation and mutual friction happen, and the shot charging efficiency and the shot conveying reliability are influenced is avoided. Meanwhile, the pitch of the supporting spring section and the transition section is larger than that of the bearing spring section, on the premise that the shot conveying reliability is guaranteed, the free length of the magazine spring is reduced, accordingly, the used stress is reduced, and the service life is prolonged.

Owner:JIANGSU XIANGYING HARDWARE SPRING CO LTD

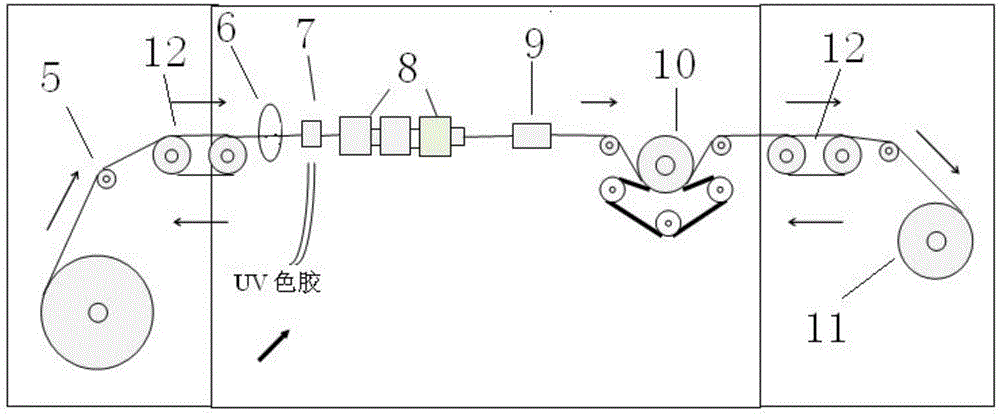

Method of reducing optical fiber coloring unevenness and apparatus thereof

InactiveCN106091993AGuaranteed to be installed in placeReduce free lengthUsing optical meansLight spotEngineering

The invention relates to a method of reducing optical fiber coloring unevenness and an apparatus thereof. The method comprises the following steps that before an optical fiber is assembled, a laser is arranged between a pay-off disc and an eye film die holder; the laser is arranged at a preset center line and irradiates towards an eye film die hole along the set center line; after an eye film is installed, a light spot condition projected by the laser on the eye film is recorded and whether the installed eye film is usable is determined; power of original UV lamps is increased and a quantity of the UV lamps is reduced, and two guide wheels are additionally installed at positions where the UV lamps are removed. The method and the apparatus have advantages that on one hand, through confirming the size of the light spot, whether a center of the light spot is deviated is observed at any time so as to ensure that the eye film is installed on the place; on the other hand, through reducing an optical fiber free length and additionally installing the guide wheels, optical fiber jitter is reduced and adverse factor generation is decreased so as to solve a problem that optical fiber coloring is uneven.

Owner:NANJING WASIN FUJIKURA OPTICAL COMM LTD

Bracket anchor for fastening a facing in a supporting wall, and web plate of a bracket anchor

ActiveUS20170306612A1Easy to produceLower the heatConstruction materialCovering/liningsSingle plateEngineering

A bracket anchor for fastening a facing to a supporting wall has a bracket head for fastening the bracket anchor to the supporting wall, a web plate, a support element for supporting the facing, and a pressure element for transmitting pressure from the bracket anchor to the supporting wall. The support element and the pressure element are secured to the web plate. The entire web plate is formed from a single plate of constant wall thickness. The web plate includes a tension strut and a compression strut which are connected to one another only at their ends facing the support element and at most over half of the projecting length of the bracket anchor.

