Patents

Literature

69results about How to "Improve transfer yield" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

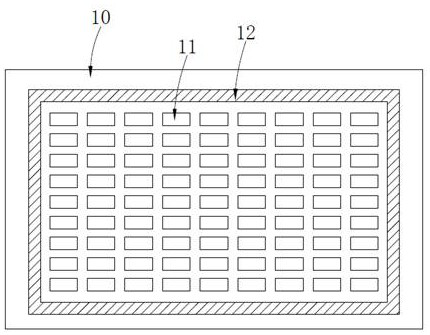

Micro light emitting diode substrate and preparation method thereof and display device

InactiveCN108538878AImprove transfer yieldAvoid missingSolid-state devicesSemiconductor devicesDisplay deviceLight-emitting diode

The invention provides a micro light emitting diode substrate and a preparation method thereof and a display device. The preparation method comprises the steps that 1, a first growth substrate is provided, wherein the first growth substrate is provided with a first growth surface, and the first growth surface is provided with first color micro light emitting diode units; 2, a receiving substrate is provided, wherein the receiving substrate is provided with a receiving surface, and a plurality of receiving bonding pads are arranged on the receiving surface at intervals; 3, the first growth substrate is attached to the receiving substrate, so that the first color micro light emitting diode units at the transferring position are attached to the receiving bonding pads respectively; 4, the first color micro light emitting diode units are fixed to the receiving surface through the receiving bonding pads; 5, the first growth substrate and the first color micro light emitting diode units are stripped, and the receiving substrate to which the first color micro light emitting diode units are fixed is obtained.

Owner:ELEC TECH PHOTOELECTRIC TECH DALIAN

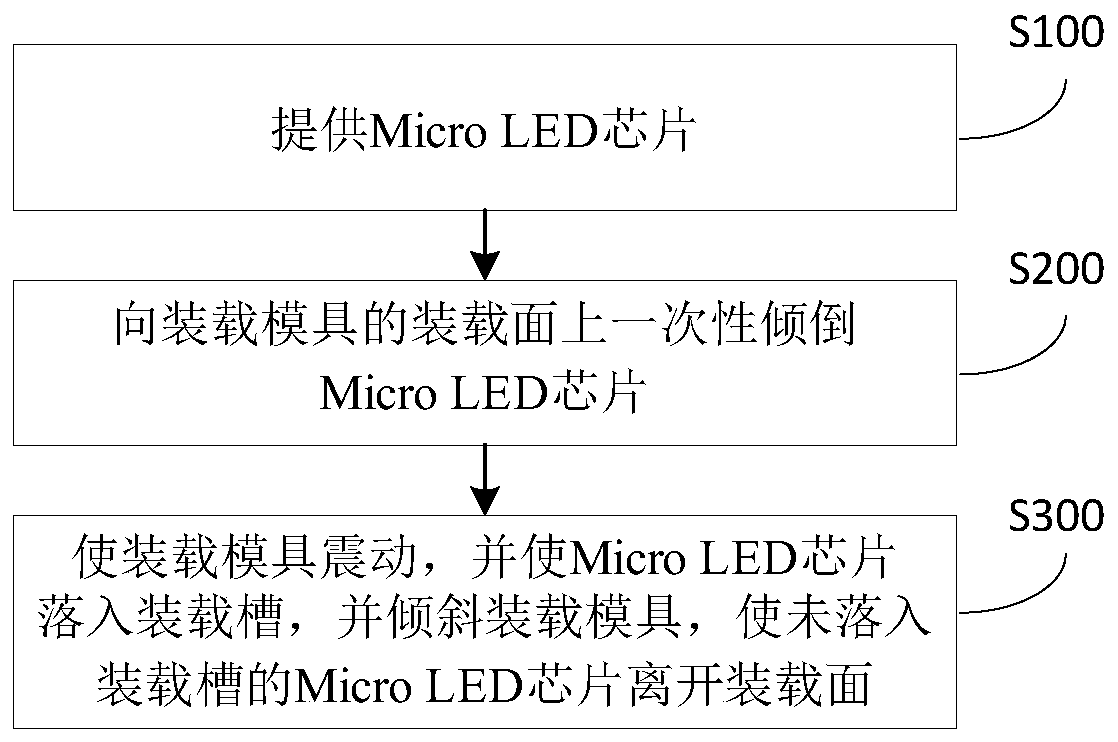

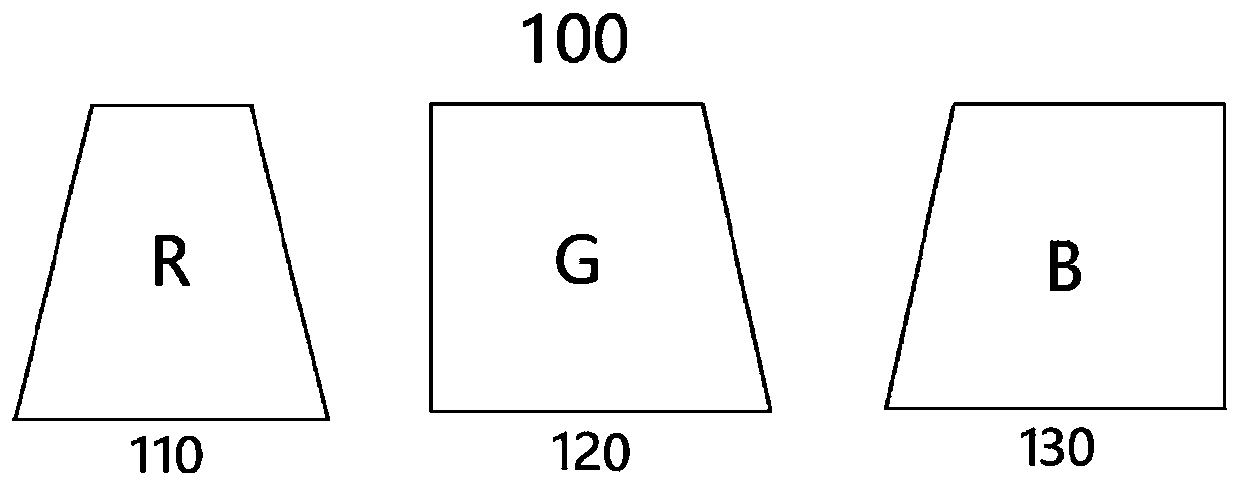

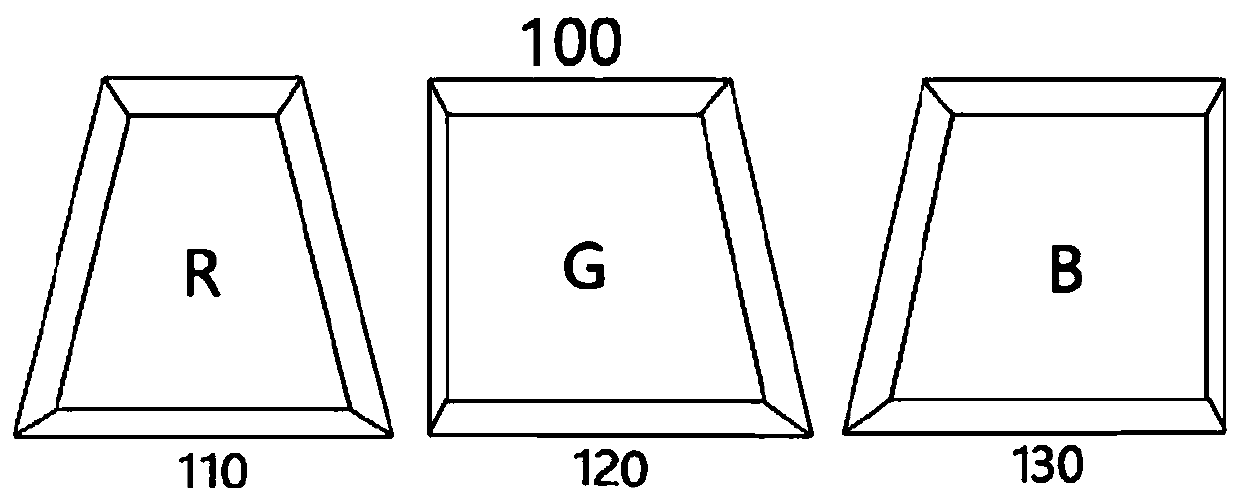

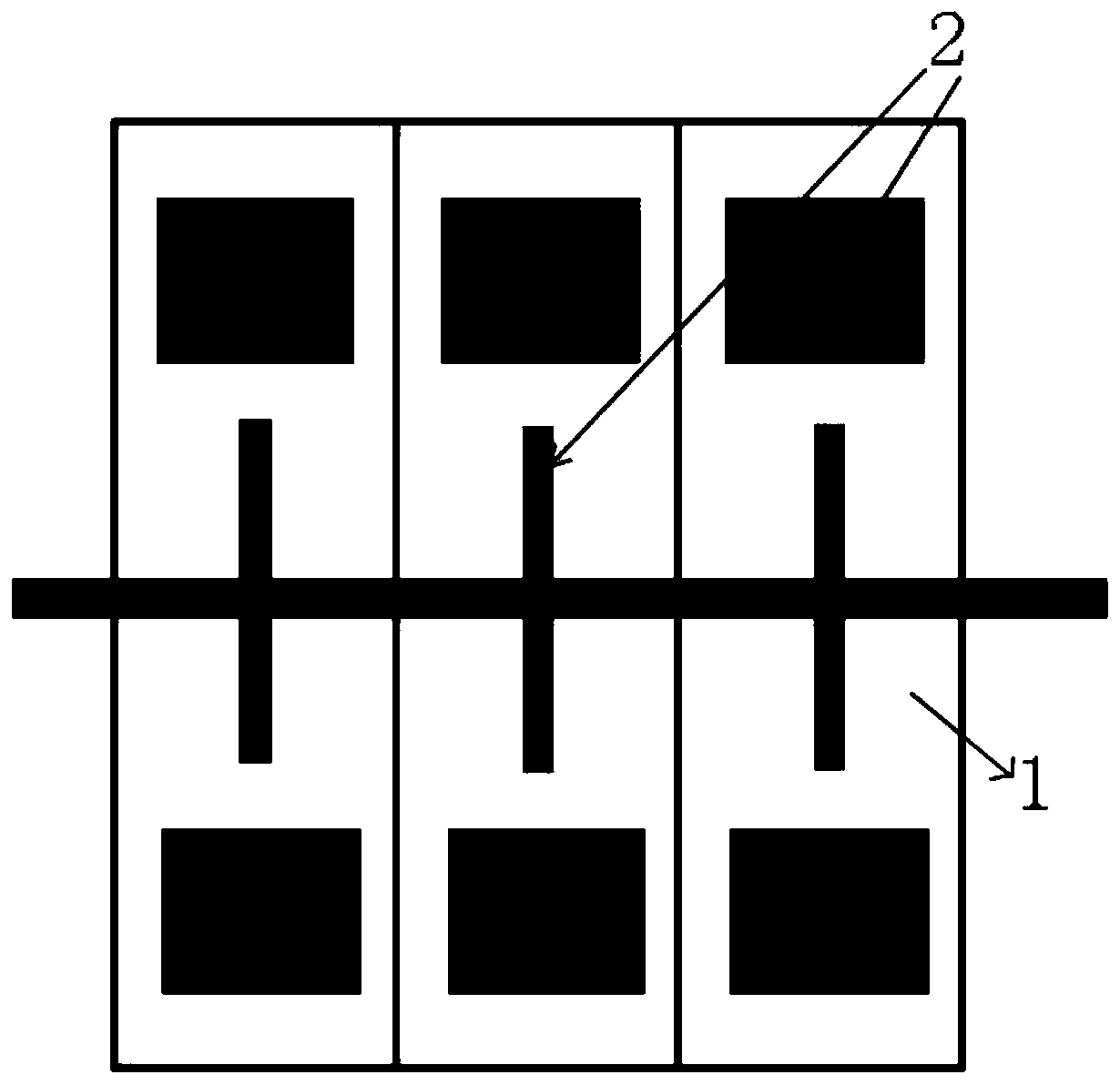

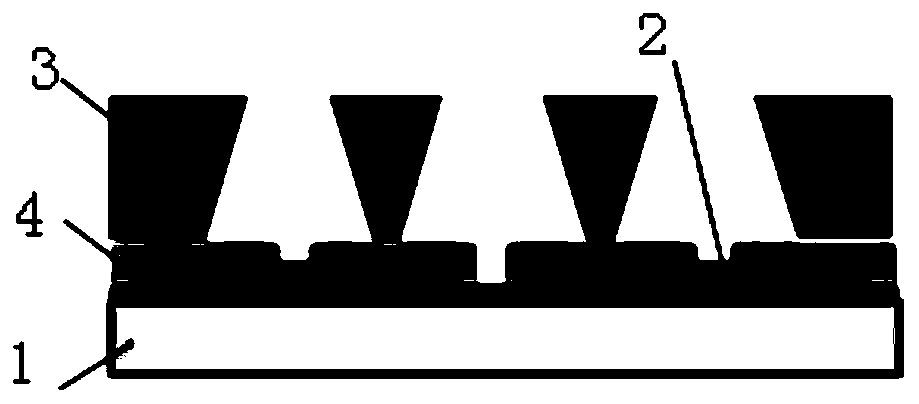

Mass Micro LED transfer method and mass transfer device

InactiveCN109950182AImprove transfer efficiencyImprove transfer yieldSemiconductor/solid-state device testing/measurementSolid-state devicesEngineeringMass transfer coefficient

The invention proposes a mass Micro LED transfer method and a mass transfer device. The method comprises a step of providing Micro LED chips, wherein the cross-sectional shapes of first Micro LED chips capable of emitting a first color is different from the cross-sectional shapes of second Micro LED chips capable of emitting a second color, a step of dumping the Micro LED chips on a loading surface of a loading mold at one time, wherein the loading surface is provided with loading slots with first shapes matched with the shapes of the first Micro LED chips and second shapes matched with the shapes of the second Micro LED chips, and a step of vibrating the loading mold and allowing the Micro LED chips to fall into the matched loading slots, and tilting the loading mold such that Micro LED chips that do not fall into the loading slots leave the loading surface. The mass transfer method proposed by the invention can realize the mass transfer process of a plurality of Micro LED chips withdifferent colors at one time, and the high transfer yield can be ensured while the transfer efficiency is multiplied.

Owner:HEFEI XINSHENG OPTOELECTRONICS TECH CO LTD +1

Micro light emitting diode transfer substrate and method, display panel and preparation method

ActiveCN109449260ARealize batch transferSimplify the transfer processSolid-state devicesSemiconductor devicesProcess complexityLight-emitting diode

The invention discloses a micro light emitting diode transfer substrate and method, a display panel and a preparation method, and aims at simplifying the process complexity of micro light emitting diode preparation. The micro light emitting diode transfer substrate comprises a first substrate and an electrically induced deformation layer which is located on the first substrate, wherein the electrically induced deformation layer is used for ensuring that the thickness of the electrically induced deformation layer in a to-be-transferred area of a to-be-transferred micro light emitting diode is greater than the thickness of the electrically induced deformation layer in a not-to-be-transferred area corresponding to the micro light emitting diode.

Owner:BOE TECH GRP CO LTD

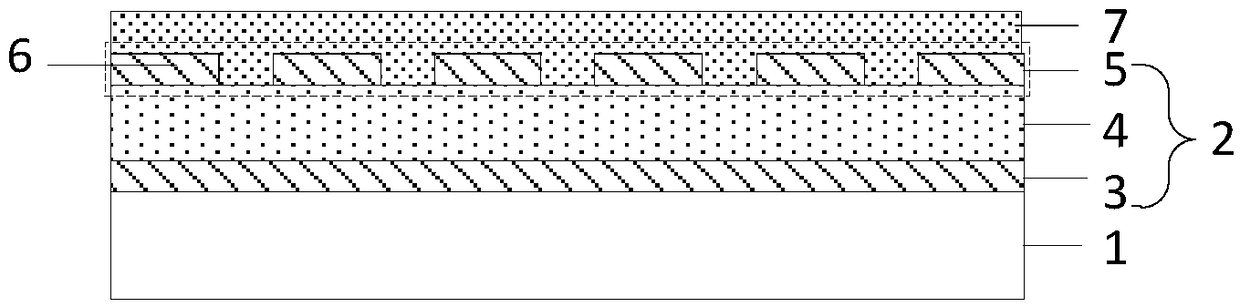

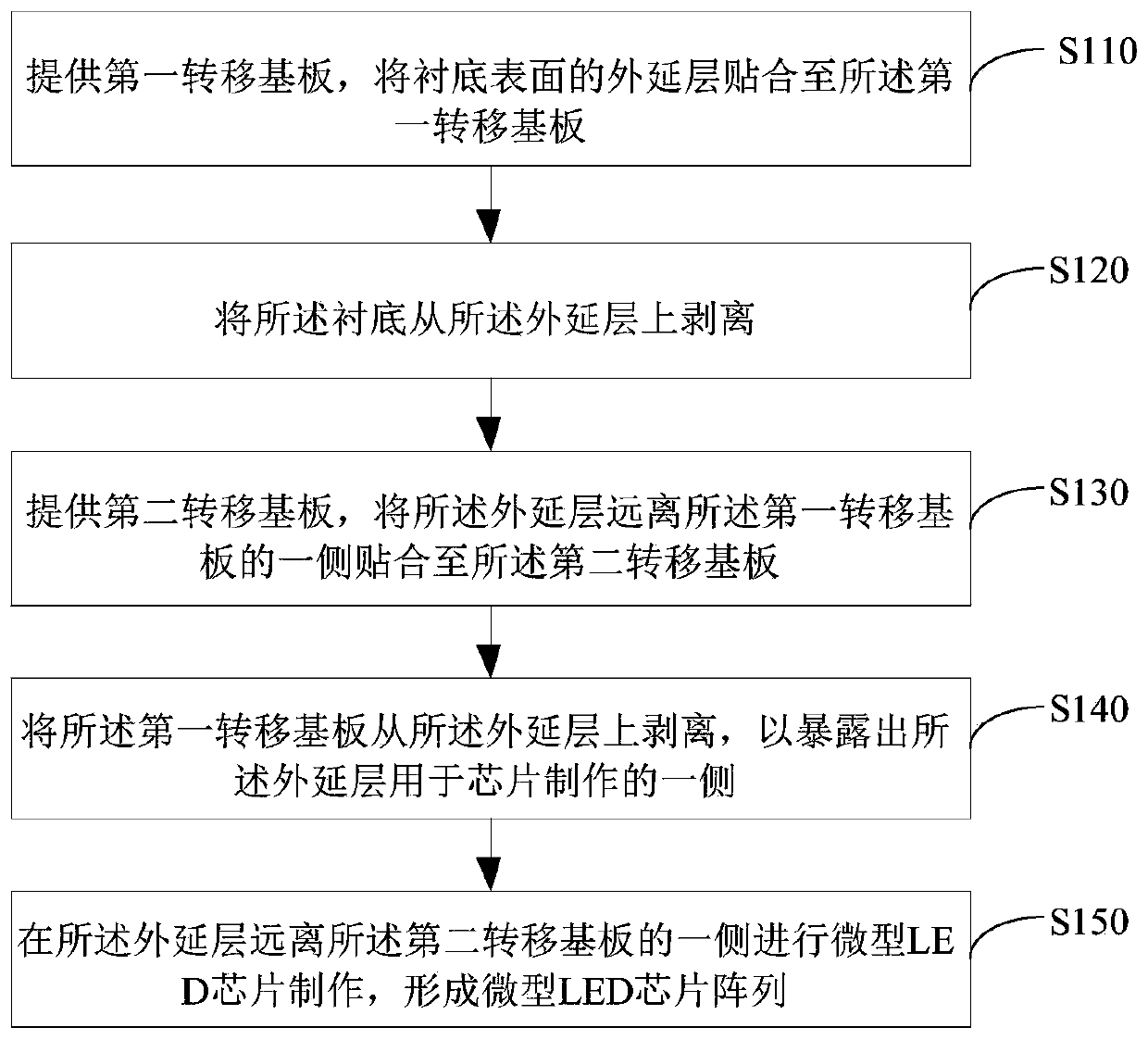

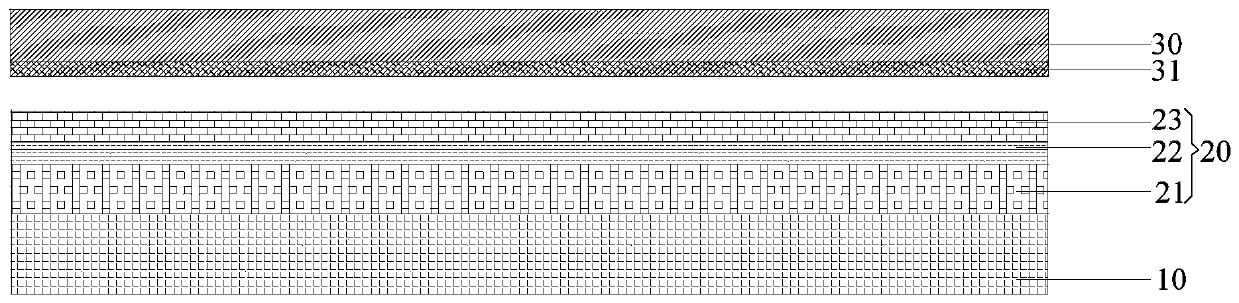

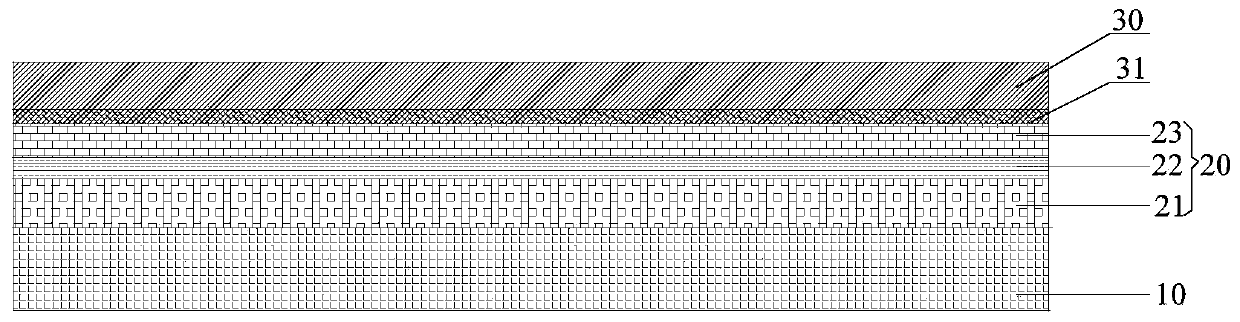

Miniature LED chip manufacturing method, miniature LED display device manufacturing method and miniature LED display device

InactiveCN110838503AAvoid chip displacement and lossImprove transfer yield and accuracySolid-state devicesSemiconductor devicesLED displayDisplay device

The embodiment of the invention provides a miniature LED chip manufacturing method, a miniature LED display device manufacturing method and a miniature LED display device. A first transfer substrate and a second transfer substrate are provided, an epitaxial layer on the surface of the substrate is firstly attached to the first transfer substrate, and the substrate is stripped from the epitaxial layer; one side, far away from the first transfer substrate, of the epitaxial layer is then attached to the second transfer substrate, the first transfer substrate is stripped from the epitaxial layer,and the side for chip manufacturing of the epitaxial layer is exposed; and finally, miniature LED manufacturing is carried out on one side, far away from the second transfer substrate, of the epitaxial layer to form a miniature LED chip array. Therefore, the problems of chip displacement and loss risks caused by transferring after chip manufacturing in a traditional mode are solved, and the transfer yield and accuracy are improved.

