Vibration sinking construction underwater guiding device and construction technology of grid plate pile large cylinder

A technology of guiding device and construction technology, which is applied in sheet pile walls, foundation structure engineering, buildings, etc., can solve problems such as buckling deformation, reduced construction efficiency, and increased pile sinking resistance, so as to reduce local deformation, improve construction quality, The effect of improving construction efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0049] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the present invention will be further described below in conjunction with specific illustrations.

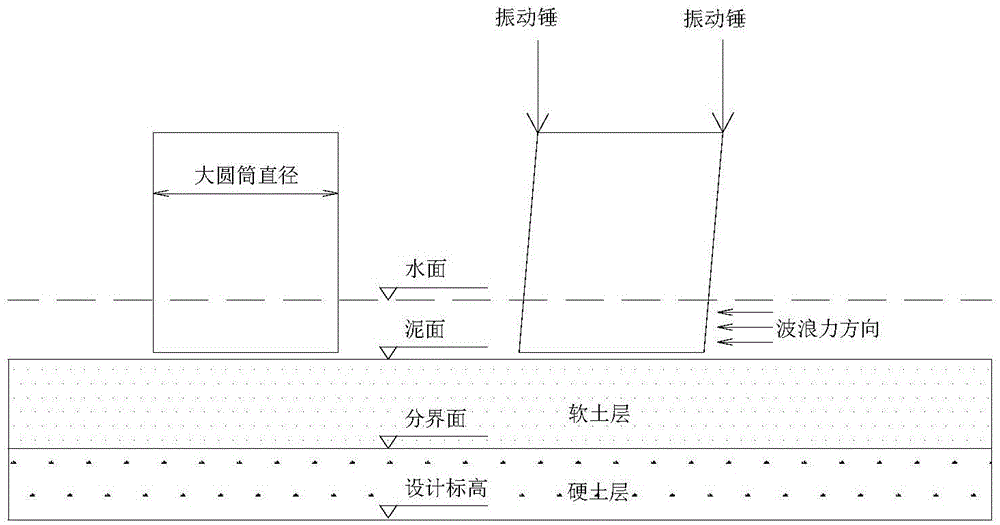

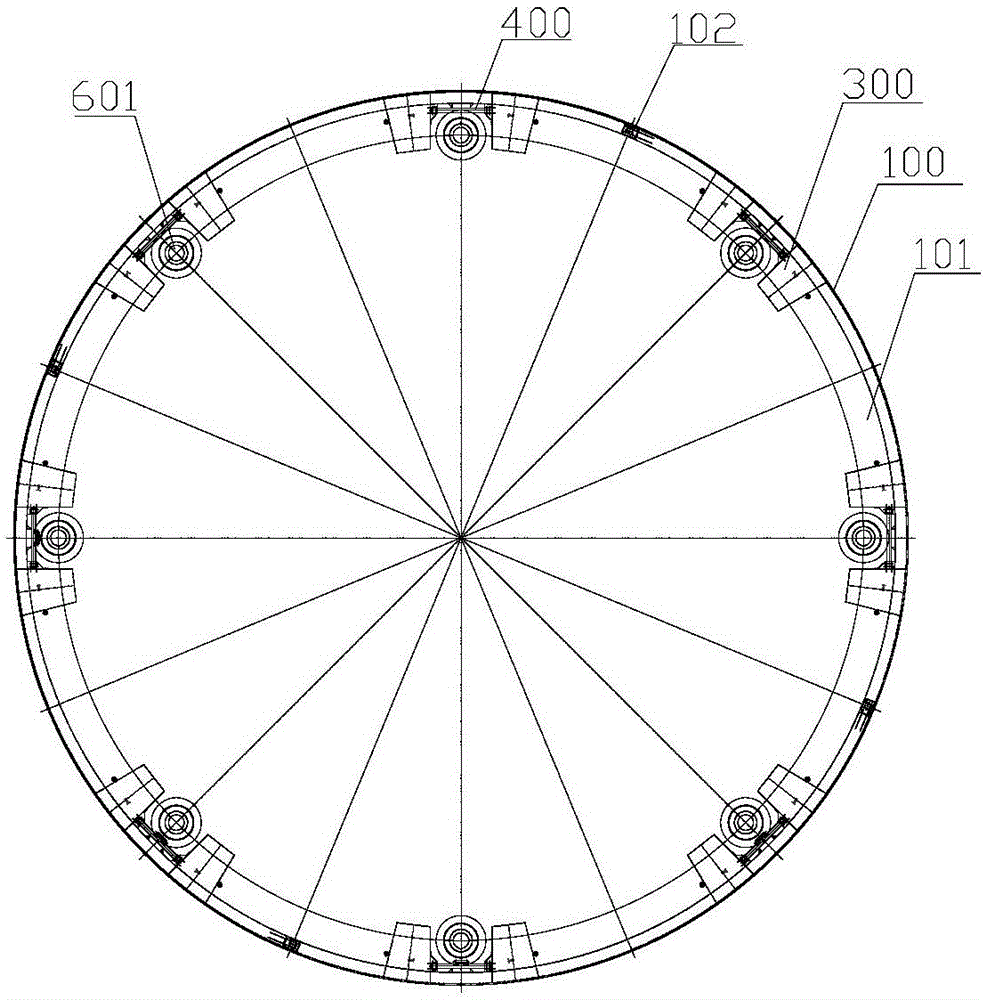

[0050] see image 3 , which is a structural schematic diagram of the underwater guide device for large cylinder vibratory sinking construction of lattice sheet piles provided by the present invention. As can be seen from the figure, the whole underwater guiding device mainly includes: a steel ring beam 100, several guiding units 200, several steel buoyancy boxes 300, several limiting devices 400 and several lifting devices 500 (see Figure 8 ).

[0051] Wherein, the steel ring beam 100 is the main body of the entire underwater guiding device to carry other components, and its outer diameter corresponds to the inner diameter of the large cylinder of lattice sheet piles to be constructed.

[0052] The steel ring beam 100 is specifically composed...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com