Owner:LEVIAT GMBH

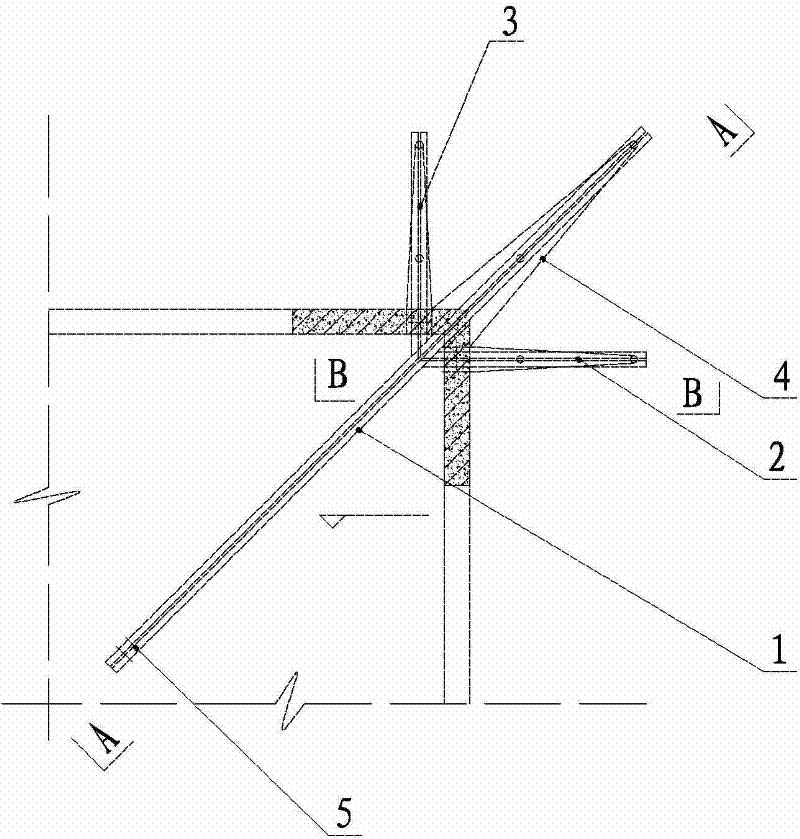

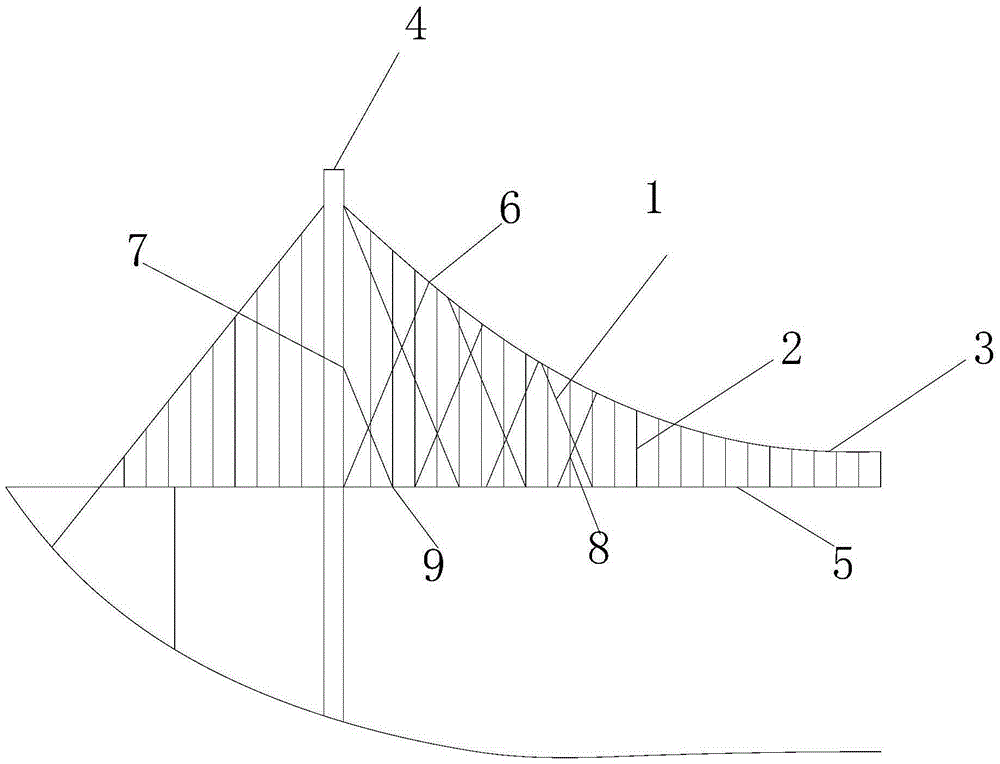

Vibration reducing device for restraining wind-induced vibration of lifting rod of large-span suspension bridge

ActiveCN105220615AReduce free lengthReduce vibrationSuspension bridgeBridge structural detailsCable netMechanical engineering

The invention discloses a vibration reducing device for restraining wind-induced vibration of a lifting rod of a large-span suspension bridge, which is an auxiliary cable net system arranged on a suspension bridge lifting rod (2); the auxiliary cable net system is a netty structure formed by across arranging multiple auxiliary cables (1); included angles between the auxiliary cables (1) and the lifting rod (2) are 30-70 degrees; and in a connecting area (8) of the auxiliary cables and the lifting rod, the auxiliary cables (1) and the lifting rod (2) are fixedly connected by bolts through two second connecting devices (10) at two sides of the lifting rod (2), connecting clamping pieces (81) of two auxiliary cables at two sides of the two second connecting devices (10) and the lifting rod and rubber washers between the connecting clamping pieces (81) of the auxiliary cables and the lifting rod and the lifting rod (2). The vibration reducing device is simple in connecting structure, has the advantages of convenience for installation and maintenance construction, and can be convenient to replace cable bodies in the use period.

Owner:TONGJI UNIV

Fluid-filled vibration damping device

ActiveUS20140327199A1Reduce free lengthReduce and avoidMachine framesLiquid springsElastomerEngineering

Owner:SUMITOMO RIKO CO LTD

Deep water open composite foundation wharf and its construction method

The invention discloses a deepwater open type wharf with a combined foundation. A foundation support system of the deepwater open type wharf comprises a caisson gravity structure system and a pile foundation structure system which are fixedly assembled and connected with each other, a caisson is fixed onto a submarine foundation bed in an implantation manner, the pile foundation structure system is of a concrete-filled steel pipe pile bundle structure comprising through long piles and non-through piles, steel pipe piles arranged along the insides of steel casings are driven into a rock-soil bearing stratum to form the through long piles, and the bottoms of the non-through piles are embedded into a top plate of the caisson to be fixedly connected with the top plate of the caisson, so that the wharf with the combined foundation which comprises an open type pile foundation and the gravity caisson is formed. The invention further provides a method for constructing the wharf. The method includes prefabricating the combined foundation on a land; processing the submarine foundation bed; positioning and sinking the combined foundation; manufacturing the through long piles; manufacturing an upper wharf face plate. The deepwater open type wharf and the method have the advantages that merits of the gravity structure and merits of a pile foundation structure are combined with one another, the problem of differential settlement is effectively solved, wharf apron mooring conditions are improved, and the wharf is high in bearing capacity and good in durability.

Owner:SHANGHAI UNIV

Rotogravure with snubber roll

InactiveCN109130455AEasy to adjustGood registration accuracyRotary intaglio printing pressOther printing apparatusWaste productSnubber