Owner:GUANGDONG INST OF SEMICON IND TECH

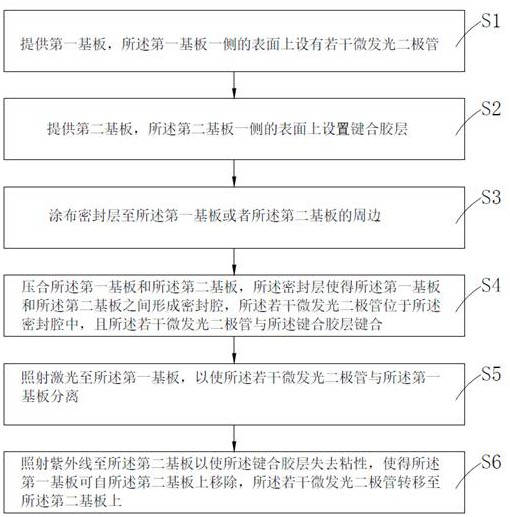

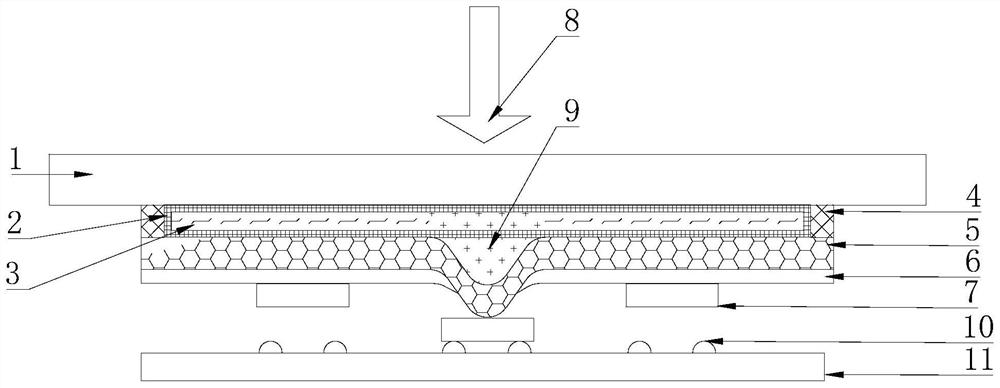

Micro light-emitting diode transfer method and display panel

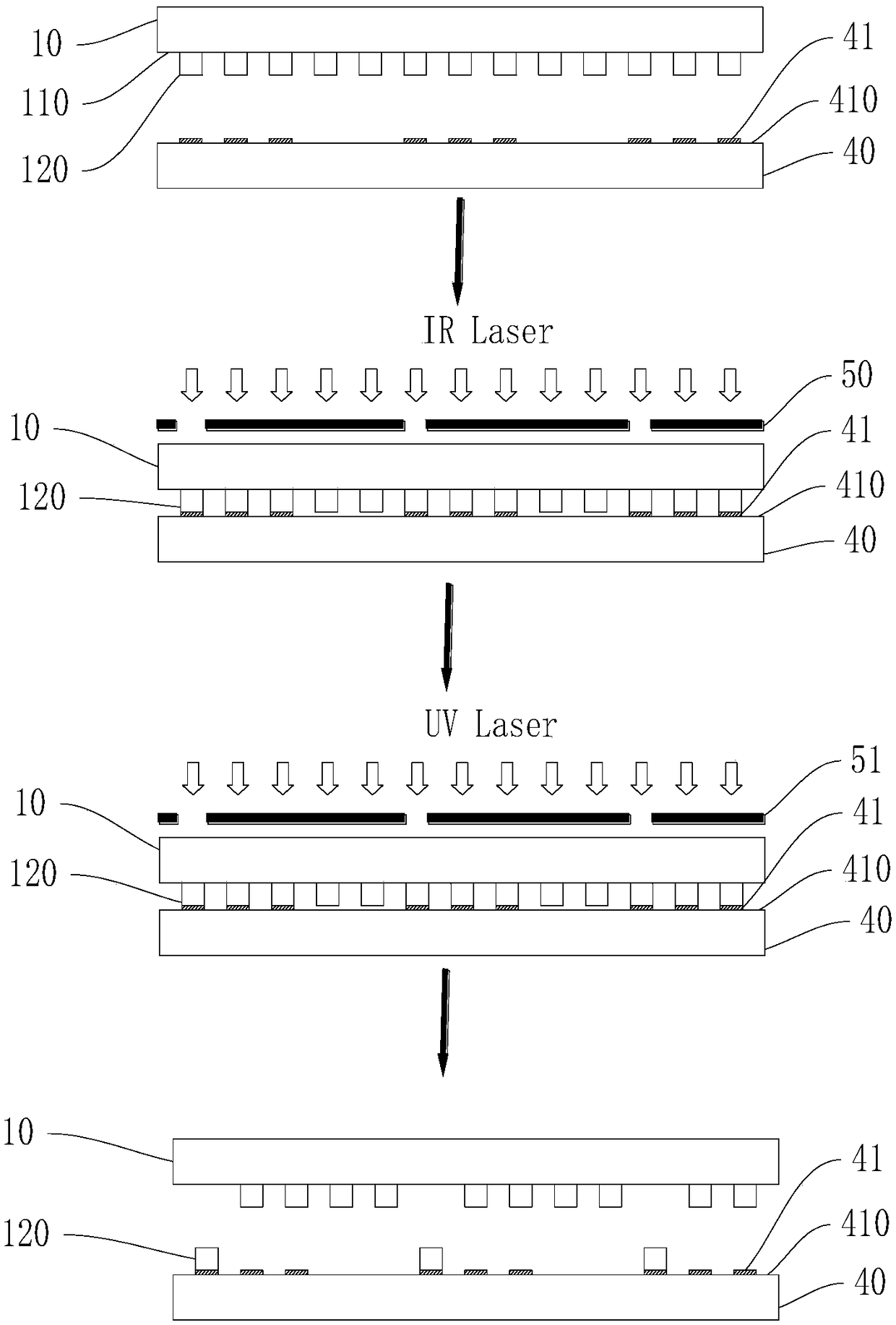

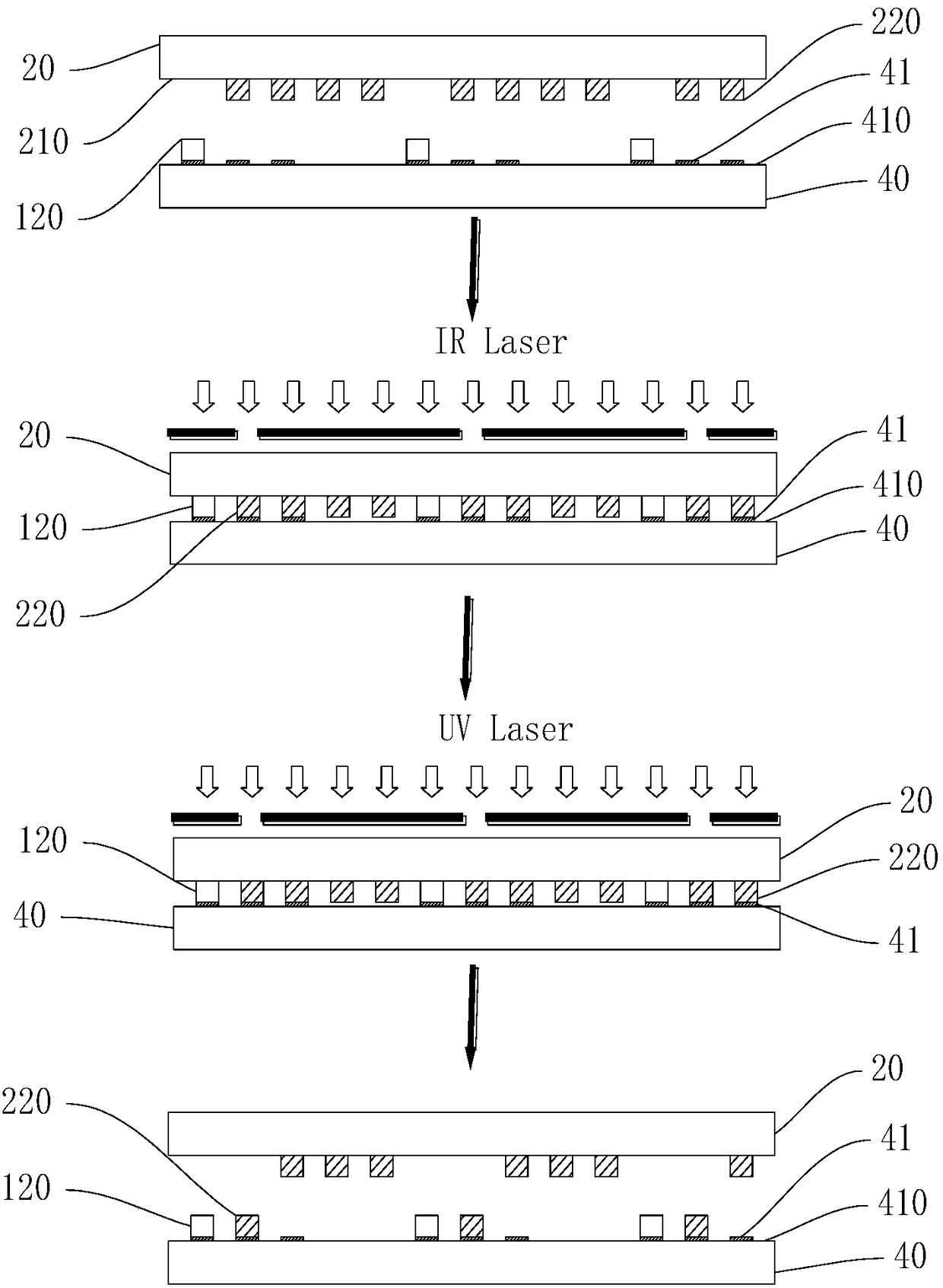

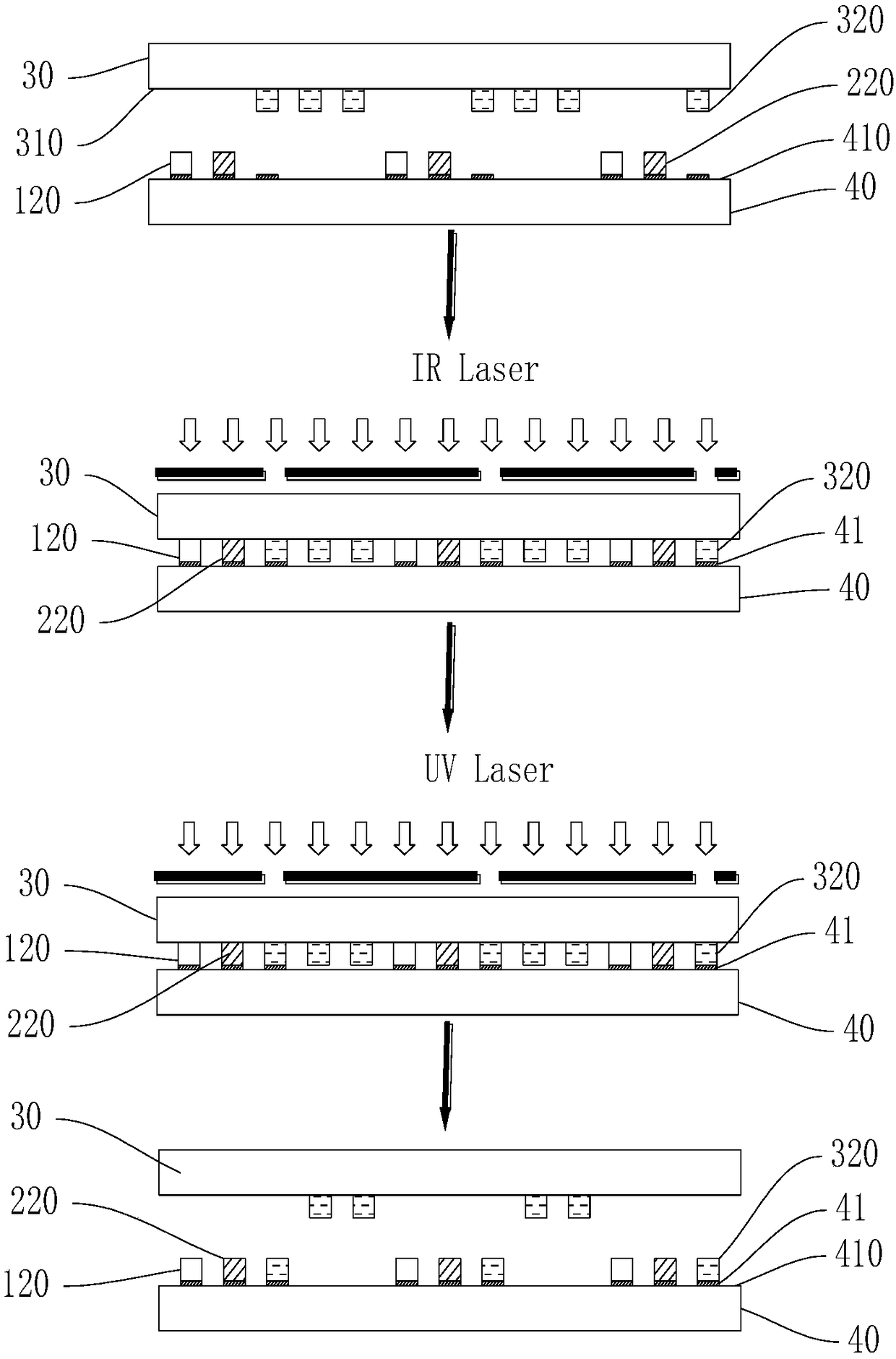

ActiveCN112582520AImprove transfer yieldImprove stabilitySolid-state devicesSemiconductor/solid-state device manufacturingEngineeringIrradiation laser

The invention provides a micro light-emitting diode transfer method and a display panel, and the method comprises the steps: S1, providing a first substrate, and arranging a plurality of micro light emitting diodes on the surface of one side of the first substrate; S2, providing a second substrate, wherein a bonding adhesive layer is arranged on the surface of one side of the second substrate; S2,coating a sealing layer to the periphery of the first substrate or the second substrate; S4, pressing the first substrate and the second substrate, enabling a sealing cavity to be formed between thefirst substrate and the second substrate through the sealing layer, enabling the plurality of micro light-emitting diodes to be located in the sealing cavity, and enabling the plurality of micro light-emitting diodes to be bonded with the bonding glue layer; S5, irradiating laser to the first substrate to separate the plurality of micro light emitting diodes from the first substrate; and S6, irradiating ultraviolet rays to the second substrate to enable the bonding adhesive layer to lose viscosity, so that the first substrate can be removed from the second substrate, and the plurality of microlight emitting diodes are transferred to the second substrate.

Owner:苏州芯聚半导体有限公司

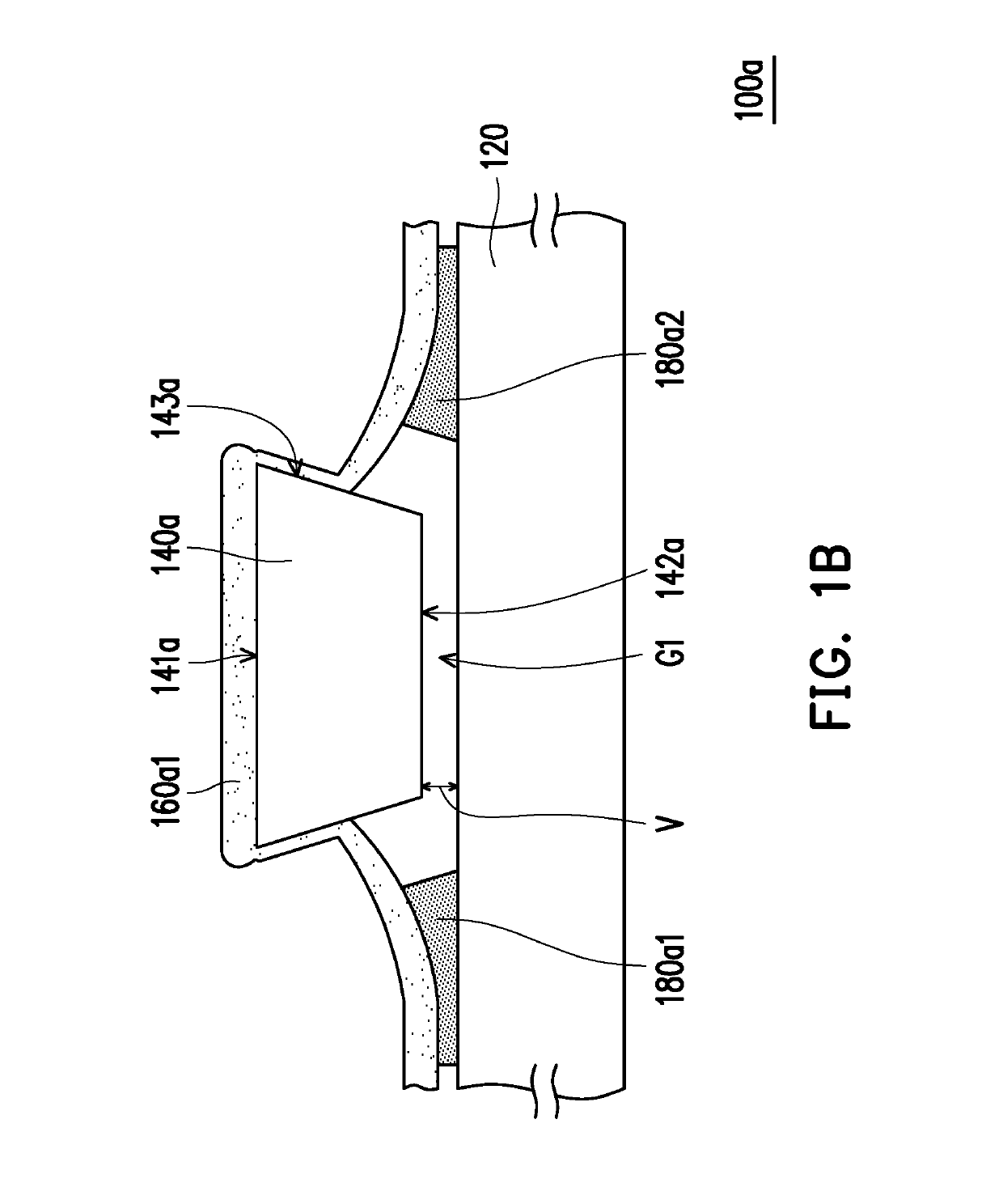

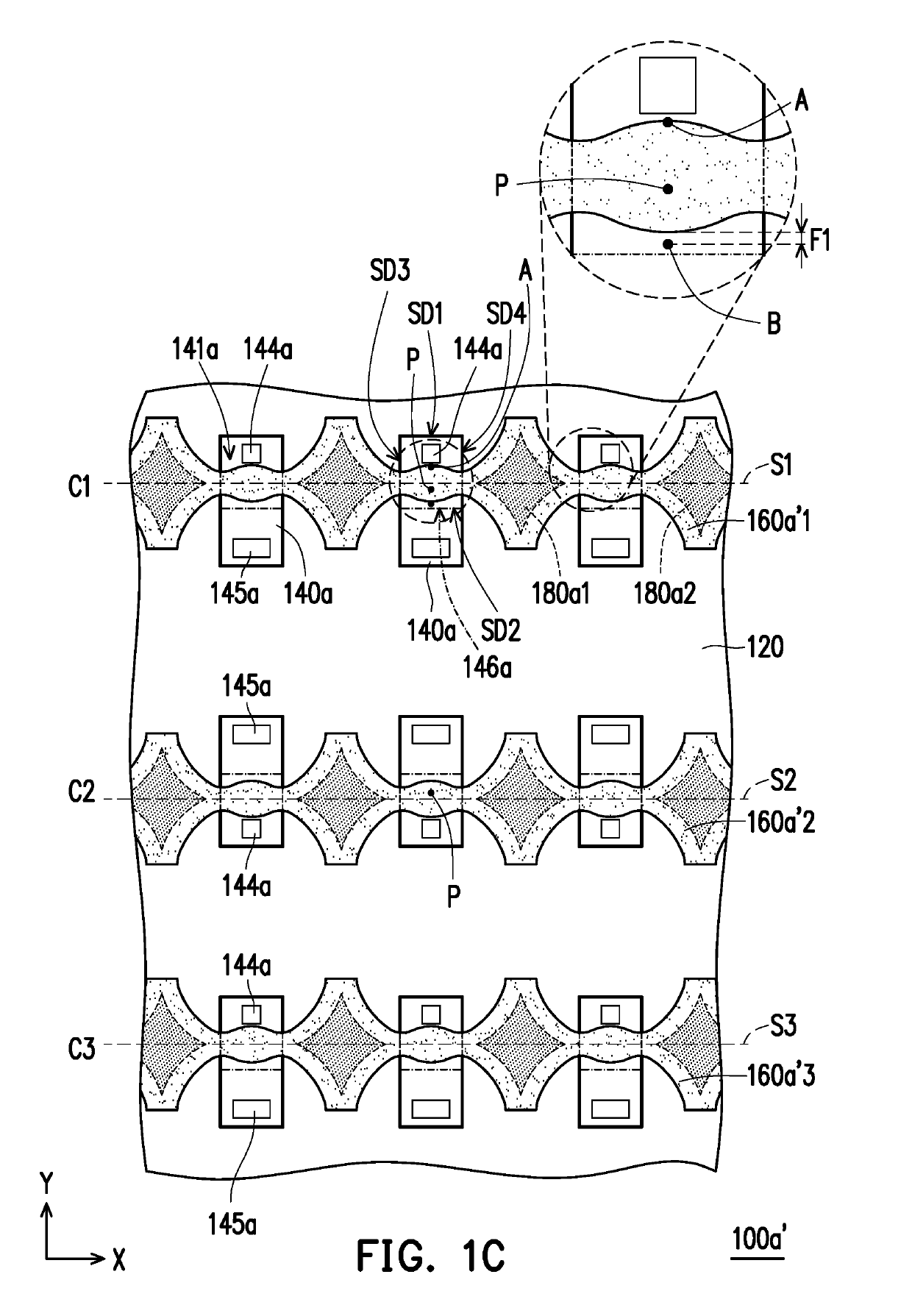

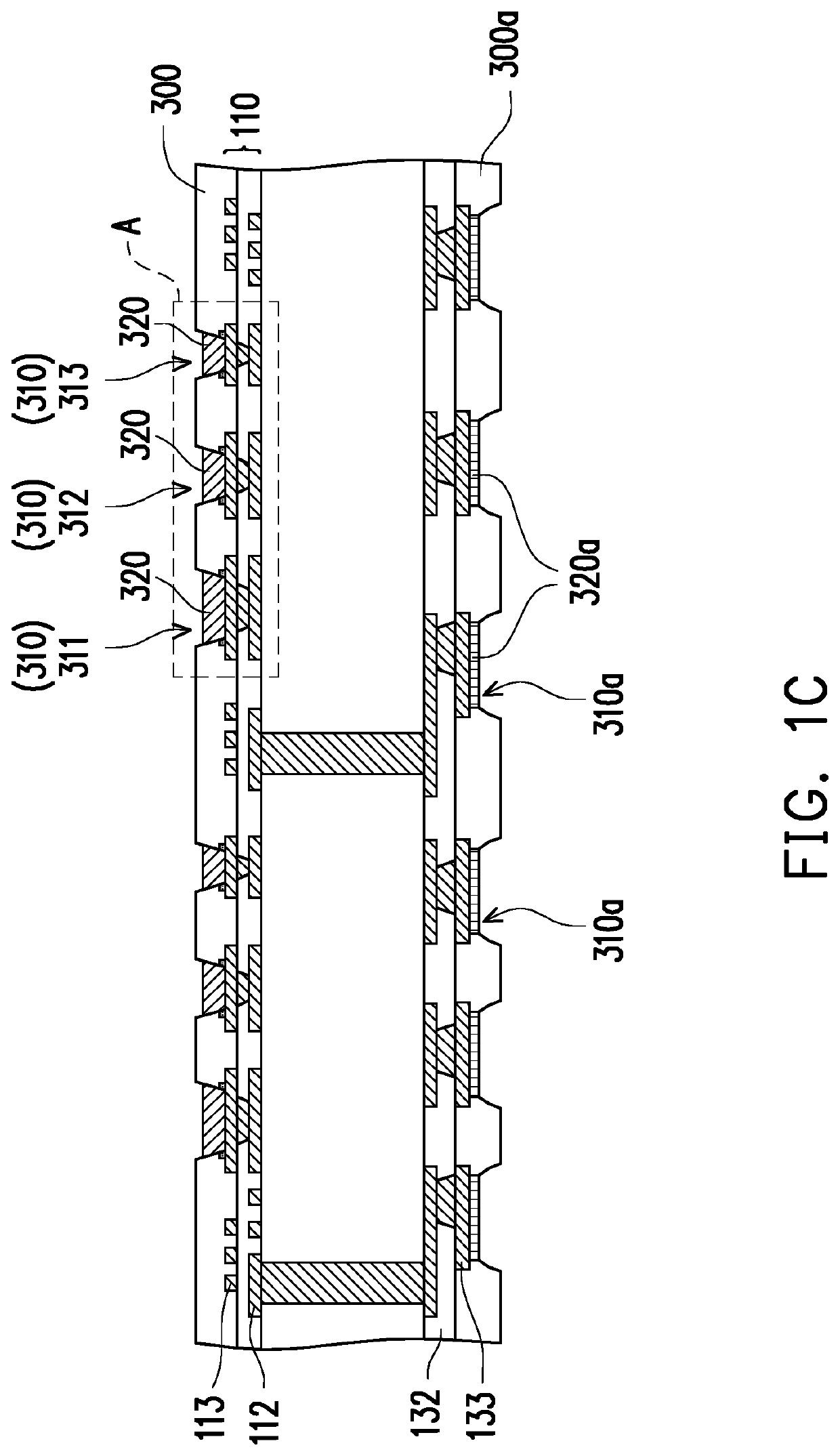

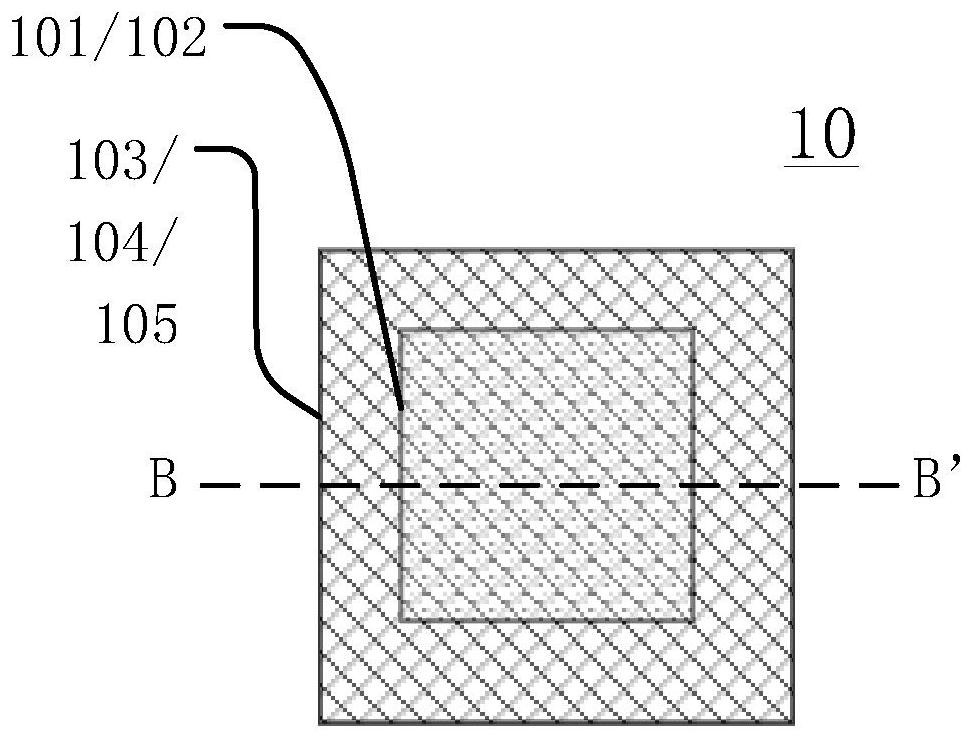

Structure with micro device

ActiveUS20190189602A1Improve transfer yieldSolid-state devicesSemiconductor/solid-state device manufacturingMicro devicesBiomedical engineering

A structure with micro device includes a substrate, a plurality of micro devices, and a plurality of holding structures. The micro devices are disposed on the substrate and arranged in multiple rows. Each of the micro devices has a top surface. The holding structures are respectively disposed on the top surface of each of the micro devices and extend to the substrate. Distances between the holding structure on the micro devices on any one of the rows and the holding structures on the micro devices on two adjacent rows are different.

Owner:PLAYNITRIDE

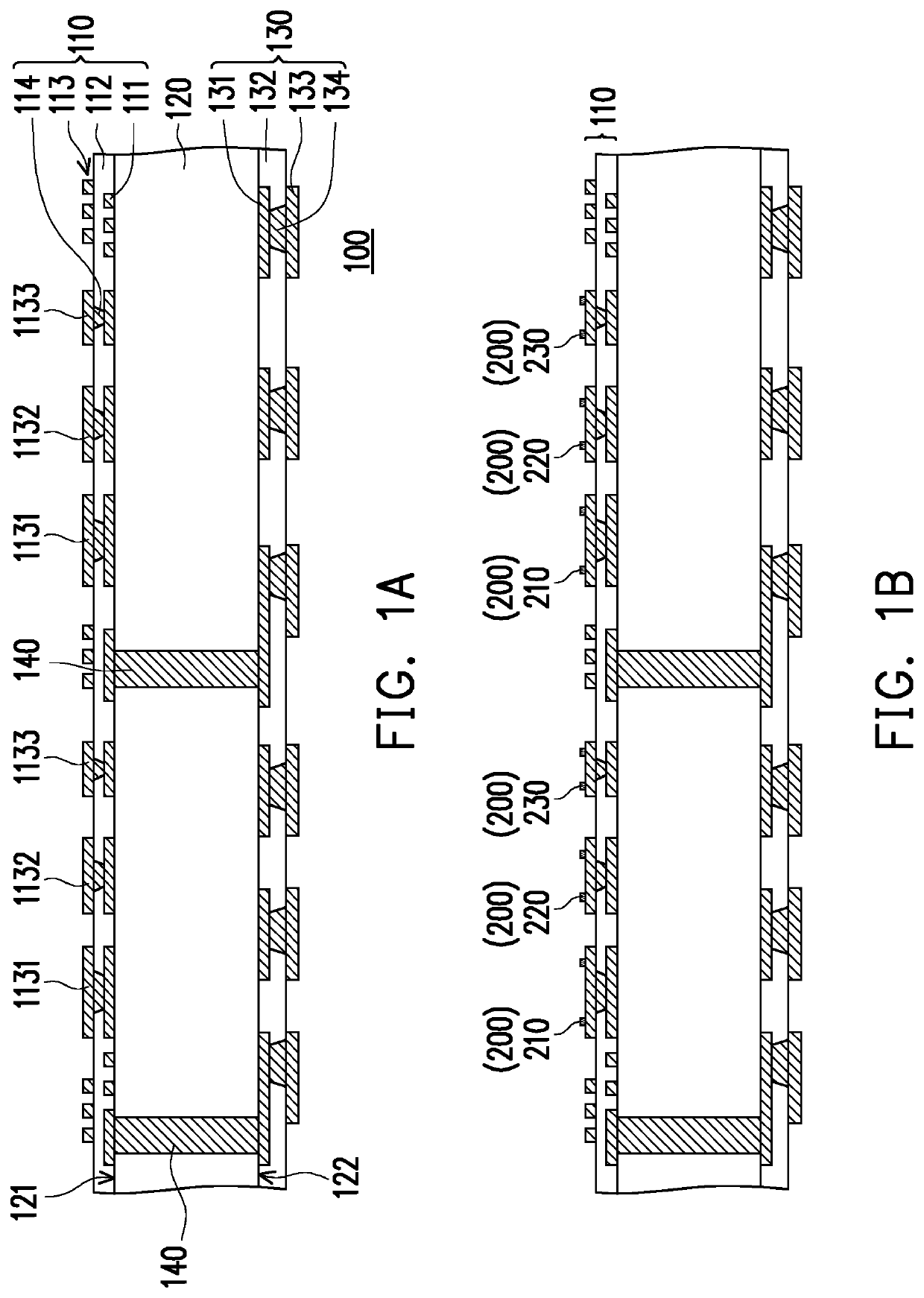

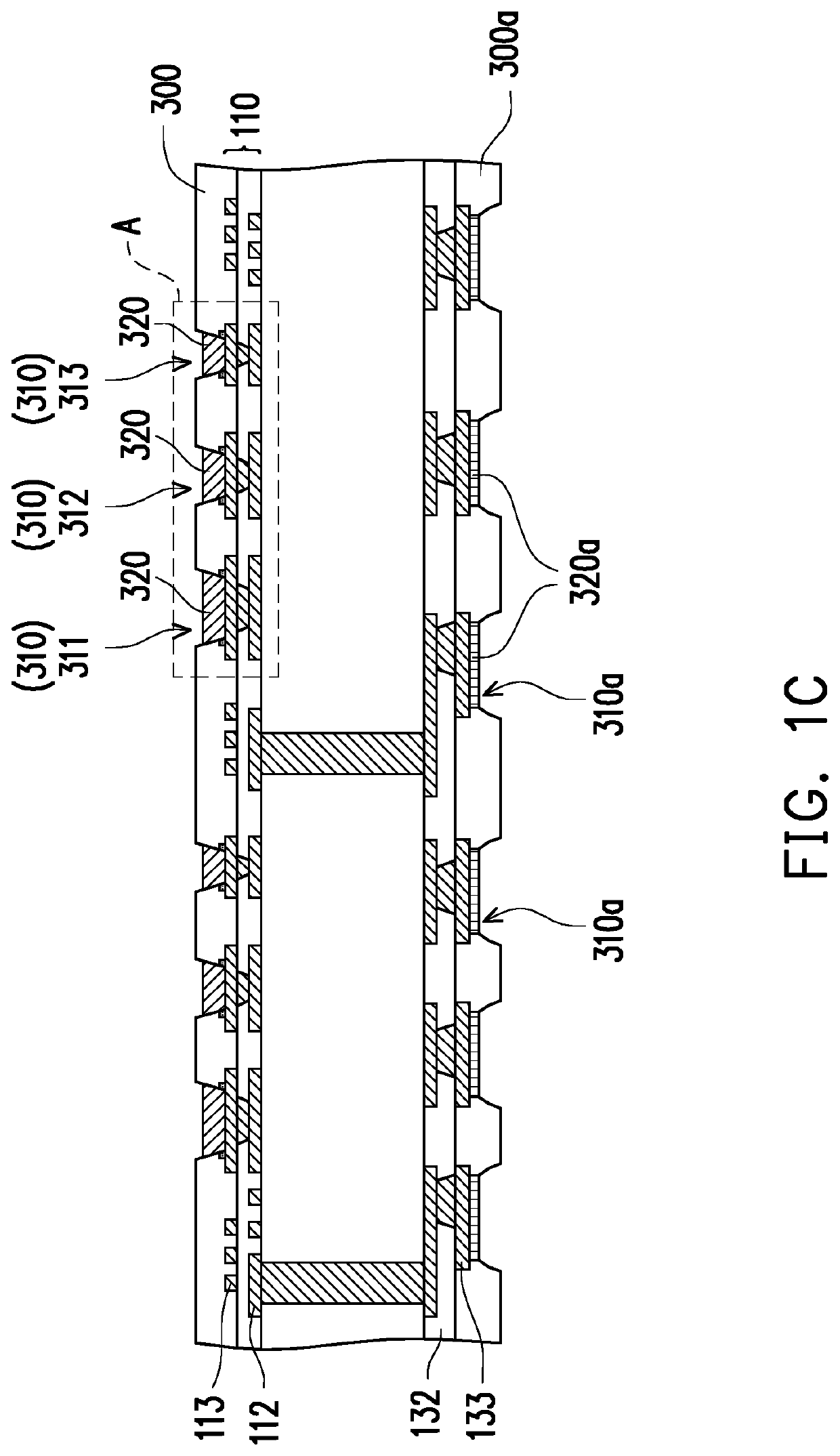

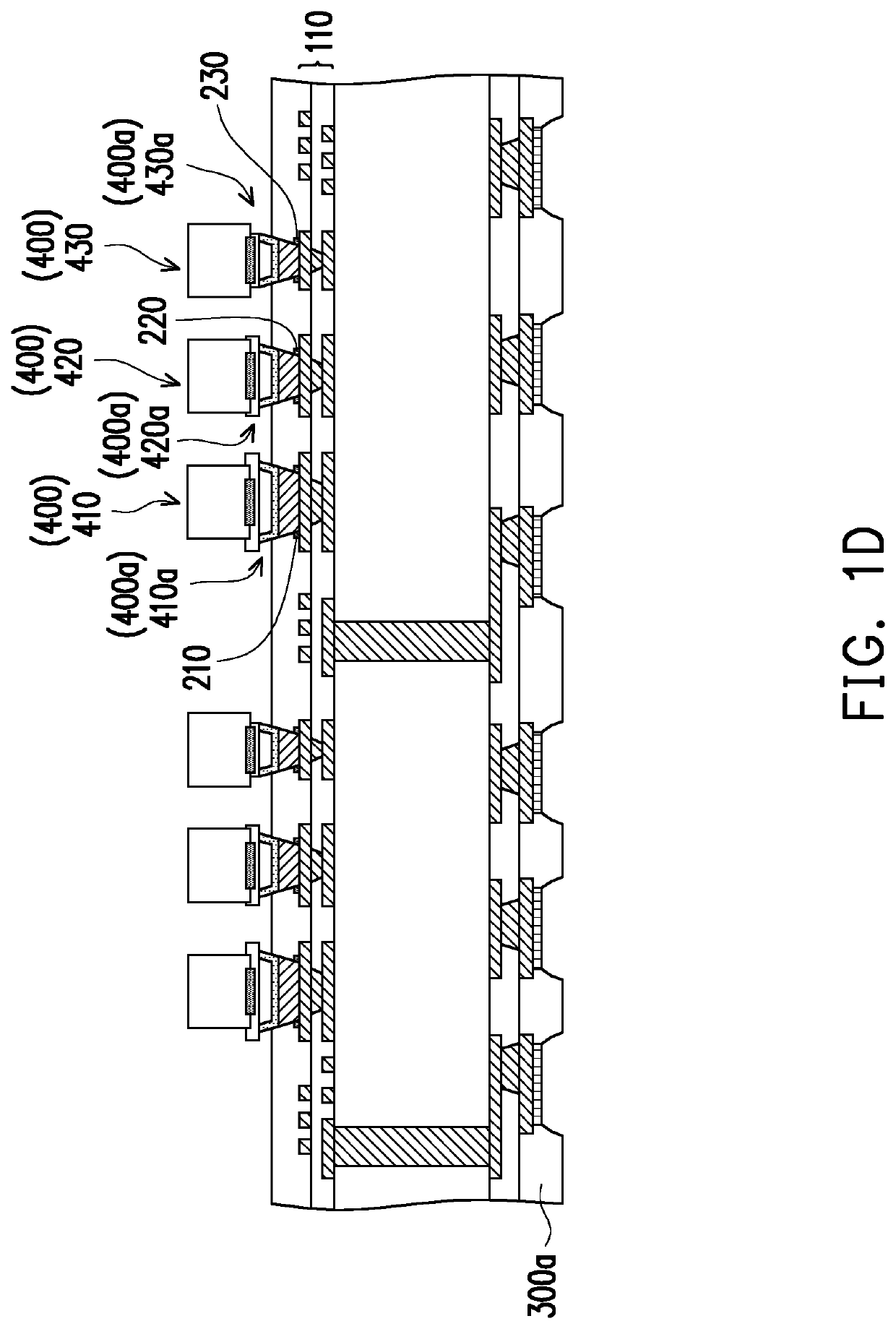

Light-emitting diode package structure and manufacturing method thereof

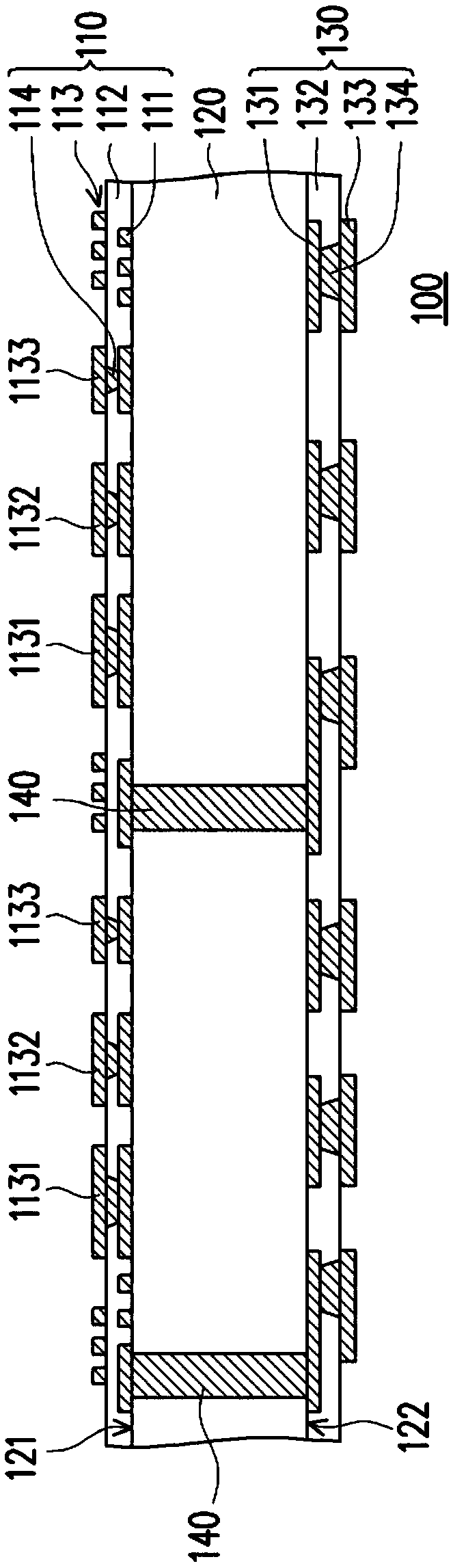

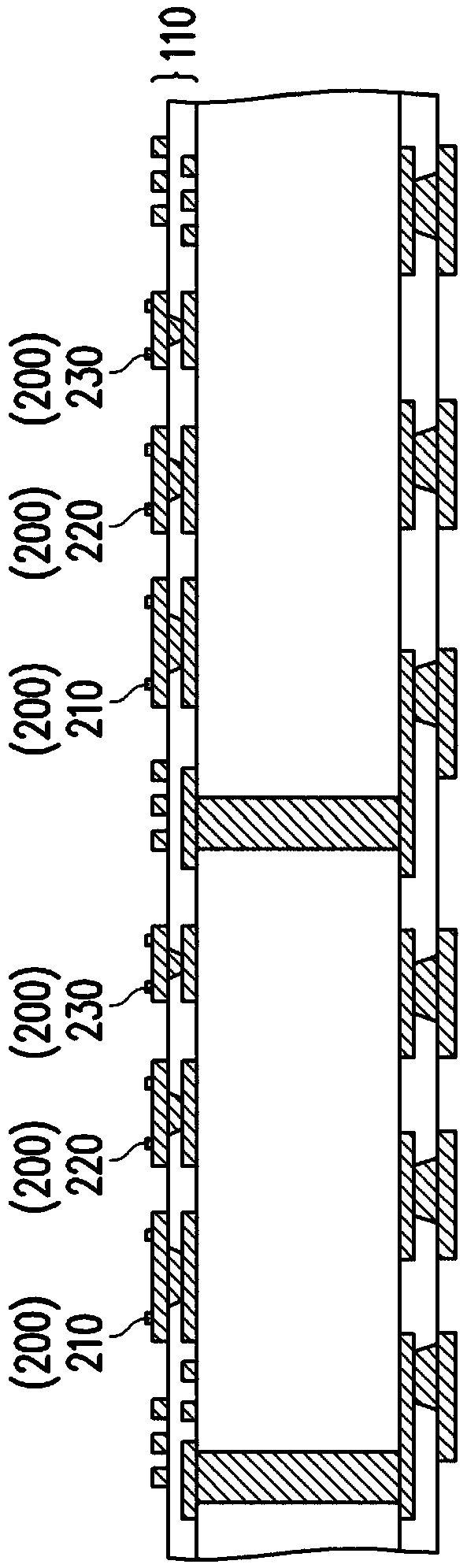

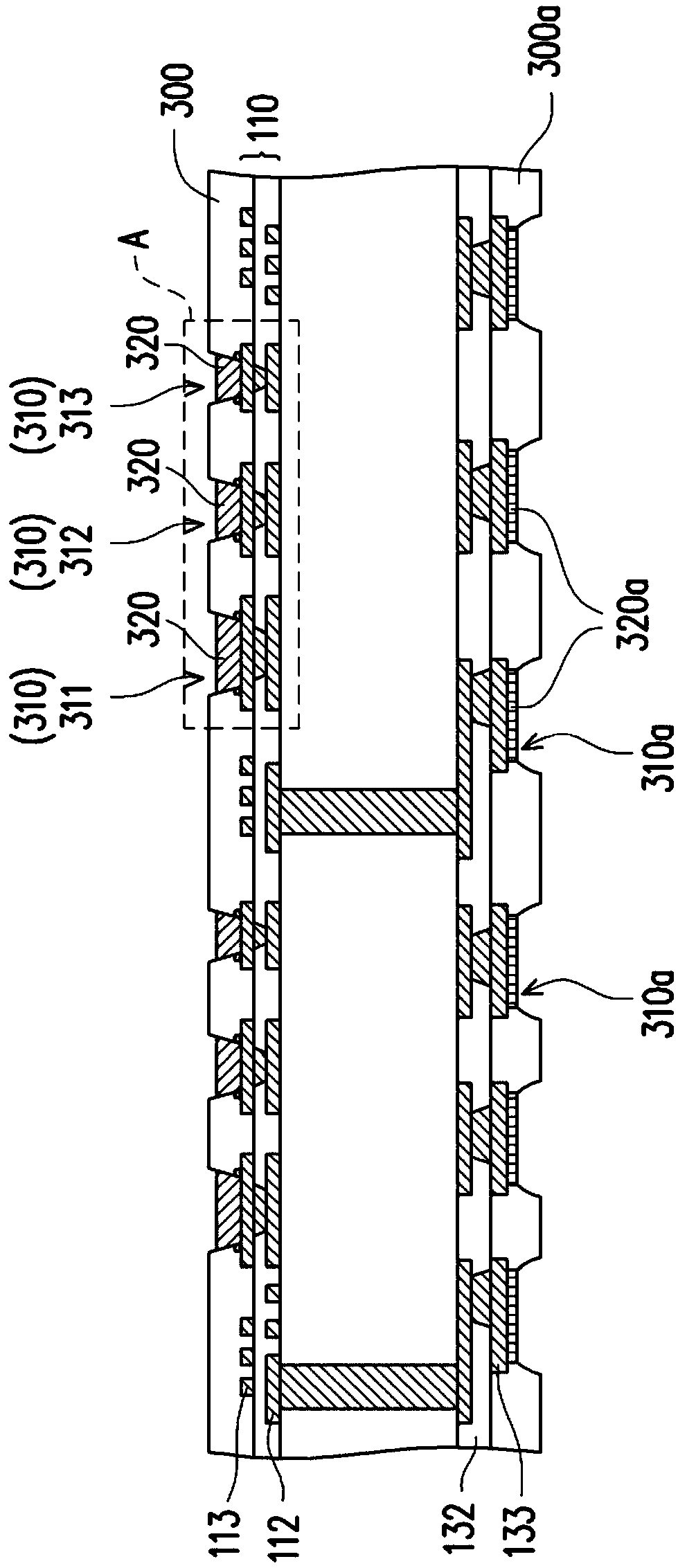

ActiveUS20200075564A1Serious problemImprove transfer yieldFinal product manufactureSemiconductor/solid-state device detailsSolder maskSelf assemble

A light-emitting diode package structure includes a carrier, at least one self-assembled material layer, a first solder mask layer, and at least one light-emitting diode. The carrier includes a first build-up circuit. The self-assembled material layer is disposed on the first build-up circuit. The first solder mask layer is disposed on the first build-up circuit. The first solder mask layer has at least one opening to expose a portion of the self-assembled material layer. The light-emitting diode is disposed on the first build-up circuit. The light-emitting diode has a self-assembled pattern. The light-emitting diode is self-assembled into the opening of the first solder mask layer through a force between the self-assembled pattern and the self-assembled material layer. A manufacturing method of the light-emitting diode package structure is also provided.

Owner:UNIMICRON TECH CORP

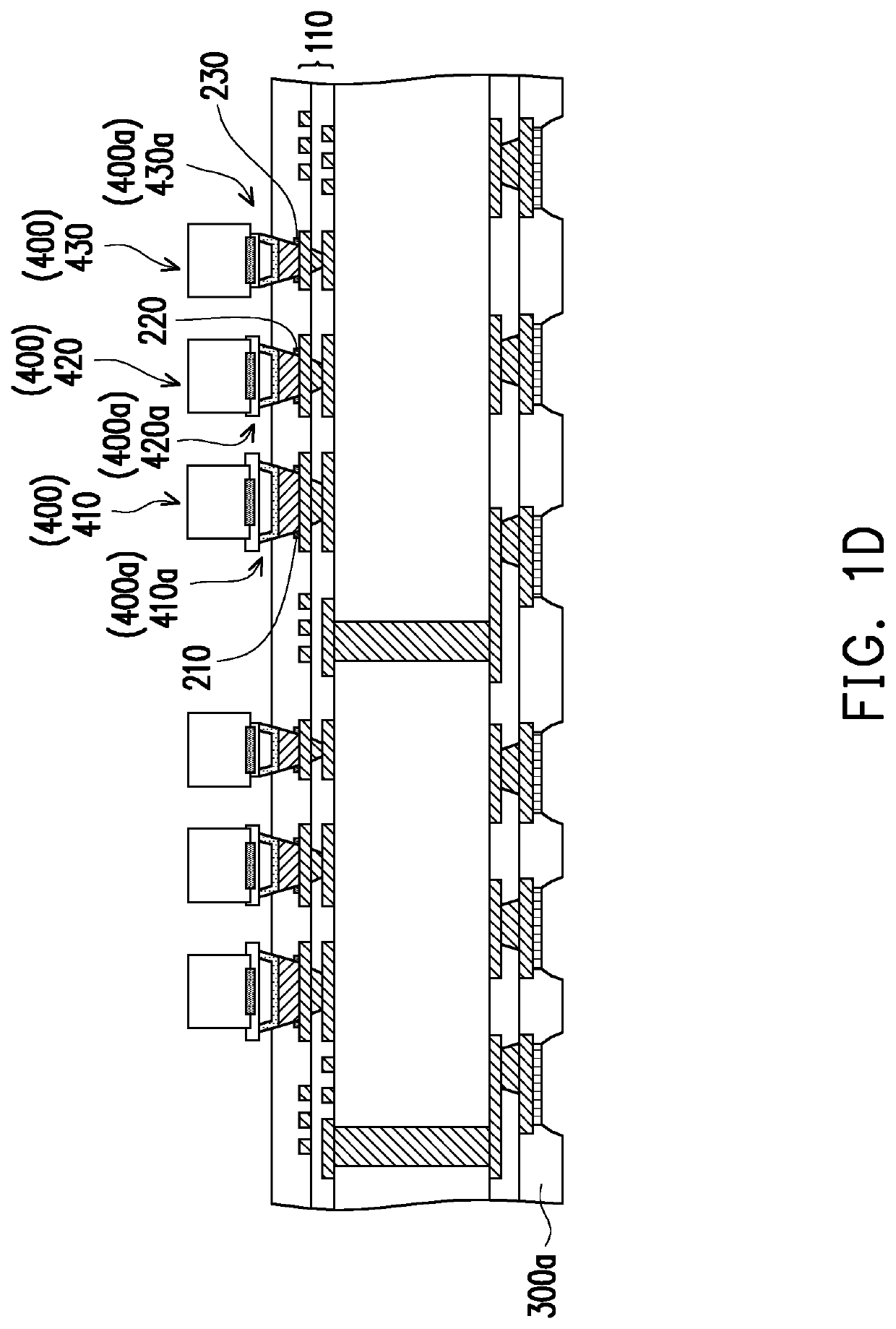

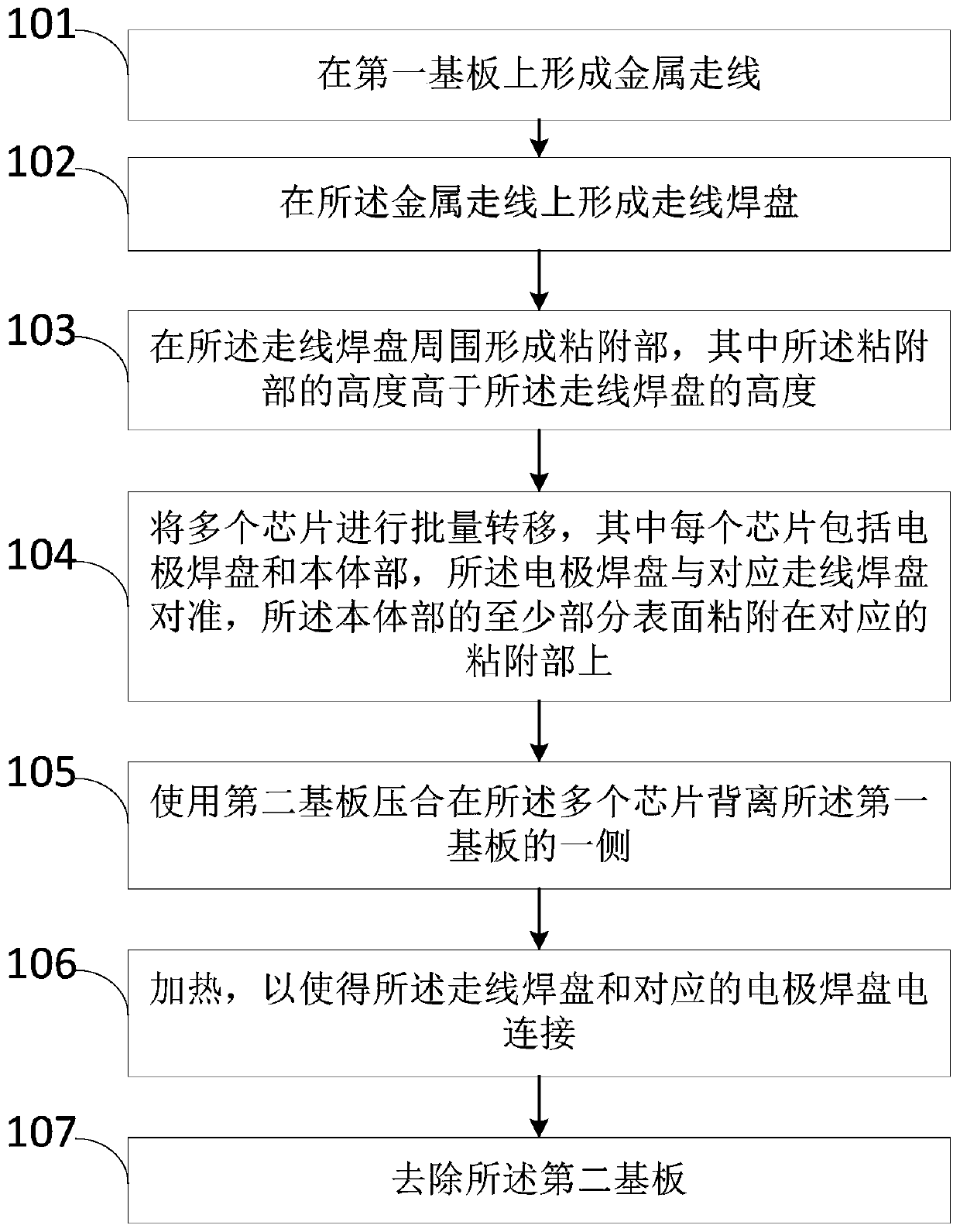

Chip transfer method and semiconductor device

ActiveCN110783254ALow costThe principle is clearSolid-state devicesSemiconductor/solid-state device manufacturingDevice materialElectrical connection

The invention discloses a chip transfer method, which includes the following steps: forming a metal wire on a first substrate; forming a wire bonding pad on the metal wire; forming an adhesive portionaround the wire bonding pad, wherein the height of the adhesive portion is greater than the height of the wire bonding pad; transferring a plurality of chips in batches, wherein each chip includes anelectrode bonding pad and a body portion, the electrode bonding pad is aligned to the corresponding wire bonding pad, and at least a part of the surface of the body portion is attached to the corresponding adhesive portion; pressing a second substrate against the sides of the plurality of chips away from the first substrate; performing heating to electrically connect the wire bonding pad to the corresponding electrode bonding pad; and removing the second substrate. The method solves the bonding problem when the chips are transferred to the substrate, can not only reduce the technical threshold and cost of a transfer device, but also can improve the transfer yield without an increase in cost.