Owner:HEIDELBERGER DRUCKMASCHINEN AG

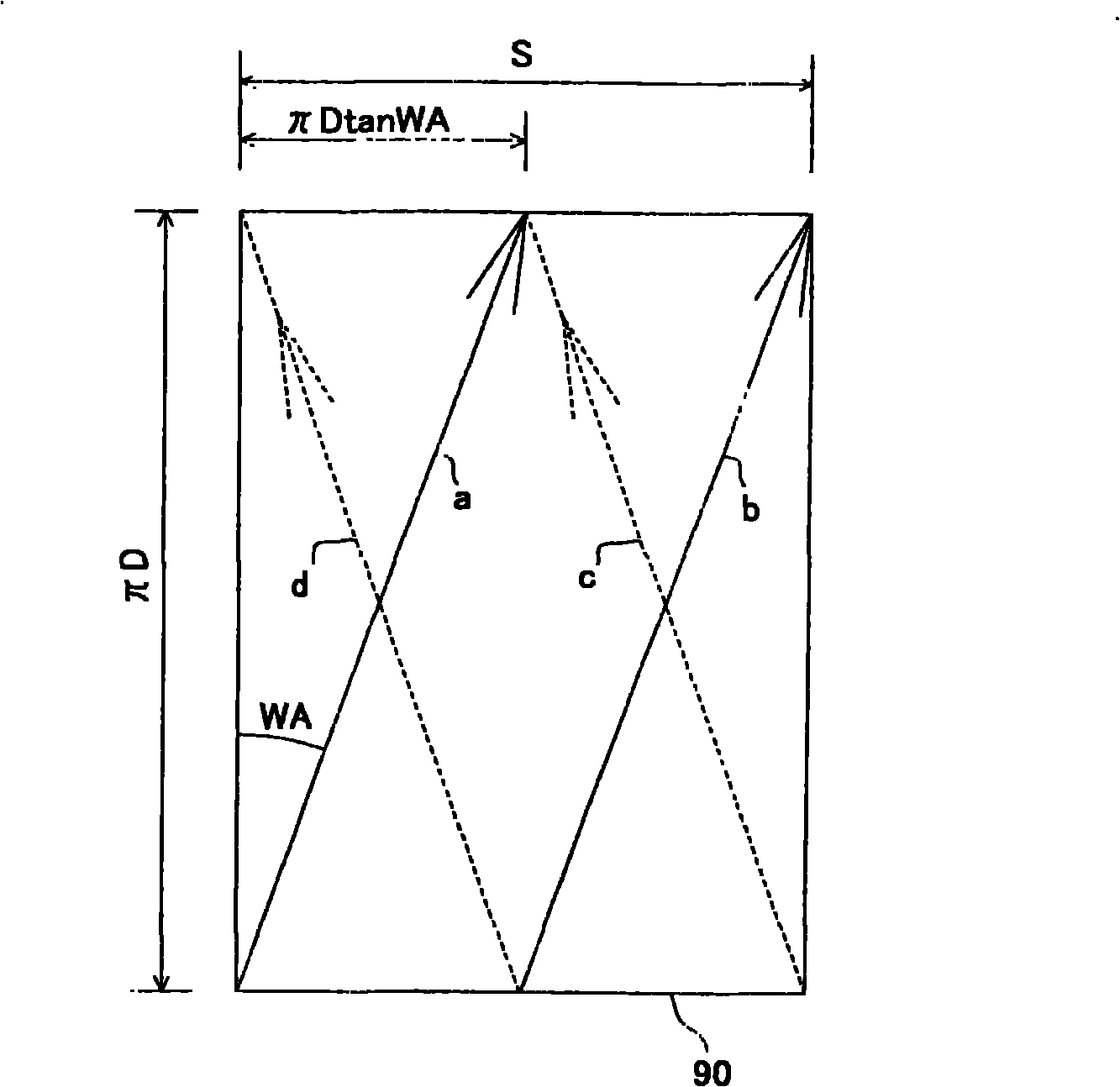

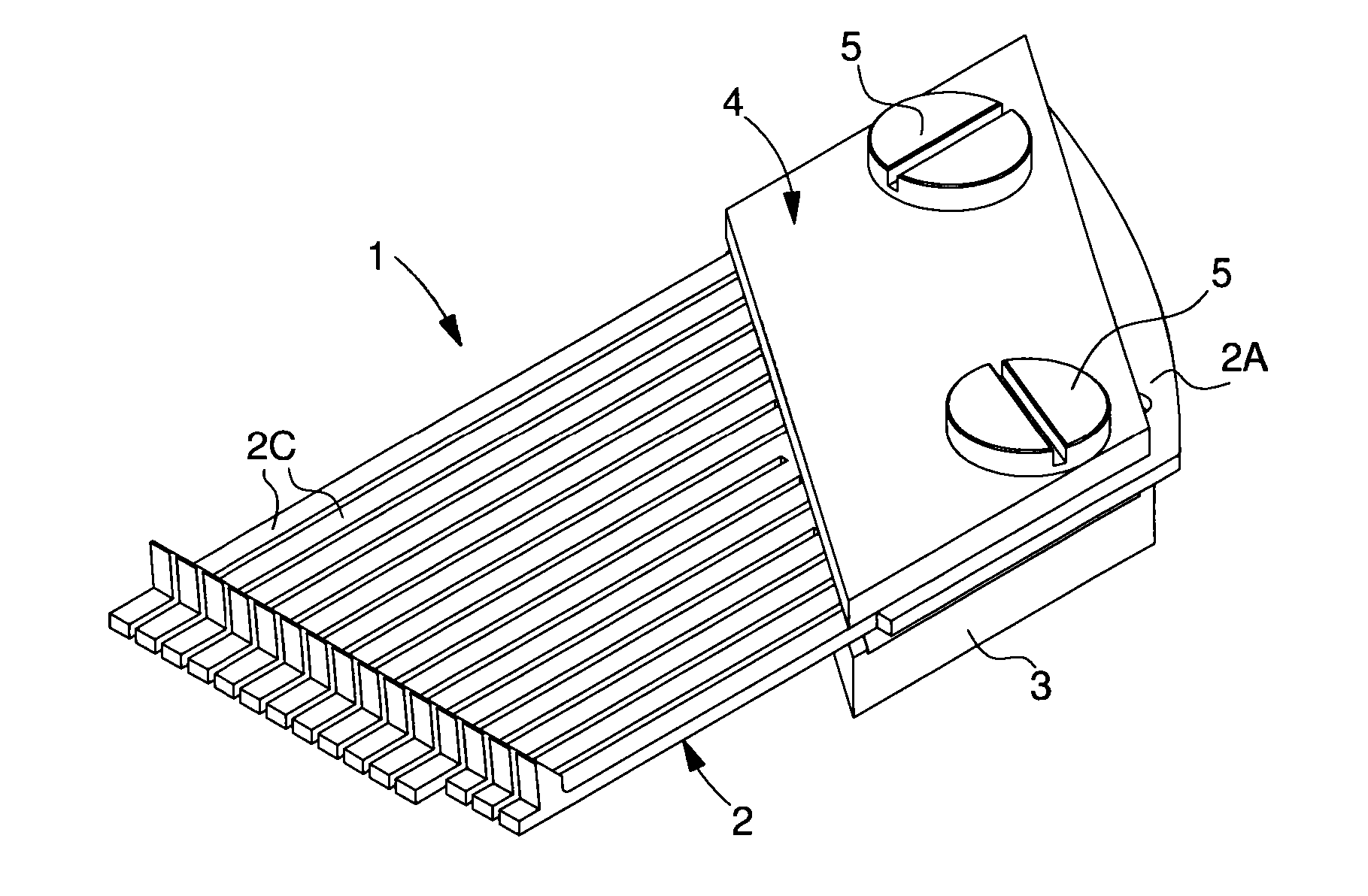

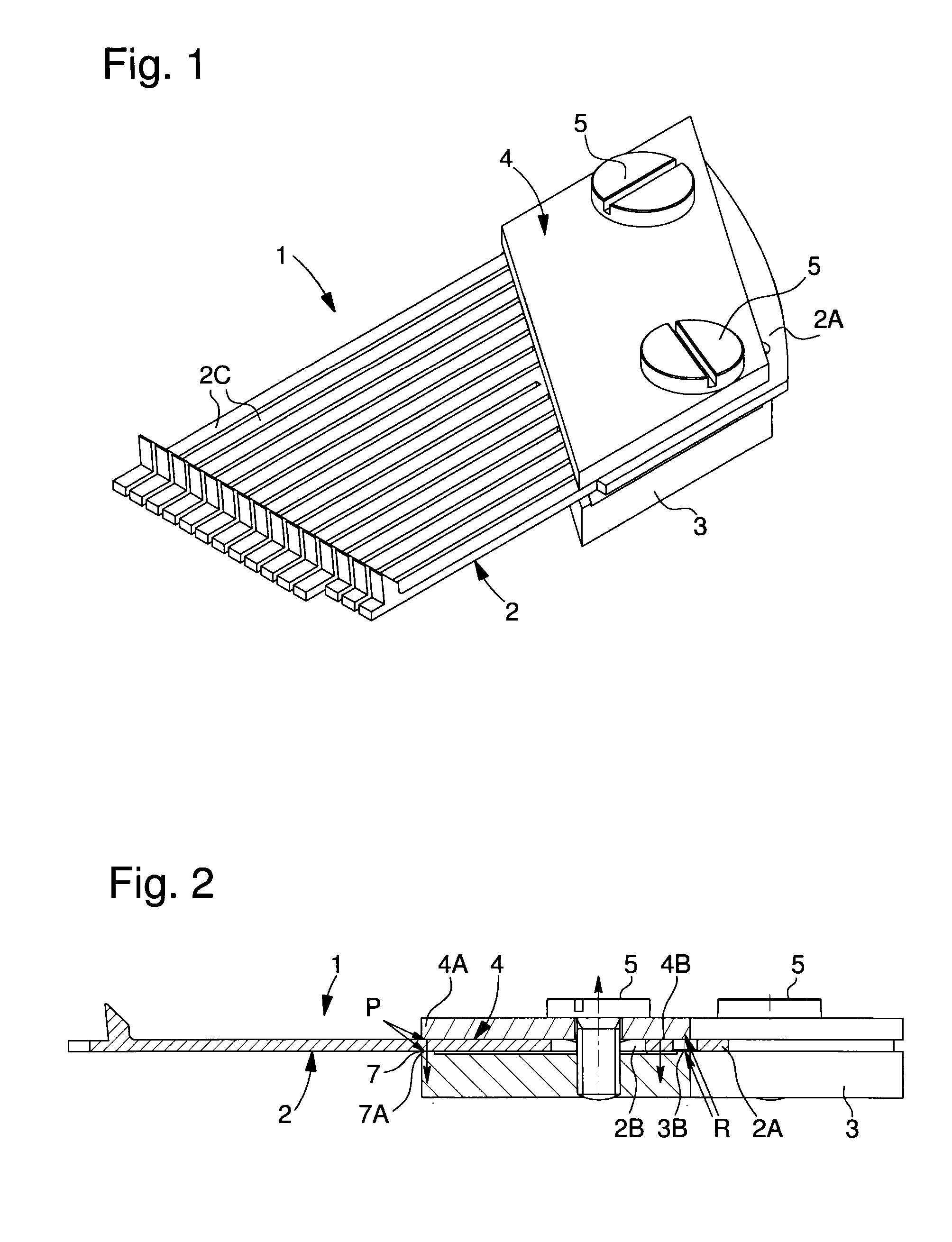

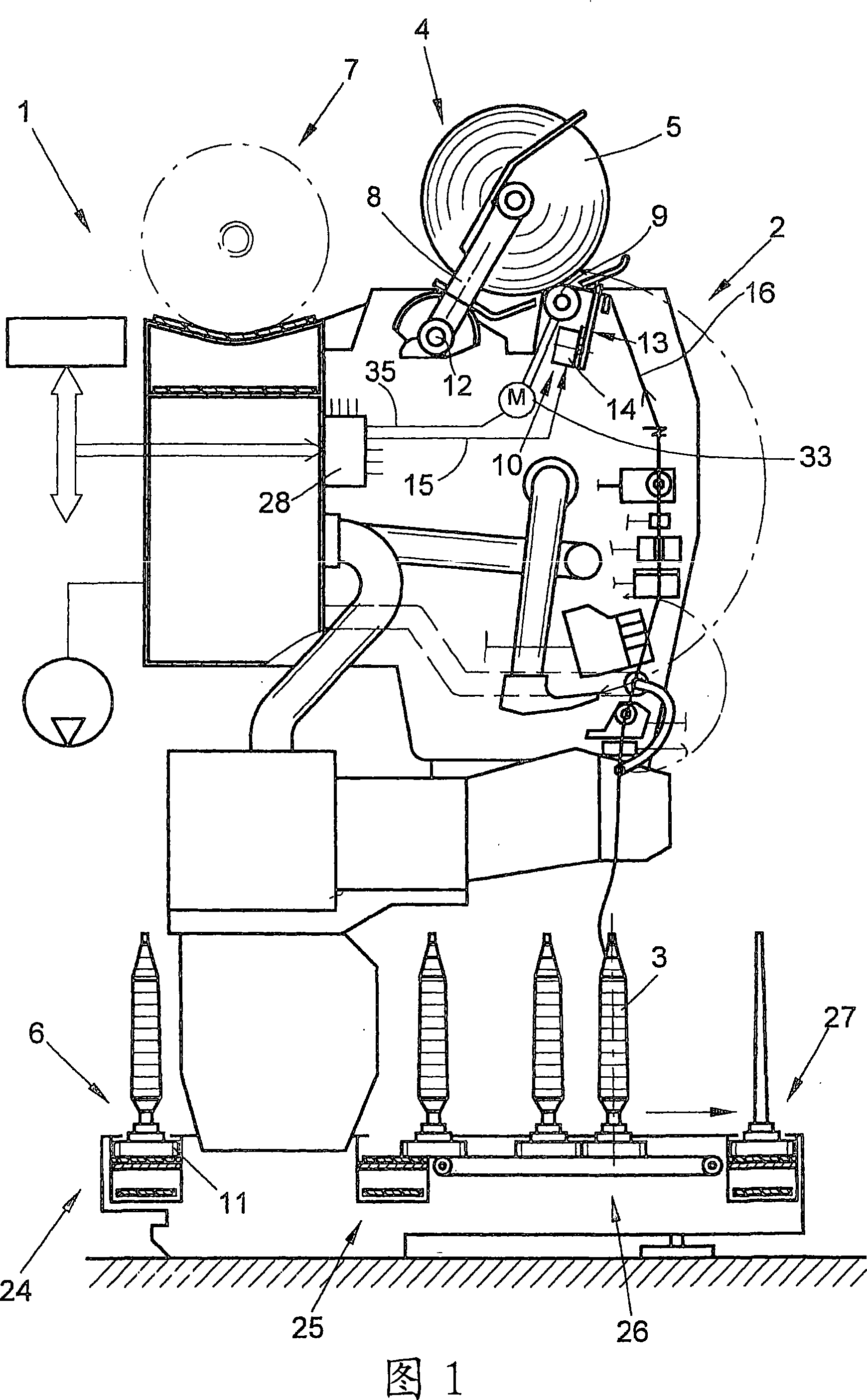

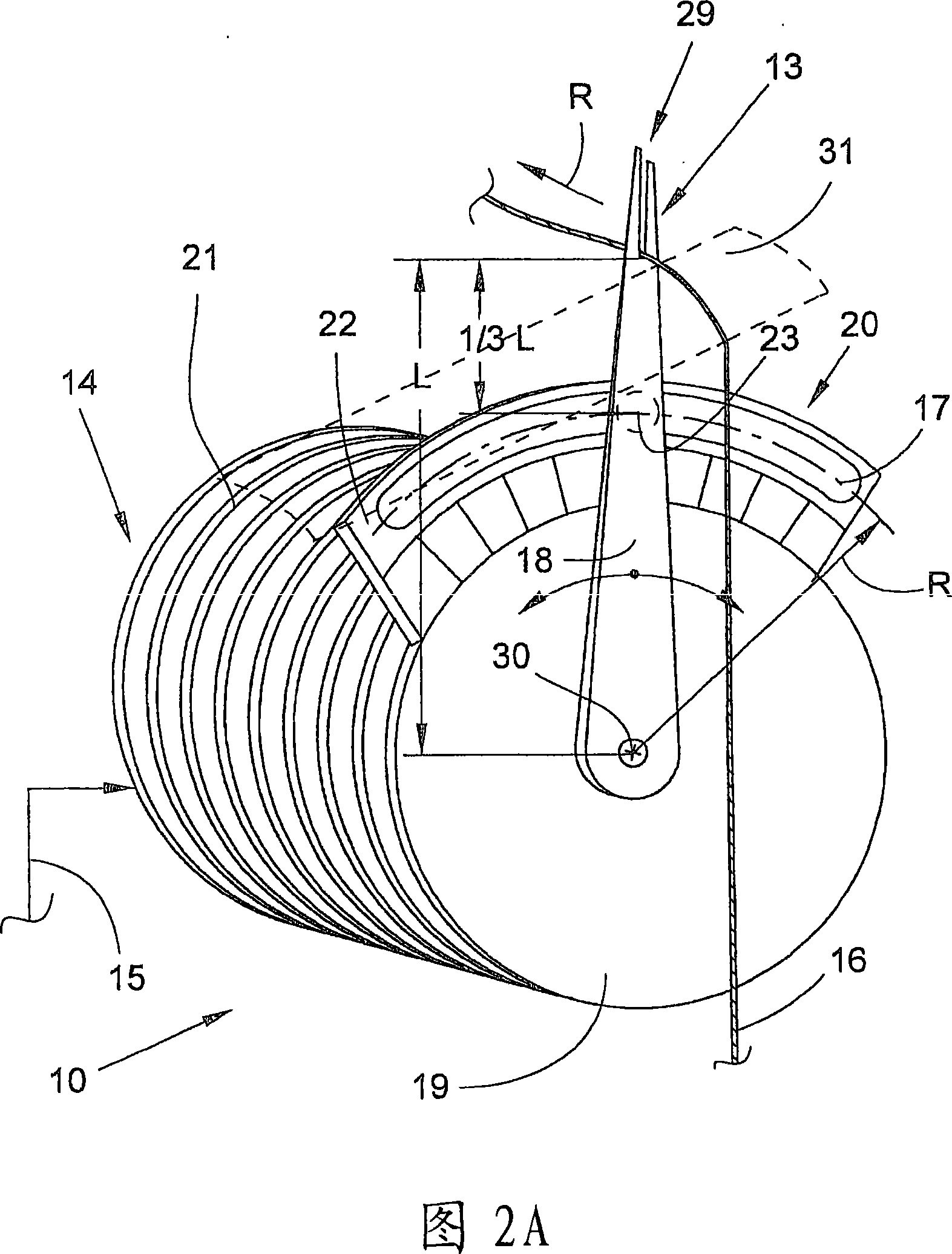

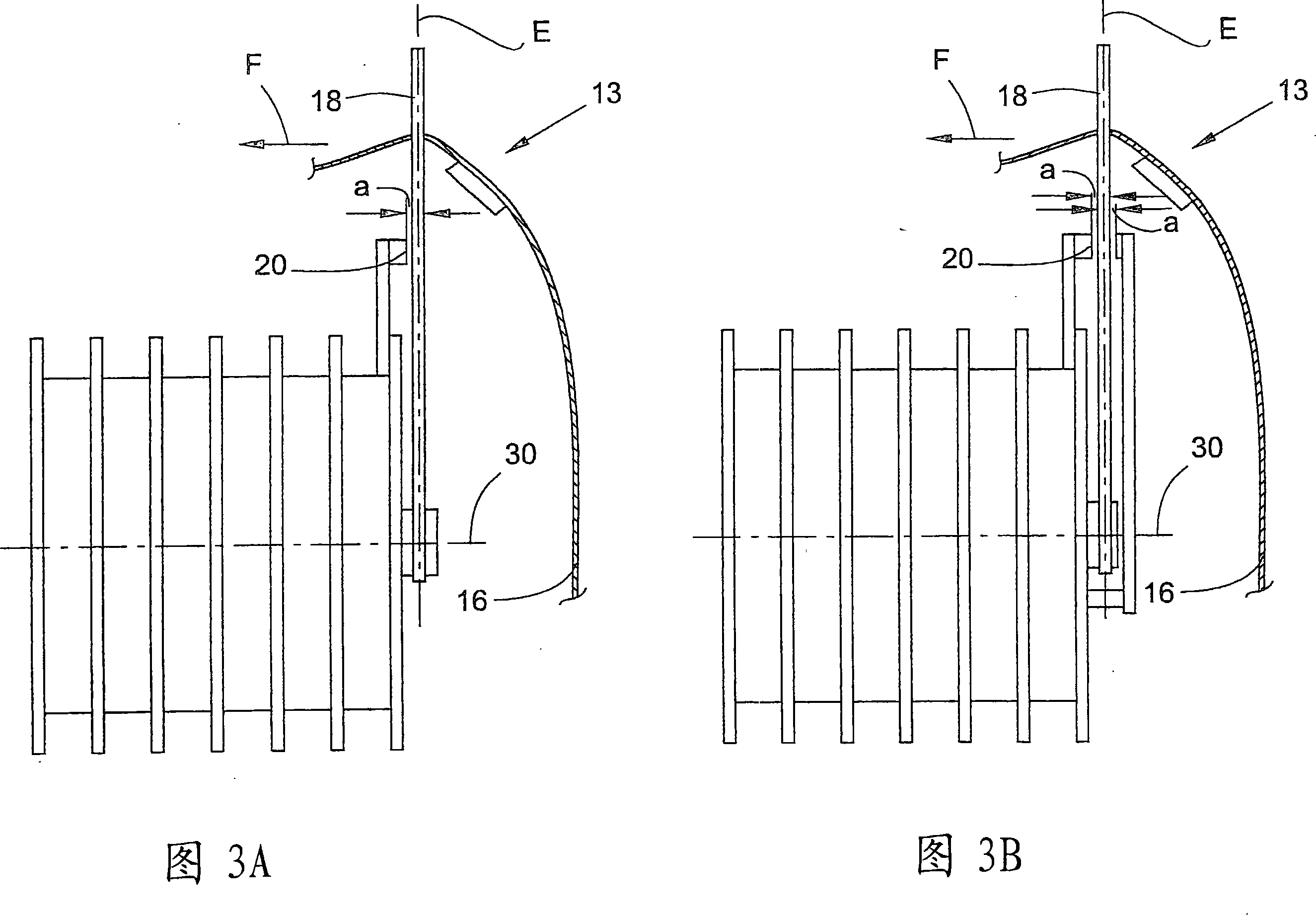

Thread traversing device for a winding device in a textile machine producing crosswound bobbins

The present invention relates to a yarn transverse device which is used for producing the coiling device of the weaving loom of the cross-winding roller. The yarn transverse device includes a feed carrier which is used for laterally feeding the yarn to the guiding roller that can be rotatablely driven. In this instance the feed carrier is designed to the form of finger-shaped feed carrier which is installed moving in the boundary of the pivoting axis and is driven by the motor driver. According to the invention at least one supporting rail (20) is arranged at the position spacing the yarn placing arm (18) of the finger-shaped feed carrier (13) and facilitate that in the lateral movement period of the yarn the yarn placing arm (18) generates the shift perpendicular to the moving plane (E) or when the twisting of the yarn placing arm (18) exists, the yarn placing arm (18) leans to the supporting rail (20).