Owner:BOE TECH GRP CO LTD

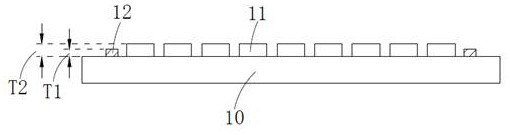

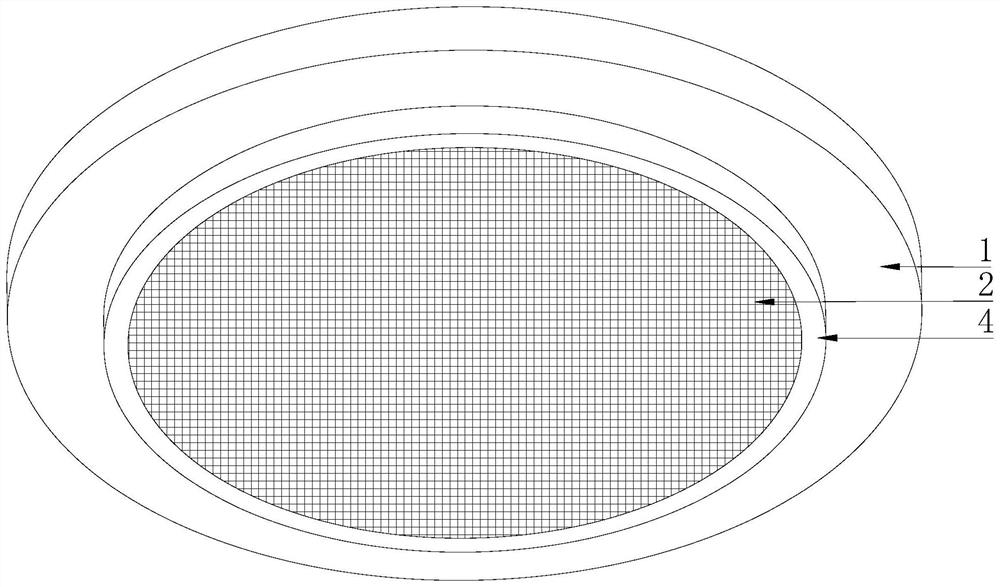

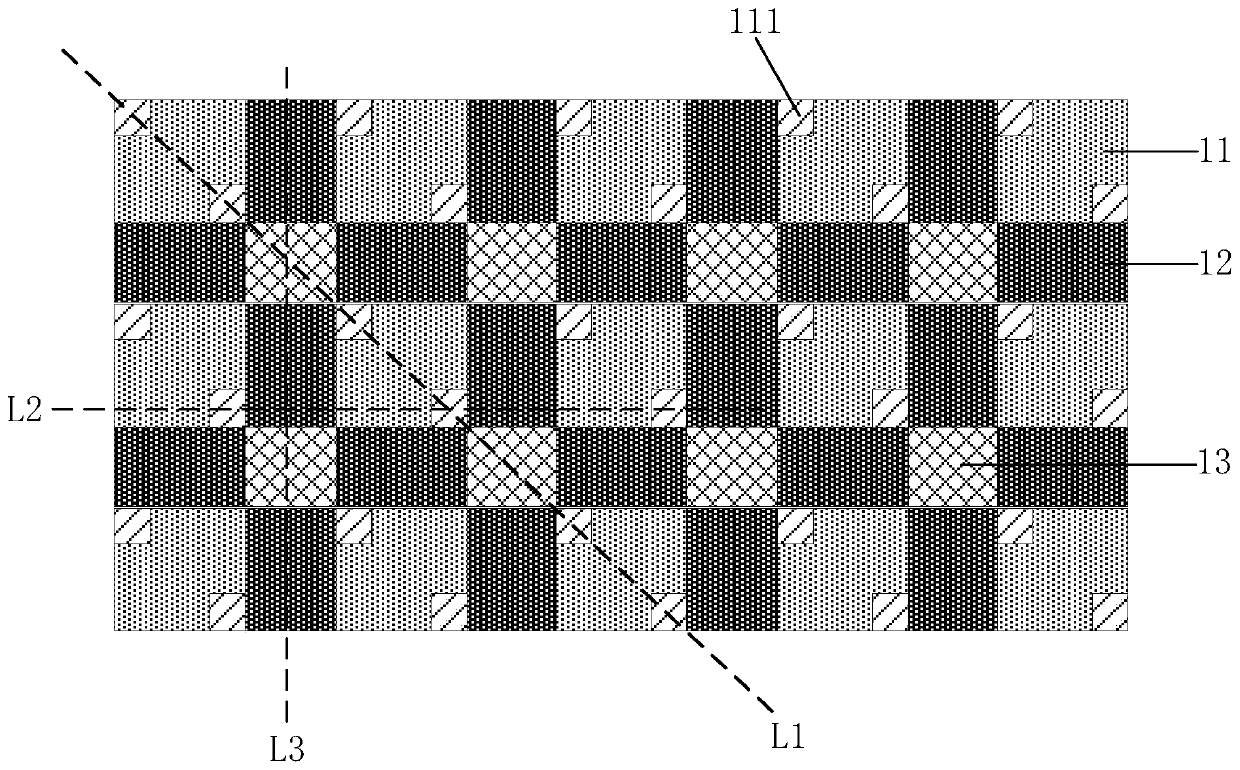

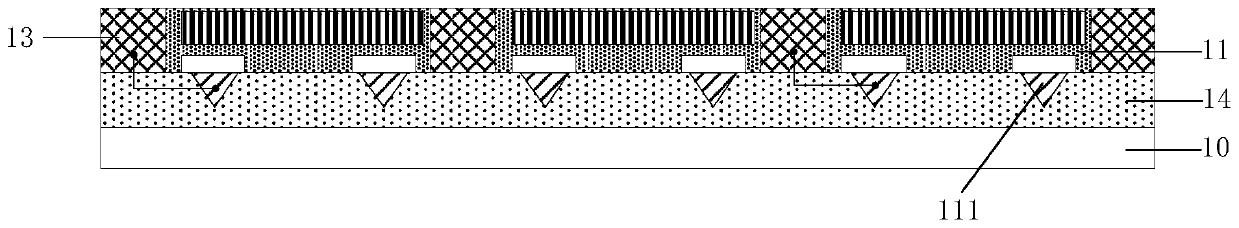

Pixel arrangement structure, =electroluminescent device and = display device

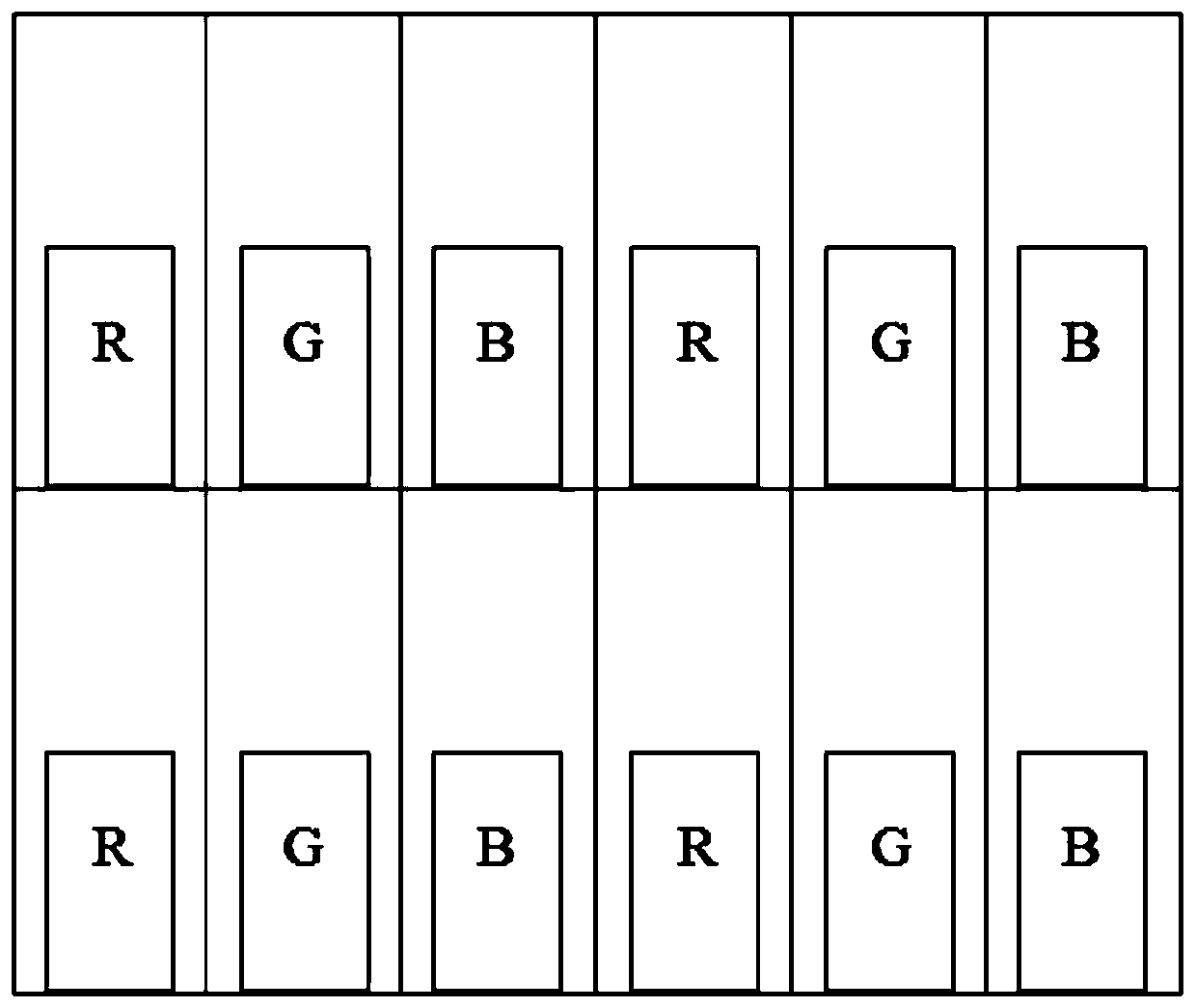

InactiveCN110998852AIncrease distanceHigh resolutionSolid-state devicesSemiconductor devicesImage resolutionEngineering

The invention provides a pixel arrangement structure, an electroluminescent device and a display device, and the pixel arrangement structure comprises a plurality of pixel groups, each pixel group comprises a plurality of pixels, and the adjacent pixels in each pixel group are arranged in an up-and-down staggered manner. According to the array substrate, the pixels are divided into the plurality of pixel groups, the adjacent pixels in each pixel group are arranged in an up-down staggered manner, and the shapes and the long axis directions of the pixels are changed, so that the distance betweenthe adjacent pixels in a single pixel group is increased; by arranging the sub-pixel groups in mirror symmetry, the pixel distance between the adjacent pixel groups is increased, the LED transfer yield is improved, and the requirements of small-size and high-resolution electroluminescent display devices can be met.

Owner:CHONGQING KONKA PHOTOELECTRIC TECH RES INST CO LTD

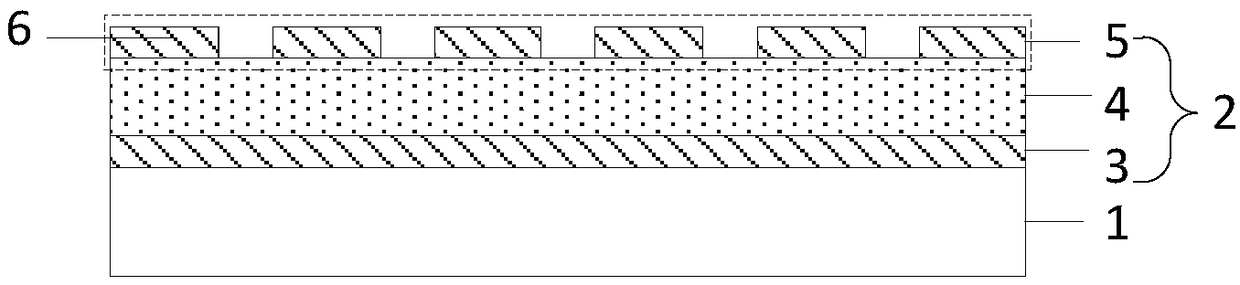

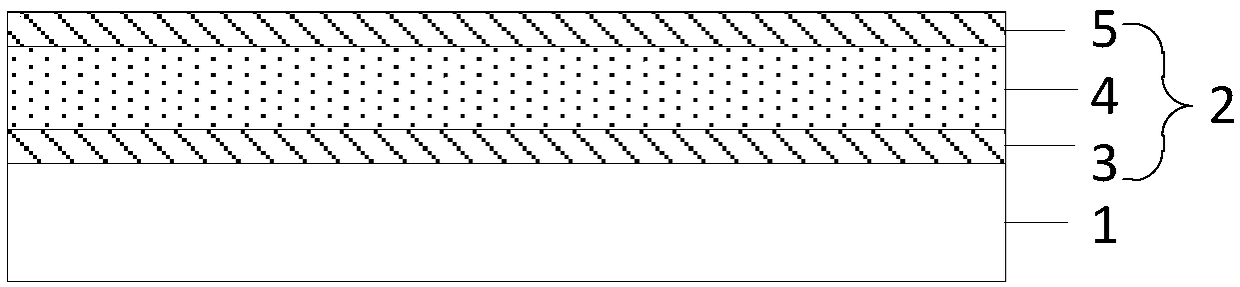

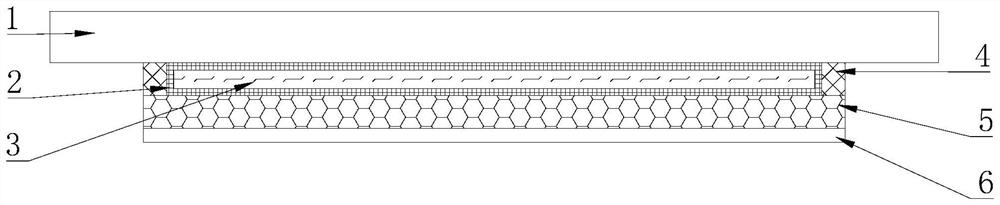

Liquid-gas dual-state Mini/Micro LED chip mass transfer crystal film and manufacturing method thereof

PendingCN114709163AAvoid uneven viscosity variationAvoid uneven forceSolid-state devicesSemiconductor/solid-state device manufacturingPhysical chemistryGas bubble

The invention discloses a liquid-gas dual-state Mini / Micro LED chip mass transfer crystal film and a manufacturing method thereof. The liquid-gas dual-state Mini / Micro LED chip mass transfer crystal film comprises a substrate, a medium storage grid, a liquid-gas dual-state medium, a sealant, an elastic layer and a bonding layer, by means of the characteristics that a liquid-gas dual-state medium is easy to heat and low in boiling point and the viscosity of a bonding layer is obviously reduced after being heated, laser matched with an absorption pattern of the liquid-gas dual-state medium penetrates through a substrate to irradiate the liquid-gas dual-state medium so that the liquid-gas dual-state medium can be gasified to generate bubbles, a chip is pushed to be transferred to a target substrate, and mass transfer of the chip is achieved. Compared with the existing heat release and ablation release, the method has the advantages that the repeated utilization of the crystal film and the high-precision mass transfer of the chip can be realized under the conditions of environment-friendly temperature and no pollutant generation.

Owner:BEIJING INSTITUTE OF PETROCHEMICAL TECHNOLOGY

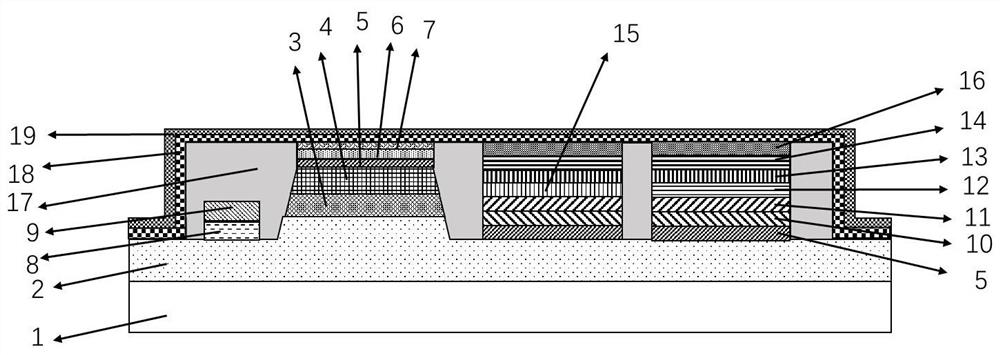

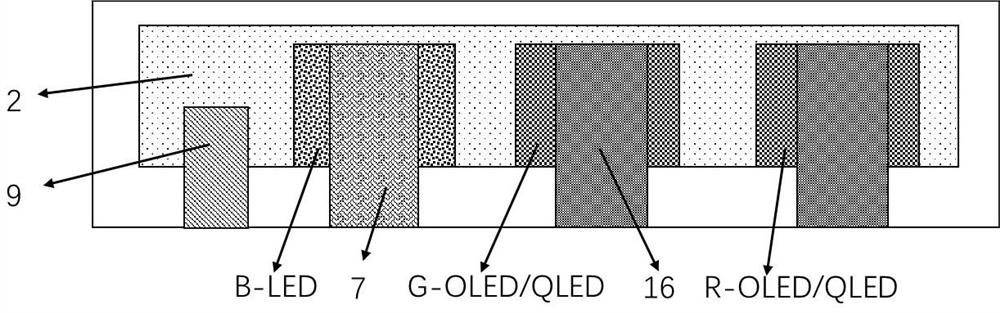

Integrally packaged micro-display chip and preparation method thereof

PendingCN113299678AImprove transfer yieldImprove convenienceSolid-state devicesSemiconductor/solid-state device manufacturingEngineeringGreen-light

The invention relates to an integrated packaging micro display chip, and the chip is characterized in that the chip comprises a substrate, a blue light Micro-LED sub-pixel, a red light Micro-OLED or Micro-QLED sub-pixel and a red light Micro-OLED or Micro-QLED sub-pixel; an n electrode of the Micro-LED sub-pixel is connected with one electrode of the Micro-OLED or the Micro-QLED, and a p electrode of the Micro-LED sub-pixel, the other electrode of the red light Micro-OLED or the Micro-QLED and the other electrode of the green light Micro-OLED or the Micro-QLED are respectively led out to form four leading-out electrodes of the integrated packaging micro-display chip. According to the invention, a blue light Micro-LED sub-pixel, a red light Micro-OLED or Micro-QLED sub-pixel, and a green light Micro-OLED or Micro-QLED sub-pixel are combined, and a micro-display pixel chip with a larger size and controllable luminescence of three primary colors is formed through wafer-level integration and packaging.

Owner:FUZHOU UNIV +1

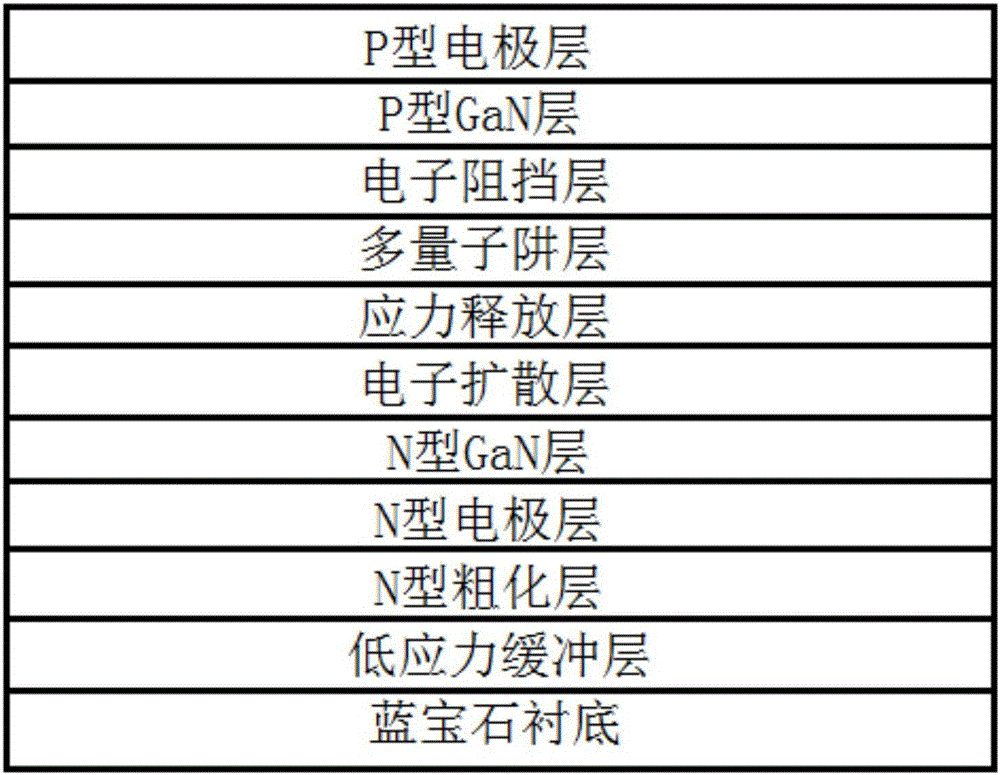

LED purple light epitaxial structure of vertical structure and preparation method thereof

ActiveCN106129197ALarge adjustment rangeReduce carrier wavefunction mismatchSemiconductor devicesP type dopingOff time

The invention discloses an LED purple light epitaxial structure of a vertical structure and a preparation method thereof. The preparation method comprises the following steps: using ammonia gas, high-purity trimethyl indium (TMIn), TMAl, TEGa and high-purity trimethyl gallium (TMGa) as sources respectively, using SiH4 and Cp2Mg as an n-type doping agent and a p-type doping agent respectively, using hydrogen or nitrogen as carrier gas, introducing the carrier gas into a reaction chamber to perform a chemical reaction with the ammonia gas at the temperature of 900-1100 DEG C, generating a three-five compound semiconductor, and depositing on sapphire, a silicon wafer, a silicon carbide sheet or a quartz glass sheet according to a certain lattice sequence to prepare the epitaxial structure. The components, doping concentration, thickness and the like of the epitaxial layer can be controlled by accurately controlling the flow and on-off time of a gas source, the regulating range of growth rate is relatively wide, and the relatively high growth rate can be applicable to batch growth.

Owner:CHINA UNITED NORTHWEST INST FOR ENG DESIGN & RES

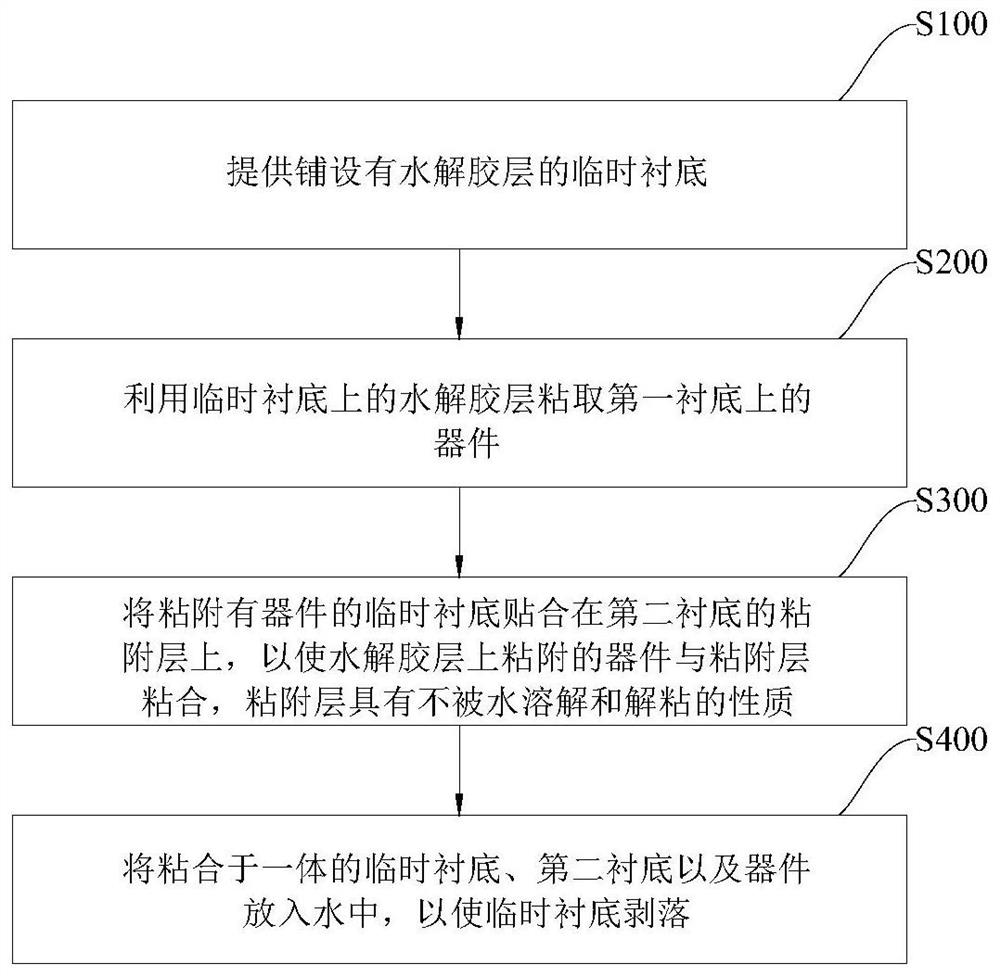

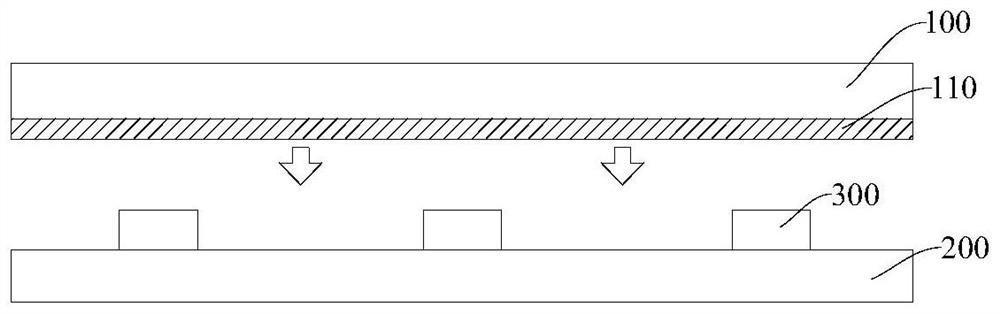

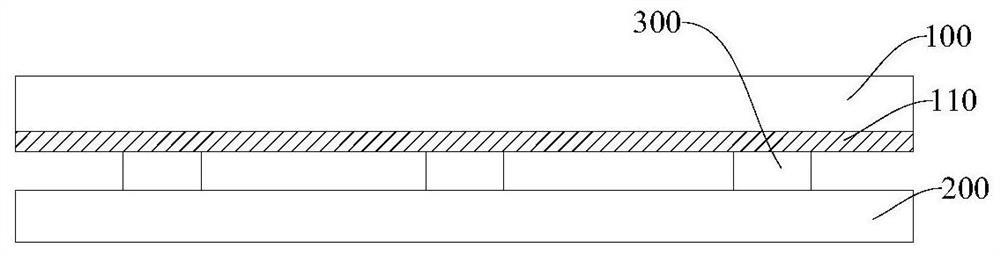

Device transfer method

PendingCN112701077AImprove transfer efficiencyTroubleshoot problems left on temporary substratesSolid-state devicesSemiconductor/solid-state device manufacturingAdhesiveSemiconductor technology

The invention discloses a device transfer method, and relates to the technical field of semiconductors. According to the device transfer method provided by the invention, a device on a first substrate is bonded off by using a hydrolytic adhesive layer, and then the bonded device is bonded on the adhesive layer of a second substrate, so that the device bonded on the hydrolytic adhesive layer is bonded with the adhesive layer, and the adhesive layer has the property of being not dissolved and debonded by water. And finally, a temporary substrate, the second substrate and the device which are bonded into a whole are put into water, the hydrolytic adhesive layer is disssolved in water, and the temporary substrate is peeled off to obtain the second substrate to which the device is bonded, thereby completing the transfer of the device. According to the device transfer method provided by the invention, the hydrolytic adhesive is used as a transfer adhesive and can be completely removed after transfer, so that the problem that part of devices are left on the temporary substrate is solved, and the transfer yield is improved. And the hydrolytic adhesive can be applied to the temporary substrate in a large area coating manner, and large-area and large-quantity transfer can be realized, so that the transfer efficiency of the device is improved.

Owner:GUANGDONG INST OF SEMICON IND TECH

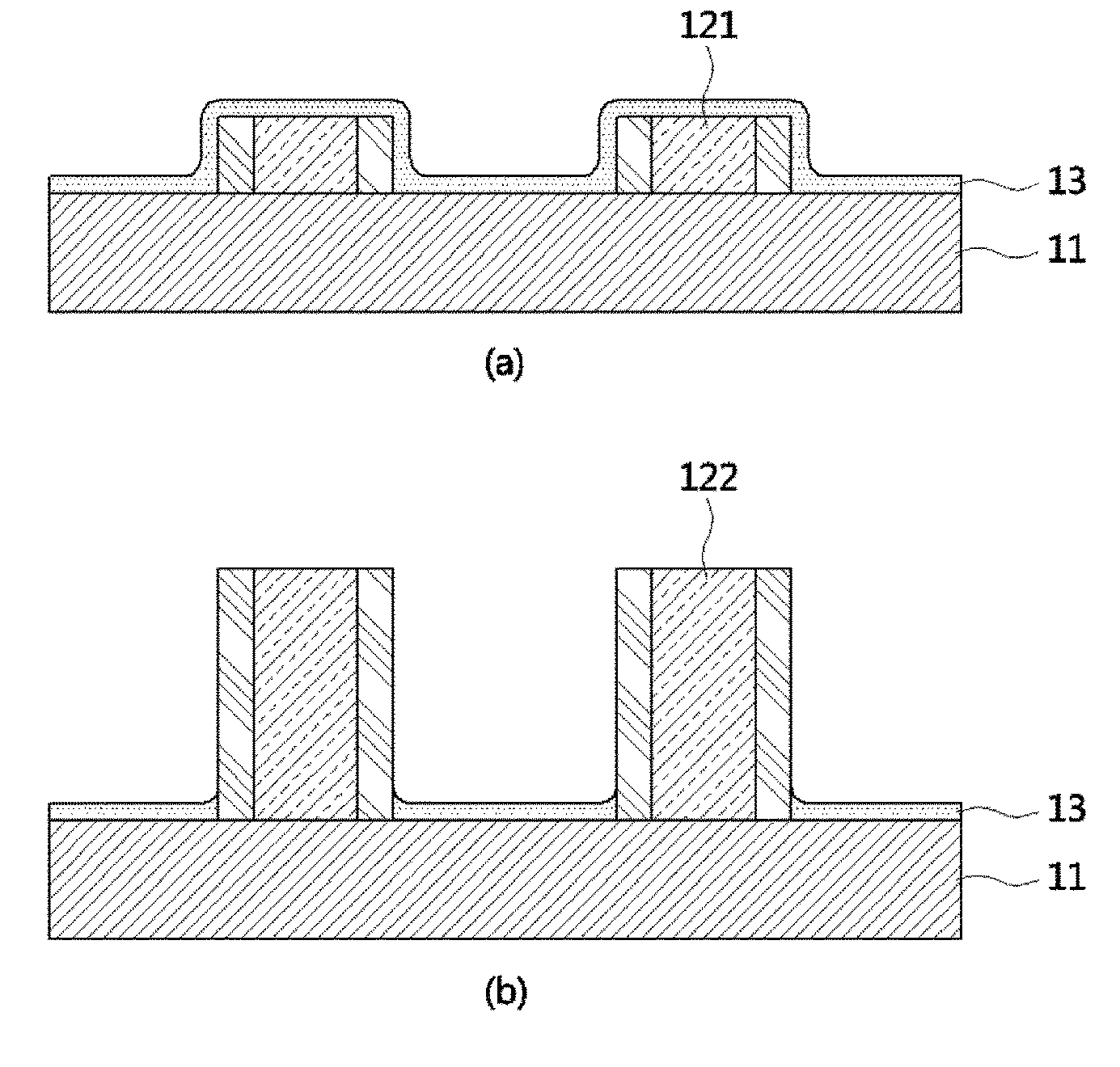

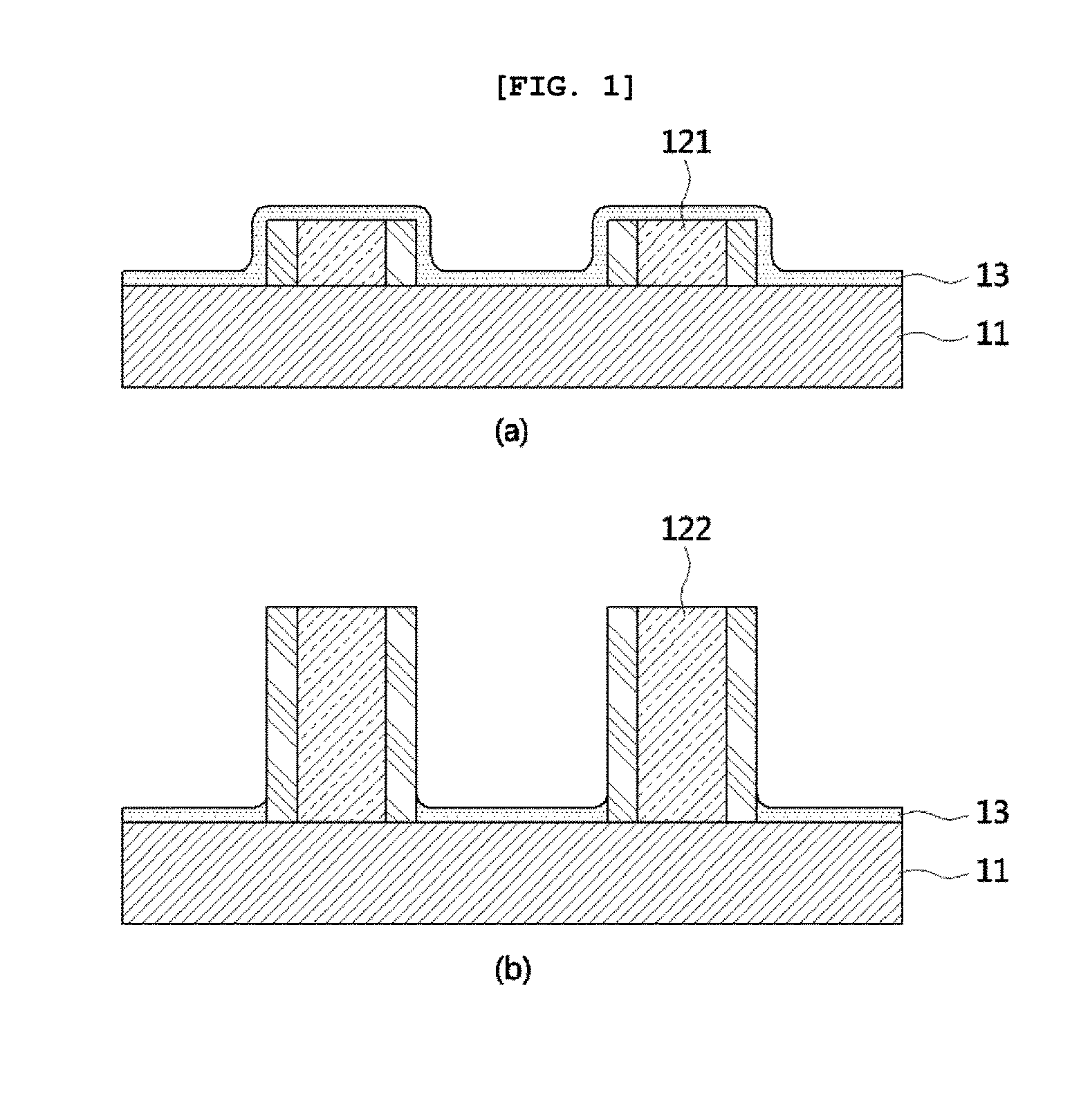

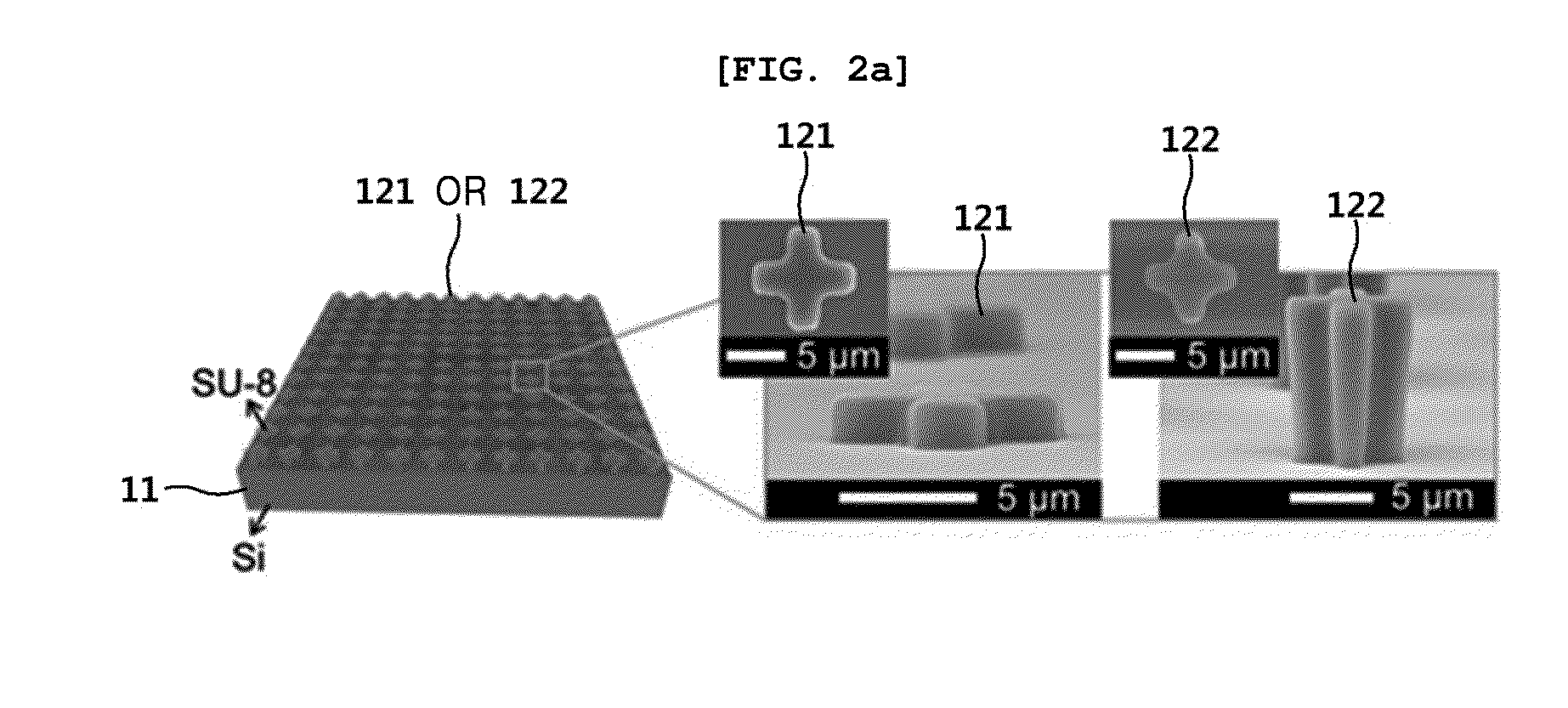

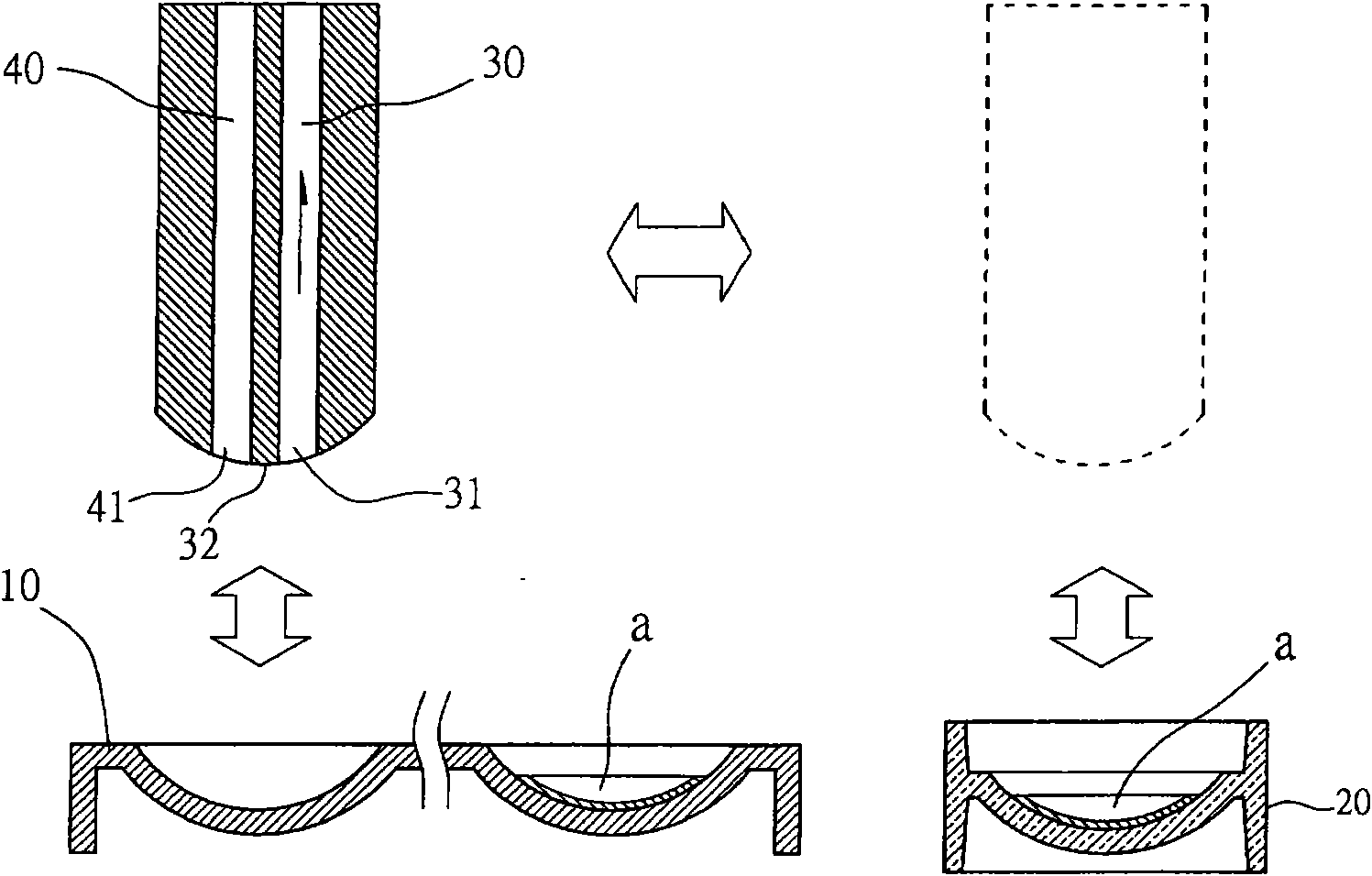

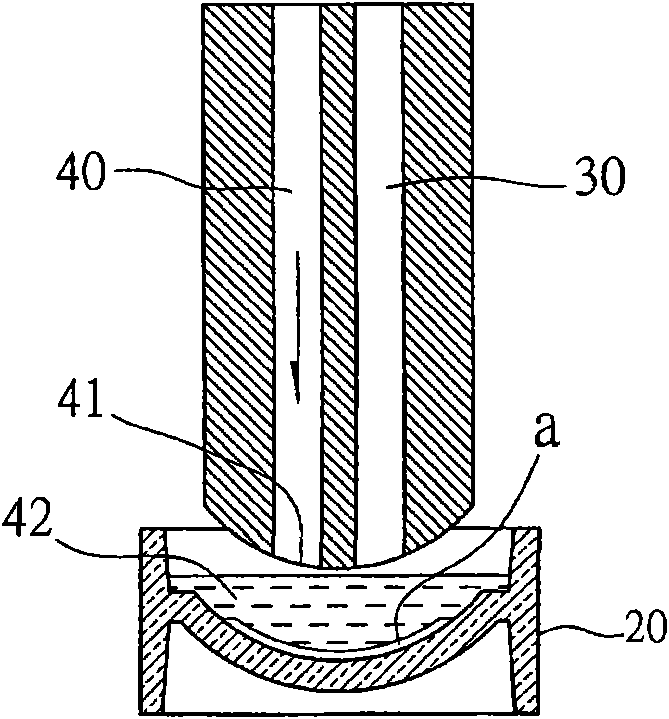

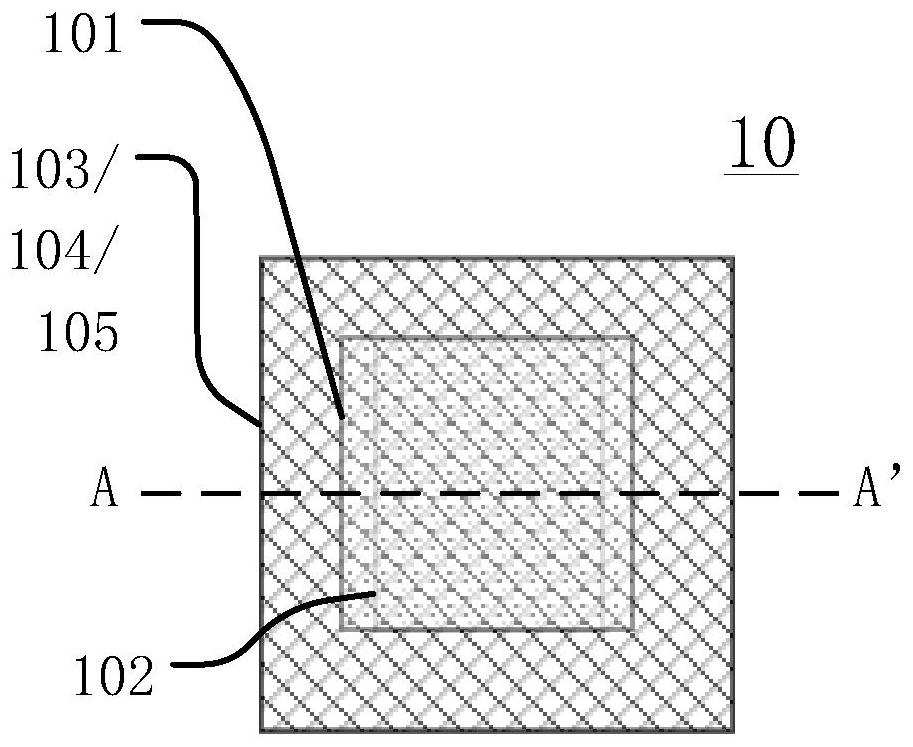

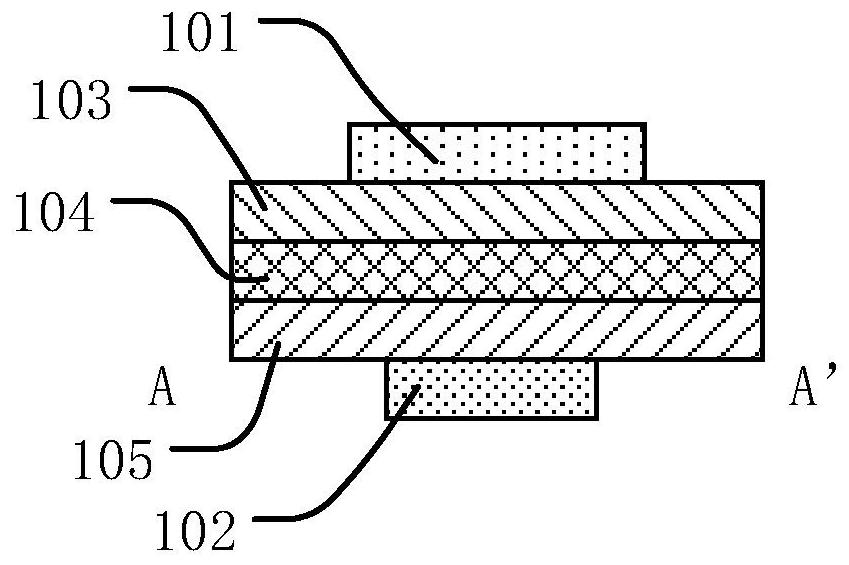

Transfer printing substrate, manufacturing method thereof, and method of transfer printing

ActiveUS20140345794A1Improve transfer yieldEasy alignmentTransfer printingLayered productsEngineeringTransfer printing

Disclosed herein is a transfer printing technology. A transfer printing substrate includes a plurality of pillar structures and a sacrificial layer applied thereon. In situ alignment of a transfer layer is performed by the pillar structures and a structural confinement by a concave structure formed on a bottom surface of the transfer layer corresponding to the pillar structures, or a chemical bond of the pillar structure and the transfer layer. In the in situ alignment by the structural confinement, the remaining sacrificial layer after being removed may serve as an adhesive component. The transfer process is performed by a separation of the bond by the sacrificial layer, a cutting of the pillar structures in the chemic bonding state of the pillar structures and the transfer layer, or a separation of the bond between the pillar structures and the handling substrate.

Owner:GWANGJU INST OF SCI & TECH

Micro device facilitating picking and testing, manufacturing, testing and transferring method and display

PendingCN112447787AReach permutationAchieve the purpose of sortingSemiconductor/solid-state device testing/measurementSolid-state devicesDisplay deviceStructural engineering

The invention provides a micro device facilitating picking and testing, a manufacturing, testing, transferring method and a display. A first sacrificial layer is arranged on the surface of a groove, and all testing electrodes are distributed above the first sacrificial layer corresponding to the groove at intervals and are far away from an LED core particle; the device also comprises multiple metal bridges, the metal bridges and the test electrodes are distributed in a crossed manner, the metal bridges are used for connecting the electrodes of two adjacent LED core particles in series, and themetal bridges are connected with the test electrodes at the corresponding grooves of the two adjacent LED core particles; the second sacrificial layer coats each LED core particle to form an independent coating unit; therefore, the integration of the LED core particles and the test structure is realized, and meanwhile, the purposes of arranging and sorting the LED core particles are achieved, sothat the perfect connection of subsequent test and transfer processes is ensured.

Owner:XIAMEN QIANZHAO SEMICON TECH CO LTD

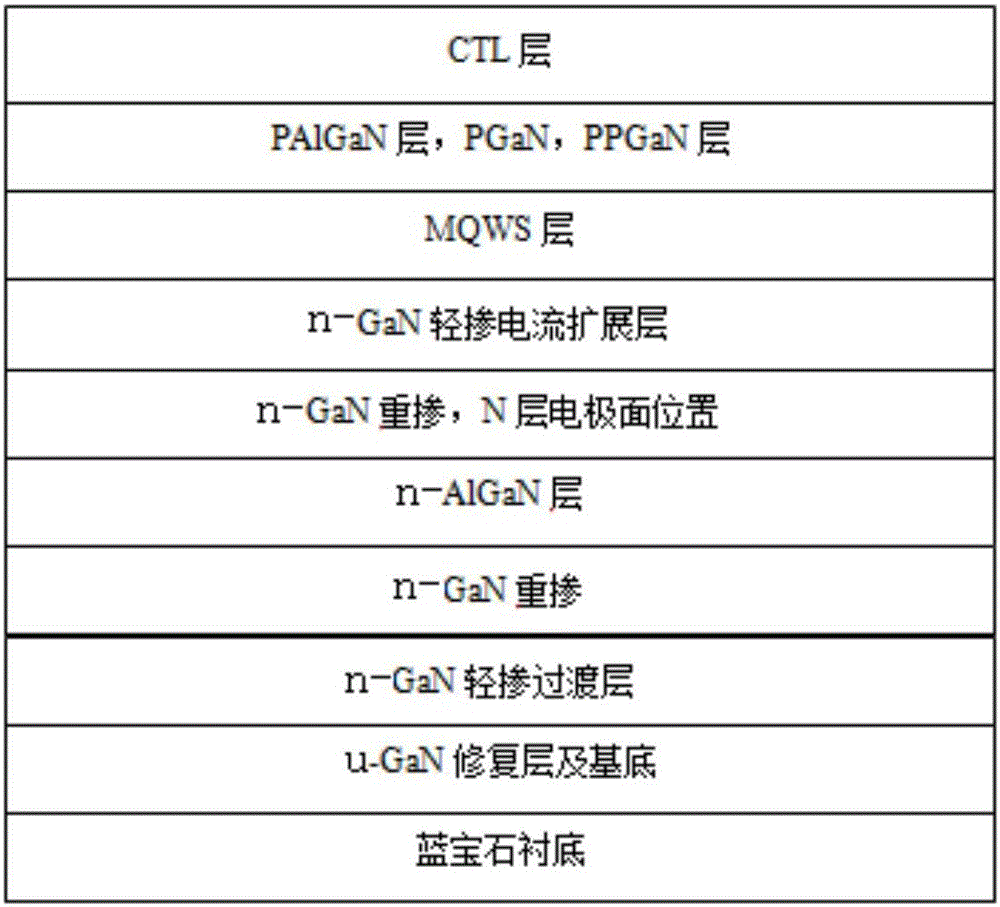

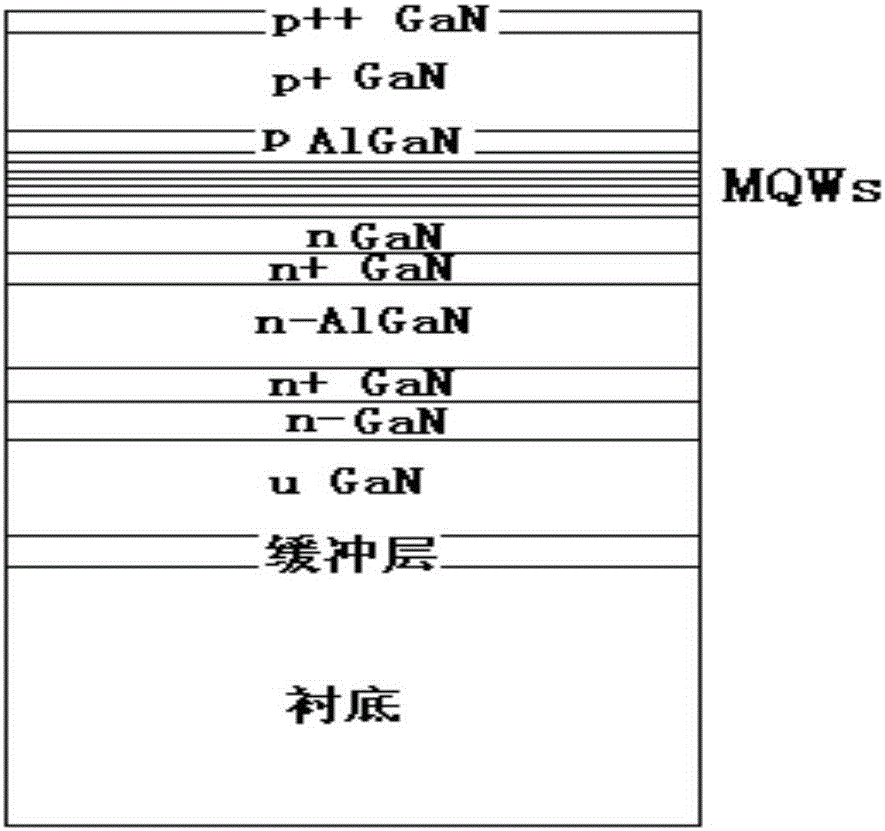

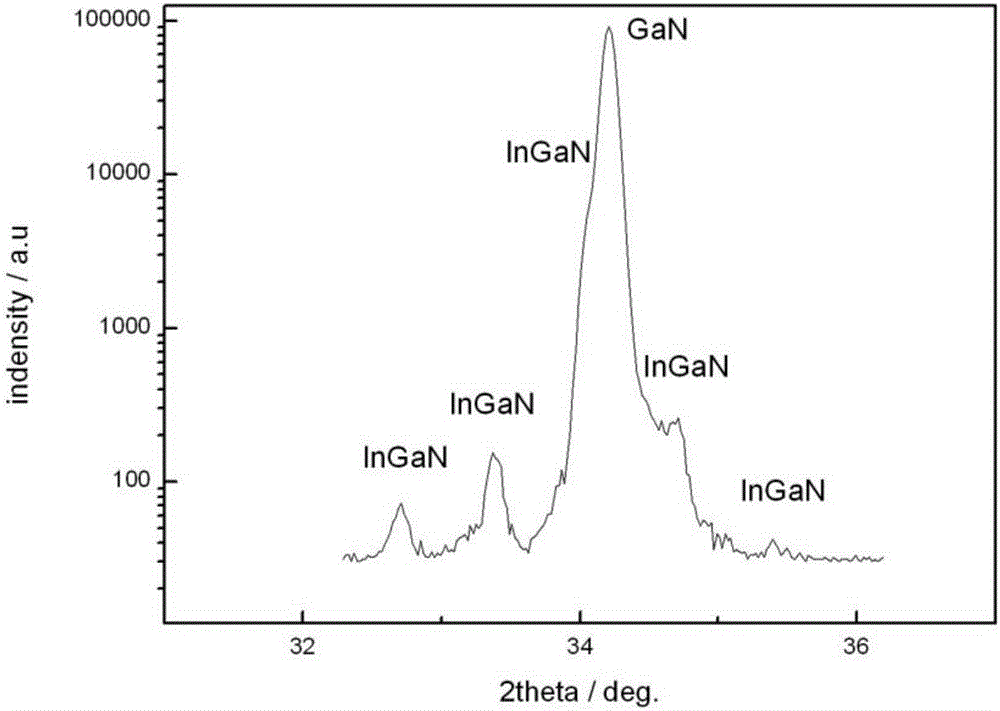

Method for preparing InGaN/AlGaN MQW ultraviolet LED

ActiveCN106206880ALarge adjustment rangeSuitable for batch growthSemiconductor devicesUltravioletP type doping

The invention discloses a method for preparing a high-performance InGaN / AlGaN MQW ultraviolet LED. Blue ammonia, high-purity trimethylindium and high-purity trimethyl gallium serve as an N source, an In source and a Ga source respectively, and SiH4 and Cp2Mg serve as an n type doping agent and a p type doping agent respectively. The method comprises the following steps that firstly, a sapphire substrate or a SiC substrate or a Si substrate is nitrided; secondly, a buffering layer is grown and crystallized, and then a uGaN nucleating layer is grown; thirdly, a low Si-doped n-GaN layer is grown first, and then a high Si-doped n+GaN layer is grown; fourthly, an n-AlGaN layer is grown; fifthly, a Si-doped n+GaN layer is grown, and then an nGaN layer without Si is grown; sixthly, three cycles of InGaN / GaN superlattices without Al are grown, and then eight cycles of Al-doped InGaN / GaN is grown; seventhly, a PAlGaN layer is grown; eighthly, a Mg-doped P+GaN layer is grown; ninthly, a high Mg-doped P++GaN layer is grown. According to the method, InGaN / AlGaN MQW ultraviolet LED epitaxy pieces of the specific structure are grown with an LP MOCVD system, the preparing cost is low, time is saved, the prepared ultraviolet LED is good in performance, and the ultraviolet LED epitaxy industrialization is promoted.