Owner:OERLIKON TEXTILE GMBH & CO KG

Vessel comprising a crane

ActiveUS20140093334A1Increased freedom of movementLow positionCargo handling apparatusMechanical machines/dredgersEngineering

A vessel (4) includes a crane (1) connected to a deck (5) of the vessel. The crane (1) includesa frame (10) which is rotatable about a horizontal hinge axis (H),a rotation mechanism (20) connected to the frame (10) at a position away from the horizontal hinge axis (H), arranged to rotate the frame (10) about the horizontal hinge axis (H) from an upper position to a lower position and vice versa, anda swivel member (30), which is with a first end (31) rotatable connected to the deck (5) and which is with a second end (32) rotatable connected to the rotation mechanism (20).The swivel member (30) is rotatable between an inward position associated with the upper position of the frame (10) to an outward position associated with the lower position of the frame (10).

Owner:IHC HOLLAND NV

Compensation device for valve opening and closing mechanism

InactiveCN109611587AReduce areaNo reduction in stiffnessOperating means/releasing devices for valvesEqualizing valvesMedia controlsDifferential pressure

The invention discloses a valve for compensation device for fluid medium control valve opening and closing mechanism. The valve is composed of a valve body, a valve cover, an opening and closing mechanism and a compensation device. The opening and closing mechanism comprises a pressure sensing element, a main spring and a valve plug, and is arranged in the valve body. The pressure sensing elementand the valve cover form a pressure sensing element cavity. The compensation device comprises an upper compensation spring, a lower compensation spring and a piston, and is arranged in the valve body.Pressure on two sides of the pressure sensing element separately acts on two ends of the piston. When P1-(P3+F) is greater than 0, the piston moves to the direction of less pressure, the lower compensation spring is compressed and the valve plug is closed until the P1-(P3+F) is equal to 0, the differential pressure is controlled to be a preset value, and the valve plug is in a balanced state; andwhen the P1-(P3+F) is less than 0, the piston moves to the direction of greater pressure, the upper compensation spring is compressed and the valve plug is opened until the P1-(P3+F) is equal to 0, the differential pressure is controlled to be the preset value, and the valve plug is in a balanced state. The problem in the prior art that control precision error is high is effectively solved.

Owner:海林阀门科技河北有限公司

Elastic fiber production and yarn guide device

The invention relates to the technical field of production of elastic fibers and particularly relates to an elastic fiber production and yarn guide device. The elastic fiber production and yarn guidedevice comprise an elastic fiber spinning machine, an elastic fiber, a first yarn guide device and at least one group of second yarn guide device, the first yarn guide device is arranged at the lowerpart of the outputted elastic fiber of the elastic fiber spinning machine, the second yarn guide yarn guide device is further arranged in the conveying direction of the elastic fiber, the diameters ofthe first yarn guide device and the second yarn guide device are the same, at least one feeding roller is arranged at the lower part of any second yarn guide device, a winder is arranged below each feeding roller; the elastic fiber led out from the first yarn guide device and an outlet of the elastic fiber spinning machine is connected with the at least one second yarn guide device, and the feeding roller is connected with a reel in the winder through the elastic fiber. The feeding roller is added between the second yarn guide device and the winder and has a roller structure, the frictional force of the roller structure on the elastic fiber is relatively small, and the tension required for preventing the elastic fiber from being wound in the roller is reduced.

Owner:湖州泰鑫无纺布有限公司

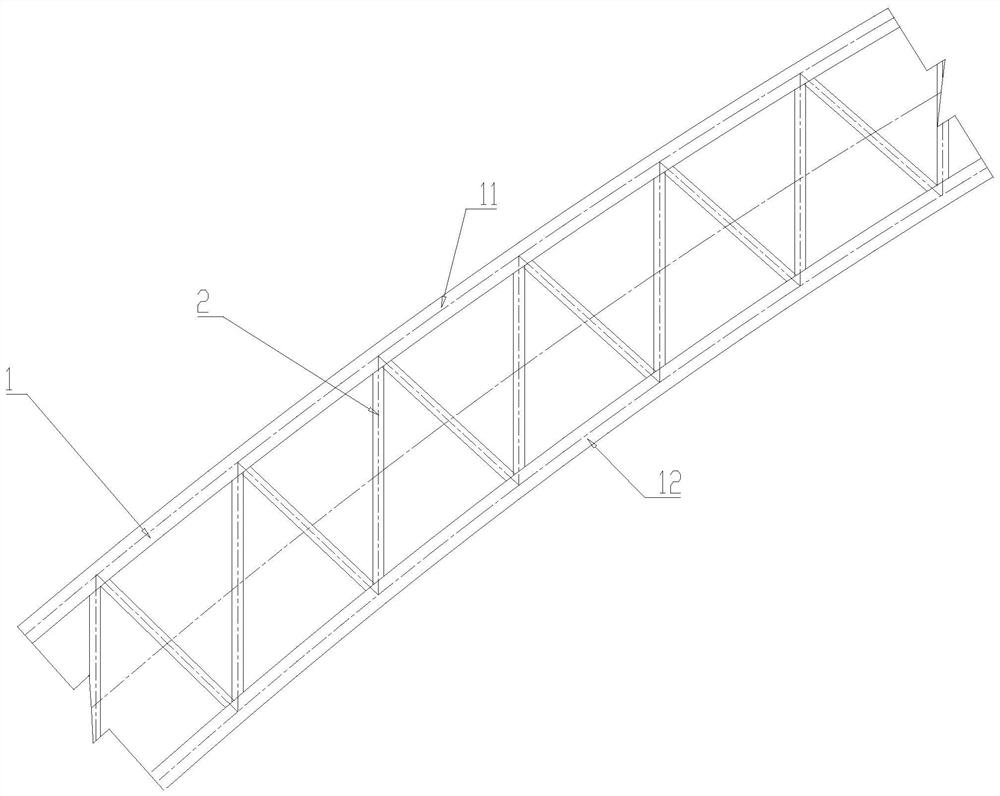

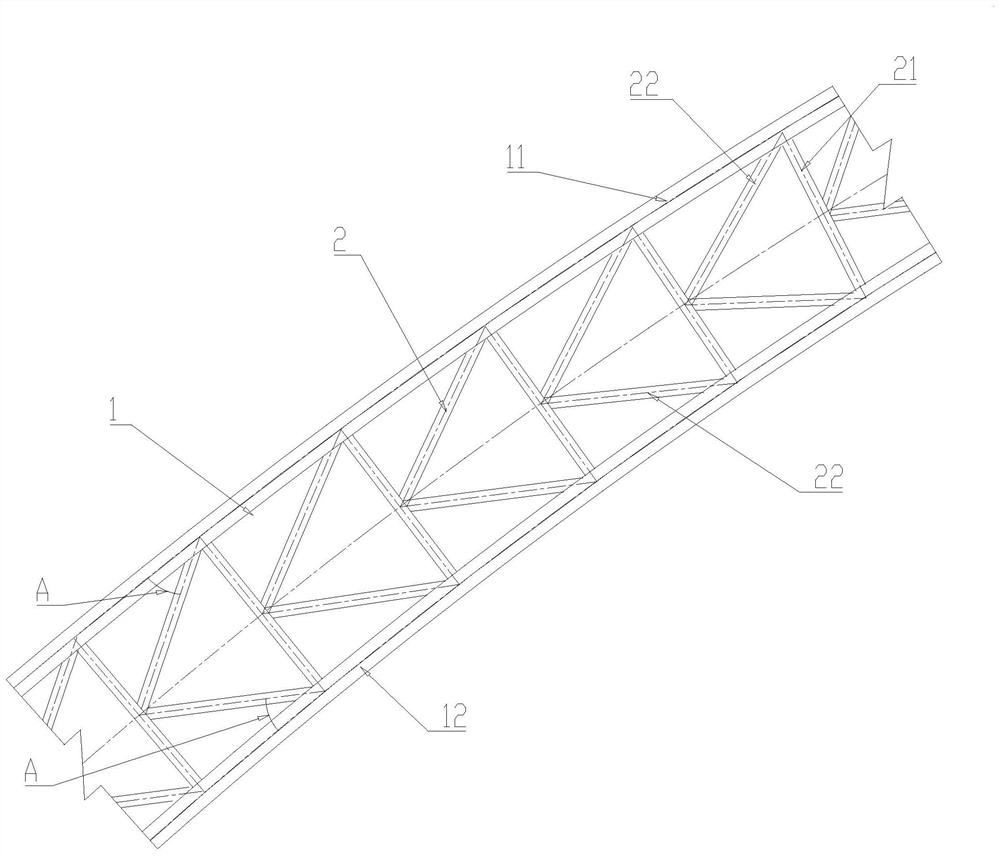

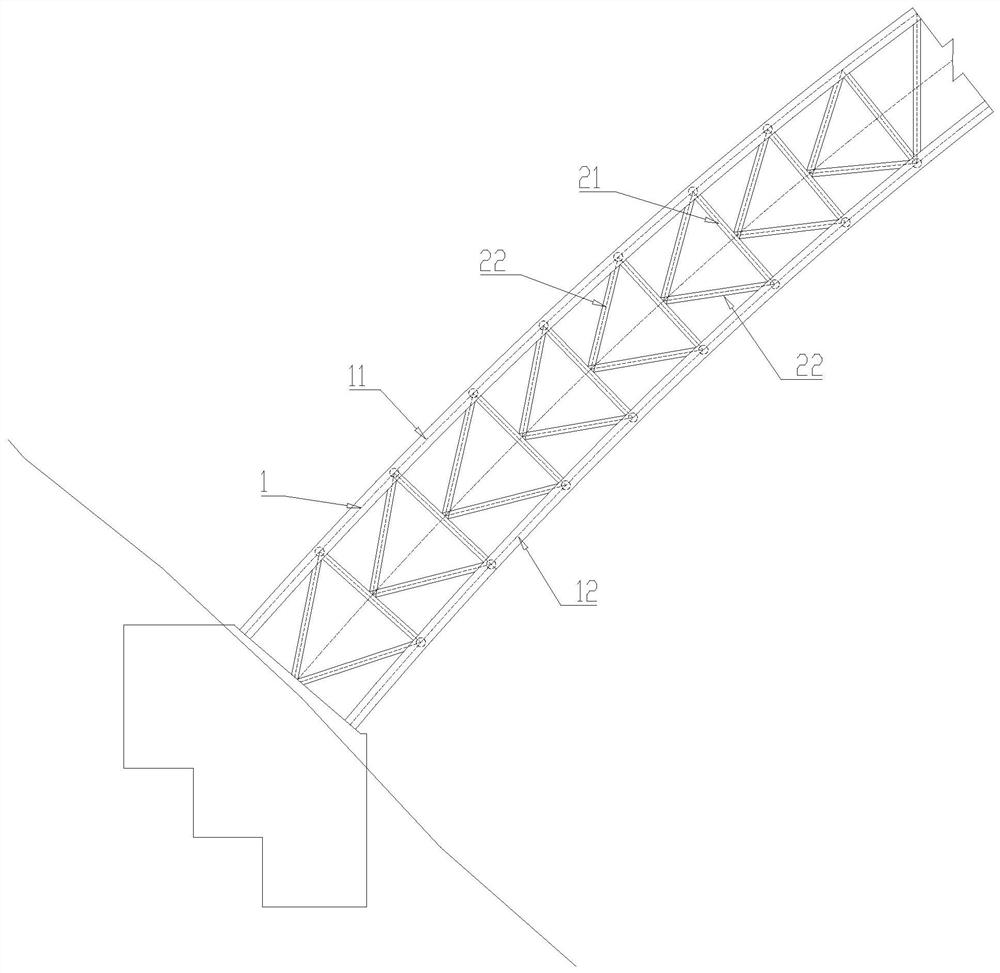

Web member structure of concrete-filled steel tube truss type main arch and bridge

PendingCN112482189AShorten the lengthReduce aspect ratioArch-type bridgeBridge materialsMechanical engineeringIndustrial engineering

The invention discloses a web member structure of a concrete-filled steel tube truss type main arch and a bridge. The web member structure comprises a plurality of sets of web member assemblies. Eachweb member assembly comprises a transverse web member and two inclined web members, the transverse web member and the two inclined web members form a triangular unit, the two ends of the transverse web member are used for being connected with the upper chord and the lower chord of the main arch on the same side respectively, one end of one inclined web member is used for being connected with the upper chord, and the other side of the inclined web member is connected with the middle of the transverse web member in the adjacent web member assembly; one end of the other inclined web member is used for being connected with the lower chord, and the other side of the inclined web member is connected with the middle of the transverse web member in the adjacent web member assembly. The free lengths of the inclined web members and the transverse web members are smaller than or equal to the height of the section of the main arch, the free lengths and slenderness ratios of the web members are reduced, if cutting is conducted in the direction of the cross section of the main arch, at least two intersection points exist between the tangential direction and the web member assemblies, compressiverigidity and shear rigidity of the web members are improved, and local instability of the main arch web members is effectively avoided.