Owner:江苏晶曌半导体有限公司

Light emitting diode packaging structure and manufacturing method thereof

ActiveCN110911541AImprove misalignmentImprove transfer yieldSolid-state devicesSemiconductor devicesSolder maskSelf assemble

The invention provides a light emitting diode packaging structure and a manufacturing method thereof. The light emitting diode packaging structure comprises a carrier plate, at least one self-assemblymaterial layer, a first solder mask layer and at least one light emitting diode. The carrier plate includes a first build-up line. The self-assembly material layer is disposed on the first build-up circuit. The first solder mask layer is disposed on the first build-up line. The first solder mask layer has at least one opening to expose a portion of the self-assembly material layer. The light emitting diode is disposed on the first build-up circuitry. The light emitting diode has a self-assembled pattern. The light emitting diode is self-assembled in the opening of the first solder mask layerthrough the acting force between the self-assembly pattern and the self-assembly material layer.

Owner:UNIMICRON TECH CORP

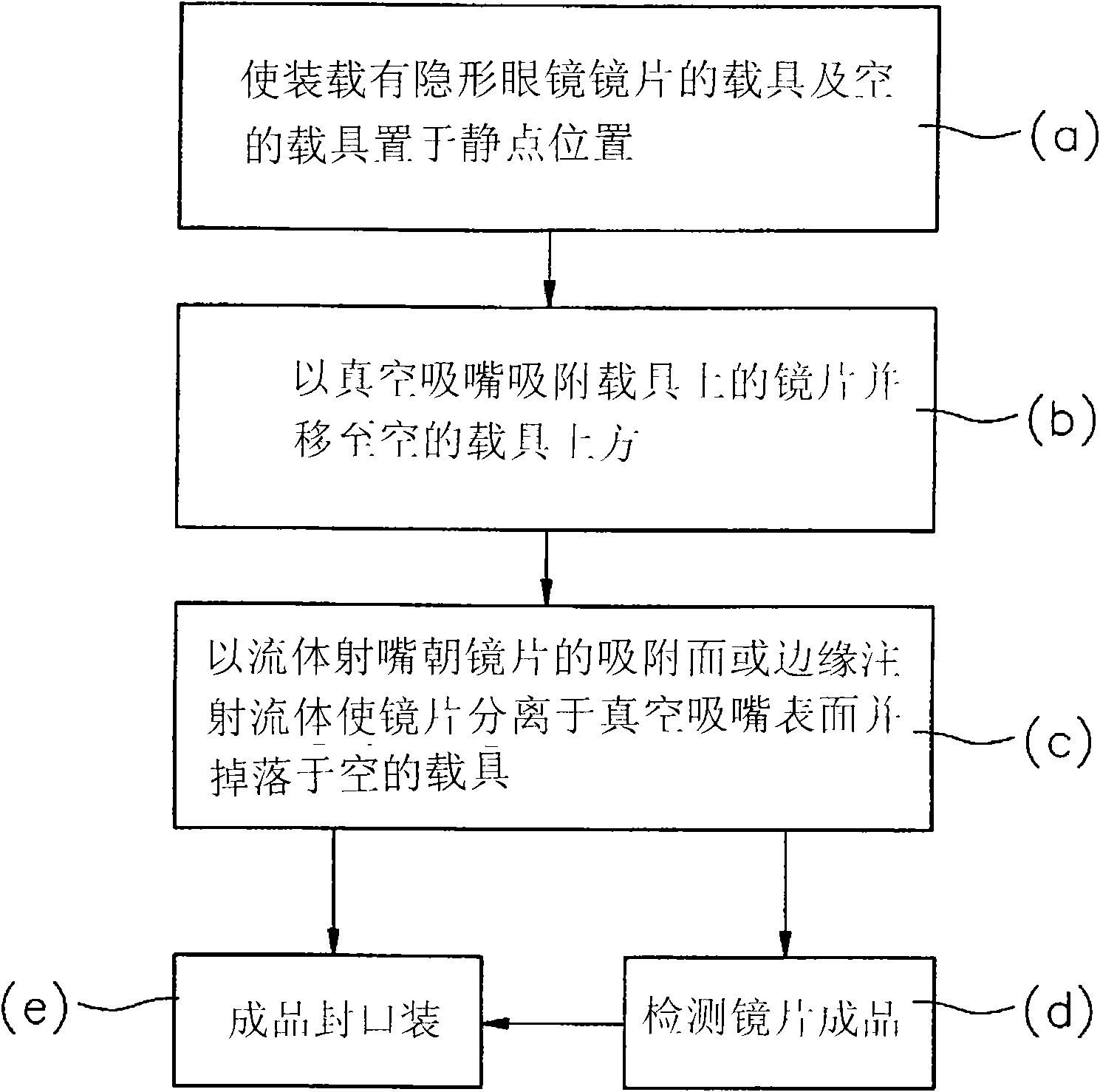

Method for shifting contact lenses

InactiveCN101559883AImprove transfer yieldImprove transfer efficiencyGripping headsUsing protective liquidsLens plateBiomedical engineering

The invention relates to a method for shifting contact lenses, comprising the following steps: (a) a carrier loaded with the contact lenses and an empty carrier are placed into fixed point positions; (b) the lenses in the carrier are absorbed by a vacuum nozzle and shifted on the empty carrier; (c) fluid is injected towards the absorbing surfaces or edges of the lenses by a fluid nozzle to enable the lenses to be separated from the surface of the vacuum nozzle by the fluid and shifted to the empty carrier in a falling mode. The invention has the effects of high shifting efficiency and accurate actions, can save the time and the cost required by manpower and manufacture procedures and can improve the shifting yield of the lenses.

Owner:BINGJIAN ENTPR

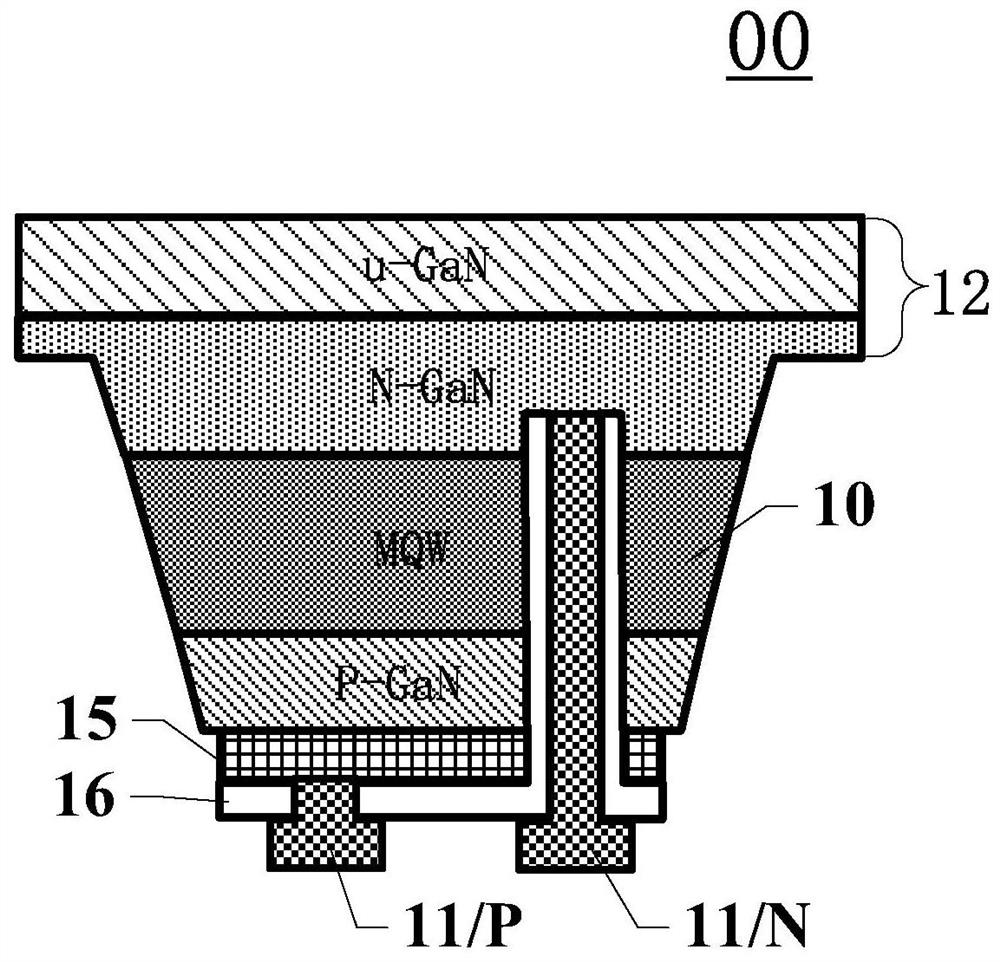

Light emitting diode display apparatus and manufacturing method thereof

ActiveUS20200083206A1Wide color gamut color specificationImprove mass transfer rateSolid-state devicesSemiconductor devicesEngineeringLight-emitting diode

The light emitting diode display apparatus including a first substrate, a plurality of light emitting diodes, an adhesive layer, a color layer, and a second substrate is provided. The first substrate has a plurality of switching elements. The light emitting diode includes a first semiconductor layer, a plurality of second semiconductor layers, a plurality of light emitting layers, a first electrode, and a plurality of second electrodes. The first electrode is disposed on the first semiconductor layer. The second electrodes are respectively disposed on the corresponding second semiconductor layers. Each of the second electrodes is electrically connected to the corresponding switching element. The adhesive layer and the first substrate are respectively located at two opposite sides of the light emitting diode. The color layer is disposed on the first substrate and covers the adhesive layer and the light emitting diode. The second substrate is disposed opposite to the first substrate.

Owner:AU OPTRONICS CORP

Vertical structure LED blue light epitaxy preparation method

ActiveCN106206881ALarge adjustment rangeReduced efficiencySemiconductor devicesChemistryP type doping

The invention discloses a vertical structure LED blue light epitaxy preparation method. Ammonia gas, high purity TMIn, TMAl, TEGa and high purity TMGa are respectively used as sources; SiH4 and Cp2Mg are respectively used as n and p type doping agents, and hydrogen or nitrogen is used as carrier gas; the sources, the doping agents and the carrier gas are let into a reaction chamber to react chemically with the ammonia gas at 900 to 100 DEG C so as to generate a III-V family compound semiconductor which is deposited on a sapphire, a silicon chip, a silicon carbide sheet or a quartz glass sheet in a certain crystal lattice order, and an epitaxial structure is prepared. According to the vertical structure LED blue light epitaxy preparation method, via technological parameter optimization and adjustment, epitaxial material crystalline quality (defect density) is controlled to be in a reasonable scope, certain effects are exerted on photoelectric parameters of products by the crystalline quality, a substrate transfer yield can be improved via adoption of recovered layer and base technologies, and stress between the substrate and an epitaxial layer can be well released via the recovered layer and base technologies.

Owner:CHINA UNITED NORTHWEST INST FOR ENG DESIGN & RES

Transfer substrate, driving backboard, transfer method and display device

ActiveCN111244014AImprove transfer yieldImprove alignment accuracyStatic indicating devicesSolid-state devicesDisplay deviceEngineering

The invention discloses a transfer substrate, a driving backboard, a transfer method and a display device, and the transfer substrate comprises a base material, a plurality of light emitting diodes located on the base material, and a plurality of connection structures located between the adjacent light emitting diodes. The connecting structures are used for connecting the adjacent light emitting diodes, the plurality of connecting structures respectively correspond to the alignment structures on the driving back plate, and the plurality of connecting structures are used for aligning with the corresponding alignment structures in the transferring process of the light emitting diode. According to the transfer substrate Provided by the embodiment of the invention, the plurality of light emitting diodes can be connected into a whole through a plurality of connecting structures; in the transferring process of the light-emitting diodes, the light-emitting diodes are not prone to being lost and abraded; and, in the transferring process of the light-emitting diodes, alignment can be conducted through the multiple connecting structures and the corresponding connecting structures, the light-emitting diodes are aligned with the corresponding driving electrode set, the alignment precision is improved, dislocation is reduced, and the transferring yield of the light-emitting diodes is increased.

Owner:FUZHOU BOE OPTOELECTRONICS TECH CO LTD +1

Transfer method of light-emitting chip, display panel and display device

PendingCN114284309AImprove transfer yieldSolve the problem that it cannot be easily grasped by the elastic impressionSolid-state devicesSemiconductor devicesEngineeringElectrical and Electronics engineering

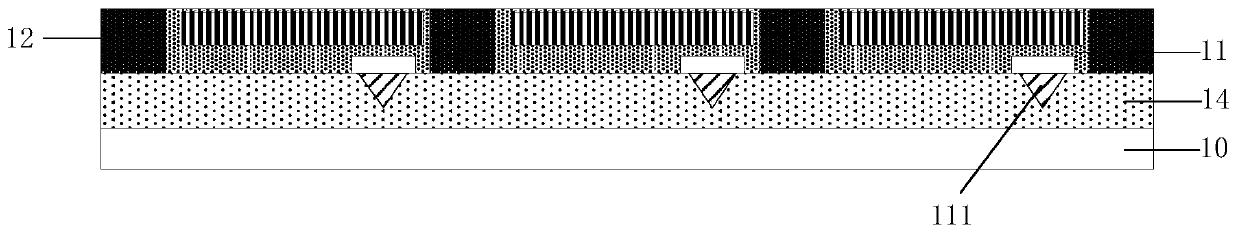

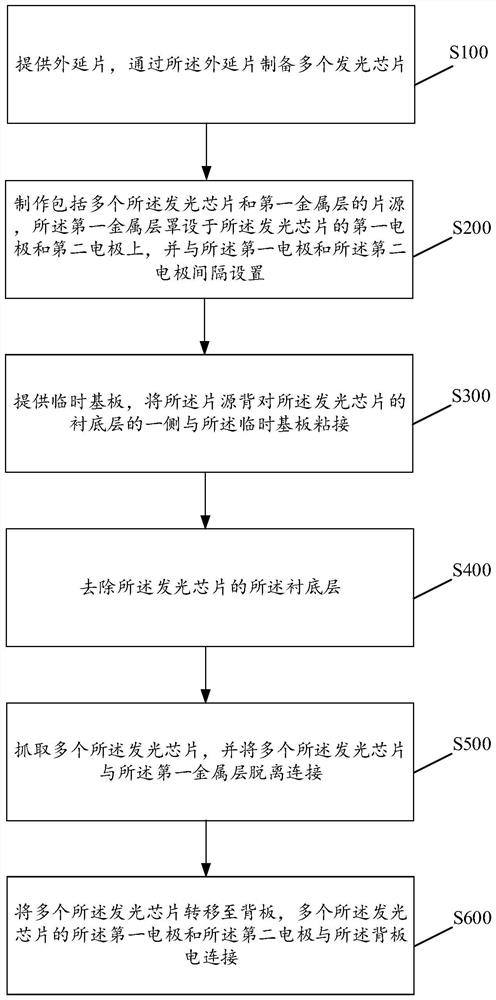

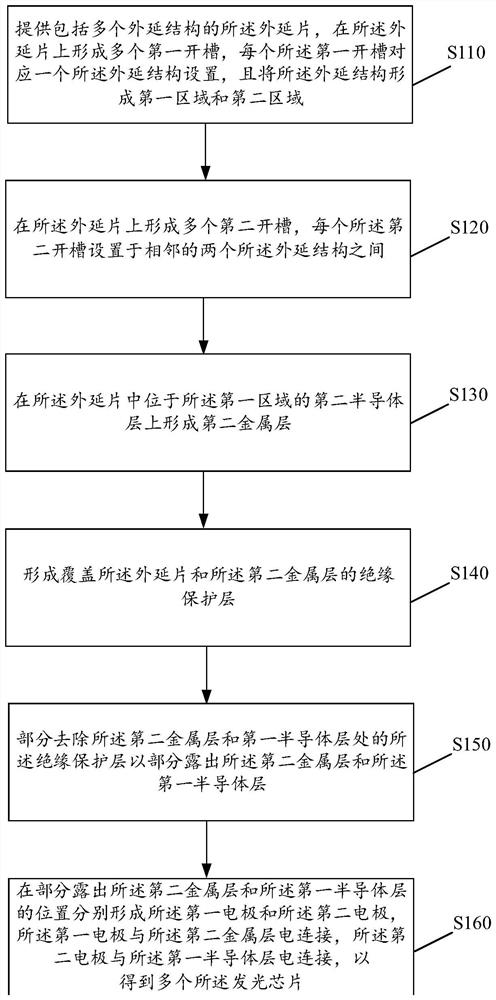

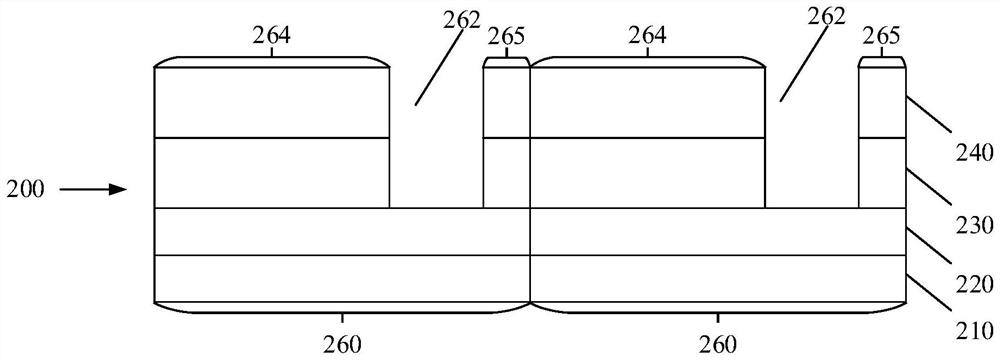

The invention relates to a light-emitting chip transfer method, and the method comprises the steps: providing an epitaxial wafer, and preparing a plurality of light-emitting chips through the epitaxial wafer; a film source comprising the multiple light-emitting chips and a first metal layer is manufactured, the first metal layer covers the first electrodes and the second electrodes of the light-emitting chips, and the first metal layer, the first electrodes and the second electrodes are arranged at intervals; providing a temporary substrate, and bonding one side, back to the substrate layer of the light-emitting chip, of the film source with the temporary substrate; removing the substrate layer of the light-emitting chip; the plurality of light-emitting chips are grabbed, and the plurality of light-emitting chips are separated from the first metal layer; and the multiple light-emitting chips are transferred to a back plate, the first electrodes and the second electrodes of the multiple light-emitting chips are electrically connected with the back plate, and the problem that in the prior art, the light-emitting chips cannot be conveniently grabbed is solved. The invention further provides a display panel and a display device with the display panel.

Owner:CHONGQING KONKA PHOTOELECTRIC TECH RES INST CO LTD

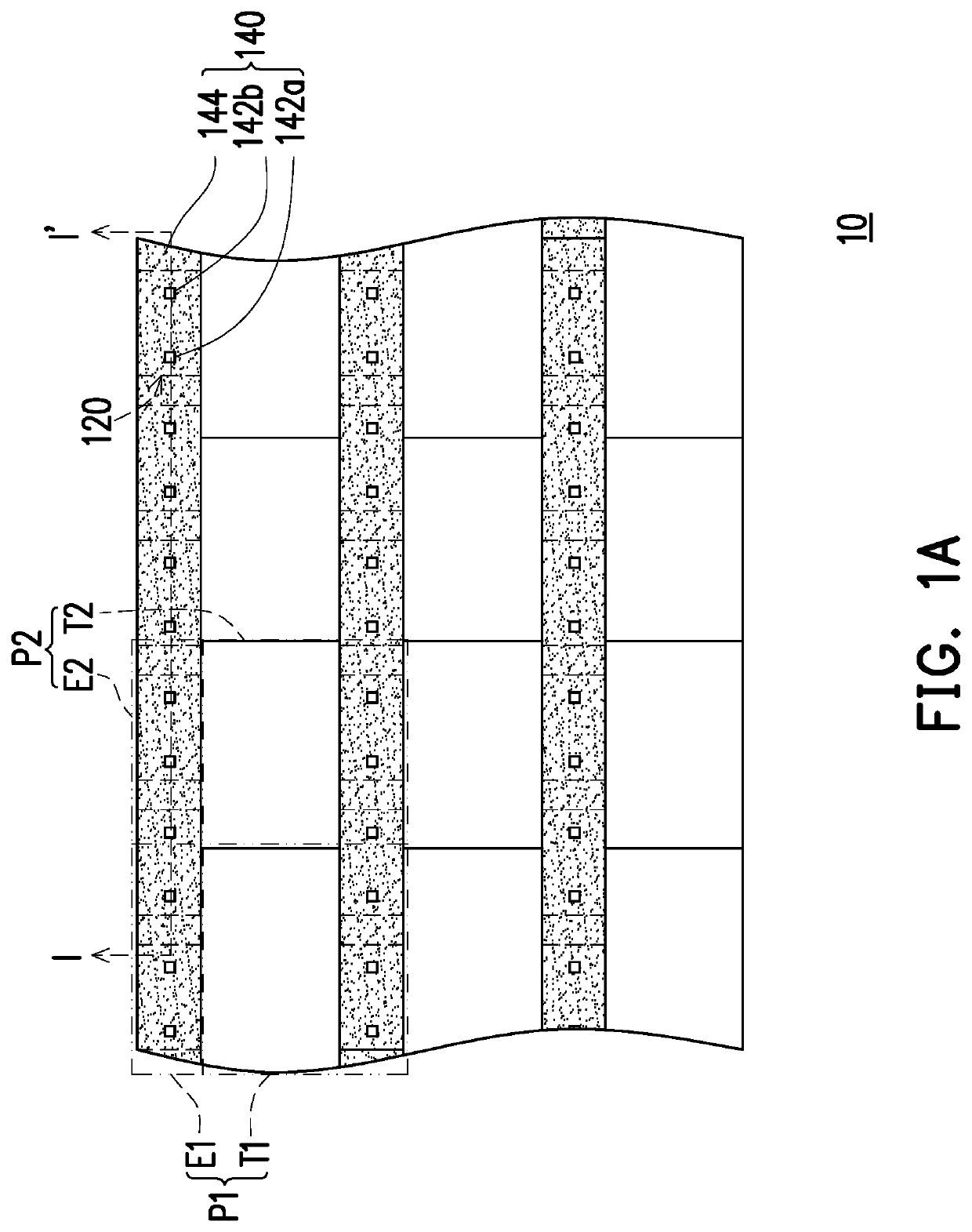

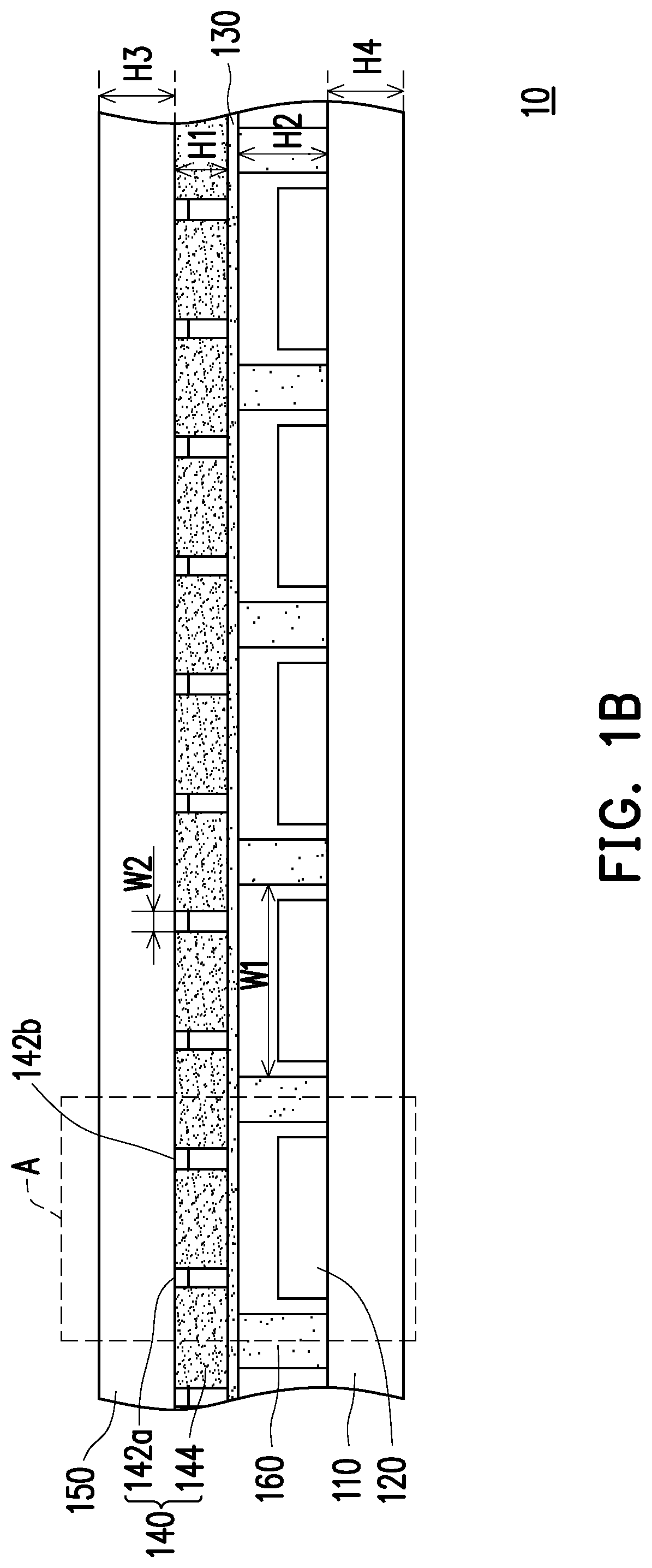

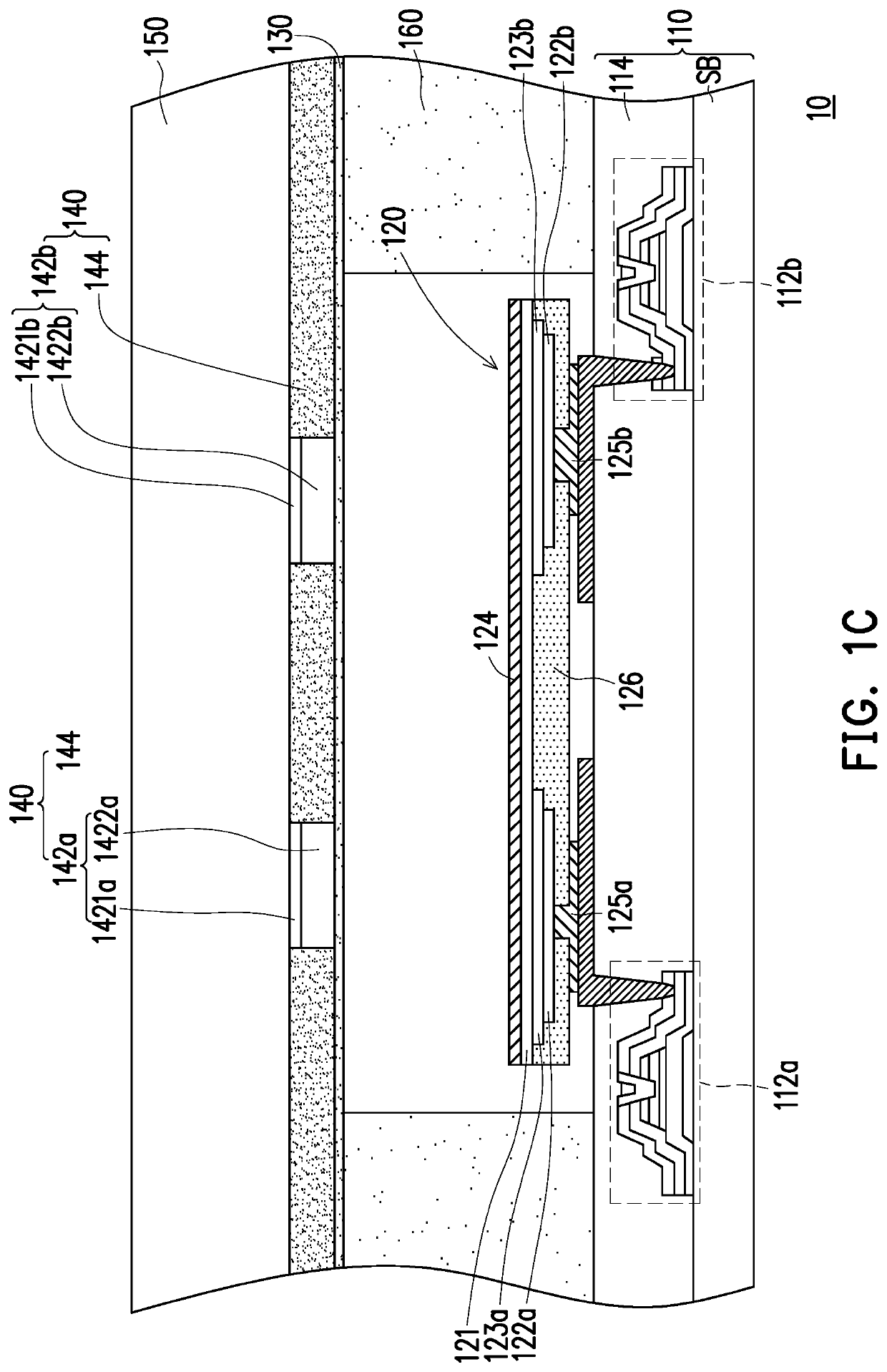

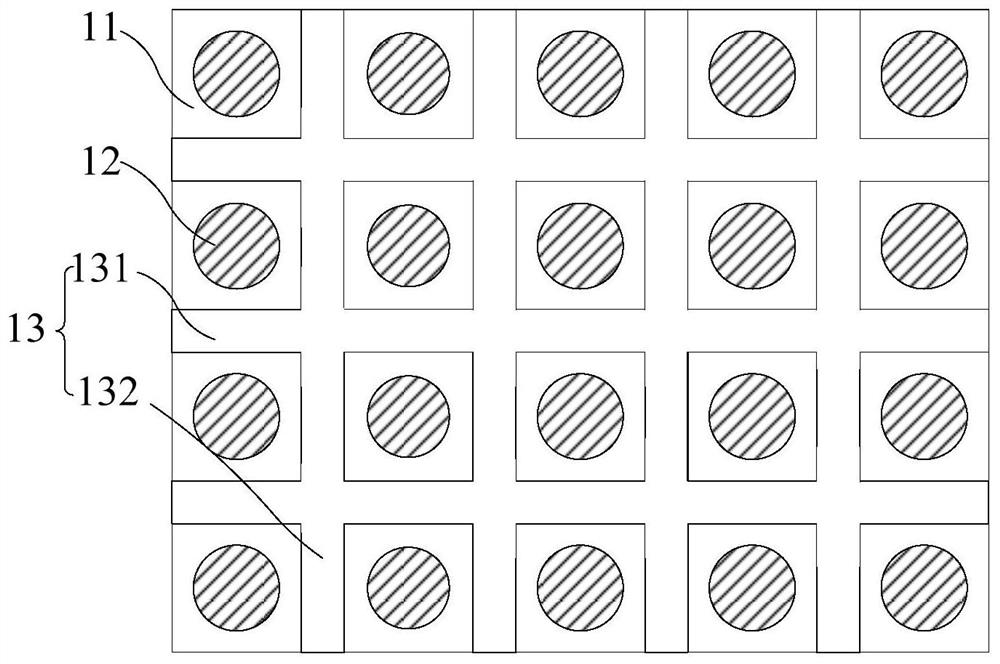

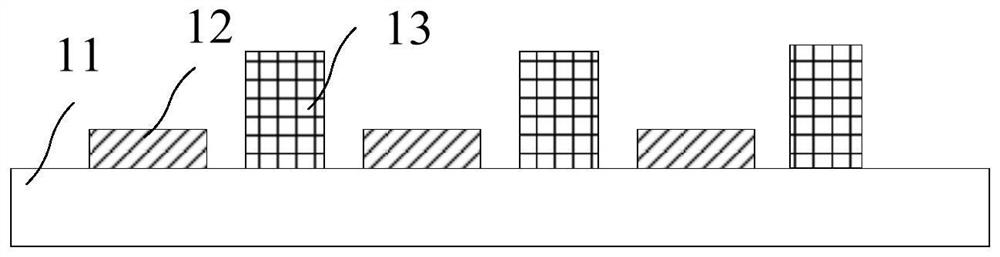

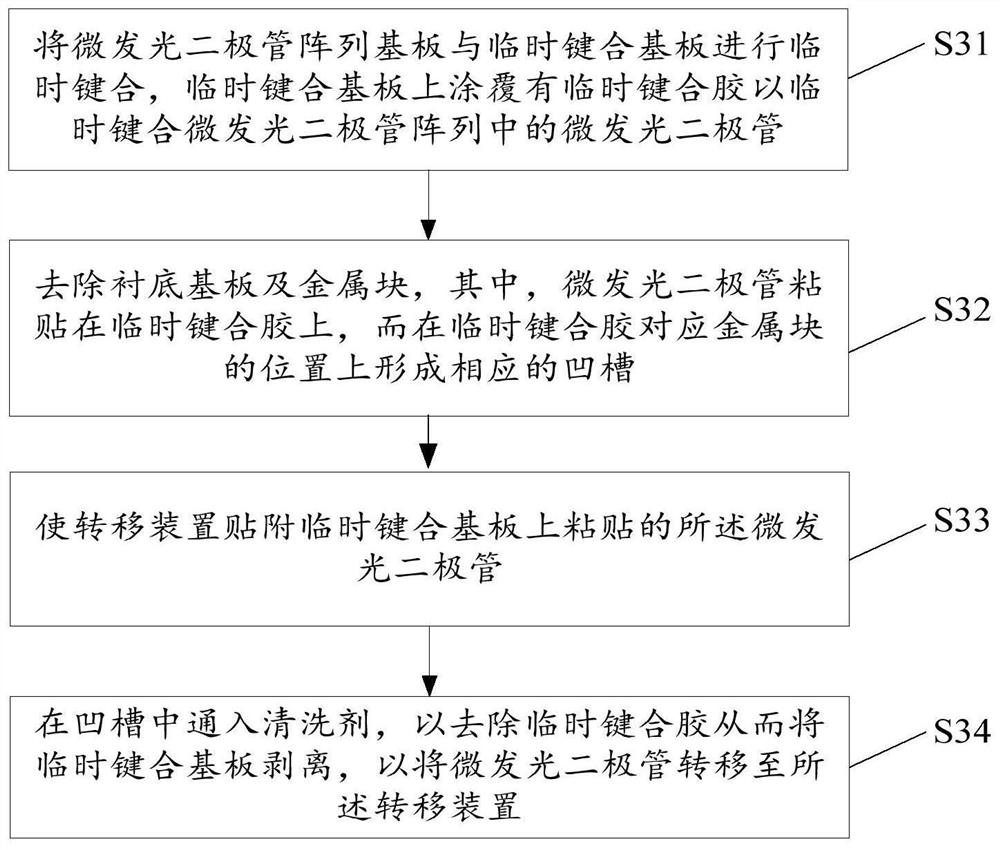

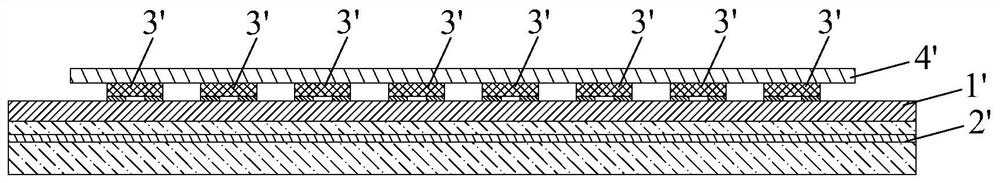

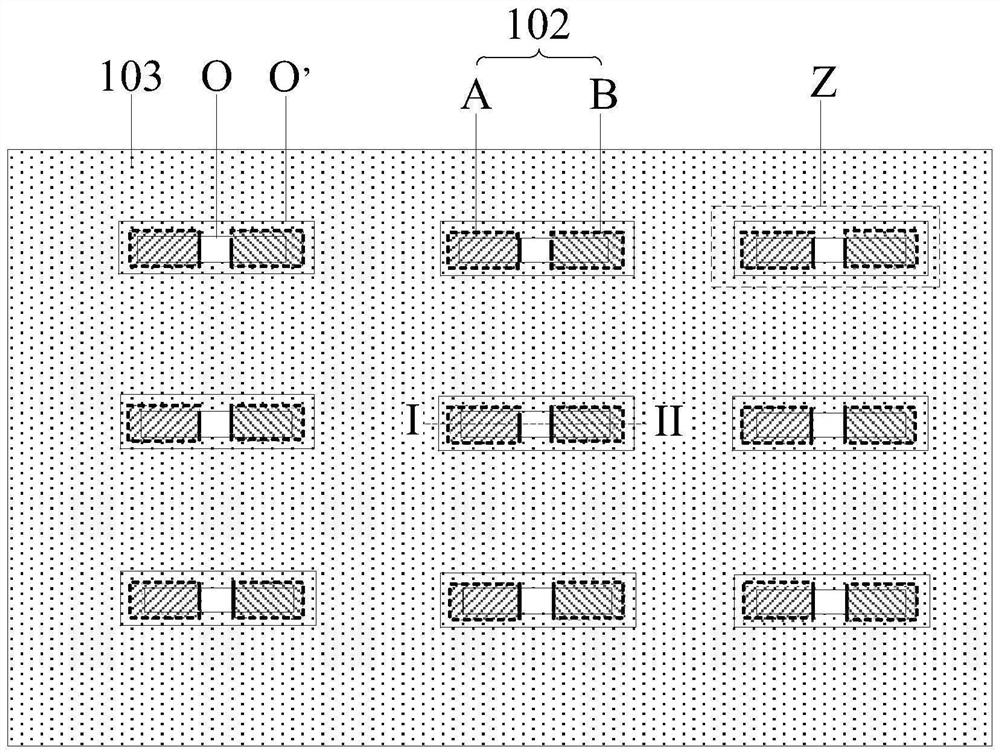

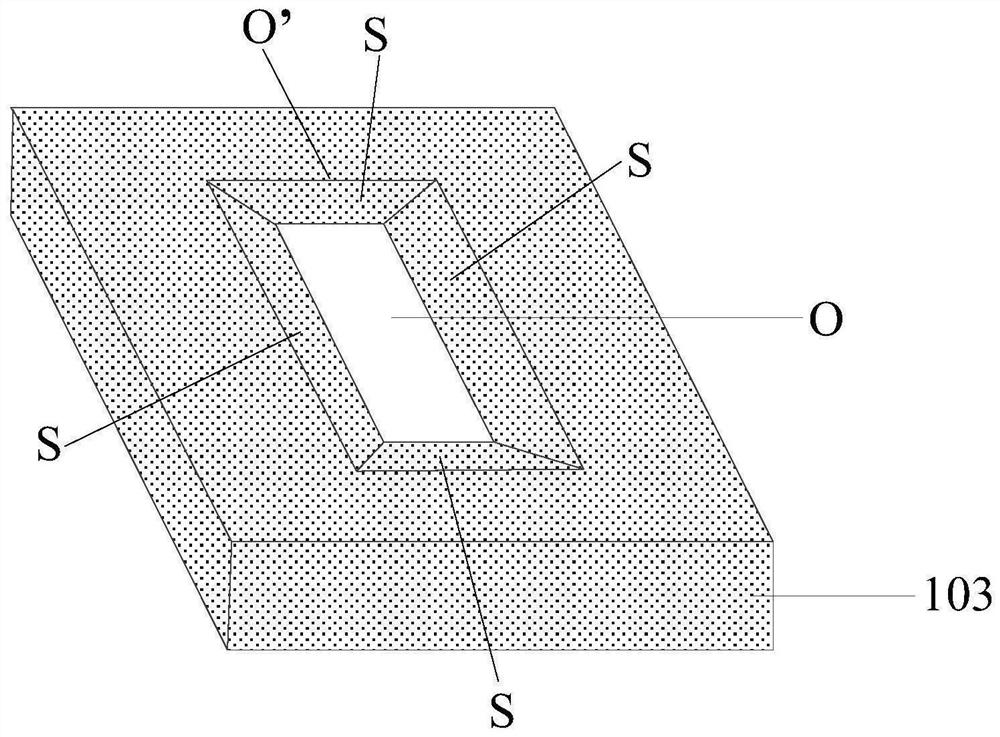

Micro light-emitting diode array substrate and micro light-emitting diode transfer method

ActiveCN112820752AImprove transfer yieldEfficient removalSolid-state devicesSemiconductor/solid-state device manufacturingLight-emitting diodePolydimethylsiloxane

The invention provides a micro light-emitting diode array substrate and a micro light-emitting diode transfer method. The micro light-emitting diode array substrate specifically comprises a substrate and a plurality of micro light-emitting diodes arranged on the substrate in an array mode. The adjacent micro light emitting diodes are separated by a metal block, and the height of the metal block in the direction perpendicular to the substrate is greater than that of the micro light-emitting diodes. In this way, in the transferring process, a groove is reserved in the temporary bonding glue after the metal block is removed, and the temporary bonding glue is removed by introducing a cleaning agent into the groove, so that the micro light-emitting diodes are picked up by the polydimethylsiloxane transferring device at the normal temperature, and the transferring yield of the micro light-emitting diodes is increased.

Owner:YUNGU GUAN TECH CO LTD +1

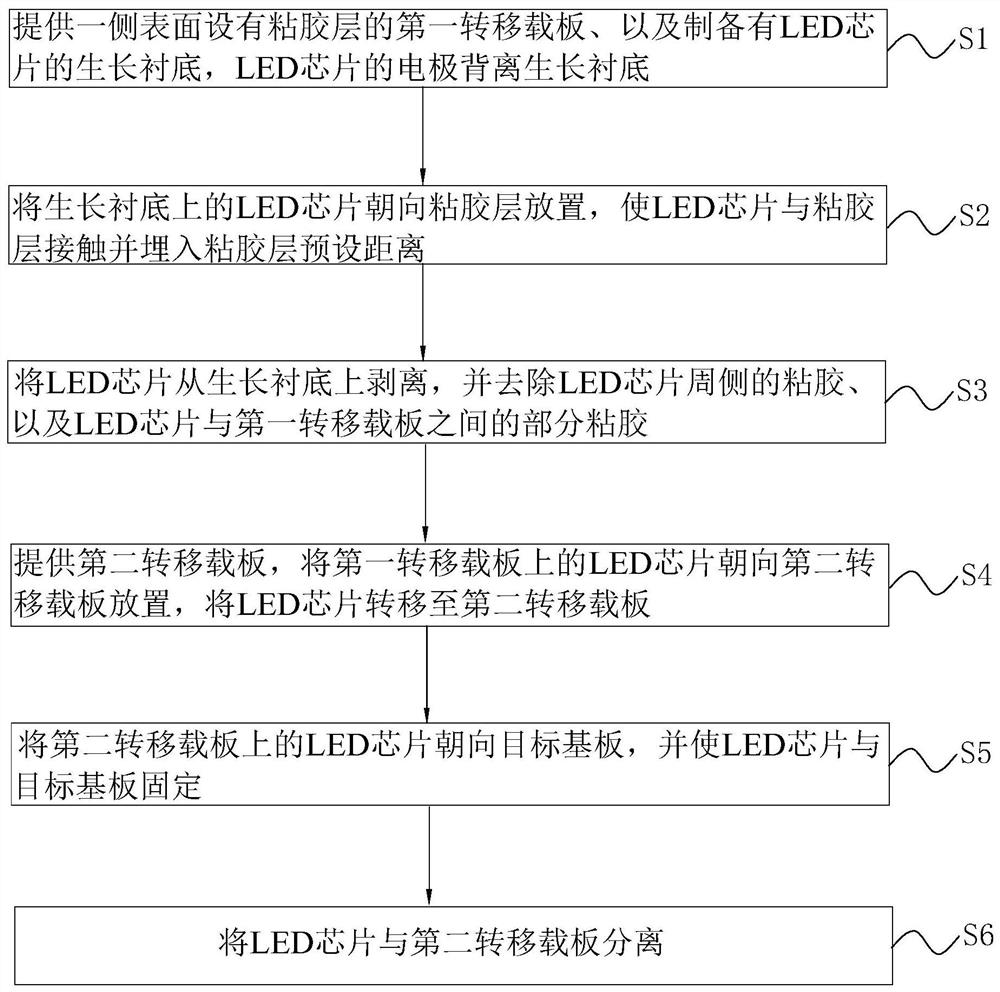

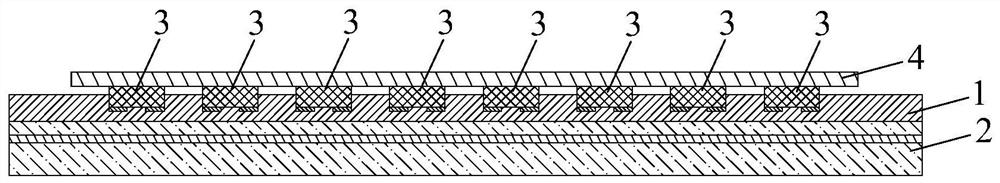

LED chip mass transfer method with high stripping yield and convenient film inversion

ActiveCN113611786AImprove stripping yieldEasy to pour filmSolid-state devicesSemiconductor/solid-state device manufacturingAdhesivePhysical chemistry

The invention discloses an LED chip mass transfer method with high stripping yield and convenient film inversion. According to the method, an LED chip is embedded into an adhesive layer of a first transfer support plate in the process of transferring the LED chip from a growth substrate to the first transfer support plate through a laser stripping mode; the LED chip is protected through the adhesive layer, so that the problem that when the LED chip is stripped from the growth substrate, the LED chip is broken is solved, and the transfer yield of the LED chip is improved; and on the basis, after the LED chip is stripped from the growth substrate, subsequent film inversion is carried out, and before the LED chip is transferred from the first transfer carrier plate to a second transfer carrier plate, part of the adhesive at the peripheral side of the LED chip and part of the adhesive between the LED chip and the first transfer carrier plate are removed, and only the rest part of the adhesive is adhered between the LED chip and the first transfer carrier plate, so that the LED chip can be conveniently separated from the first transfer carrier plate in the process of transferring the LED chip from the first transfer carrier plate to the second transfer carrier plate.

Owner:HCP TECH CO LTD

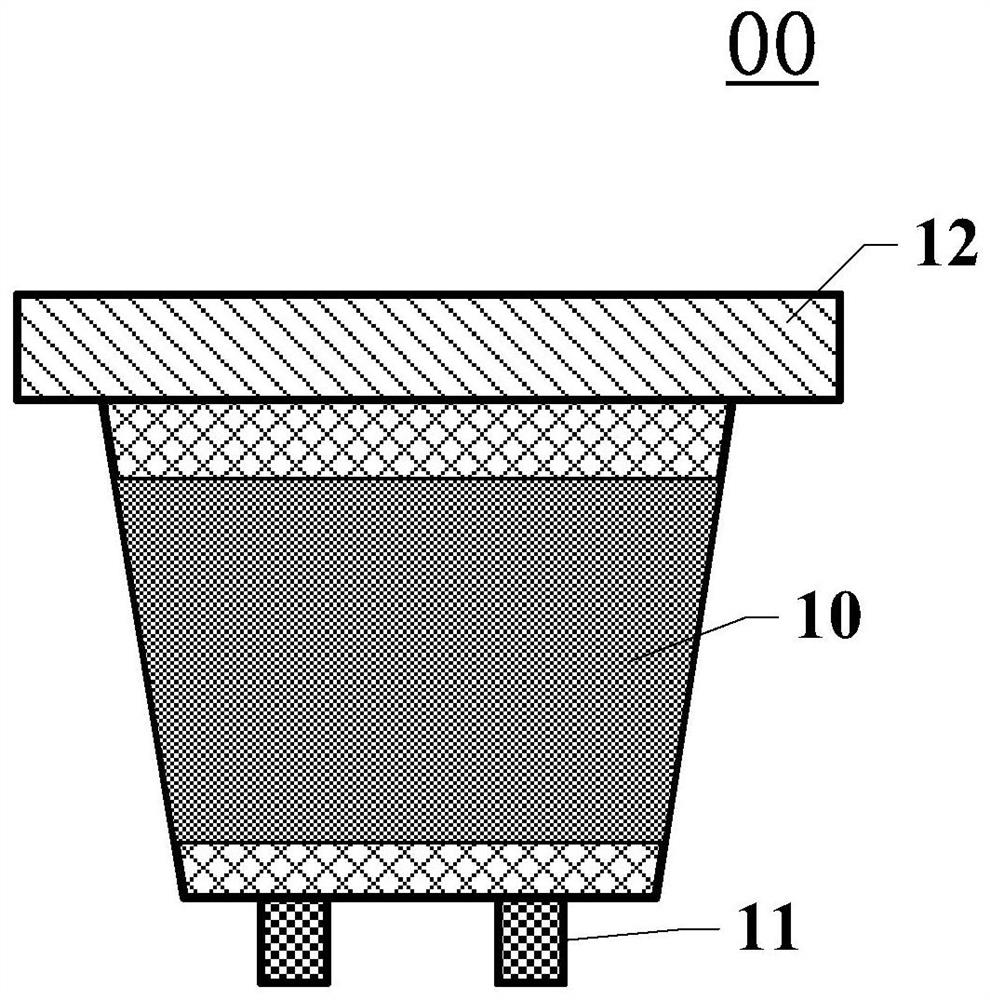

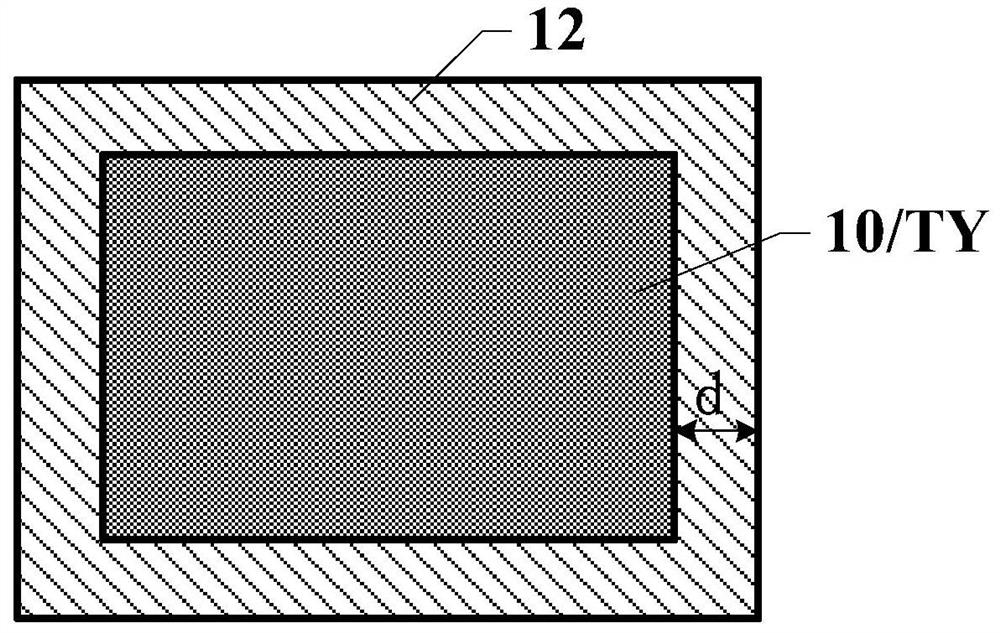

Micro light-emitting diode and transfer device and transfer method thereof

PendingCN113764326AEasy to pick upAvoid damageSolid-state devicesSemiconductor/solid-state device manufacturingLight-emitting diodeMaterials science

The invention discloses a micro light-emitting diode and a transfer device and a transfer method thereof, and relates to the technical field of display. The micro light-emitting diode comprises a light-emitting body, an electrode and a supporting body, and the light-emitting body is located between the supporting body and the electrode in the direction perpendicular to the plane where the supporting body is located; the orthographic projection of the light-emitting body on the plane where the supporting body is located is a first projection, the area of the first projection is smaller than that of the supporting body, the distance between the edge of the first projection and the edge of the supporting body is d, and d is larger than 0. When the micro light-emitting diode is arranged on the transfer substrate, the light-emitting body and the electrode of the micro light-emitting diode are not in contact with the inner wall of the opening of the transfer substrate, so that when the micro light-emitting diode on the transfer substrate is transferred, the interference of the inner wall of the transfer substrate on the light-emitting body and the electrode in the transfer process is effectively avoided; the transfer process of the micro light-emitting diode is simplified, and the transfer yield is improved.

Owner:HUBEI YANGTZE IND INNOVAION CENT OF ADVANCED DISPLAY CO LTD

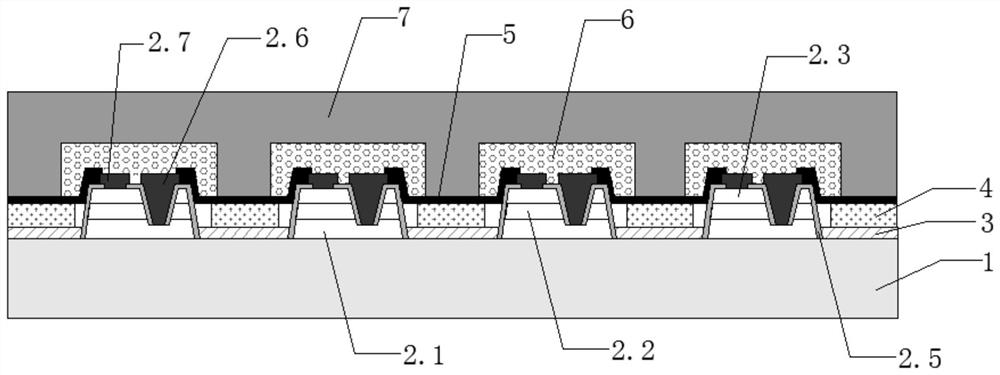

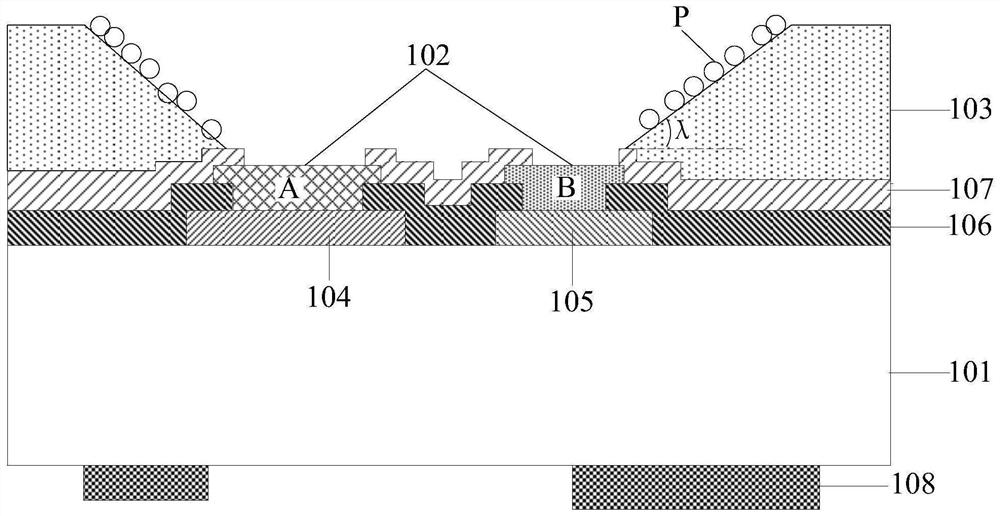

Driving backboard, manufacturing method thereof and light-emitting substrate

PendingCN113161373ANot easy to moveImprove transfer yieldSolid-state devicesSemiconductor devicesPhysicsComposite material

The invention provides a driving backboard, a manufacturing method thereof and a light-emitting substrate. The driving backboard comprises an underlayment substrate, a plurality of connecting electrode groups, and a shading layer. The plurality of connecting electrode groups are positioned on the substrate, and each connecting electrode group is used for being connected with one light-emitting element in a binding manner. Each connecting electrode group comprises a first connecting electrode and a second connecting electrode. The shading layer is positioned on a layer on which the plurality of connecting electrode groups are positioned. First openings are formed in the surface, close to the underlayment substrate, of the shading layer, second openings are formed in the surface, away from the underlayment substrate, of the shading layer, the first openings and the second openings are communicated, and the first openings are larger than the second openings. The first openings expose at least part of the surfaces of the first connecting electrodes and at least part of the surfaces of the second connecting electrodes. The shading layer further comprises a side face connecting the surface, close to the underlayment substrate, of the shading layer and the surface, away from the underlayment substrate, of the shading layer, the side face is a rough face, and the included angle between the side, away from the connecting electrode groups, of the side face and the plane where the underlayment substrate is located is an acute angle.