Owner:SICHUAN VOCATIONAL & TECHN COLLEGE OF COMM

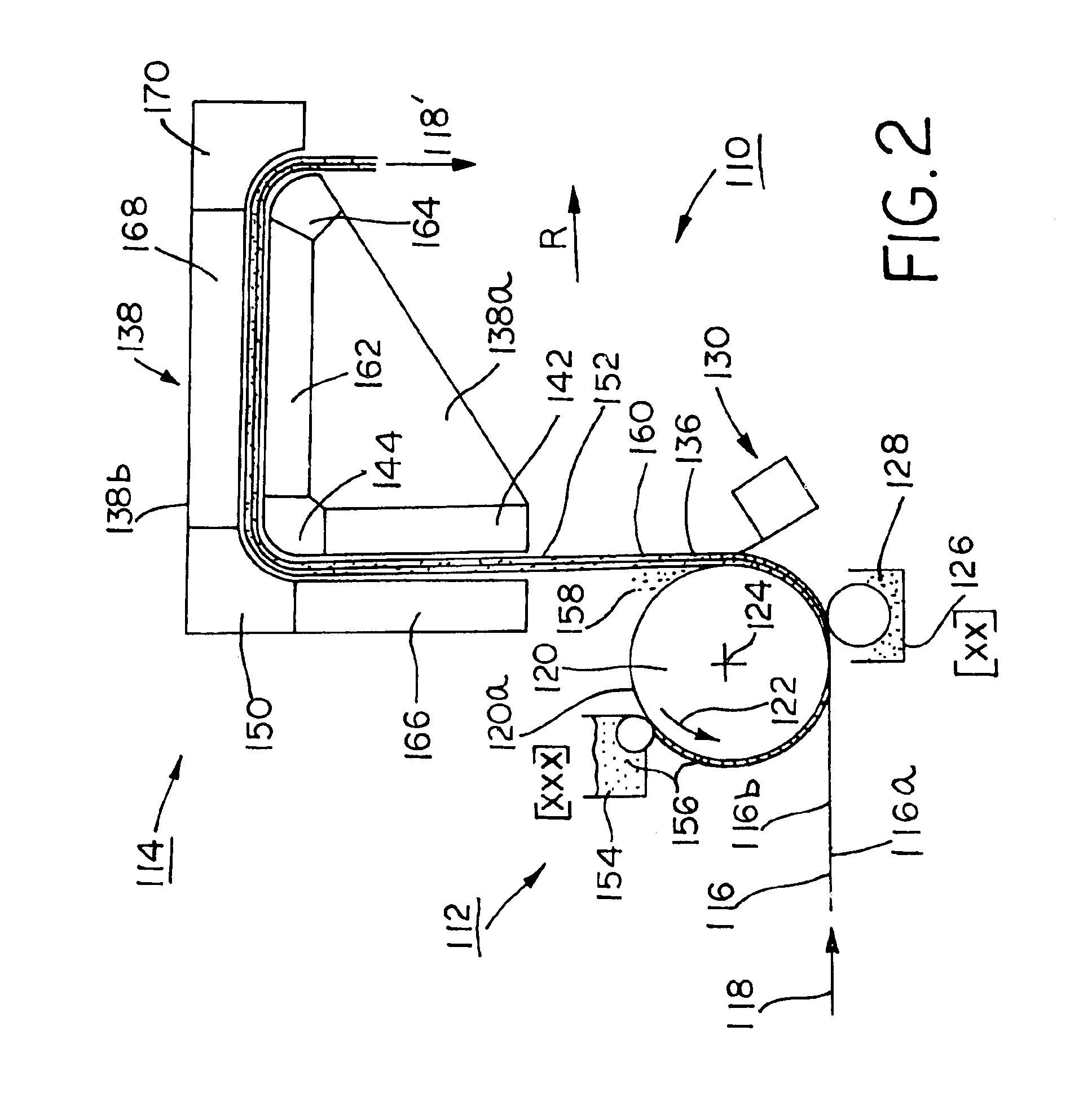

Elastic yarn winding system and elastic yarn winding machine and elastic yarn winding method

ActiveCN100522779CPeripheral speedResidual systolic inhibitionNew-spun product collectionFilament handlingWinding machineYarn

PROBLEM TO BE SOLVED: To provide a winder for a resilient yarn capable of suppressing low the residual shrinkage ratio when a roll is formed and establishing a good package shape. SOLUTION: The winder for the resilient yarn is equipped with a contacting roller 18 installed downstream in the yarn advancing direction with respect to a godet roller couple and contacting with the peripheral surface of a roll 3 to be prepared while the resilient yarn Y is being taken up. A traversing device 4 is installed upstream of the contacting roller 18 about the yarn advancing direction. The resilient yarn Y put in the traverse motion by the traversing device 4 is taken up on the roll 3 being prepared through the contacting roller 18. A feed roller 27 is installed upstream of the traversing device 4 about the yarn advancing direction (between the godet roller and the traversing device 4), and the rotating speeds of the feed roller 27 and the contacting roller 18 are controlled so that the peripheral linear speed V2 of the feed roller 27 becomes higher than that V1 of the contacting roller 18. COPYRIGHT: (C)2005,JPO&NCIPI

Owner:TMT MACHINERY INC

An integrated deep water foundation and its construction method

ActiveCN111636465BShorten the construction periodImprove carrying capacityArtificial islandsUnderwater structuresSuction forceSteel columns

This application relates to an integrated deep-water foundation and its construction method, and relates to the technical field of bridge deep-water foundations, including multiple suction single wells, multiple steel pipe columns, multiple bored piles and caps. The steel casing used for bored pile construction, and the steel pipe column and the single suction well are an integrated structure prepared in advance. After the drainage operation of the single suction well, the steel pipe column and the single suction well can sink to the design elevation. There is no need to erect a large jacket platform and carry out processes such as hoisting, turning over, and sinking of steel casings in the marine environment with harsh swell conditions, and the suction well base and steel pipe columns can participate in the stress of the deep water foundation during the bridge use stage Among them, the free length of the single pile can be effectively reduced, and the horizontal and vertical bearing capacity of the pile body can be improved. Therefore, the application can not only reduce the construction risk, difficulty and cost, but also shorten the construction period and improve the horizontal bearing capacity and vertical bearing capacity of the pile body.

Owner:CHINA MAJOR BRIDGE ENERGINEERING

Apparatus for coating moving fiber webs

InactiveUS6895690B2Improve stabilityIncrease the lengthLiquid surface applicatorsDryer sectionFiberCardboard

An apparatus for coating a moving web, in particular a paper or cardboard web, on one or both sides with a liquid or pastous coating material includes a coating station for applying the coating material onto the web, as well as a non-contact turning apparatus following the coating station in the moving direction of the web. The web moves in only one plane from the point of exit from the coating station to the point of entry into the non-contact turning apparatus, without changing direction.

Owner:VOITH PATENT GMBH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com