Owner:BOE TECH GRP CO LTD +1

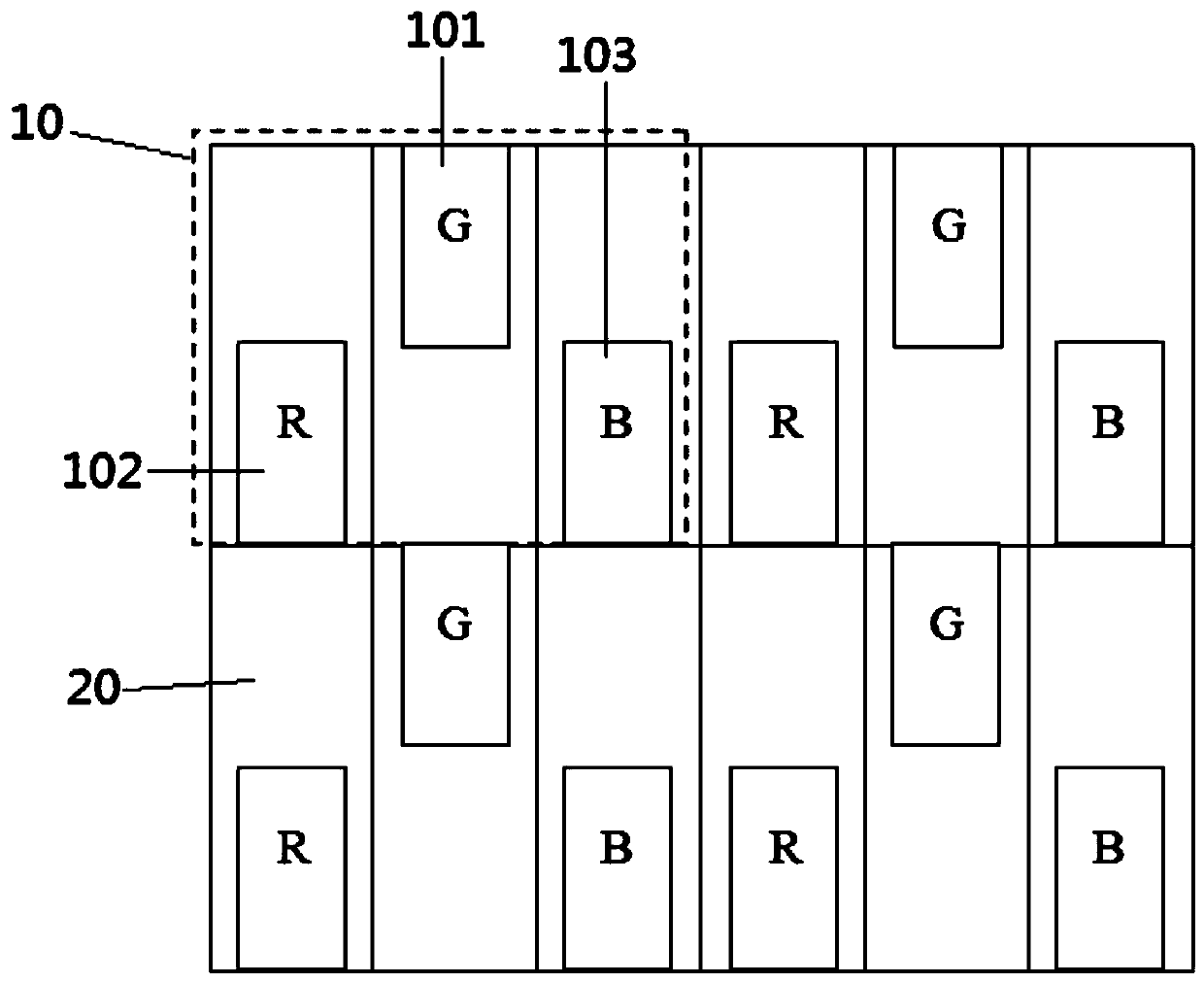

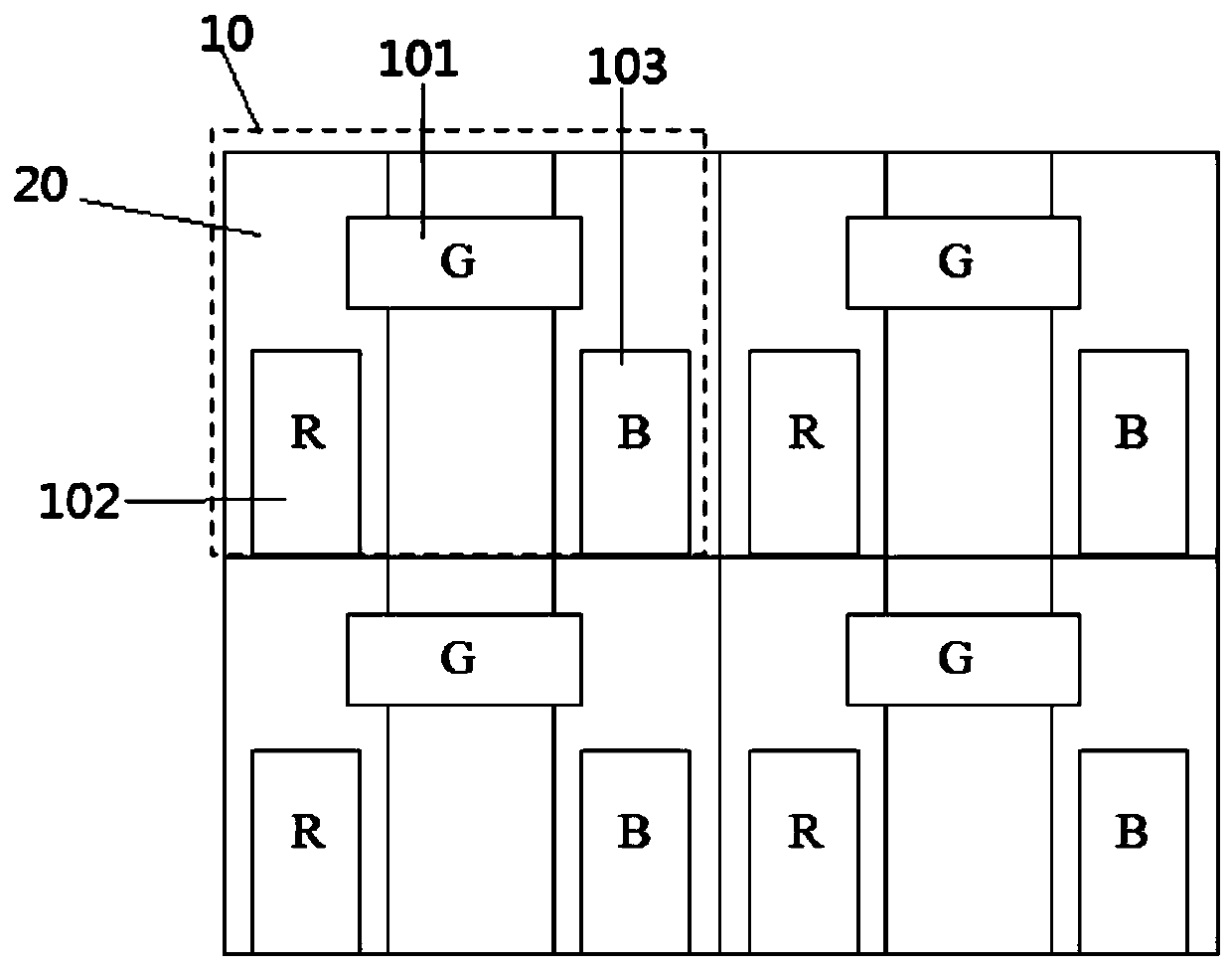

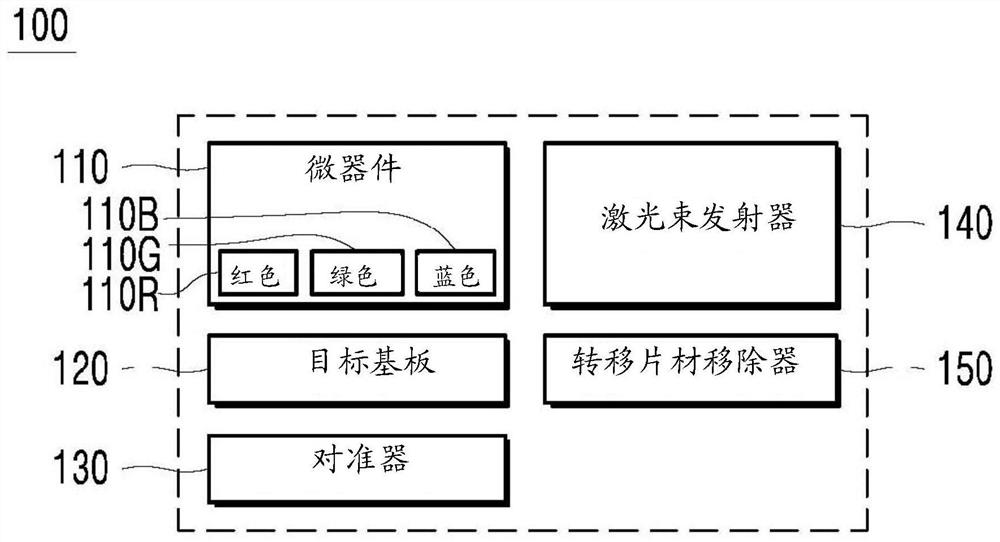

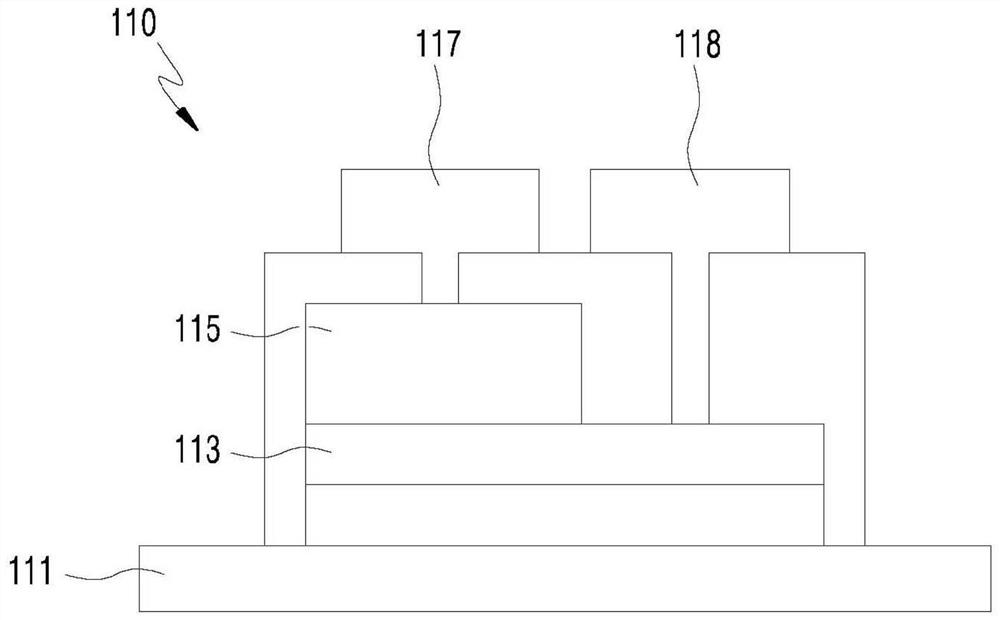

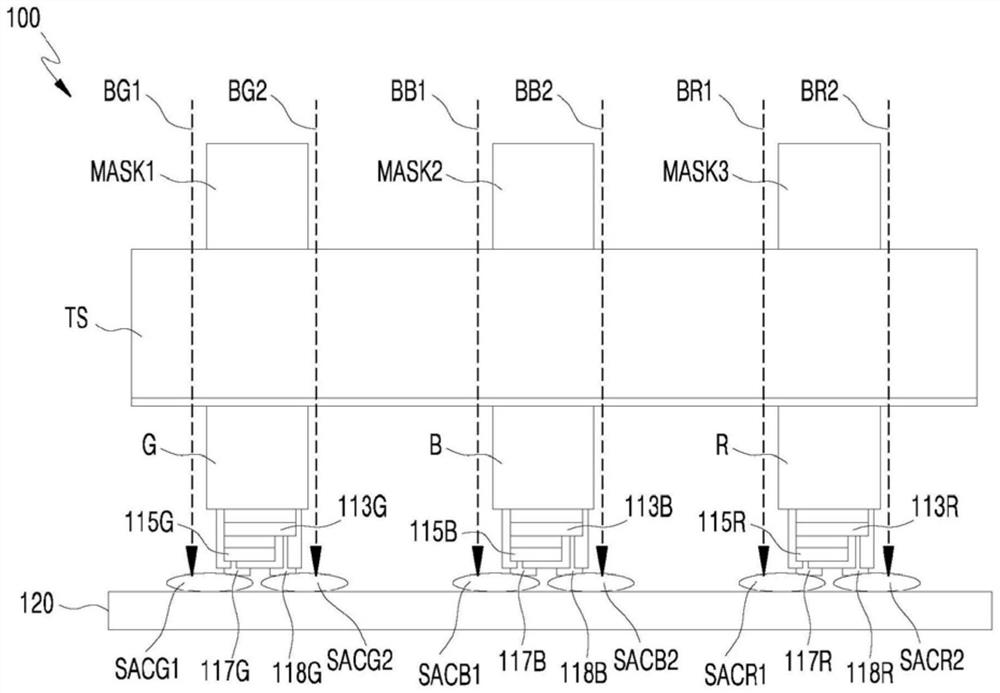

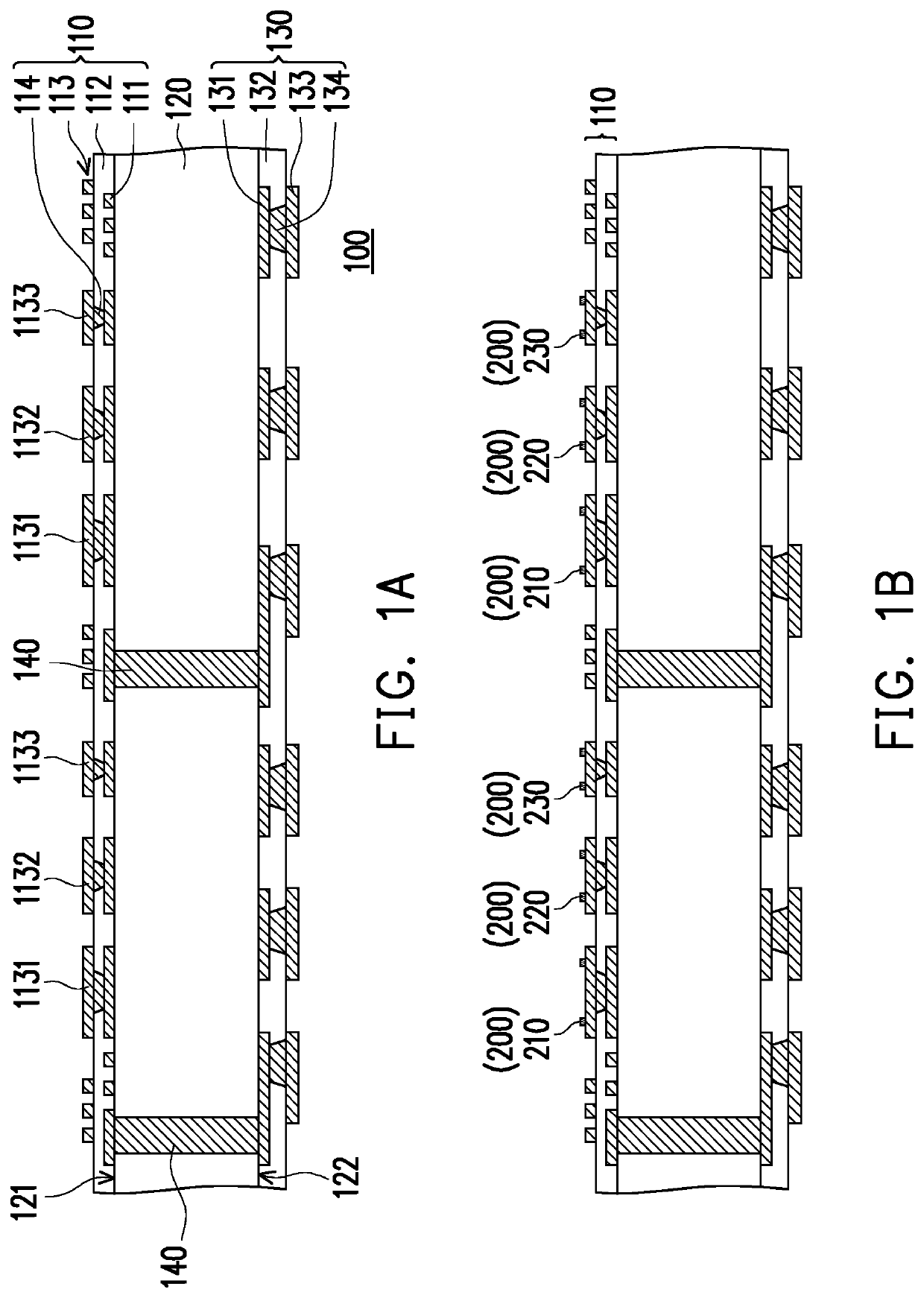

Apparatus for simultaneously transferring micro-devices to target object

PendingCN112292754AImprove transfer yieldEasy to produceSolid-state devicesSemiconductor/solid-state device manufacturingLight beamEngineering

Disclosed is an apparatus for simultaneously transferring micro-devices to a target object. The apparatus may comprise: multiple red (R), green (G), and blue (B) micro-devices attached to a carrier sheet by an adhesive material; a target substrate to which the micro-devices are transferred; an alignment unit for aligning the multiple micro-devices with the substrate; and a laser beam unit disposedabove the carrier sheet so as to emit a beam having a specific wavelength in the direction passing through the carrier sheet, wherein the micro-devices each comprise: a growth substrate; a first semiconductor layer and a second semiconductor layer disposed on the growth substrate; a first pad disposed on the first semiconductor layer; a second pad disposed on the second semiconductor layer; and an adhesive material disposed on the first pad and the second pad, and when the micro-devices and the substrate are aligned in transfer positions by the alignment unit, the laser beam unit applies energy to the adhesive material so as to allow the micro-devices to be transferred to the substrate. Accordingly, the efficiency of transfer can be improved.

Owner:兰蒂斯有限公司

Light-emitting diode package structure and manufacturing method thereof

ActiveUS10700049B2Serious problemImprove transfer yieldFinal product manufactureSemiconductor/solid-state device detailsSolder maskSelf assemble

A light-emitting diode package structure includes a carrier, at least one self-assembled material layer, a first solder mask layer, and at least one light-emitting diode. The carrier includes a first build-up circuit. The self-assembled material layer is disposed on the first build-up circuit. The first solder mask layer is disposed on the first build-up circuit. The first solder mask layer has at least one opening to expose a portion of the self-assembled material layer. The light-emitting diode is disposed on the first build-up circuit. The light-emitting diode has a self-assembled pattern. The light-emitting diode is self-assembled into the opening of the first solder mask layer through a force between the self-assembled pattern and the self-assembled material layer. A manufacturing method of the light-emitting diode package structure is also provided.

Owner:UNIMICRON TECH CORP

Micro light-emitting diode, display substrate, manufacturing method of display substrate and display device

PendingCN114242864AReduce alignment accuracy requirementsImprove transfer yieldSolid-state devicesSemiconductor devicesEngineeringSemiconductor

The invention discloses a micro light-emitting diode, a display substrate, a manufacturing method of the display substrate and a display device, and belongs to the technical field of display. The micro light-emitting diode at least comprises a first electrode, a second electrode, a first semiconductor part, a light-emitting part and a second semiconductor part, the light-emitting part is located between the first semiconductor part and the second semiconductor part, the first electrode is located on the side, away from the light-emitting part, of the first semiconductor part, and the second electrode is located on the side, away from the light-emitting part, of the second semiconductor part. The orthographic projection of the first electrode on the first semiconductor part at least covers 50% of the area of the first semiconductor part. The display substrate comprises a plurality of micro light-emitting diodes. The manufacturing method of the display substrate is used for manufacturing the display substrate. The display device comprises the display substrate. According to the micro light-emitting diode provided by the invention, the alignment difficulty during transfer can be reduced, and the yield of a die bonding process is improved, so that the light-emitting efficiency is improved.

Owner:XIAMEN TIANMA MICRO ELECTRONICS

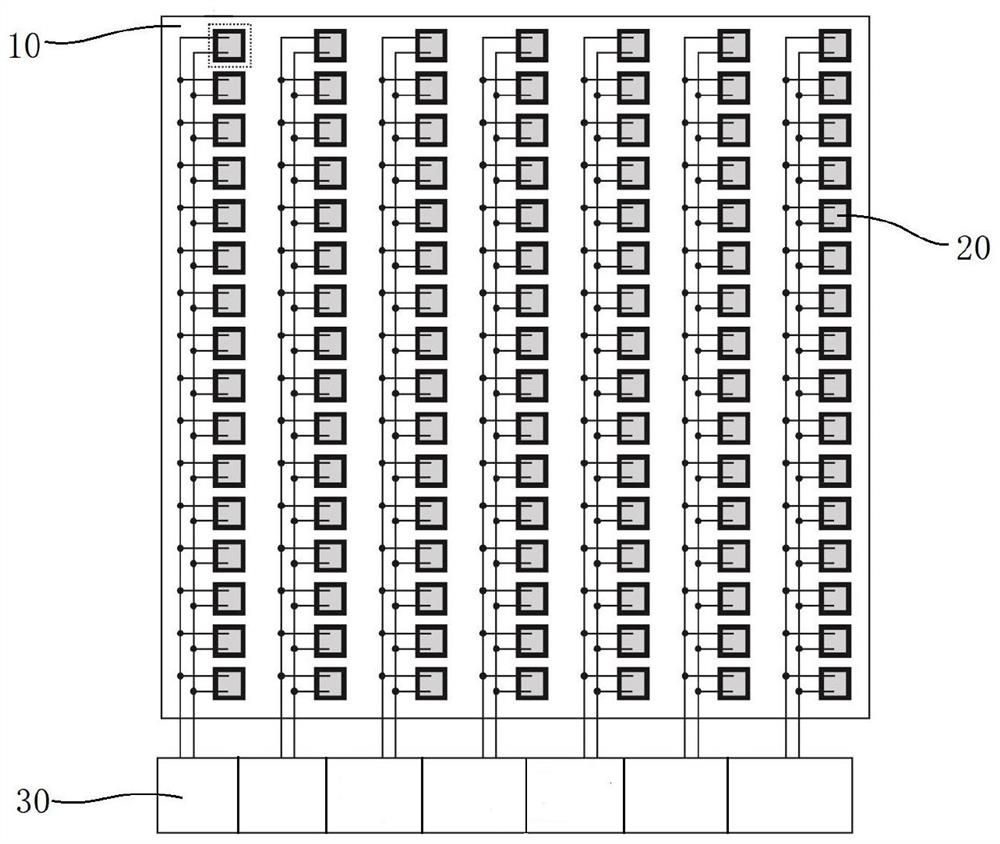

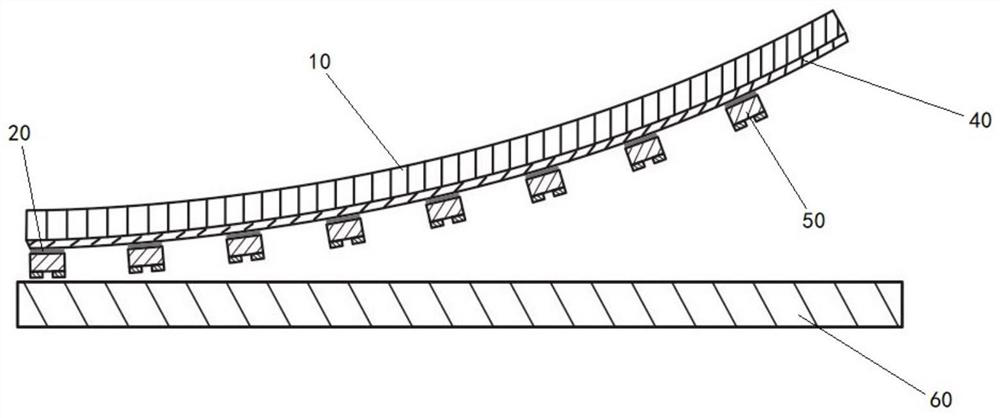

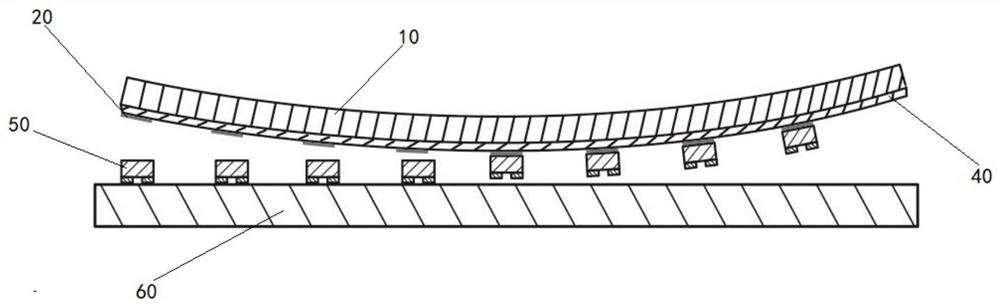

Micro device transfer device and transfer method

ActiveCN113437195AUniform pressureImprove production efficiencySolid-state devicesSemiconductor/solid-state device manufacturingMicro devicesMechanical engineering

The invention discloses a micro device transfer device and a transfer method, the transfer device comprises a control module, a supply substrate and transfer heads, a first side surface of the supply substrate is provided with a plurality of rows of transfer heads, the first side surface of the supply substrate is a curved surface bent towards the direction of the supply substrate, and the control module is used for controlling the plurality of rows of transfer heads to adsorb and release the micro devices so as to transfer the micro devices. According to the invention, the micro devices on the plurality of columns of transfer heads are in contact with the receiving substrate in sequence by rotating the supply substrate, and the plurality of columns of transfer heads are controlled by the control module to release the micro devices in sequence, so that the micro devices on the plurality of columns of transfer heads are transferred in sequence. The micro devices are transferred in batches and rows. Therefore, the transfer yield of the mass transfer mode of the micro devices is effectively improved, and the generation efficiency of the micro devices is improved.

Owner:JIHUA LAB

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com